Gear preliminary forged piece water-spraying descaling device

A technology for descaling and forging, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of irregular gear shape, damage to the surface of the workpiece, unsuitable for steel brushes, etc., to eliminate The effect of forging oxidation pit, improving forging accuracy and improving surface quality of forgings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

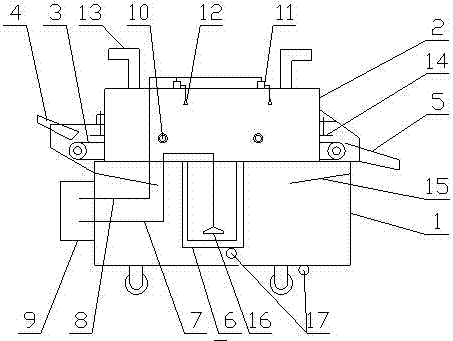

[0016] see figure 1 , the embodiment of the present invention provides a device for descaling by spraying water on primary forgings of gears, including a control structure (not shown in the figure), a circulating water tank 1, a conveying tunnel 2 arranged on the circulating water tank 1, a The chain plate conveying structure 3, the feeding structure 4 arranged at the front end of the chain plate conveying structure 3, the unloading structure 5 arranged at the rear end of the chain plate conveying structure 3, at least one sprinkler 12 (generally 2 or 3), the filtered water tank 6 on the circulating water tank 1, the high-pressure pump 9 on the circulating water tank 1, at least one photoelectric sensor 10 on the conveying tunnel 2, etc. Among them, the upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com