Manufacturing method of CuNi90/10 alloy socket welding flange

A manufacturing method and welding flange technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of small deformation of the core of the material, large potential safety hazards in use, poor air tightness of the material, etc., and achieve reduction Machining cutting amount, improving strength and good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for manufacturing a CuNi90 / 10 alloy socket welding flange, comprising the following steps:

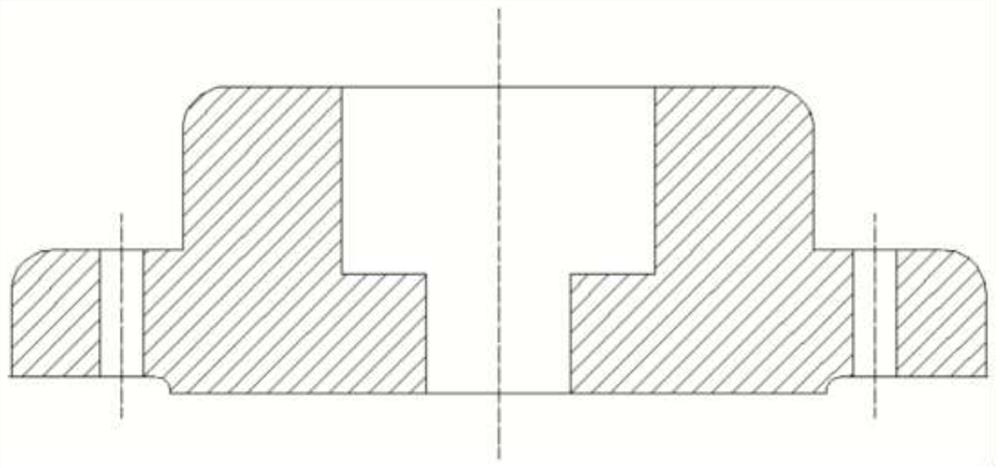

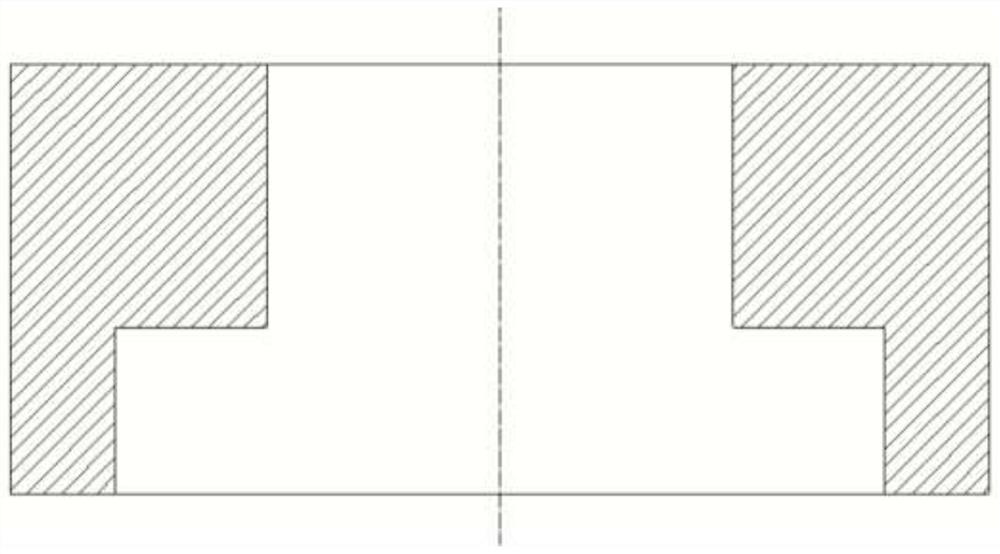

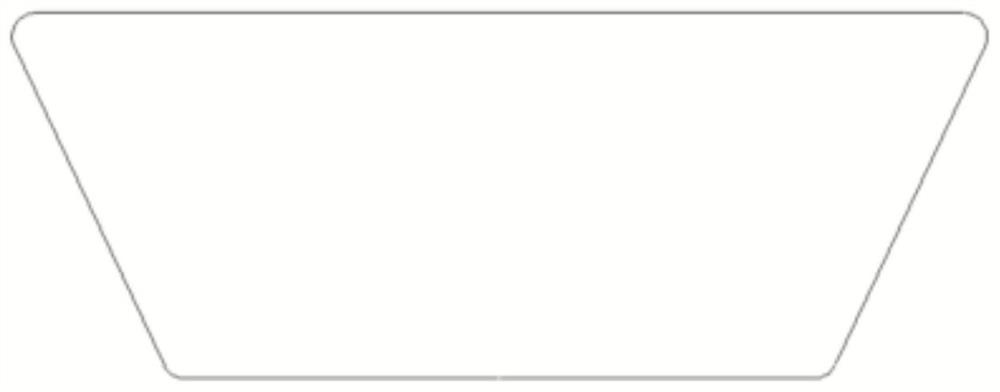

[0038] S1 modeling: such as figure 1 As shown, the shape of the CuNi90 / 10 alloy socket welding flange is a combination of two cylindrical shapes with a small top and a large bottom. There is a through hole in the middle of the CuNi90 / 10 alloy socket welding flange. Dimensions of CuNi90 / 10 alloy socket welding flange, such as Figure 2-4 As shown, a set of mold is manufactured. The mold is made of low carbon steel, which is divided into two parts: the outer mold and the punch, and the punch is divided into two parts: the blind hole punch and the through hole punch;

[0039] S2 Heating Billet: Heating the CuNi90 / 10 alloy ingot to the forging temperature, the ratio of ingot diameter to holding time is 1:1.6, and the numerical units are mm and min respectively, which can accurately control the heating time and ensure the processing quality of subsequent processes , forged...

Embodiment 2

[0047] A method for manufacturing a CuNi90 / 10 alloy socket welding flange, comprising the following steps:

[0048] S1 modeling: such as figure 1 As shown, the shape of the CuNi90 / 10 alloy socket welding flange is a combination of two cylindrical shapes with a small top and a large bottom. There is a through hole in the middle of the CuNi90 / 10 alloy socket welding flange. Dimensions of CuNi90 / 10 alloy socket welding flange, such as Figure 2-4 As shown, a set of mold is manufactured. The mold is made of low carbon steel, which is divided into two parts: the outer mold and the punch, and the punch is divided into two parts: the blind hole punch and the through hole punch;

[0049] S2 heating billet: heating the CuNi90 / 10 alloy ingot to the forging temperature, the ratio of ingot diameter and holding time is 1:1.8, and the numerical units are mm and min respectively, which can accurately control the heating time and ensure the processing quality of the subsequent process , for...

Embodiment 3

[0057] A method for manufacturing a CuNi90 / 10 alloy socket welding flange, comprising the following steps:

[0058] S1 modeling: such as figure 1 As shown, the shape of the CuNi90 / 10 alloy socket welding flange is a combination of two cylindrical shapes with a small top and a large bottom. There is a through hole in the middle of the CuNi90 / 10 alloy socket welding flange. Dimensions of CuNi90 / 10 alloy socket welding flange, such as Figure 2-4 As shown, a set of mold is manufactured. The mold is made of low carbon steel, which is divided into two parts: the outer mold and the punch, and the punch is divided into two parts: the blind hole punch and the through hole punch;

[0059] S2 heating billet: heating the CuNi90 / 10 alloy ingot to the forging temperature, the ratio of ingot diameter to holding time is 1:2.0, and the numerical units are mm and min respectively, which can accurately control the heating time and ensure the processing quality of the subsequent process , forg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com