Volume closed-loop synchronous oil cylinder and control system

A closed-loop synchronization and oil cylinder technology, applied in the direction of fluid pressure actuation devices, etc., can solve the problems of complex system control, short transmission distance, high reliability, etc., and achieve low pollution control requirements, insensitivity to temperature changes, and strong anti-eccentric load capability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

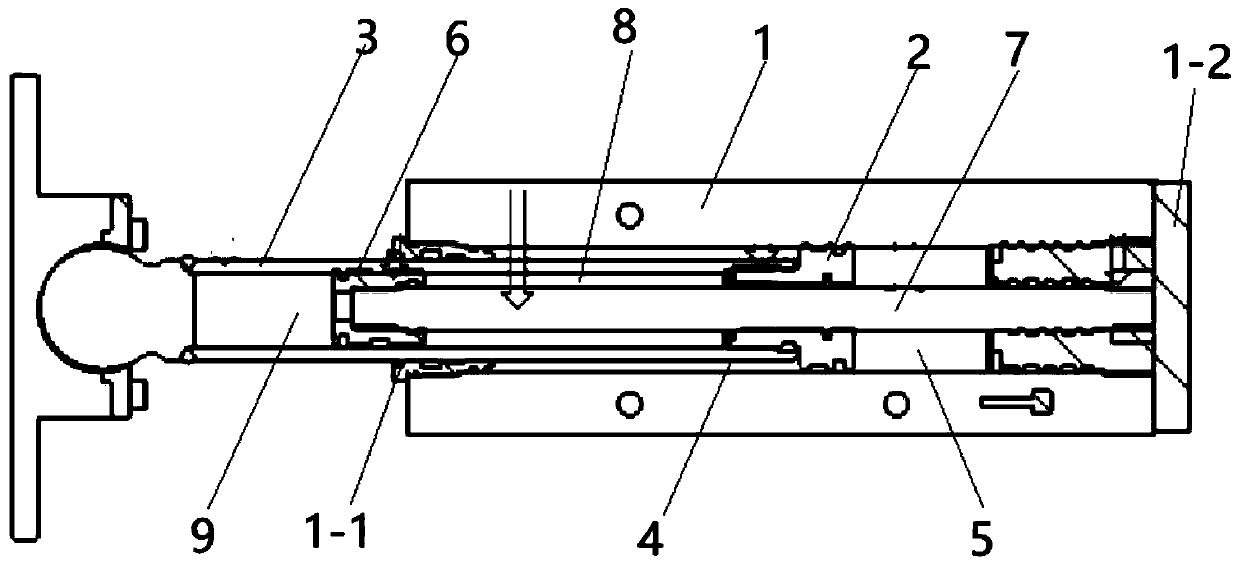

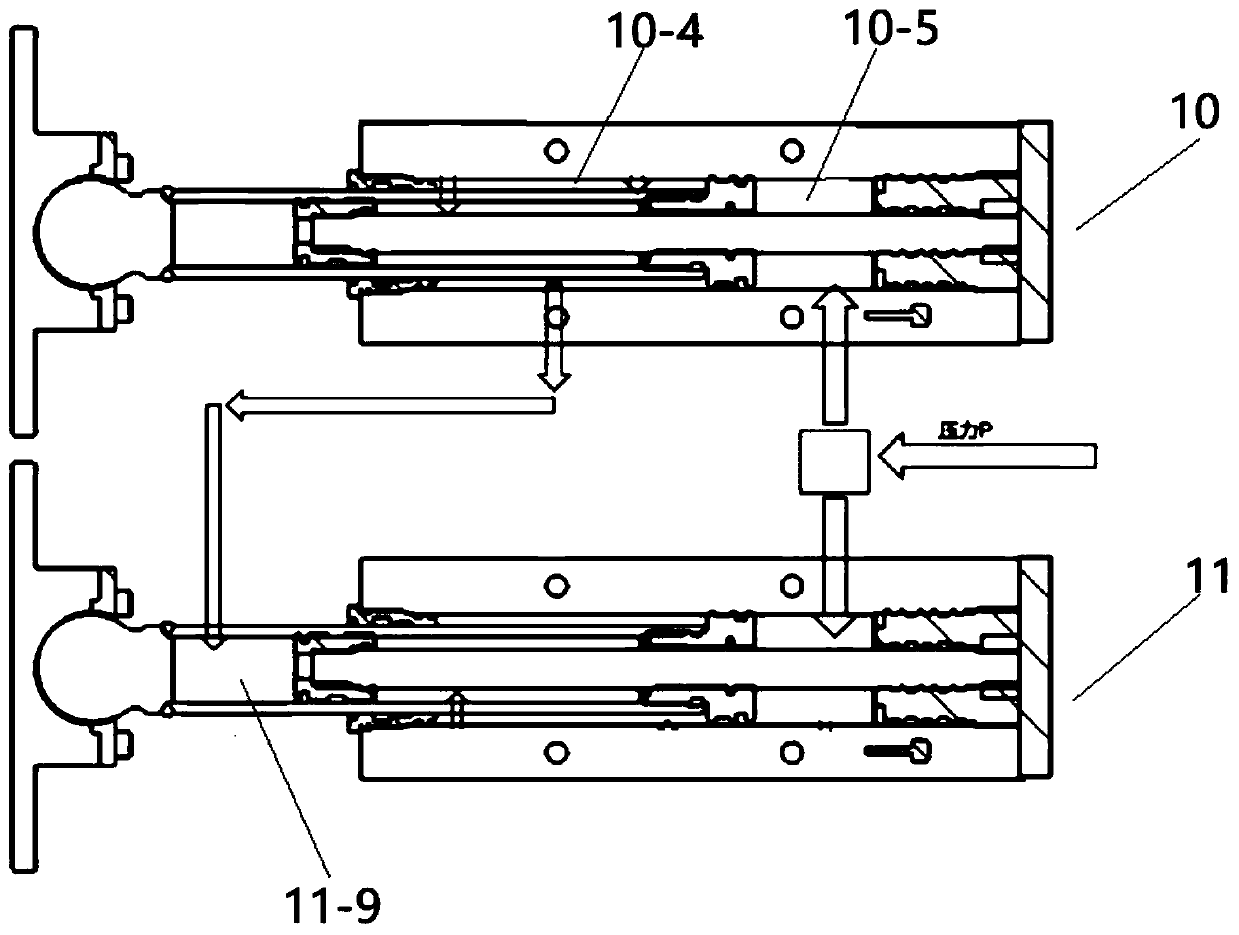

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Figure 1-Figure 2 , including outer cylinder 1, piston 2, piston rod 3, outer cylinder with rod cavity 4, outer cylinder without rod cavity 5, second piston 6, second piston rod 7, inner cylinder with rod cavity 8, inner cylinder without rod Rod chamber 9, master cylinder 10, master cylinder piston 10-2, master cylinder outer cylinder rod chamber 10-4, master cylinder outer cylinder rodless chamber 10-5, auxiliary cylinder 11, auxiliary cylinder inner cylinder rodless chamber 11- 9 etc.

[0024] like figure 1 As shown, the present invention is a volume closed-loop synchronous oil cylinder, comprising an outer cylinder 1, the outer cylinder 1 is a hollow structure, a piston 2 is slidably arranged in the outer cylinder 1, one side of the piston 2 is connected to a piston rod 3, and the outer cylinder 1 The left end cover 1-1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com