Plowing machine and plowing method thereof

A farming machine and frame technology, which is applied in the field of farming machines and tools, can solve the problems of increased tillage depth, easy breakage, unstable tillage depth, etc., and achieve the effects of deepened tillage depth, stable operation, and good stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

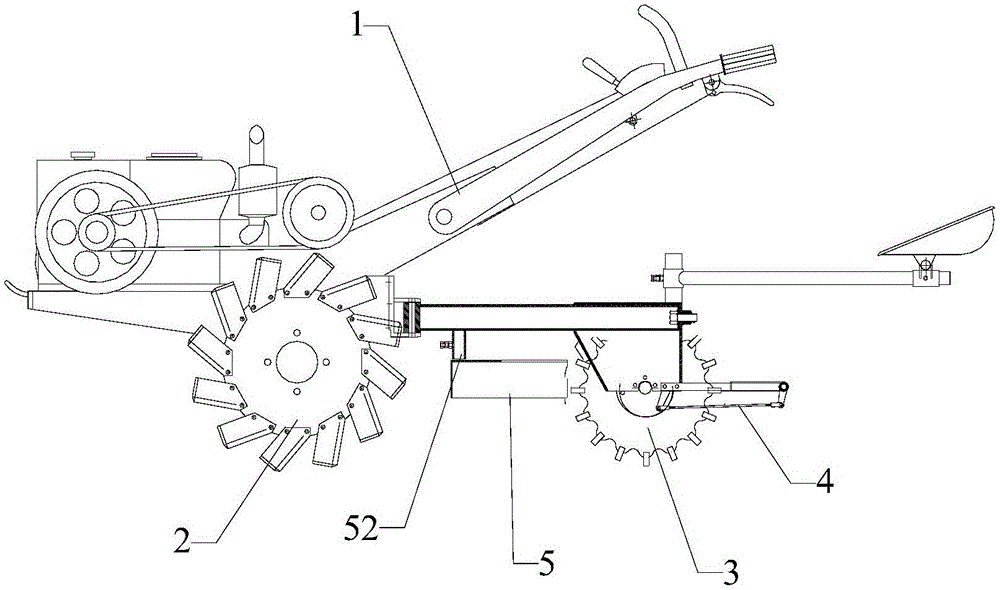

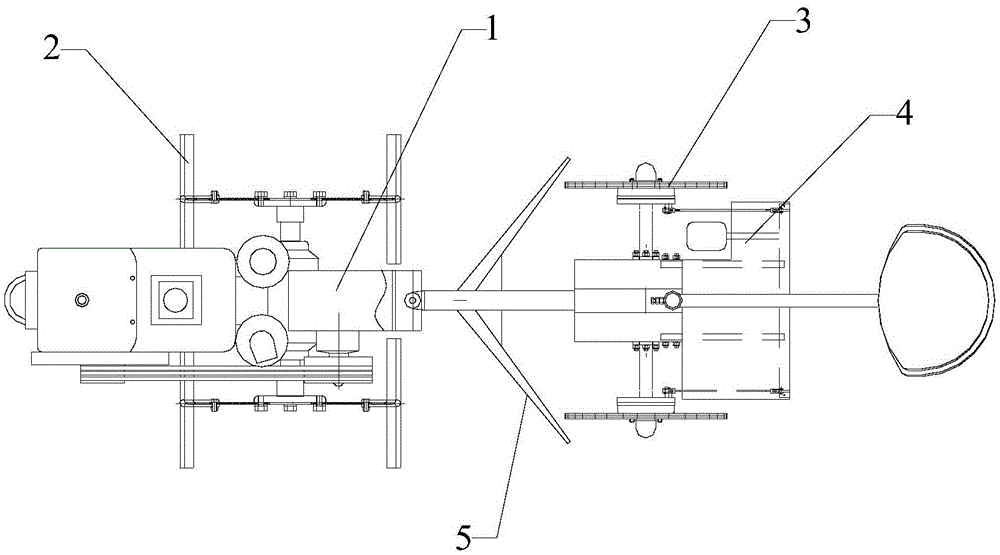

[0041] Please refer to Figure 1 to Figure 6 Shown, embodiment one of the present invention is:

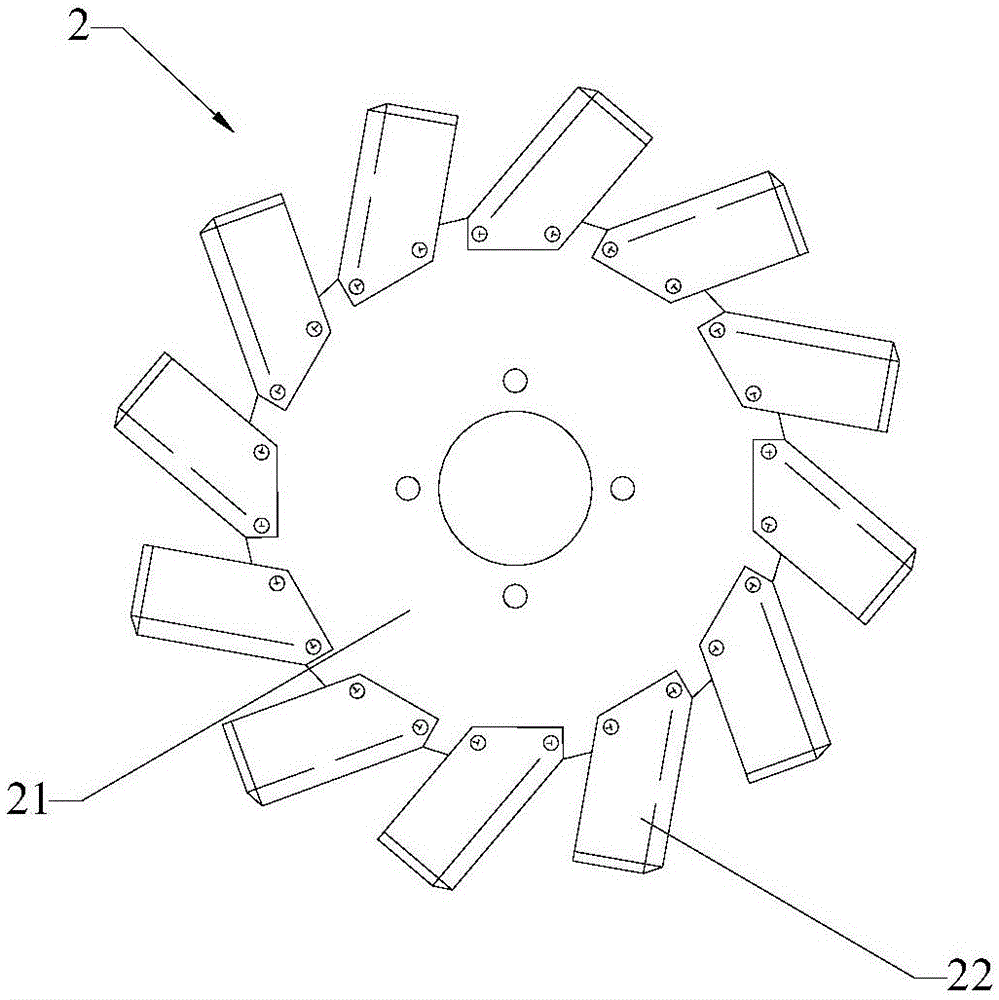

[0042]An agricultural machine and its farming method, comprising a frame 1, a coulter wheel 2, a resistance wheel 3 and a scraping device 5, the coulter wheel 2 is arranged in front of the resistance wheel 3, and the coulter wheel 2 includes a flange Disk 21 and a plurality of coulters 22, the coulters 22 are evenly installed on the outer edge of the flange plate 21, the adjacent coulters 22 are installed in reverse, the resistance wheel 3 is provided with a braking device 4, the scraper The leveling device 5 is arranged between the coulter wheel 2 and the resistance wheel 3, and the leveling device 5 includes a vertically arranged scraping plate 51 and a height adjuster 52, and the one scraping plate 51 is symmetrically fixed on the On both sides of the frame 1, the scraper plate 51 is arranged inclined to the rear of the agricultural machine, the scraper plate 51 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com