Under-drive punch press

A technology of punch press and lower toggle lever, which is applied to punch presses, presses, manufacturing tools, etc., can solve the problems of undisclosed lower transmission punch transmission mechanism, etc., and achieve strong anti-eccentric load capacity, small deformation, and low noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

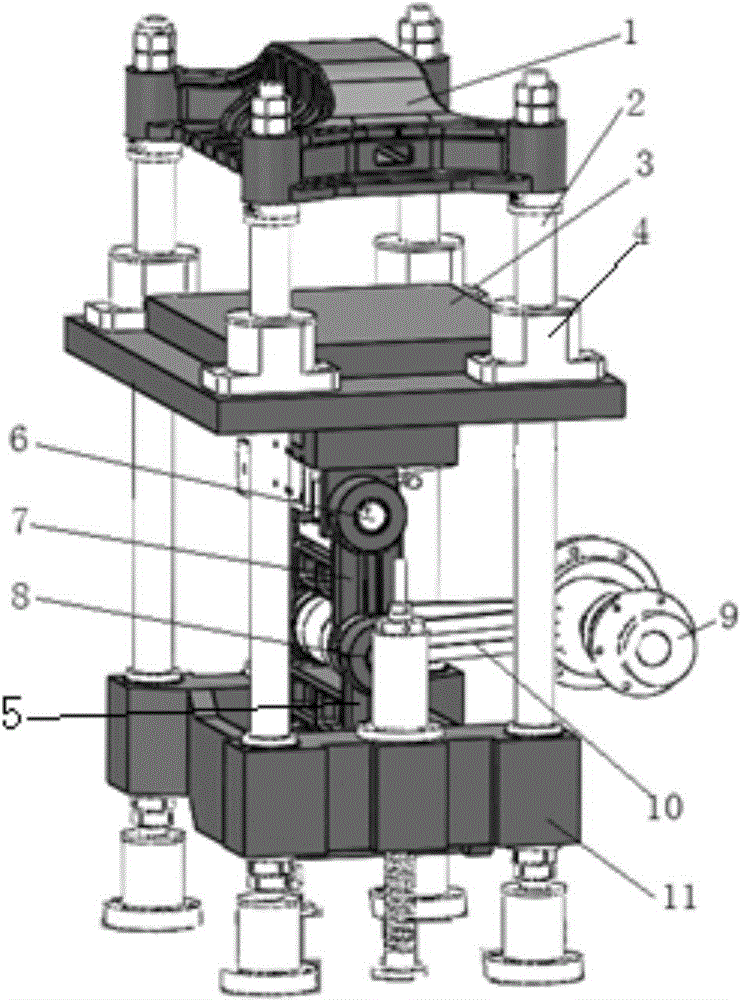

[0011] As shown in the figure, upper slider 1, four columns 2, worktable 3, upper working platform 4, lower toggle 5, installation shaft 6, upper toggle 7, toggle 8, servo drive mechanism 9, connecting rod 10. Bottom plate 11.

[0012] The lower transmission punching machine of the present invention includes a frame, and the frame includes a bottom plate, four uprights distributed in a rectangular shape, and also constitutes the frame of the whole machine, an upper working platform sliding along the uprights, the lower part of the upper working platform is a servo drive mechanism, a crankshaft connecting rod Mechanism and toggle mechanism, the toggle mechanism includes upper and lower toggles and toggle shafts, one end of the upper and lower toggles is connected through the toggle shaft, the servo drive mechanism drives the crankshaft linkage mechanism, and the other end of the linkage One end is sleeved on the toggle shaft of the toggle mechanism, the other end of the upper t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com