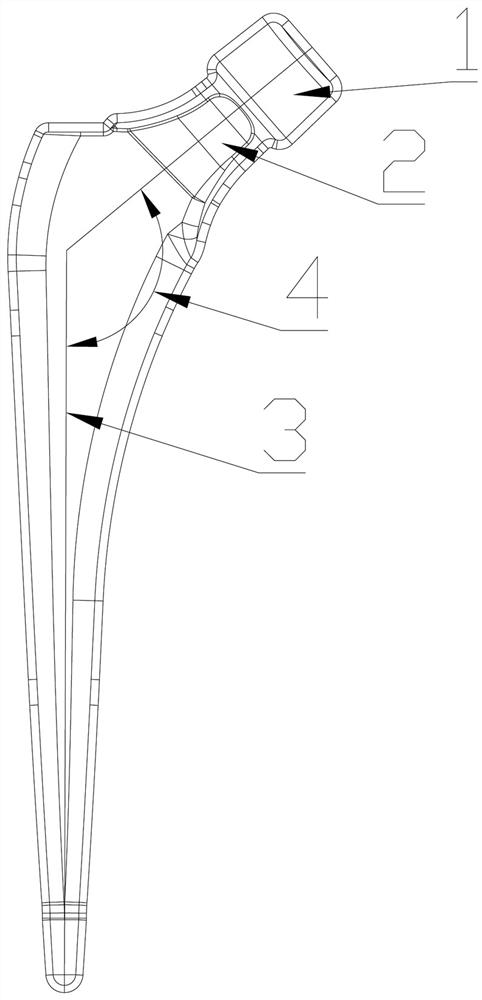

Forging method for alloy femoral component forged part

A femoral stem and alloy technology, which is applied in the forging field of alloy femoral stem forgings, can solve problems such as inconsistency in size and mechanical properties of forgings, excessive neck-shaft angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Taking the forging process of a femoral stem made of CoCrMo alloy as an example, a method for forging an alloy femoral stem forging of the present invention is described, which includes the following steps.

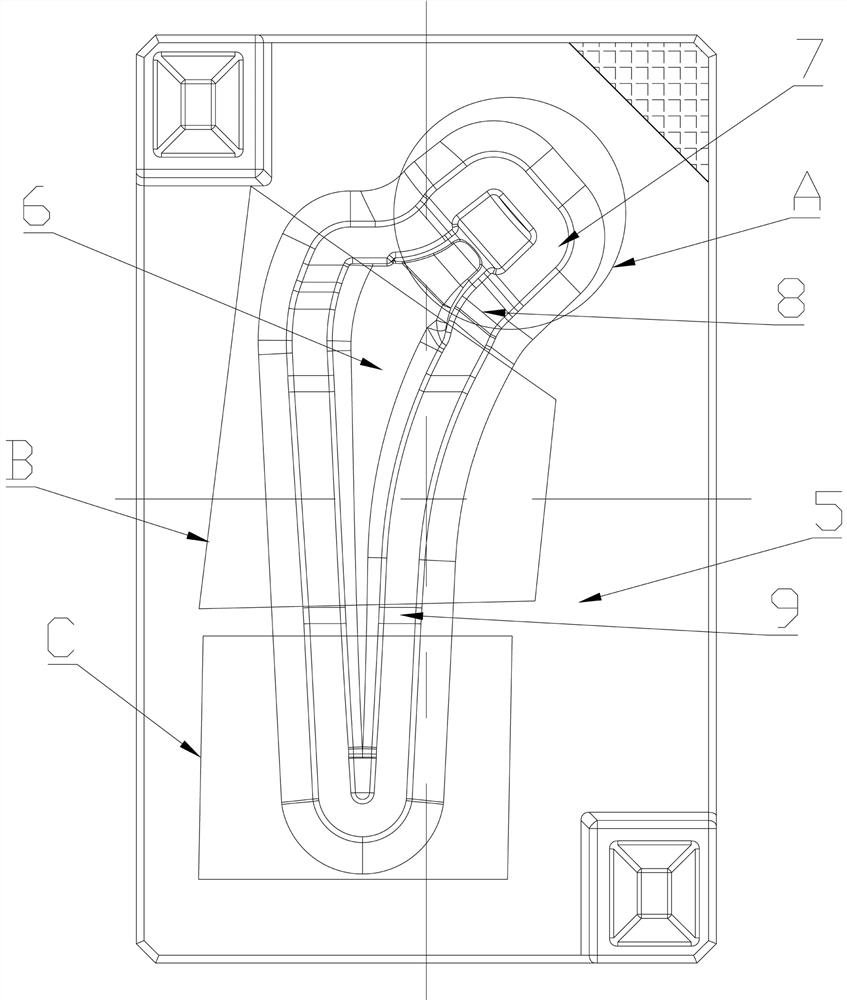

[0029] S1: Design the femoral stem mold; figure 2 As shown, the mold cavity 6 is arranged in the warehouse part 5 of the mould, and the bridge part 7 is formed along the periphery of the mold cavity 6; when designing the femoral handle mould, the mold cavity is divided according to the area size of the cross section of the mold cavity 6; The cavity partition with the smallest cross-section is the reference partition, and the height of the bridge portion of the other cavity partitions is reduced according to the ratio of the cross-sectional area of the reference partition; the bridge portion of the cavity partition with a larger cross-section The lower the height; when implementing it, divide the mold cavity according to the specific shape of the product;

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com