L-shaped multifunctional oil press and work method

A hydraulic press, multi-functional technology, applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems that die forgings cannot be processed, single-shaped products, etc., and achieve strong anti-eccentric load capability, high positioning accuracy, and guiding performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

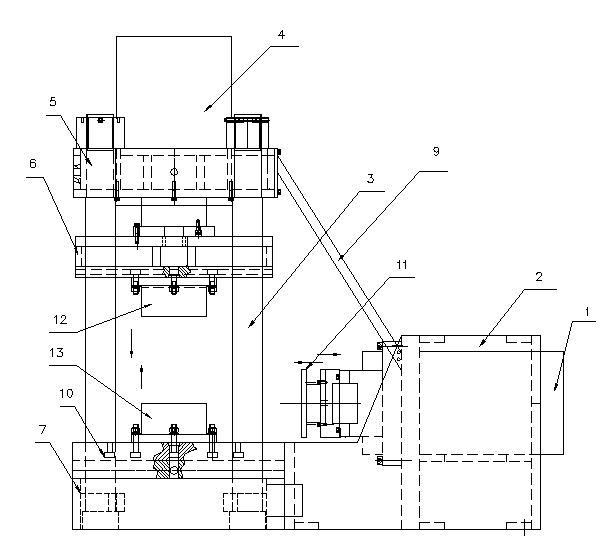

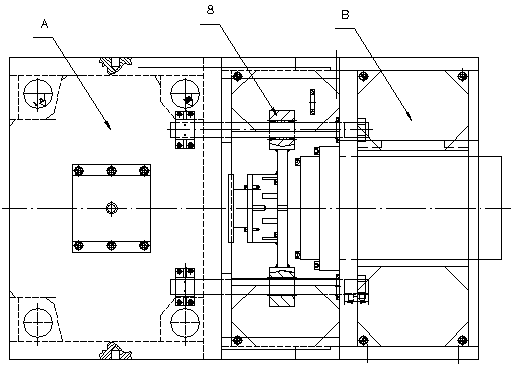

[0020] Example 1, such as figure 1 , figure 2 The L-shaped multifunctional hydraulic press shown is composed of a vertical hydraulic press A and a horizontal hydraulic press B, wherein the horizontal hydraulic press B includes: a horizontal hydraulic press cylinder assembly 1; a horizontal hydraulic press frame 2; a horizontal hydraulic press Hydraulic right mold 11; horizontal hydraulic press guide mechanism 8; wherein, the horizontal hydraulic press cylinder assembly 1 is placed on the upper part of the horizontal hydraulic press frame 2, and the horizontal hydraulic right mold 11 is movably connected to the horizontal hydraulic press guide mechanism 8; Described vertical hydraulic machine is by four columns 3; Vertical hydraulic machine cylinder assembly 4; Vertical hydraulic machine upper beam 5; Slider 6; Workbench 7; Placed on the upper part of the upper beam 5 of the vertical hydraulic press, the slider 6 is movably connected with the four columns 3, the upper mold 12...

Embodiment 2

[0021] Embodiment 2, the structure is the same as that of Embodiment 1, a working method of an L-shaped multifunctional hydraulic press: when processing piston workpieces, in the first step, the vertical hydraulic press A works, and the upper mold 12 moves vertically downwards, and is combined with the lower mold 13 The mold completes the positioning, clamping, and forming of the left end of the piston workpiece; the second step, the horizontal hydraulic press B drives the right mold 11 to move horizontally from right to left, and molds with the right end of the upper and lower molds of the vertical hydraulic press to complete the overall molding of the piston workpiece; third In the first step, the horizontal hydraulic press B drives the right mold 11 to eject from left to right; in the fourth step, the vertical hydraulic press A drives the upper mold 12 to eject from the bottom to the top to complete the integral precision forging of the product piston. The left end face of t...

Embodiment 3

[0022] Embodiment 3, the workpiece of Embodiment 2 is replaced with a bearing. When the hydraulic press is working, the first step is to work the vertical hydraulic press. The hydraulic automatic control system controls and drives the upper mold to move vertically downwards, and molds with the lower mold to complete positioning, Clamping and workpiece forming; the second step, the vertical hydraulic press A drives the upper mold 12 to move from bottom to top to eject. Through the above two steps, the forming of ordinary workpieces is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com