Plate liquid-filling shaping hydraulic machine

A liquid-filled forming and hydraulic press technology, which is applied in the field of hydraulic machinery, can solve the problems of mechanical properties of parts surface strain, lack of versatility of molds, and high cost of mold manufacturing, so as to save machine height, speed up no-load descending speed, and simplify machine structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

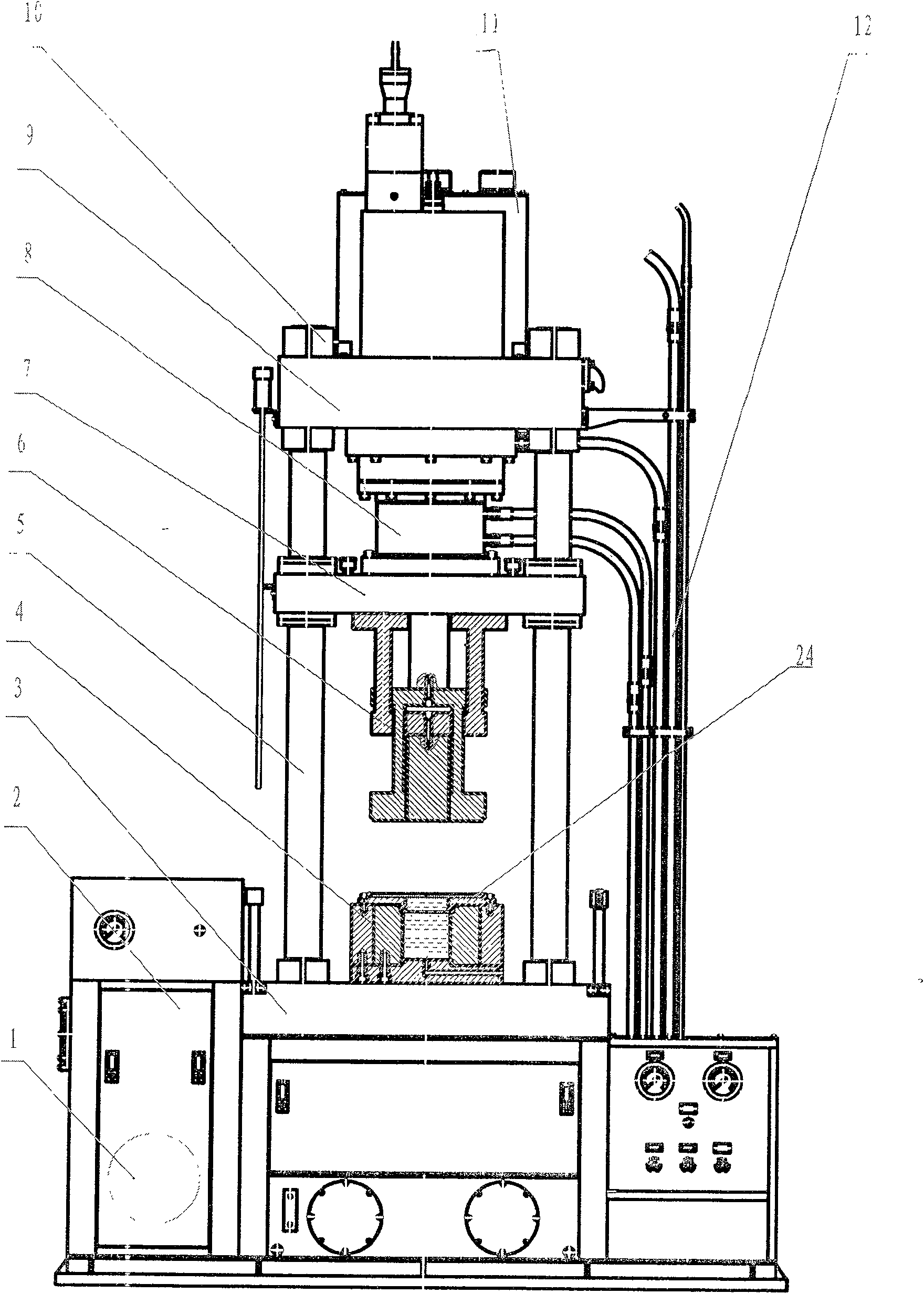

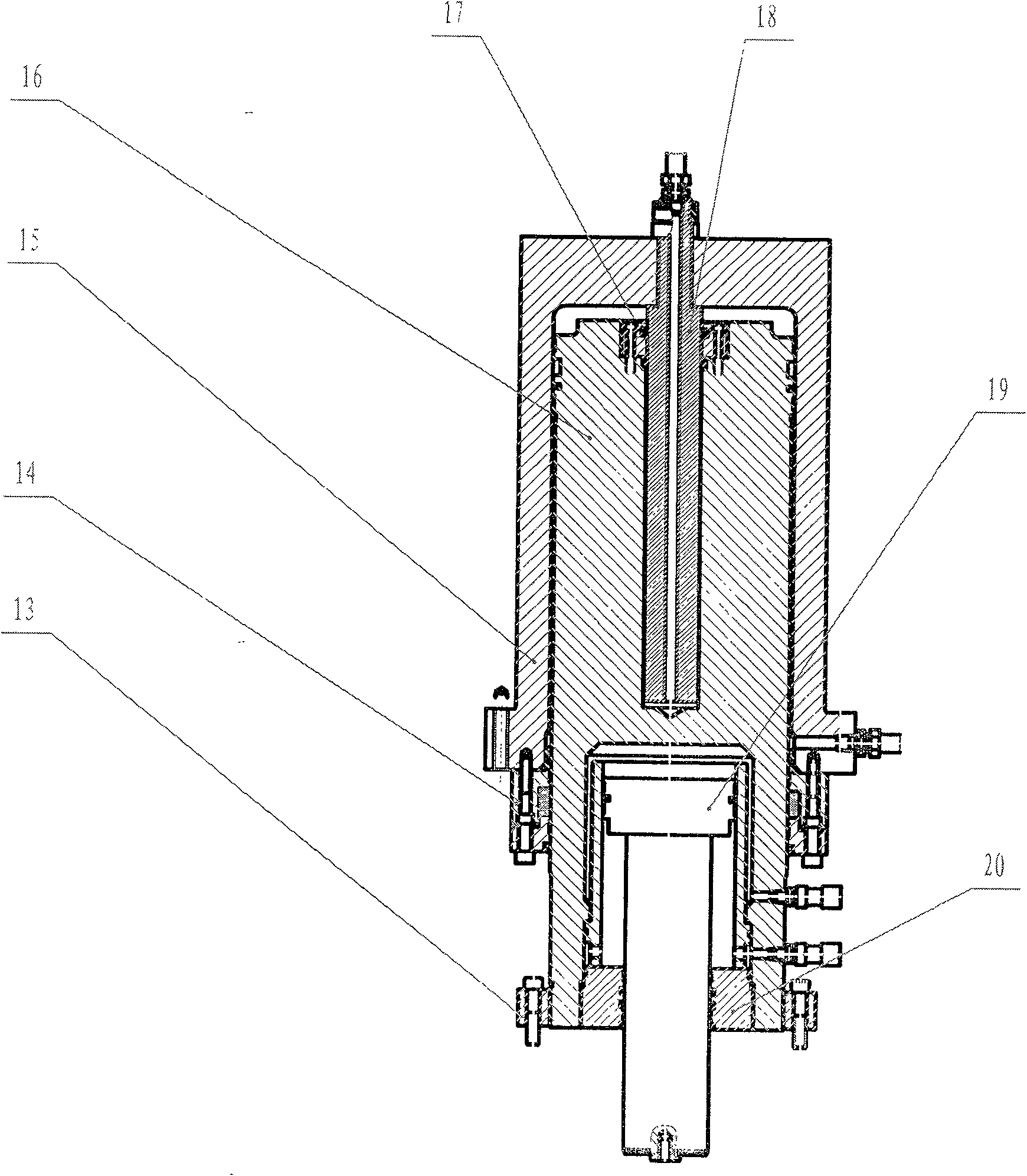

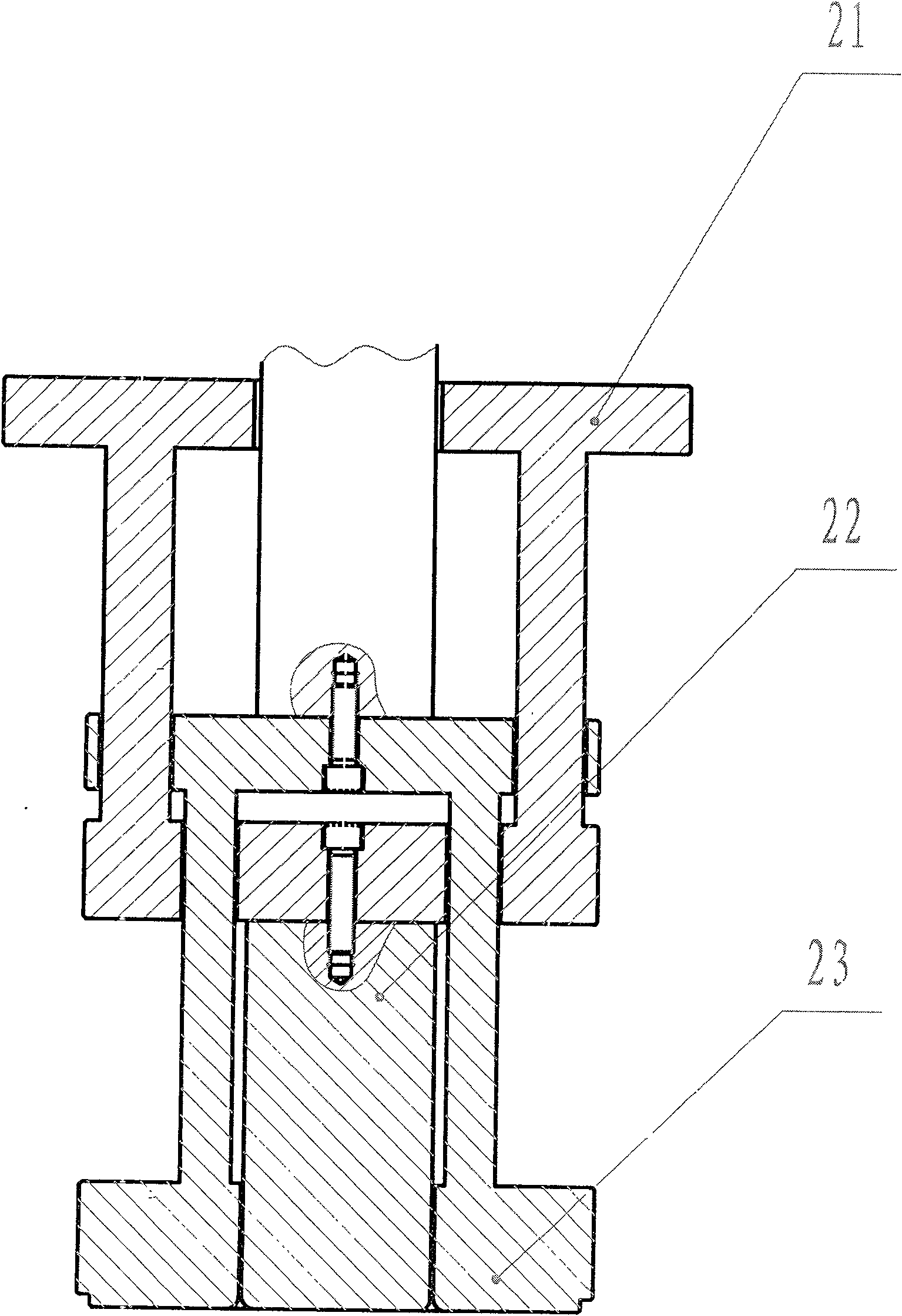

[0018] Such as figure 1 , figure 2 , image 3 As shown, the structure of the plate liquid-filled forming hydraulic press of the present invention is such that it mainly consists of a lower beam 3, a column 5 arranged on the lower beam 3, an upper beam 9 arranged on the column 5, and a stretching frame slidingly connected to the column 5. The beam 7, the composite master cylinder 8 arranged on the upper beam 9, the coaxial linkage deep-drawing edge-holding device 6 arranged under the stretching beam 7, the liquid chamber 4 arranged on the lower beam 3, the support oil tank 2 ( Including hydraulic power control system), supercharger 1, column nut 10, liquid filling tank 11, pipeline 12, etc., the lower beam 3, column 5, and upper beam 9 are connected by column nut 10 to form a rigid body. Cylinder 8 consists of a cylinder body 15 fixed on the upper beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com