Hydraulic inclined blade shears

An inclined blade and hydraulic technology, applied in the field of hydraulic shears, can solve the problems of cutting inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

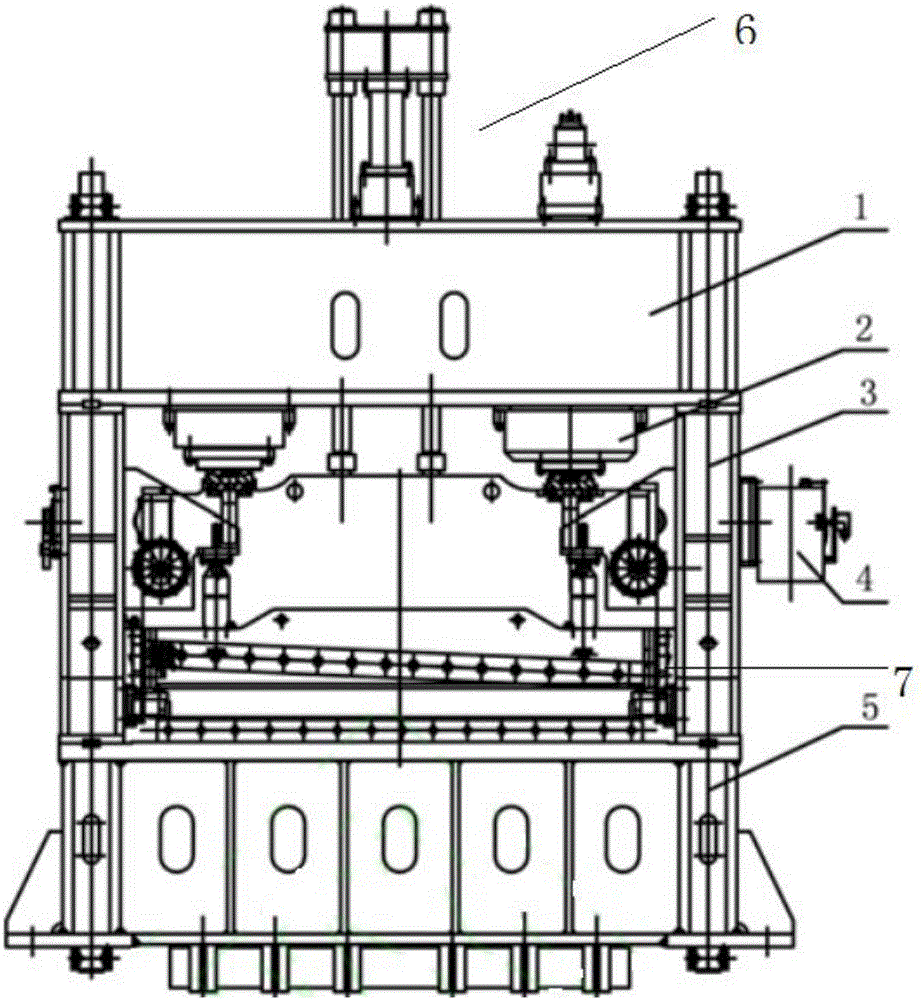

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings: a hydraulic inclined blade shear, including a frame, an upper beam, a frame center column, a shear cylinder, a side clearance adjustment device, an upper knife rest and a lower knife rest; The frame is connected by 4 large tie rods and 2 small tie rods to form a closed frame body; the upper beam is welded by multiple steel plates and fixed on the upper part of the frame. , so the requirements for its strength and rigidity are relatively high; the middle column of the frame is the intermediate support connecting the upper beam and the lower tool rest, and its force is relatively large, and it is distributed on both sides of the frame; the shearing cylinder is installed on the The bottom of the upper beam on the frame drives the upper knife rest to move downward, so that the upper shearing edge can complete the cutting work; the side clearance adjustment device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com