Prefabricated bridge structure climbing equipment and control method

A bridge structure and equipment technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems that the jacking technology cannot adapt to the construction of viaducts, etc., and achieves remarkable modular construction effects, improved construction efficiency, and high construction safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

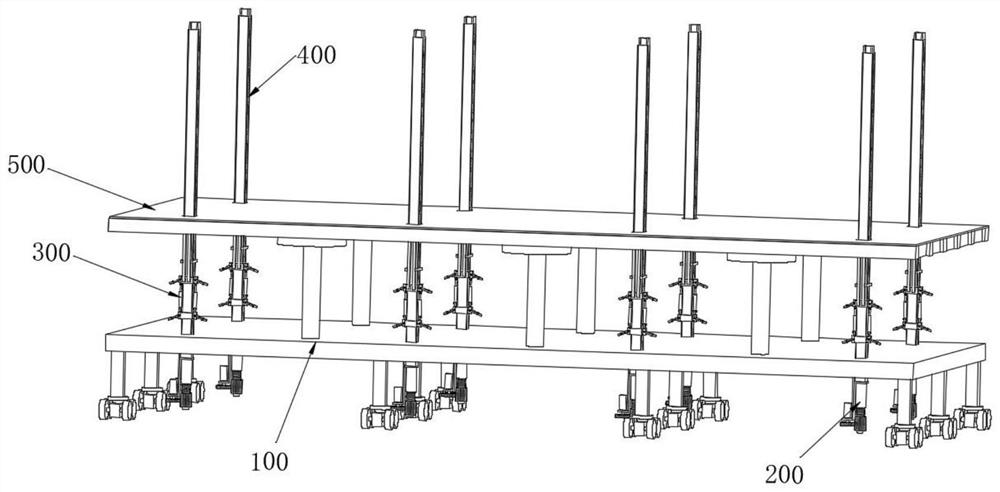

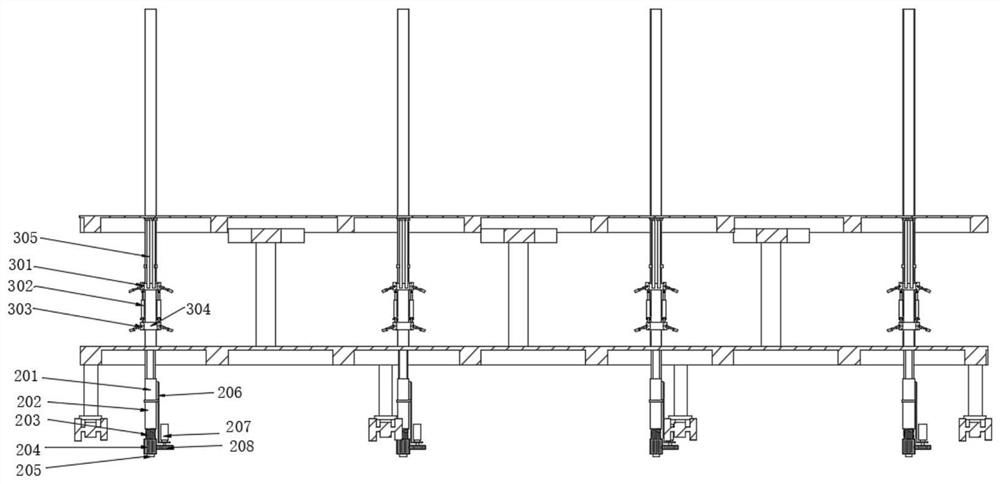

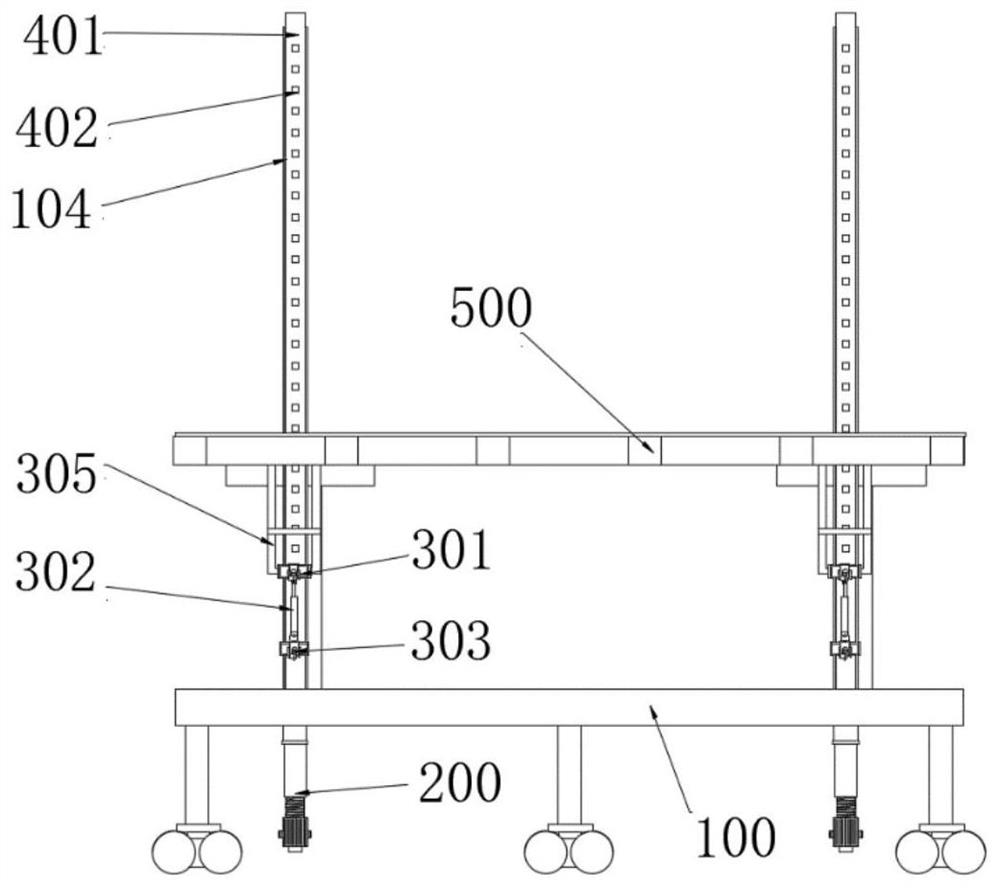

[0043] Combine below Figure 1 to Figure 9 , detailing the structural composition of the prefabricated bridge structure climbing equipment of the present invention.

[0044] Please refer to Figure 1 to Figure 9 , a prefabricated bridge structure climbing equipment, including a mobile mechanism 100, a pre-support adjustment system 200, a hydraulic drive system 300, a support steel column system 400, and a load-bearing platform 500; the top floor of the load-bearing platform 500 is provided with a reserved hole for the support steel column. The moving mechanism 100 includes an intelligent rotating wheel 101 , an equipment base layer 102 , a bearing base 103 and a limit baffle 104 . The pre-support adjustment system 200 includes a connecting member 201 , a threaded sleeve 202 , a rotating screw 203 , a rotating gear 204 , a pressure sensor 205 , a fixing bracket 206 , a driving motor 207 and a motor gear 208 . The supporting steel column system 400 includes a supporting steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com