Symmetric outer planetary wheel combined precision forging die

An outer planetary gear, combined technology, applied in the direction of wheels, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of affecting the service life of the mold, affecting the structure and accuracy of the mold, and the economic loss of users, and achieves a high level of improvement. Service life, extended service life, and the effect of eliminating machining steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

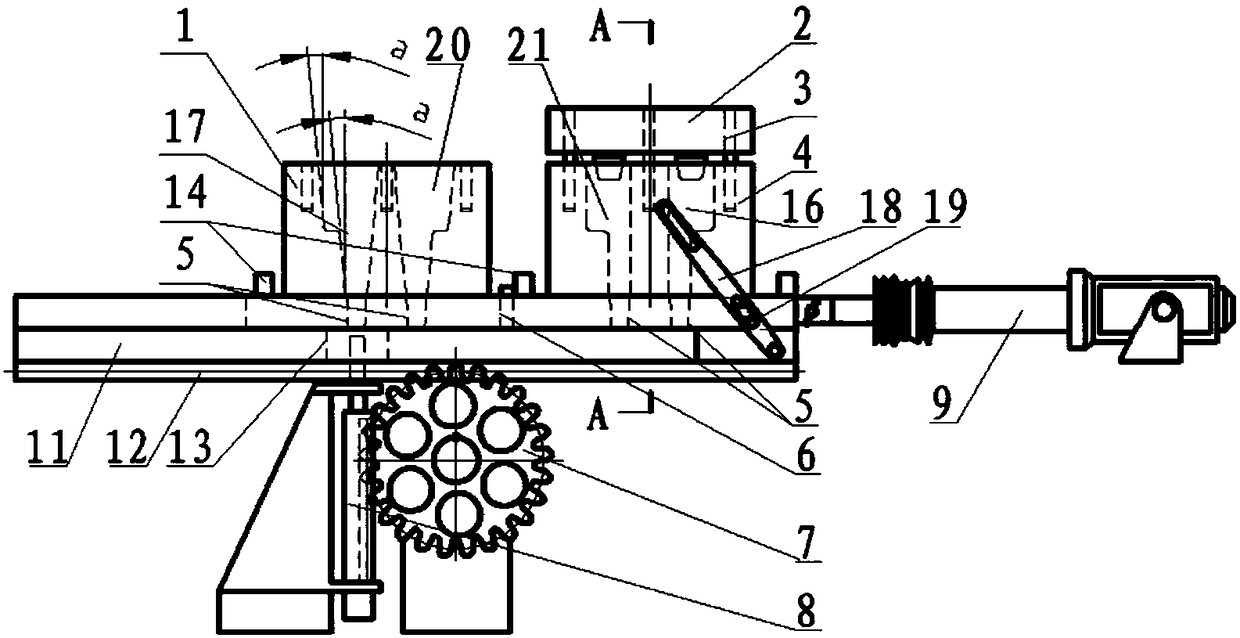

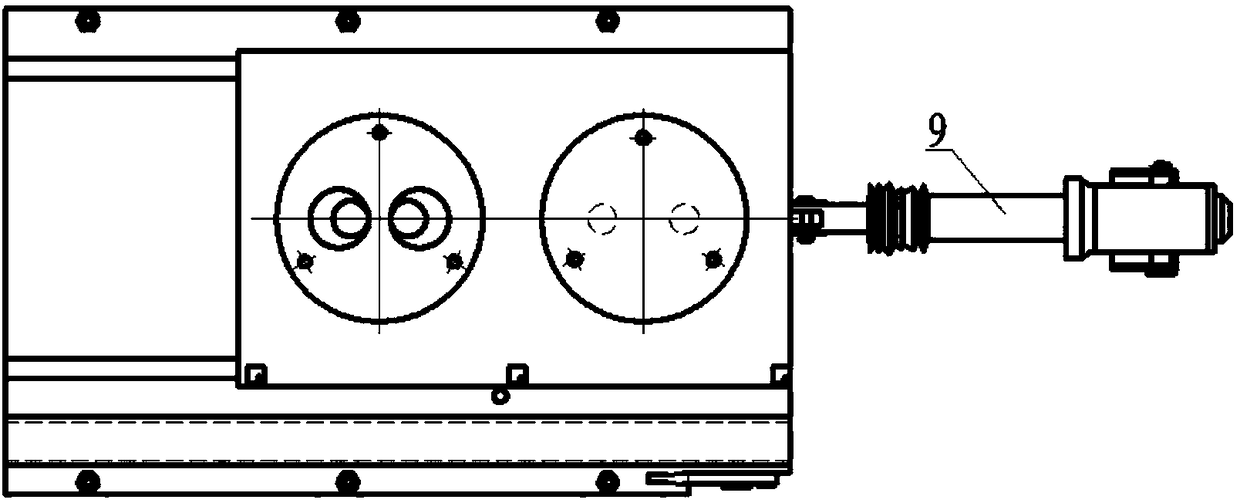

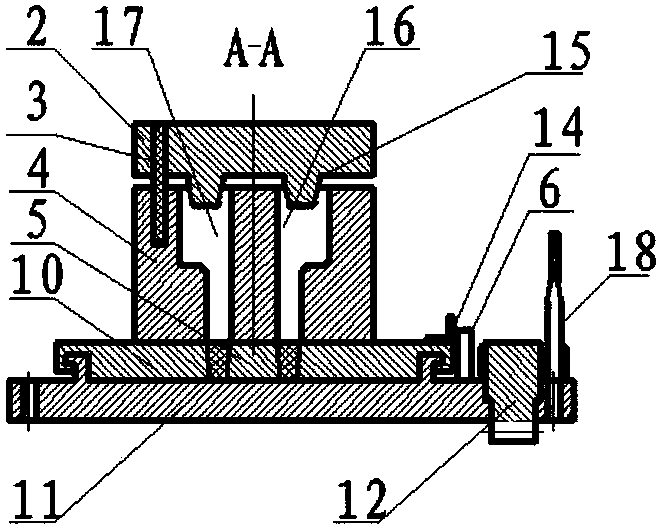

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] Such as Figure 1-3 As shown, the present invention is a symmetrical outer planetary combined precision forging die, including an upper die 2, a lower pre-mold 1, a lower final die 4, a lower die bottom plate 10, a guide rail plate 11, a rack plate 12, and a measuring rod 3 , movable plate 5, action mechanism 9, gear 7, rack ejector rod 8, hand plate 18; the upper die 2 is provided with a groove 15, and the upper die 2 is guided by the measuring rod 3 to limit the position of the lower pre-mold 1 , and limit the position of the lower final mold 4, the lower pre-mold 1 is provided with a mold cavity one 17 and a mold cavity three 20, the mold cavity one 17 and the mold cavity three 20 have a taper, and the upper cross-sectional area is greater than the lower cross-sectional area, so The cavity 2 16 and the cavity 4 21 are arranged in the lower final mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com