Wear-resistant structure without damaging matrix and preparation method of wear-resistant structure

A matrix and wear-resistant column technology, applied in the field of wear-resistant structures, can solve problems such as mounting hole swelling, equipment damage, and insufficient wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

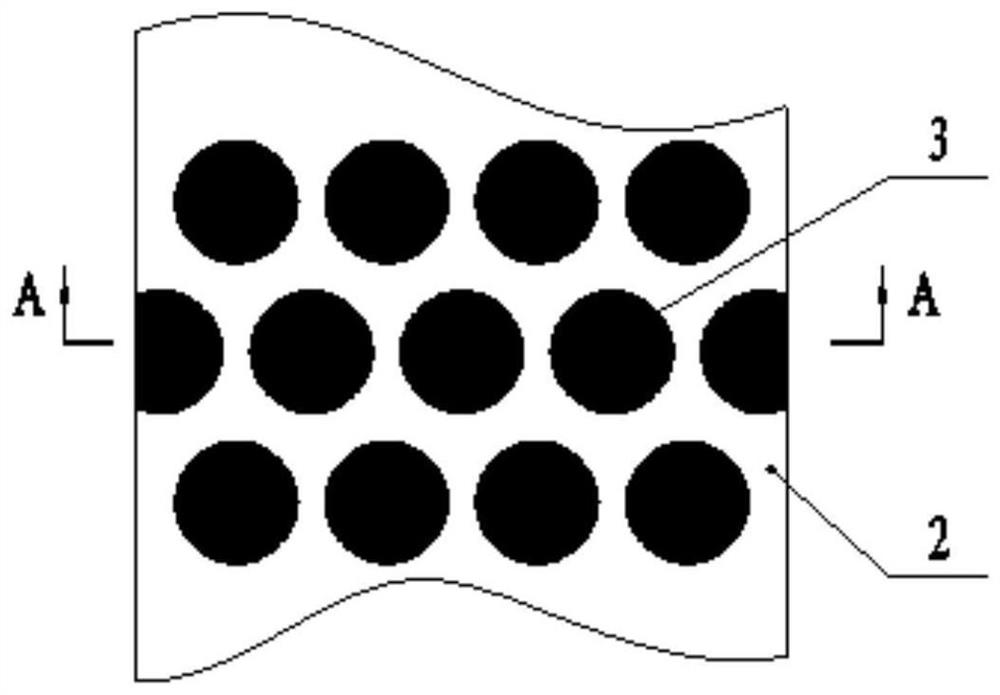

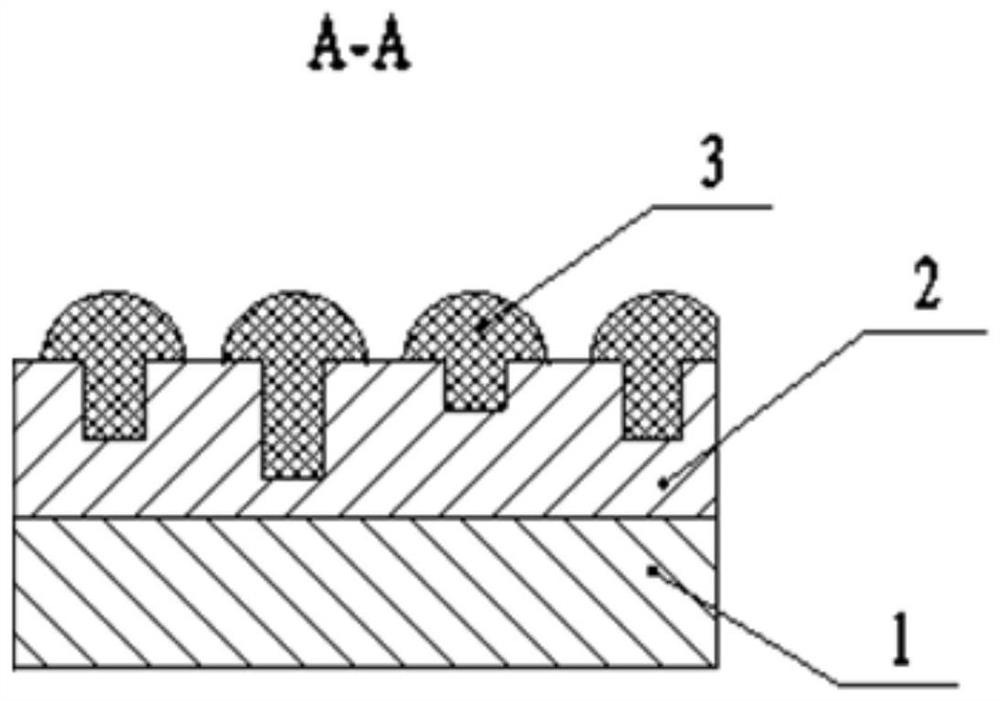

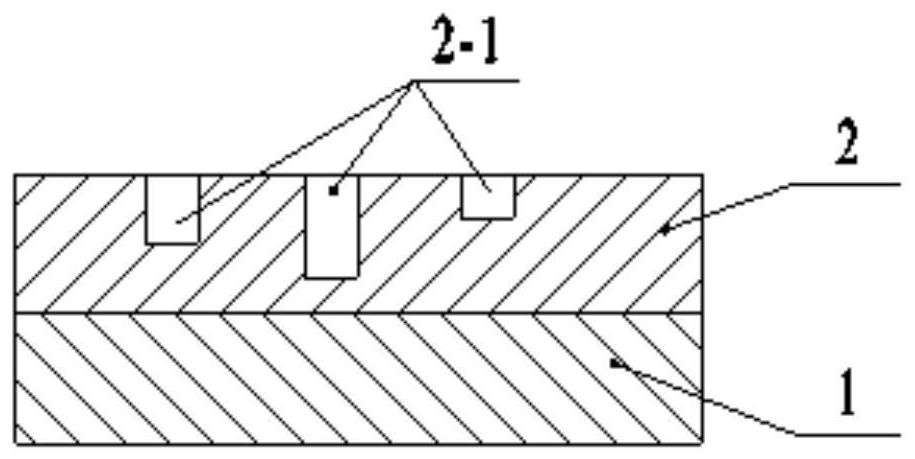

[0036] A wear-resistant structure that does not damage the parent body: including a transition layer 2 and welded wear-resistant studs 3;

[0037] The transition layer 2 is arranged on the outer surface of the matrix 1 with a thickness of 50mm; the transition layer 2 is provided with a round hole 2-1, the axis of the above round hole 2-1 is perpendicular to the surface of the transition layer 2 and is distributed in a staggered manner, and the center of the round hole 2-1 The distance is 40mm, the diameter is 20mm, the hole depth is 20-40mm, and the depth of round hole 2-1 is not exactly the same;

[0038] The above-mentioned welded wear-resistant studs 3 are set in the round hole 2-1, the part above the transition layer 2 is hemispherical, the diameter of the hemisphere is 30mm, and the height of the parts higher than the transition layer 2 is the same; the welded wear-resistant studs 3 are in the transition Leave a 10mm wide gap on layer 2.

[0039] The preparation method o...

Embodiment 2

[0044] A wear-resistant structure that does not damage the parent body: including a transition layer 2 and welded wear-resistant studs 3;

[0045] The transition layer 2 is arranged on the outer surface of the matrix 1 with a thickness of 40mm; the transition layer 2 is provided with round holes 2-1, the axes of the above round holes 2-1 are perpendicular to the surface of the transition layer 2 and are distributed in a staggered manner, and the center of the round holes 2-1 The distance is 65mm, the diameter is 30mm, the hole depth is 20-35mm, and the depth of round hole 2-1 is not exactly the same;

[0046] The above-mentioned welded wear-resistant studs 3 are set in the round hole 2-1, the part above the transition layer 2 is hemispherical, the diameter of the hemisphere is 60 mm, and the height of the parts higher than the transition layer 2 is the same; the welded wear-resistant studs 3 are in the transition A 5 mm-wide slit was formed on the layer 2 .

[0047] The prepa...

Embodiment 3

[0052] A wear-resistant structure that does not damage the parent body: including a transition layer 2 and welded wear-resistant studs 3;

[0053] The transition layer 2 is arranged on the outer surface of the flat plate 1 with a thickness of 50mm; the transition layer 2 is provided with a round hole 2-1, the axis of the above round hole 2-1 is perpendicular to the surface of the transition layer 2 and is distributed in a staggered manner, and the center of the round hole 2-1 The distance is 47mm, the diameter is 35mm, the hole depth is 20-25mm, and the depth of round hole 2-1 is not exactly the same;

[0054] The above-mentioned welded wear-resistant stud 3 is set in the round hole 2-1, the part above the transition layer 2 is hemispherical, the diameter of the hemisphere is 45mm, and the height of the part higher than the transition layer 2 is the same; the welded wear-resistant stud 3 is in the transition A 2 mm wide slit was formed on the layer 2 .

[0055] The preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com