Servo press machine using symmetrically-arranged multi-end-face cams for driving even number of independent toggle rods

A servo press, symmetrical arrangement technology, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve the problems of too long transmission chain of servo presses, frequent start and stop of motors, low transmission efficiency, etc., and achieve anti-eccentric load. The effect of strong capacity, convenient processing and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

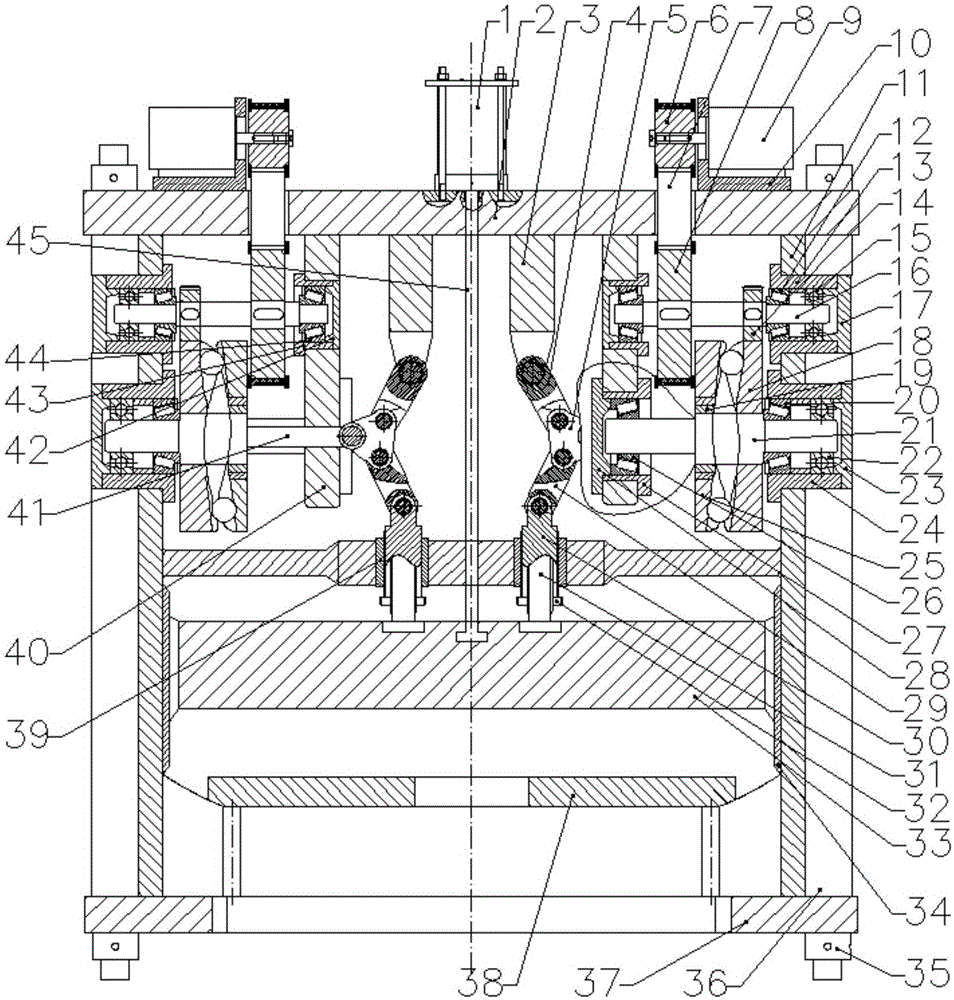

[0010] The present invention will be described in detail below in conjunction with the drawings.

[0011] With reference to the drawings, the symmetrically arranged multi-face cam drives an even number of independent toggle-type servo presses, including the upper body 2 and the lower body 37, the column 36 and the upper body 2, and the lower body 37 are connected to each other by tension bolts 35 Together, two servo motors 9 are installed on two motor brackets 10, and the two motor brackets 10 are installed symmetrically on the top of the upper body 2. The output shaft of the servo motor 9 is connected with a small pulley 6, and the small pulley 6 passes through a timing belt 7 is connected to the big pulley 8, which is keyed to the transmission shaft 16. One end of the transmission shaft 16 is installed in the first sleeve 13 through the first rolling bearing 15 and the first tapered roller bearing 12. The first sleeve 13 Connected to the second support plate 11, the second supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com