Three-point high speed precision press machine

A press, high-speed technology, applied in the field of presses, can solve the problems of the large increase in the weight of the slider, the inability to meet the precision blanking, the large deformation of the slider, etc., to achieve strong anti-eccentric load capacity, good working stability and precision Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

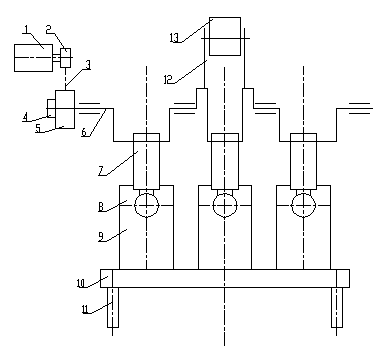

[0010] As shown in the figure, a three-point high-speed precision press mainly includes a slider 10 that is arranged above the worktable of the press and is connected by a linear guide post 9 and can slide vertically. The linear guide post 9 and the connecting rod 7 pass through a ball bearing 8 The other end of the connecting rod 7 is connected to a crankshaft 6, the crankshaft 6 drives the balance connecting rod 12, and the balance connecting rod 12 drives the dynamic balance weight 13, and the crankshaft 6 realizes the transmission of torque through the pneumatic friction clutch-brake 4 and the flywheel 5, The shaft end of the motor 1 is transmitted to the flywheel 5 through the pulley 2 and the V-belt 3 .

[0011] When working, the motor 1 rotates, and the torque is transmitted to the flywheel 5 through the transmission of the motor wheel 2 and the V-belt 3, and the flywheel 5 controls the operation of the ball bearing 6 through the pneumatic friction clutch-brake 4. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com