Electric thruster

A jacking device and electric technology, applied in the field of electric jacking device, can solve the problems of complex mechanism, poor accuracy and low energy efficiency of the electric jacking device, and achieve the advantages of precise control, large jacking force and high energy efficiency ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

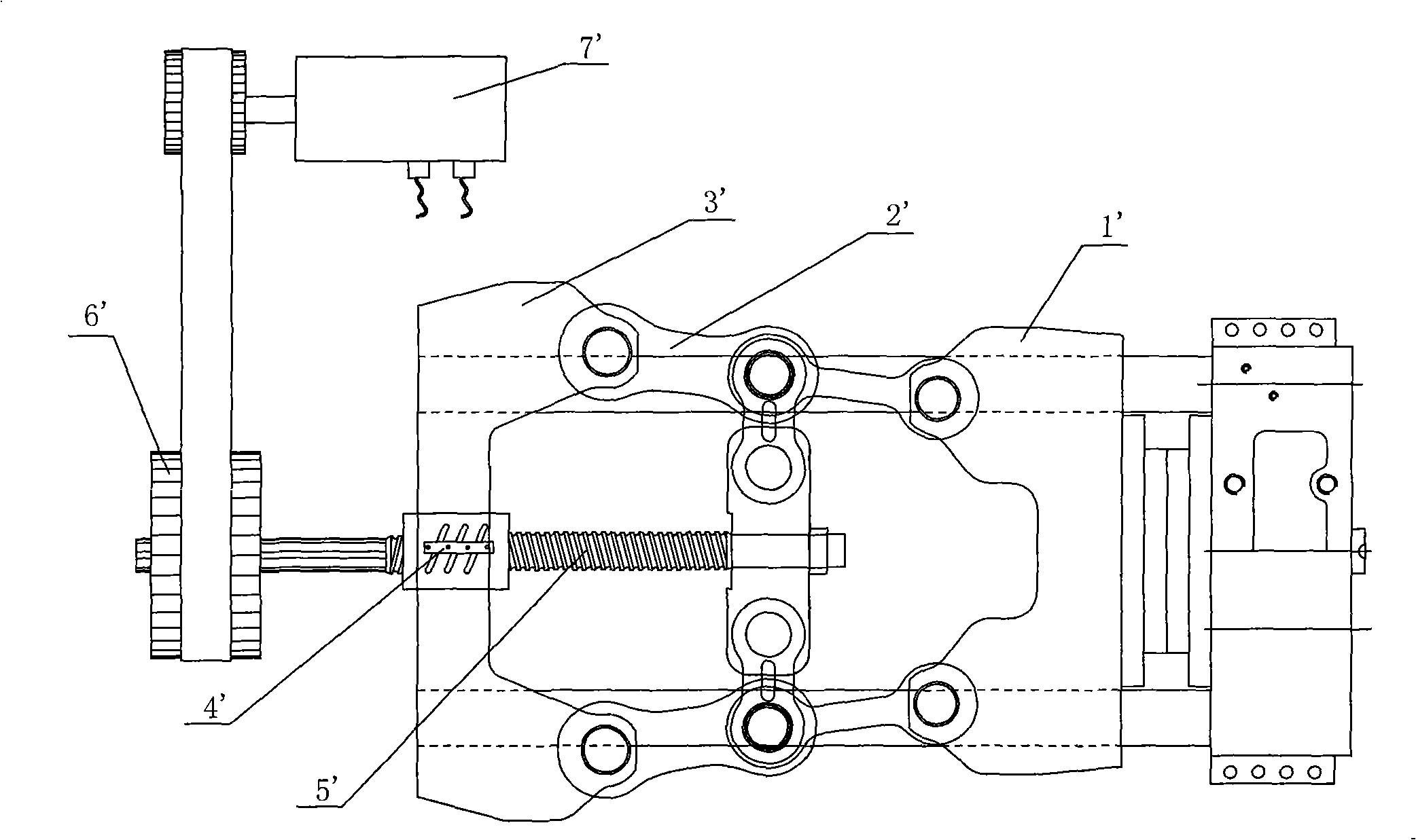

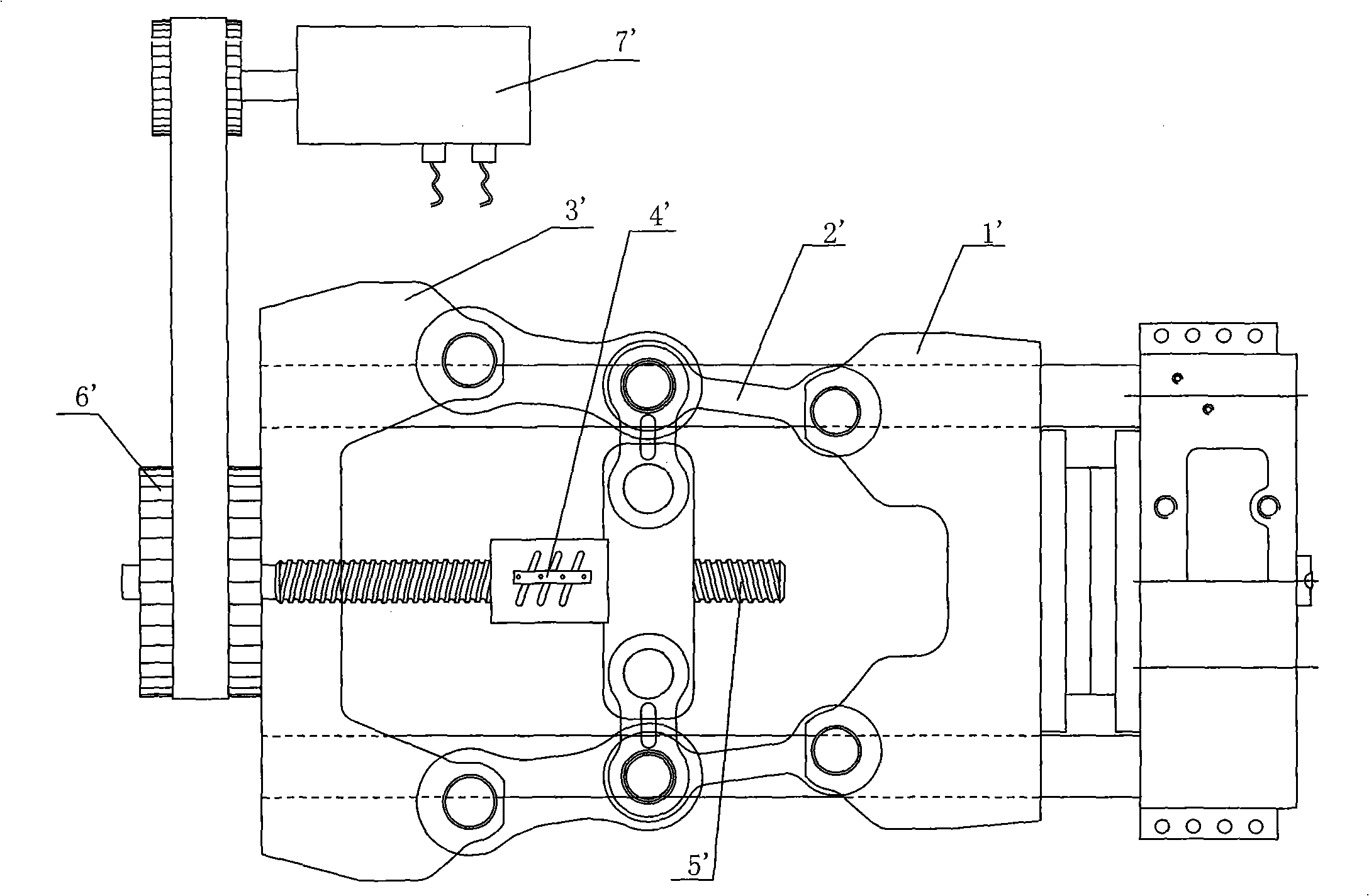

[0018] refer to image 3

[0019] This embodiment is an example when the present invention is applied to an electric mold clamping device on an injection molding machine.

[0020] The electric thrusting device of the present invention includes a base on which the screw is threaded, and also includes a screw and a nut engaged with each other. The front end of the screw is the pushing end, and an outer rotor permanent magnet servo motor is connected to the base. The nut is fixed on the rotor of the outer rotor permanent magnet servo motor; the front part of the screw is provided with a limit piece that limits the rotation of the screw but allows the screw to translate.

[0021] The rotor of the outer rotor permanent magnet servo motor is arranged on the base through a tapered roller bearing, the rotor of the outer rotor permanent magnet servo motor is coaxially arranged with the nut and the screw, and the outer rotor permanent magnet servo motor The stator is connected to the ...

Embodiment 2

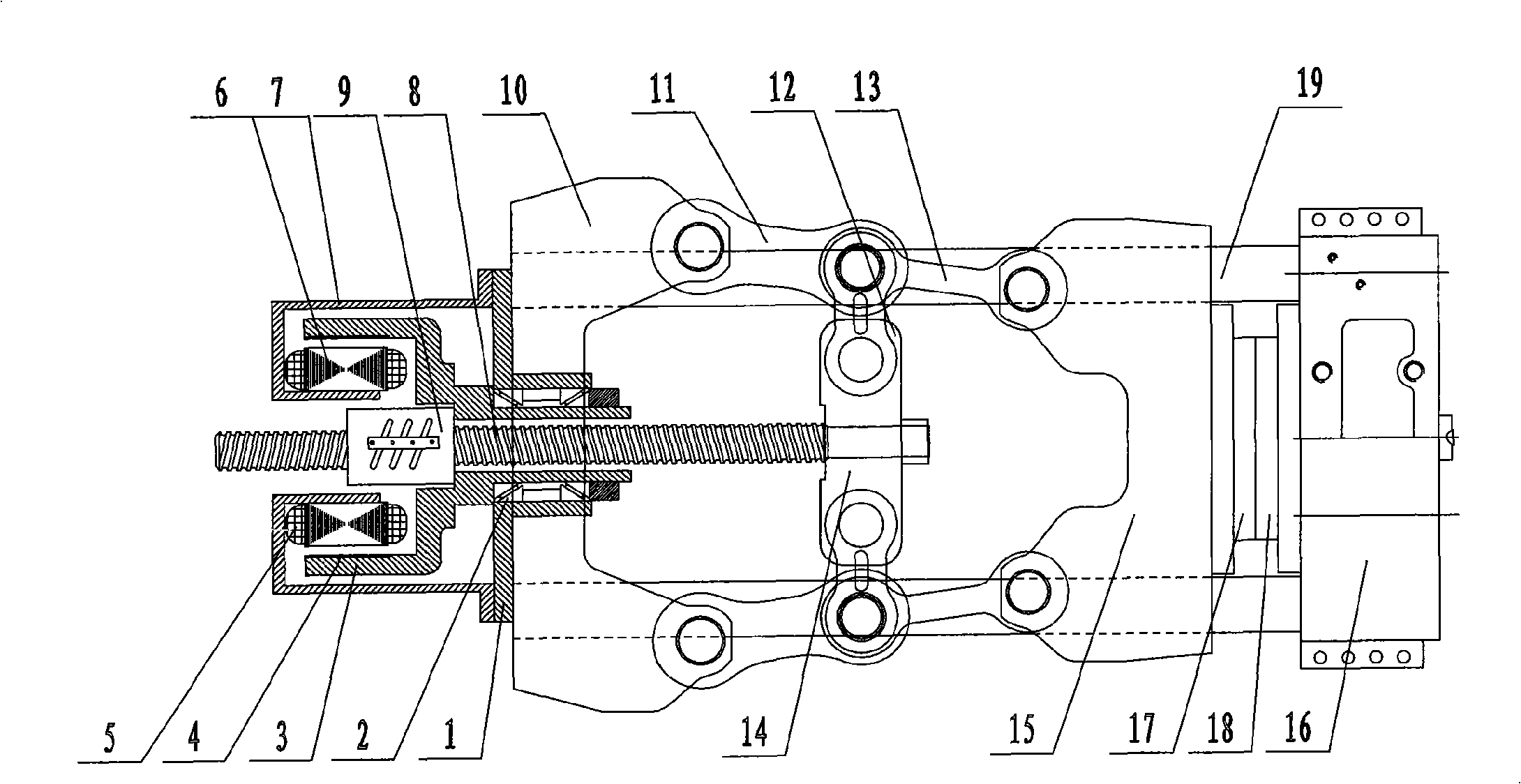

[0031] Referring to Figures 5 and 6:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com