A large-stroke multi-station stretching press

A multi-station, press technology, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems of increased stress deformation of the crankshaft, complex transmission structure, and insufficiently stable transmission, etc., to achieve strong anti-eccentric load capability, transmission The effect of compact structure and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

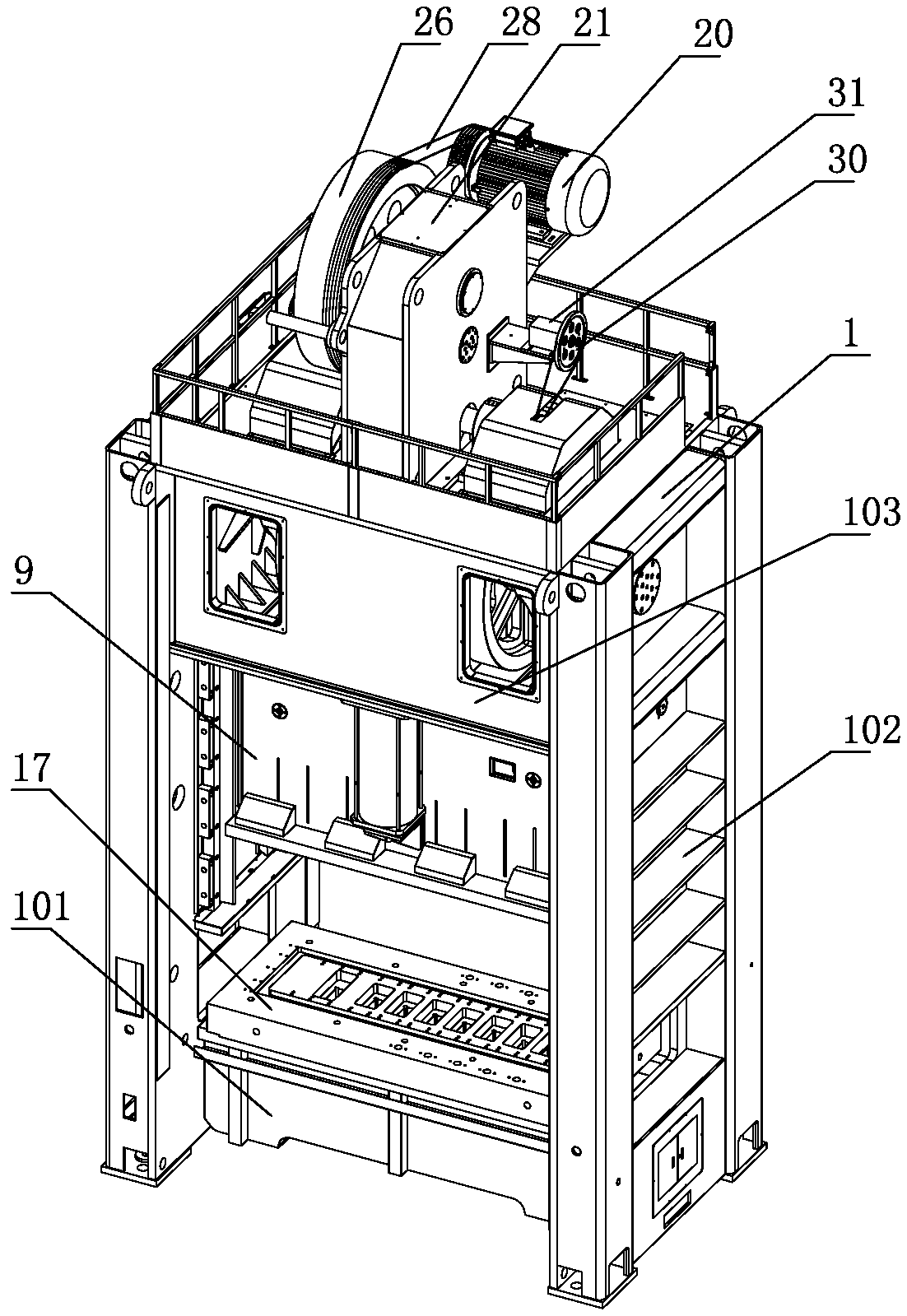

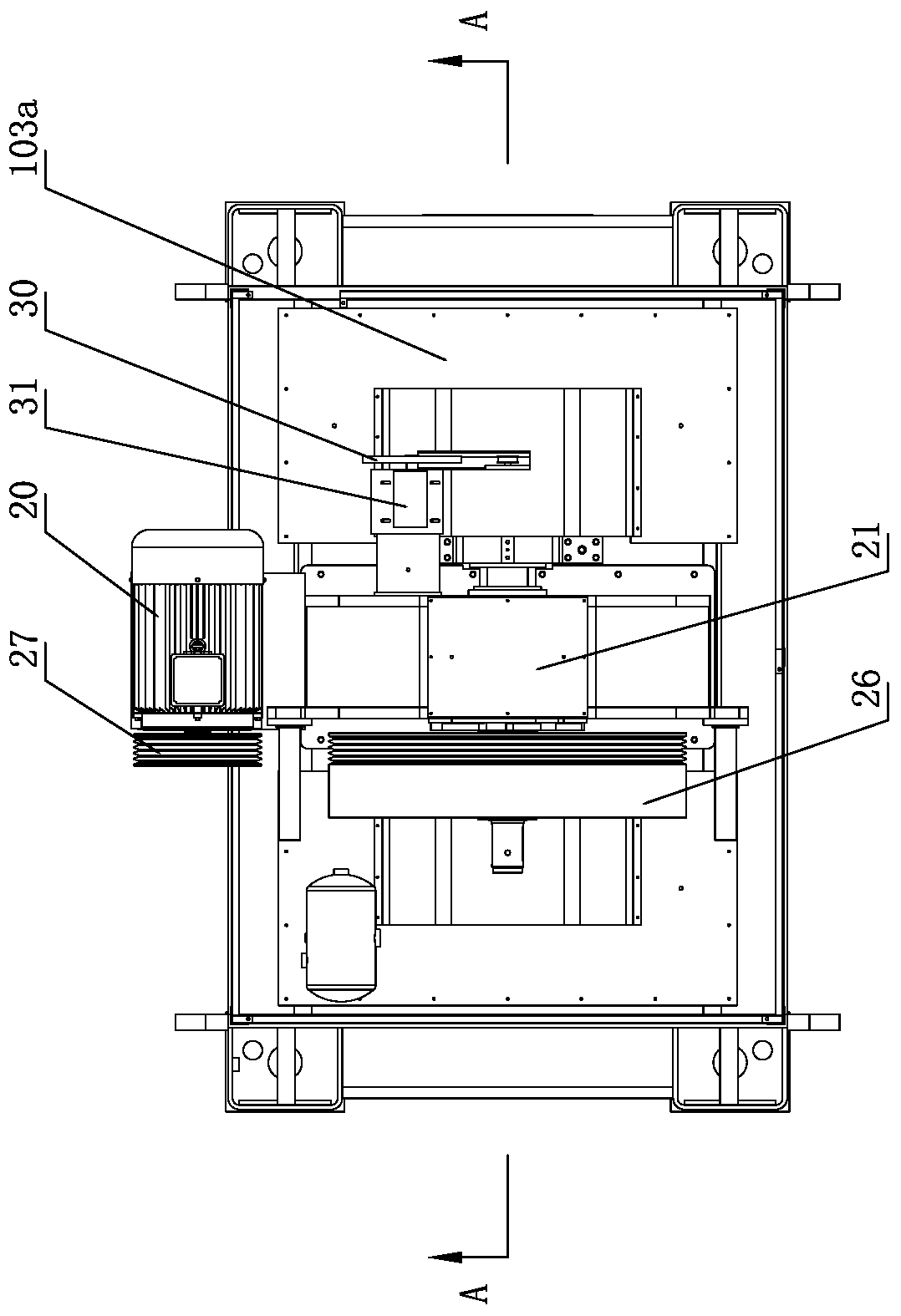

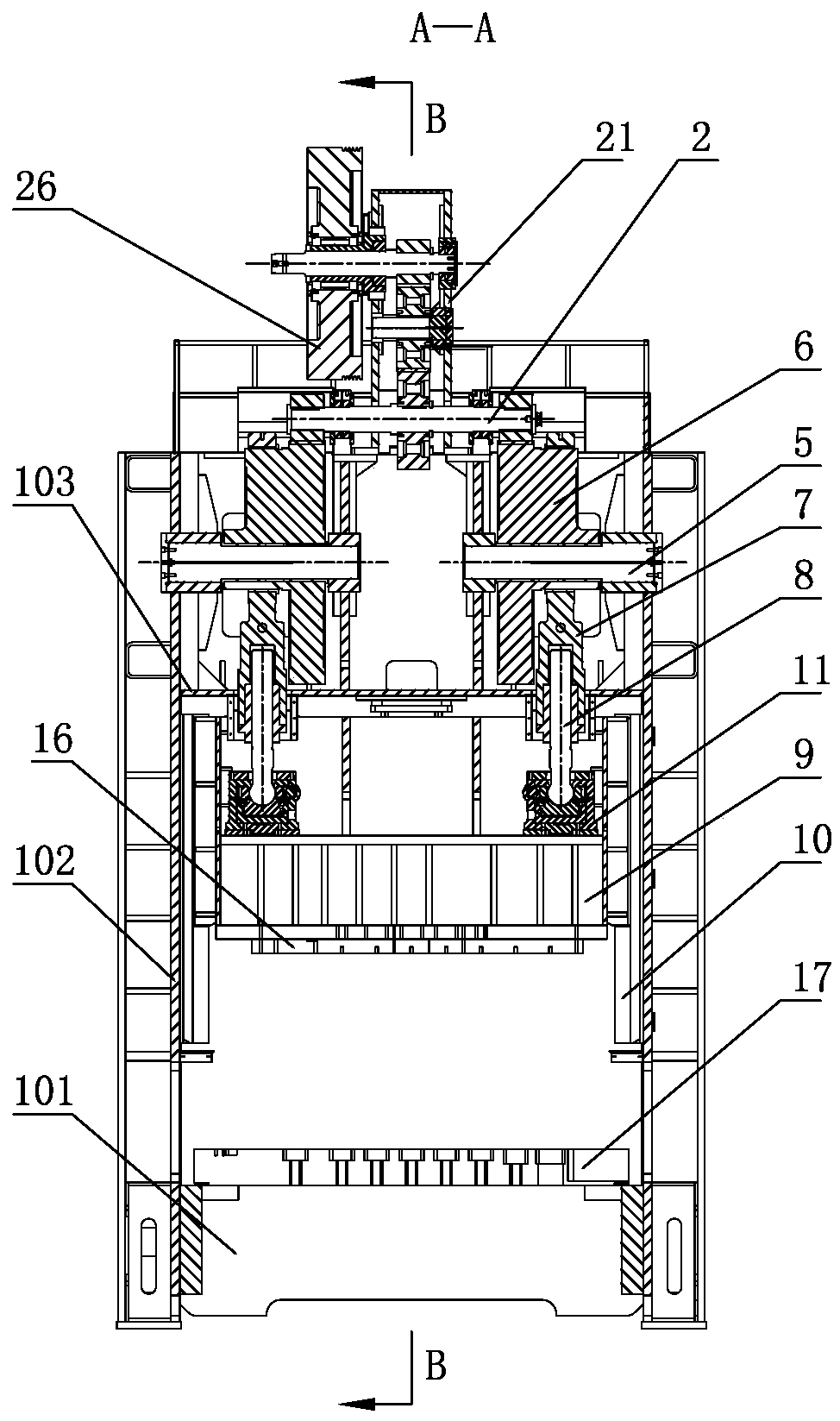

[0023] like Figure 1-9, is a large-stroke multi-station stretching press, comprising a machine body 1, a rotatable transmission shaft 2 is arranged horizontally on the upper part of the machine body 1, a first gear 3 is provided in the middle of the transmission shaft 2, two ends of the transmission shaft 2 Both ends are provided with second gears 4, and the first gears 3 are connected in transmission with the rotary drive mechanism. Power shafts 5 are respectively provided on the machine body corresponding to the second gears 4, and the axes of the two power shafts 5 coincide with each other. All are provided with eccentric gear 6, and eccentric gear 6 is meshed with corresponding second gear 4, and the eccentric wheel body of eccentric gear 6 is provided with connecting rod 7, and the bottom of connecting rod 7 is vertically provided with screw groove, and screw groove internal thread is connected with The ball screw 8 and the connecting rod 7 include a shaft 7a and a rod s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com