Porous water permeable brick having a purifying function and preparing method thereof

A technology of permeable bricks and functions, applied in the field of porous permeable bricks and its preparation, can solve problems such as human body and biological hazards, river silting, and dust generation, and achieve good compatibility, increase consistency and viscosity, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

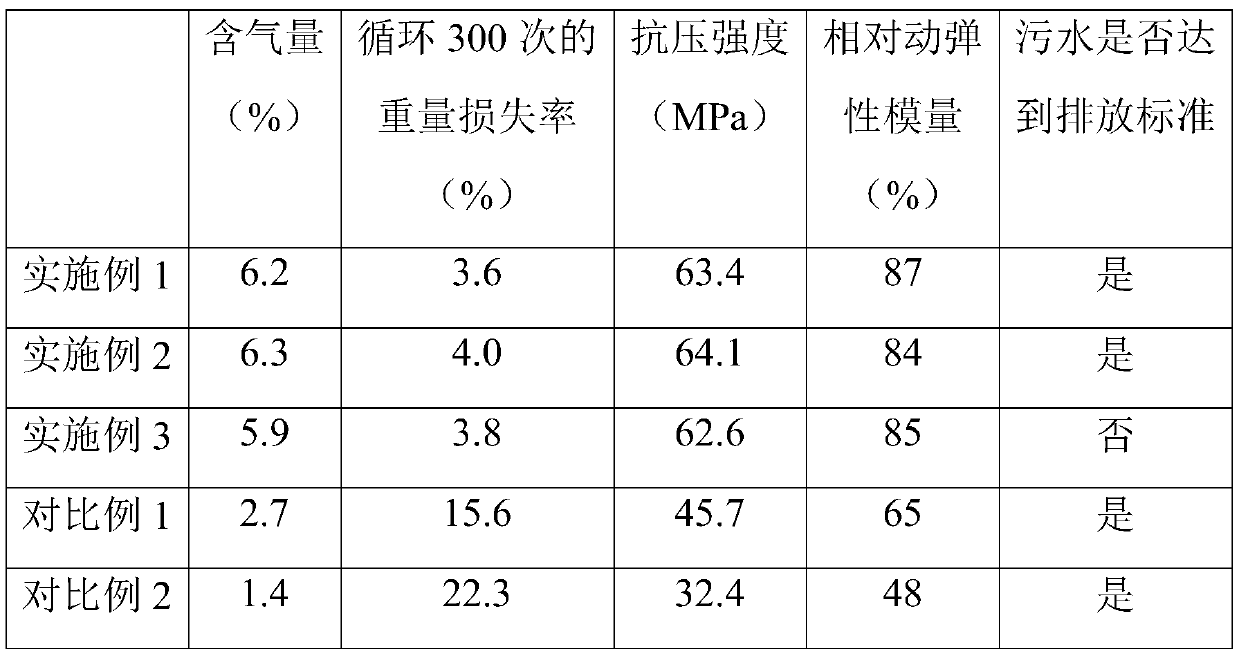

Examples

Embodiment 1

[0033] A porous permeable brick with purifying effect, comprising the following components in parts by weight:

[0034] 60 parts of waste glass, 60 parts of fly ash, 30 parts of cement, 8 parts of montmorillonite, 10 parts of sisal fiber, 10 parts of gypsum, 0.5 part of sodium lignosulfonate, 0.5 part of triterpene saponin, 0.3 part of microbial bacterial liquid , 0.5 parts of sodium lignosulfonate, 4 parts of aggregate, and 5 parts of sepiolite.

[0035] Wherein, the preparation method of microbial bacterial liquid is as follows:

[0036] (1) Weigh 10g of glucose, 15g of agar, 10g of peptone, 5g of beef extract, and 10g of sodium chloride, mix them with water, dissolve them in water, heat and stir until boiling, cool to room temperature, and then adjust the pH value to 7.0 to prepare nutrients liquid;

[0037] (2) Inoculate the Bacillus subtilis and the syntrophic bacillus into the nutrient solution, and shake and culture at a speed of 120 r / min for 48 hours in a water bath...

Embodiment 2

[0044] A porous permeable brick with purifying effect, comprising the following components in parts by weight:

[0045] 40 parts of waste glass, 40 parts of fly ash, 20 parts of cement, 5 parts of montmorillonite, 5 parts of sisal fiber, 10 parts of gypsum, 0.5 part of sodium lignosulfonate, 1 part of triterpene saponin, 0.5 part of microbial bacterial liquid , 5 parts of aggregate, and 10 parts of meerschaum.

[0046] Wherein, the preparation method of microbial bacterial liquid is as follows:

[0047] (1) Weigh 5g of glucose, 10g of agar, 5g of peptone, 5g of beef extract, and 15g of sodium chloride, mix them with water, dissolve them in water, heat and stir until boiling, cool to room temperature, and then adjust the pH value to 7.2 to prepare nutrients liquid;

[0048] (2) Inoculate the Bacillus subtilis and the syntrophic bacillus into the nutrient solution, and shake and culture at a speed of 120 r / min for 48 hours in a water bath at 30-40°C.

[0049] The preparation ...

Embodiment 3

[0055] A porous permeable brick with purifying effect, comprising the following components in parts by weight:

[0056] 50 parts of waste glass, 50 parts of fly ash, 25 parts of cement, 8 parts of montmorillonite, 5 parts of sisal fiber, 12 parts of gypsum, 0.8 part of sodium lignosulfonate, 0.5 part of triterpene saponin, 5 parts of aggregate, and 5 parts meerschaum.

[0057] The preparation method of the porous permeable brick comprises the following steps:

[0058] (1) Soak fly ash in heterogeneous ethanol solution for 30 minutes, filter and dry, and further pulverize to a particle size of 2mm, and set aside;

[0059] (2) Pulverize the waste glass to a particle size of 2mm, mix it with cement, montmorillonite, gypsum, binder and the fly ash treated in step (1) according to the formula, add water and stir for 5 hours at 50°C;

[0060] (3) Pulverizing the sisal fiber to a particle size of 2mm, mixing it with triterpene saponin and sodium lignosulfonate, adding it to the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com