Hydraulic cylinder plunger installation structure for powder hydraulic press

A powder hydraulic press and installation structure technology, applied in the field of hydraulic press manufacturing, can solve problems such as failure to meet the use requirements of large-tonnage hydraulic presses, broken connecting bolts, and damage to the plunger, so as to improve the service life and equipment work efficiency, and have strong anti-eccentric load capacity. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

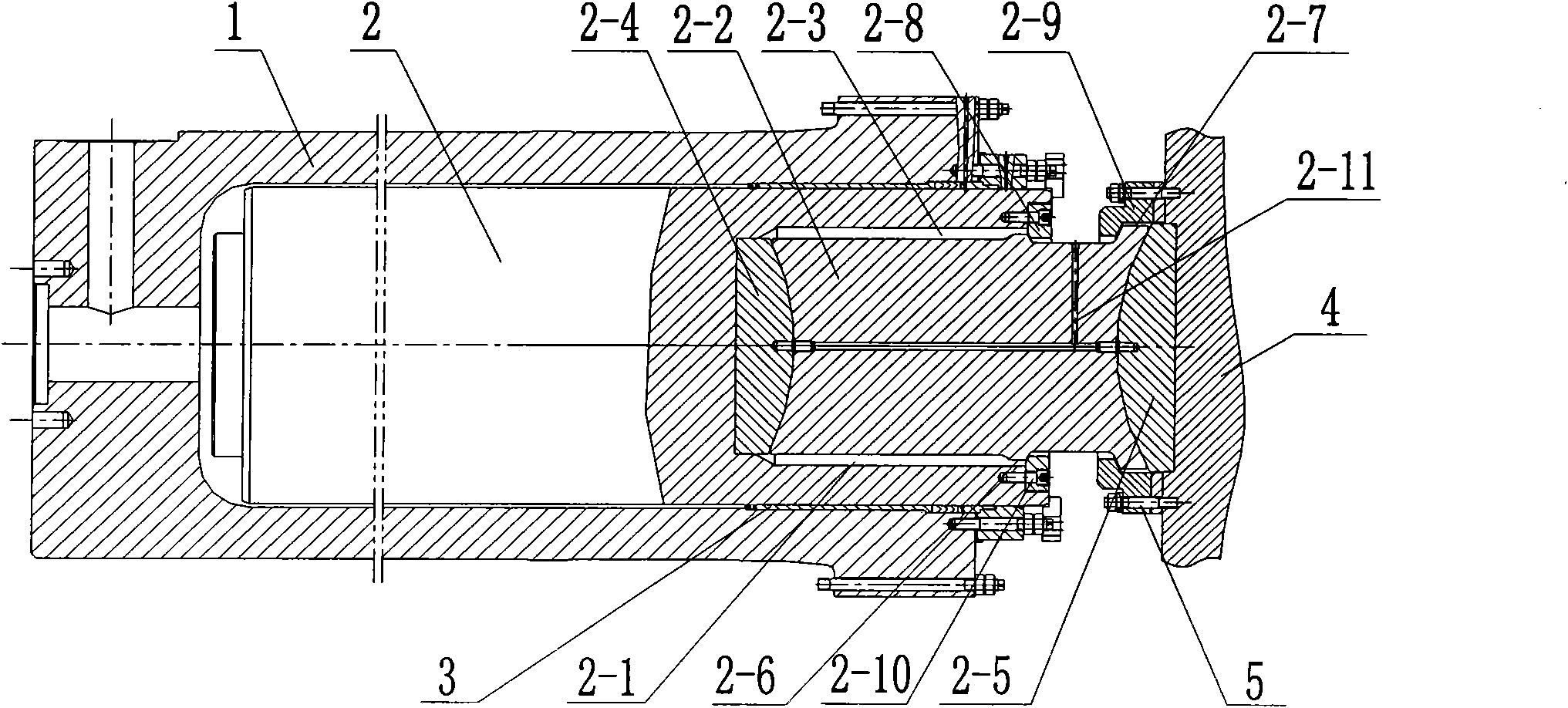

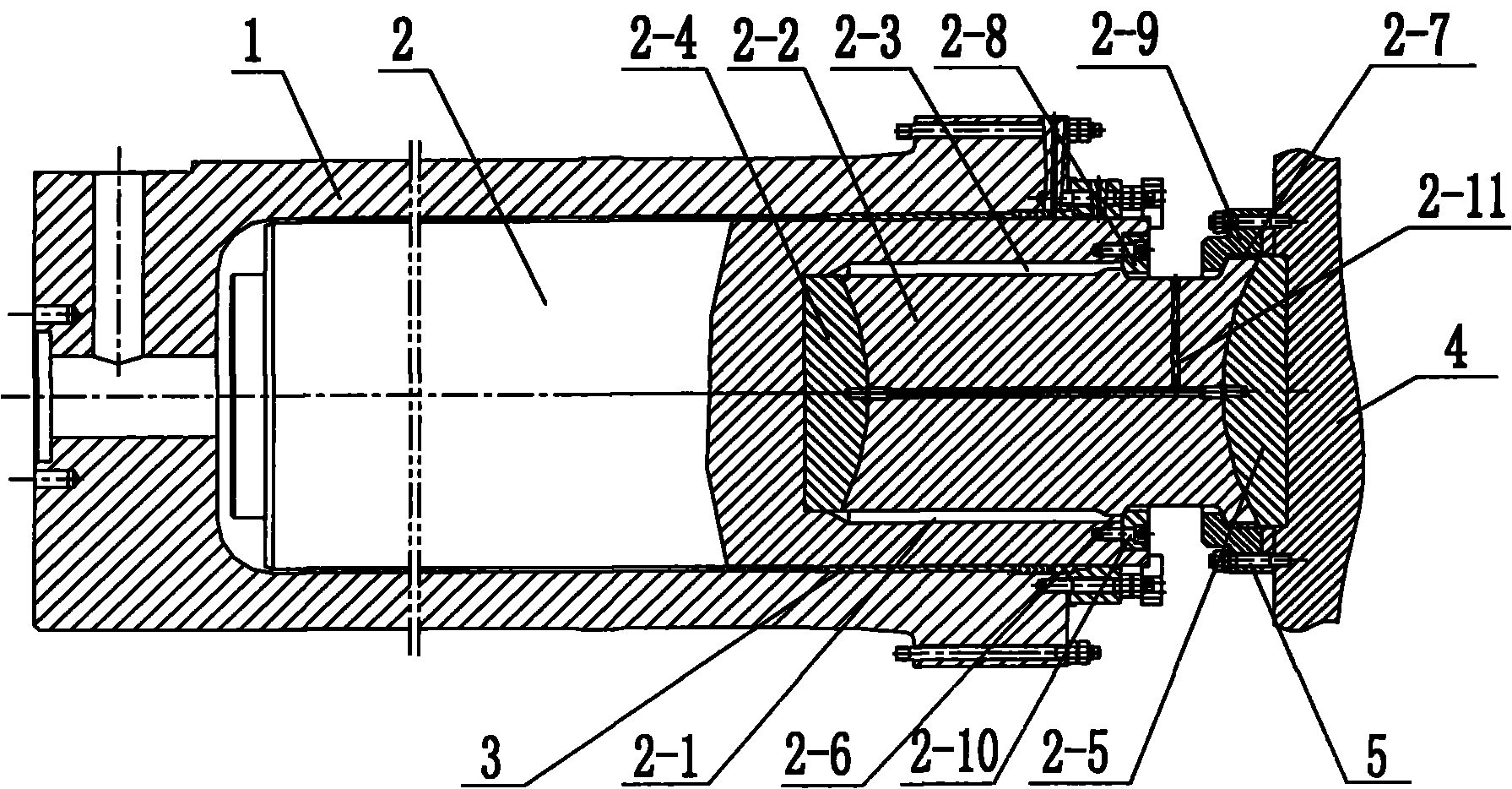

[0012] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0013] see figure 1 , a hydraulic cylinder plunger installation structure for powder hydraulic presses, including a cylinder body 1, a plunger 2 installed in the cylinder body 1, and a guide sleeve 3 between the plunger 2 and the cylinder body 1, and the plunger 2 A central blind hole 2-1 is provided at the outer connection end of the central blind hole 2-1, and a spherical column 2-2 is installed in the central blind hole 2-1, and an eccentric load gap 2-3 is left between the spherical column 2-2 and the central blind hole 2-1. A spherical pad 2-4 is provided between the spherical column 2-2 and the bottom of the central blind hole 2-1; a spherical pad 2-5 is provided between the other end of the spherical column 2-2 and the outer connector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com