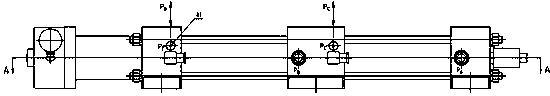

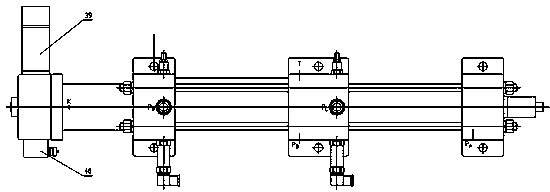

Integration series connection cylinder with adjustable stroke

A stroke, front cylinder technology, applied in the field of adjustable stroke integrated tandem cylinder, can solve the problems of adjustment, high use requirements, poor anti-eccentric load capacity, low precision, etc., to achieve strong anti-eccentric load capacity, strong control ability, integrated high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

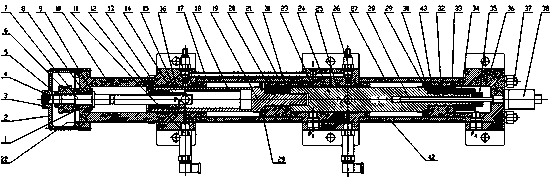

[0014]Referring to the accompanying drawings, the left side of the figure is the front, and the right side is the rear. The adjustable stroke integrated tandem cylinder includes the front piston 31, the rear piston 42, the front cylinder 22, the rear cylinder 27, the piston rod I18, and the piston rod II24. , cylinder front body 10, cylinder middle body 23, cylinder cover 36 and a group of pull rods 37, cylinder front body 10, front cylinder body 22, cylinder middle body 23, front piston 31, piston rod I 18 etc. form the front hydraulic cylinder; Body 23, rear cylinder body 27, cylinder head 36, rear piston 42, piston rod II24, etc. form the rear hydraulic cylinder; the front and rear hydraulic cylinders are connected in series by the cylinder body 23, piston rod II24 and a group of pull rods 37. Cylinder, the inner diameter of the front cylinder body and the rear cylinder body is the same, the outer diameter of the piston rod I18 and the piston rod II24 is the same, the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com