Axial force sensor

An axial force sensor and stress groove technology, applied in the field of force sensors, can solve the problems of poor anti-eccentric load capacity, easy damage to the sensor, large volume, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

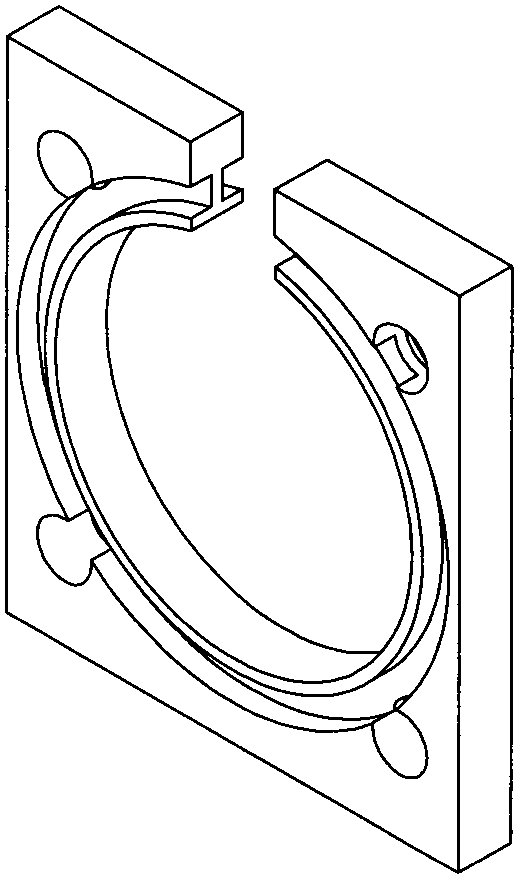

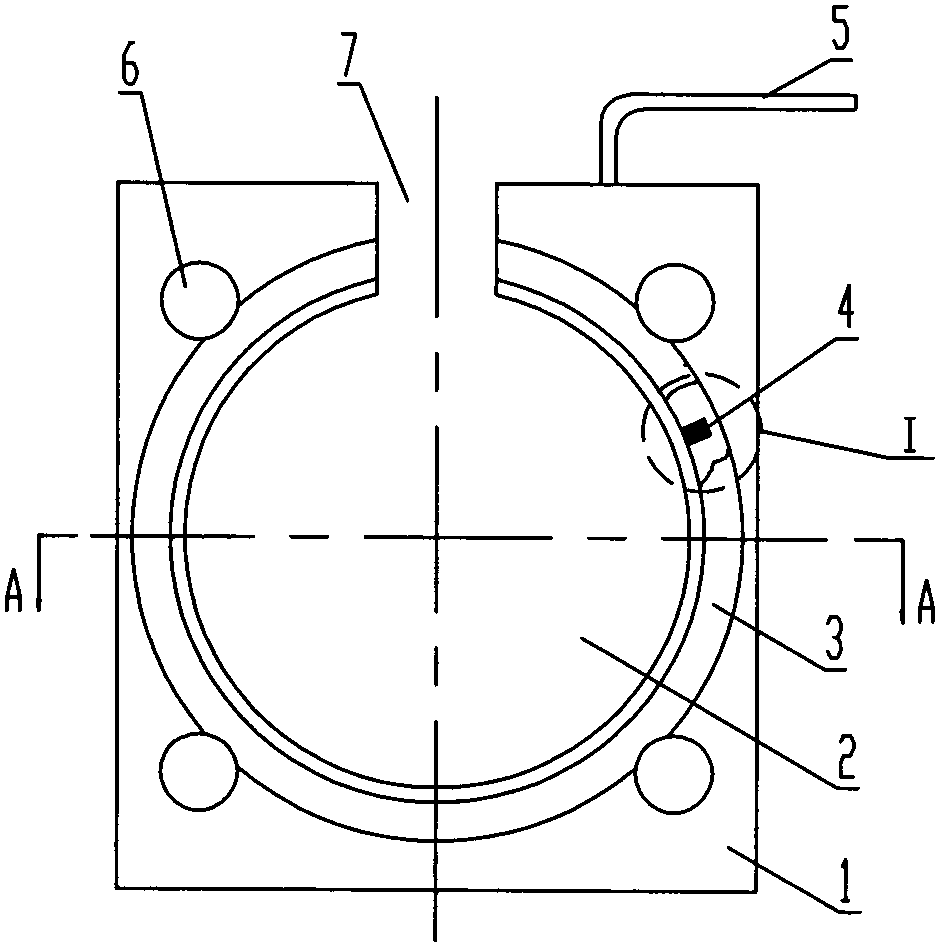

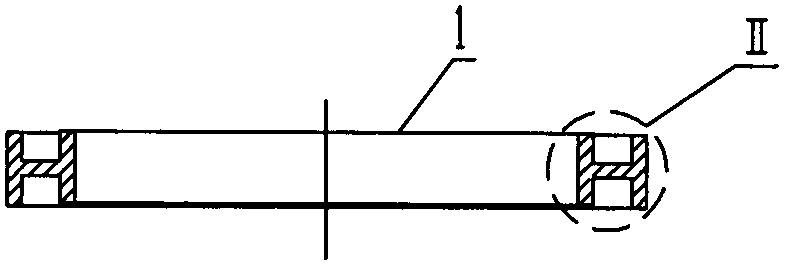

[0026] Such as Figure 1-5 As shown, the axial force sensor of the present invention includes an elastic body 1. The elastic body 1 is a flat plate. There is a shaft passing hole 2 in the middle of the plate surface, and a plurality of bolt passing holes 6 are evenly distributed around the periphery. The overall shape is similar to a flange. The disk gasket has an annular stress groove 3 on the positive surface of the elastic body 1 near the shaft through hole 2, and an annular stress groove 3 on the reverse surface of the elastic body 1, two positive and negative The stress grooves 3 have the same diameter and are concentric with the shaft through hole 2 . The resistance strain gauges 4 are attached to the stress grooves 3 . All the resistance strain gauges 4 form a Wheatstone balance bridge and are connected to external electrical appliances through cables 5 .

[0027] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com