Admixture of gypsum slurry body

A technology of admixture and gypsum slurry, applied in the field of material additives, can solve the problems of uneven board density, many bubbles, difficult to achieve, etc., and achieve the effect of improving leveling and smoothness, ensuring close contact, and improving production efficiency

Inactive Publication Date: 2012-05-02

SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The theoretical water-to-plast ratio of hemihydrate gypsum is 18.61%, while the actual water consumption in the production of gypsum boards is 65% to 80%. More water can ensure the fluidity of the gypsum slurry, but it leads to the removal of excess water. The drying process is prolonged, and due to the evaporation of a large amount of water, the internal voids of the gypsum board are increased, and the strength is greatly reduced

At present, the water reducing agents used by domestic gypsum board manufacturers are mainly lignin sulfonate and naphthalene sulfonate formaldehyde condensation products; the disadvantage of lignin type water reducing agents is that the water reducing rate is low, and it will prolong the setting time of gypsum slurry. Thereby reducing the production rate of gypsum board; the disadvantages of naphthalene-based water reducing agent are low water reducing rate and high formaldehyde content, which is not environmentally friendly

[0005] In addition, one of the key indicators to be controlled in the production of gypsum boards is the board density. Light weight is the characteristic of gypsum boards. However, it is difficult to achieve the goal of light weight under the premise of ensuring a certain strength.

Generally, the gypsum board factory foams the gypsum slurry by using a common foaming agent, but because the foaming agent produces many bubbles and the size is not uniform, it is easy to cause uneven distribution of voids inside the gypsum board, resulting in board Density inhomogeneity, reducing the strength of gypsum boards

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

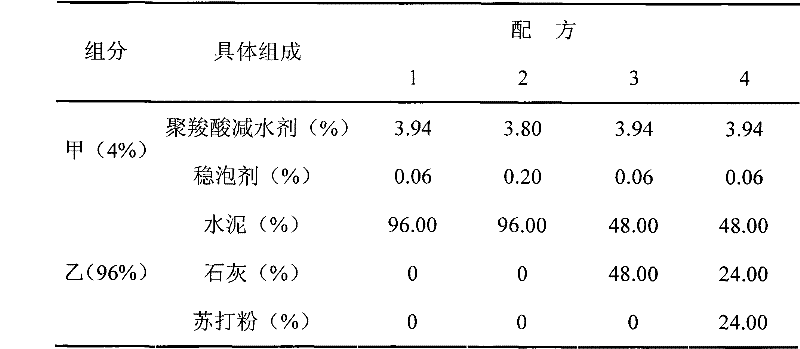

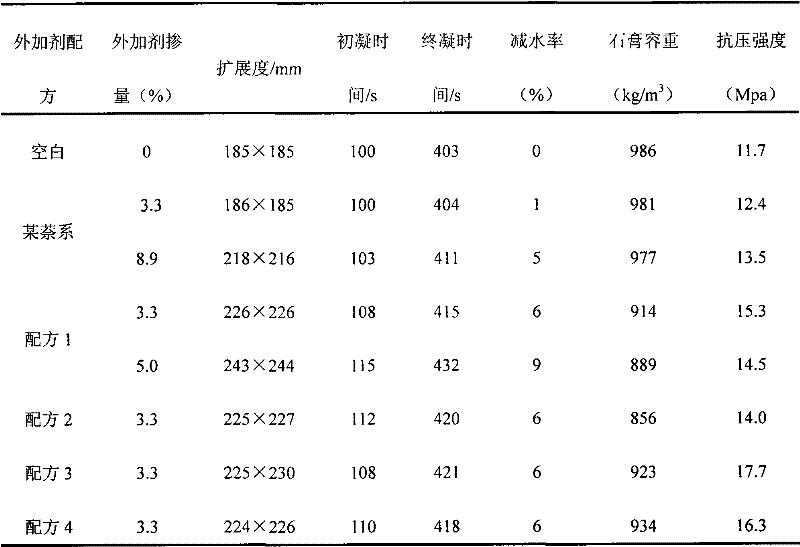

[0024] The following examples are provided in accordance with the present disclosure

[0025]

[0026] The performance of the admixture of the above formula in the gypsum slurry is tested according to the following test methods.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an admixture for a gypsum slurry body. The admixture comprises a component A and a component B, wherein the component A comprises a poly-carboxylic acid water reducer and a foam stabilizer, and the component B comprises a modifier; the component A accounts for 1.0-20.0% of the weight of the admixture, and the component B accounts for 80.0-99.0% of the weight of the admixture; and the component B is one or several of cement, lime and soda powder, and the doped quantity of the admixture is 0.5-5.0% of the weight of gypsum powder. The invention has the characteristics of high water reduction rate and no coagulation delay and can lower the volumetric weight of the gypsum. By preparing plasterboards through the gypsum admixture, the energy consumption of the production can be greatly lowered, and the production efficiency is enhanced.

Description

technical field [0001] The invention relates to material additives. Specifically, polycarboxylate water reducing agent and foaming agent are used as the A component, and cement, lime, soda powder, etc. are used as the B component. A working admixture for gypsum slurry. Background technique [0002] Gypsum is one of the three traditional inorganic cementitious materials (cement, gypsum, lime) and is an important building material. With the development of the construction industry, gypsum board, which is the leading product of new interior wall materials, has the advantages of light weight, sound insulation, heat insulation, good fire resistance, safe living, easy replacement, and regeneration. Poisonous, odorless and pollution-free real green building materials. [0003] Gypsum wall building material is a really cheap and high-quality material, and the reason for its lower cost is that the preparation process is fast and efficient. [0004] In terms of improving the produc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B24/26C04B28/14C04B103/30

CPCC04B40/0039

Inventor 傅乐峰郑柏存邓最亮冯中军张毅

Owner SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com