A multi-cylinder synchronous energy-saving and high-efficiency hydraulic lifting system and method

A hydraulic lifting and high-efficiency technology, applied in the field of lifting system, can solve the problems of large lateral force of hydraulic cylinder, unfavorable system stable operation, and large wear of elevator guide shoes and other parts, so as to achieve strong anti-eccentric load ability and improve anti-eccentric load Ability, low calorie effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

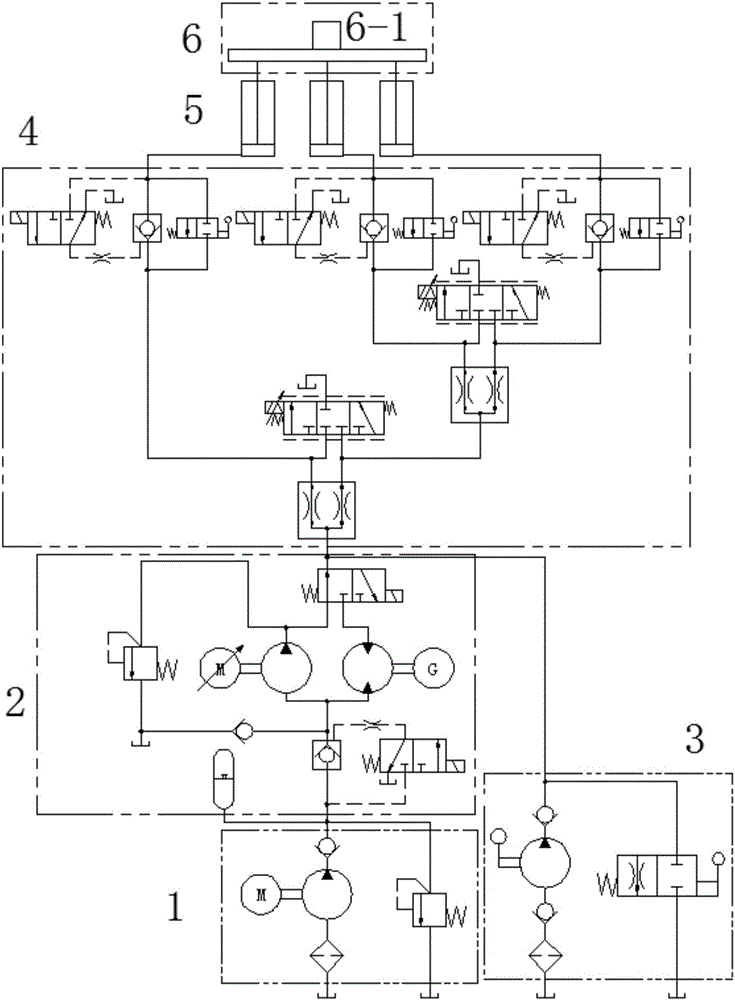

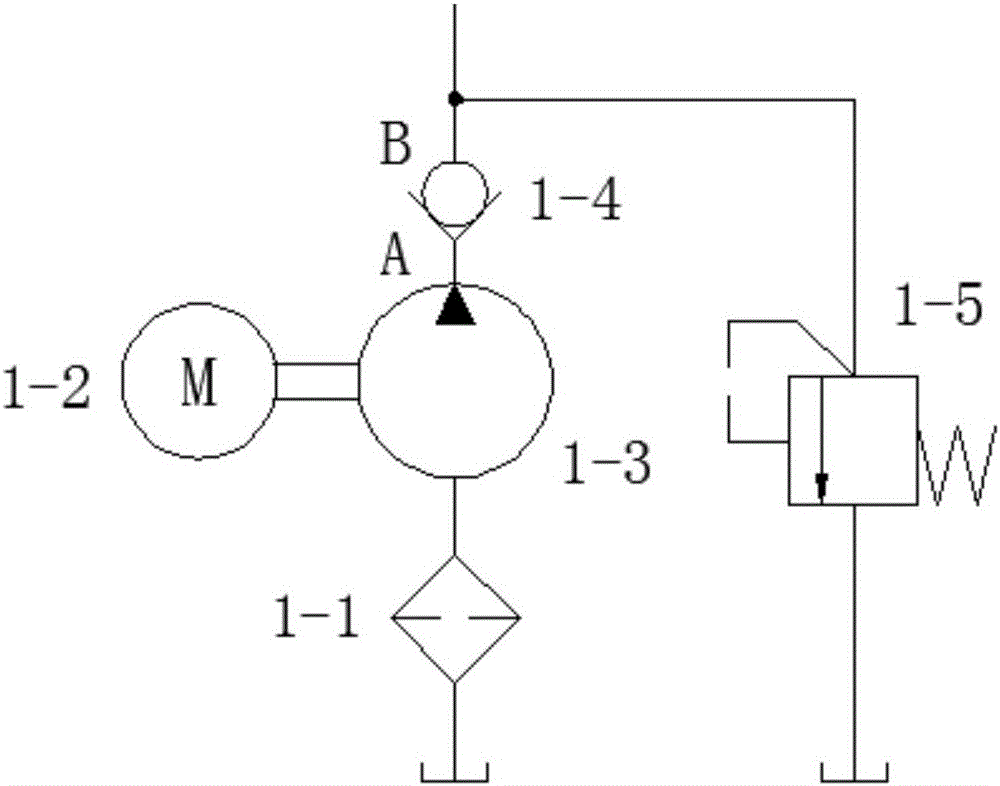

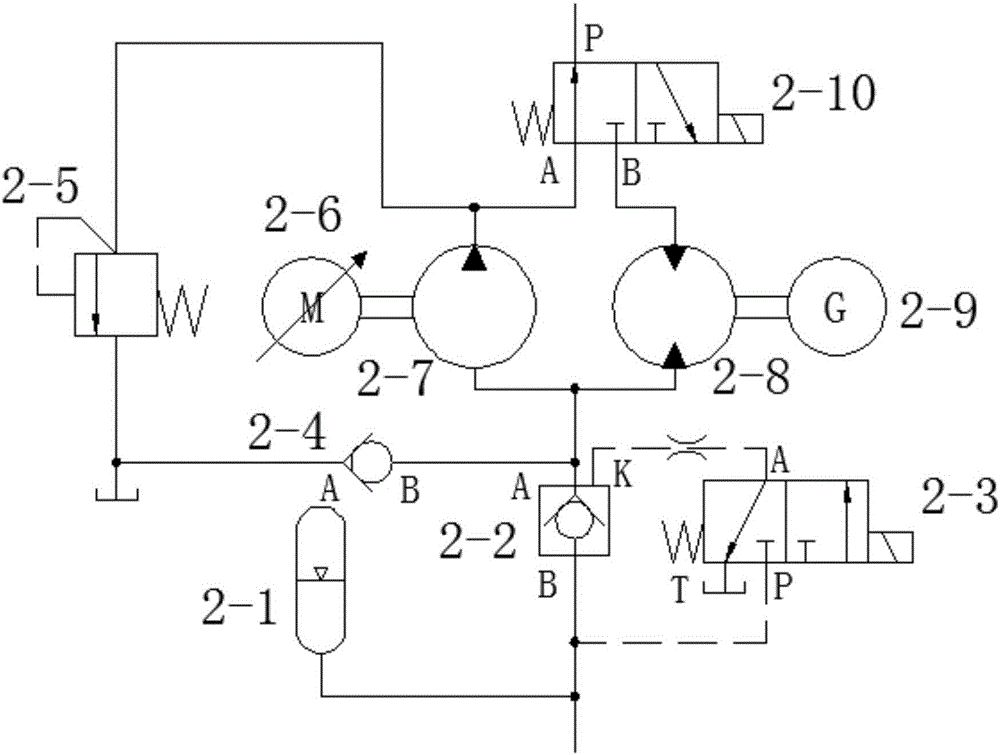

[0036] Embodiment 1, as figure 1As shown, the multi-cylinder synchronous energy-saving and high-efficiency hydraulic lifting system is mainly composed of oil supply circuit 1, volume speed regulation and energy recovery circuit 2, manual lifting circuit 3, synchronous locking circuit 4, hydraulic cylinder 5 supported under the lifting platform 6 and The inclination sensor 6-1 installed on the lifting platform 6 constitutes. The oil supply circuit 1 is connected to the volume speed regulation and energy recovery circuit 2 through pipelines, the volume speed regulation and energy recovery circuit 2, the manual lifting circuit 3 and the synchronous locking circuit 4 are connected to each other through pipelines, each A hydraulic cylinder 5 is connected with a locking circuit 4-3, and the locking circuit 4-3 is respectively connected with a diversion and flow valve 4-1 and an electro-hydraulic servo valve 4-2, and the locking circuit 4-3, the flow diversion and flow collection Th...

Embodiment 2

[0042] Embodiment 2 is basically the same as Embodiment 1, and the similarities are omitted. The difference is the synchronous locking circuit for driving two hydraulic cylinders 5 . Such as Figure 7 As shown, the synchronous locking circuit 4 that drives the three hydraulic cylinders includes a diverter-collector valve 4-1 with a split ratio of 1:1 connected to the inlet and outlet P of the lift electromagnetic reversing valve 2-10 through pipelines. The split port of the flow valve 4-1 is respectively connected with the electro-hydraulic servo valve 4-2 and the locking circuit 4-3, and the locking circuit 4-3 is connected with the rodless cavity of the corresponding hydraulic cylinder 5. Among them, after passing through the diverting and collecting valve 4-1 with a split ratio of 1:1, the oil is equally divided into two parts with roughly equal flow rates entering and leaving the locking circuit 4-3 and the hydraulic cylinder 5, and the electro-hydraulic servo valve is use...

Embodiment 3

[0043] Embodiment 3 is basically the same as Embodiment 1, the same points are omitted, and the difference is the synchronous locking circuit for driving four hydraulic cylinders. Such as Figure 8 As shown, the synchronous locking circuit 4 that drives four hydraulic cylinders includes a diversion-collection valve 4-1 with a split ratio of 1:1 connected to the inlet and outlet P of the lift electromagnetic reversing valve 2-10 through pipelines. The diversion outlet of the flow valve 4-1 is respectively connected with the electro-hydraulic servo valve 4-2 and two diversion-collection valves with a split ratio of 1:1. The locking circuit 4-3 is connected. The locking circuit 4-3 is connected with the rodless cavity of the corresponding hydraulic cylinder 5. Among them, after two diversions, the oil is divided into four equal flows into and out of the locking circuit 4-3 and hydraulic cylinder 5, and the electro-hydraulic servo valve is used to further adjust the flow in and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com