Length detection and automatic feeding and discharging device for short metal bar stocks

A technology of feeding and discharging materials and short bars, applied in conveyor control devices, transportation and packaging, conveyors, etc., can solve problems such as increasing product rejection rate, affecting forging accuracy and quality, and inconsistent heating temperature, ensuring continuity and The effect of stability, improving forging accuracy and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

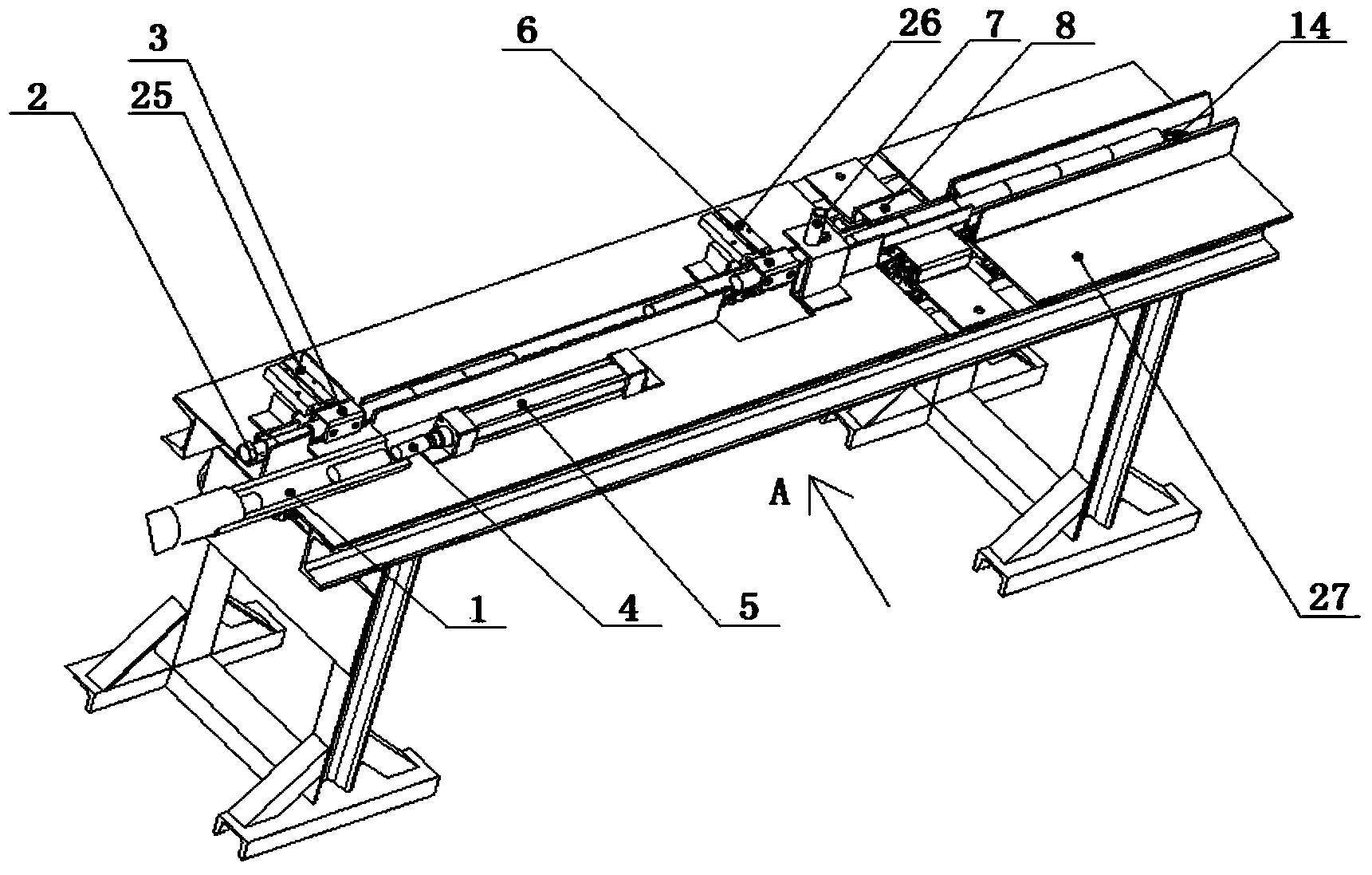

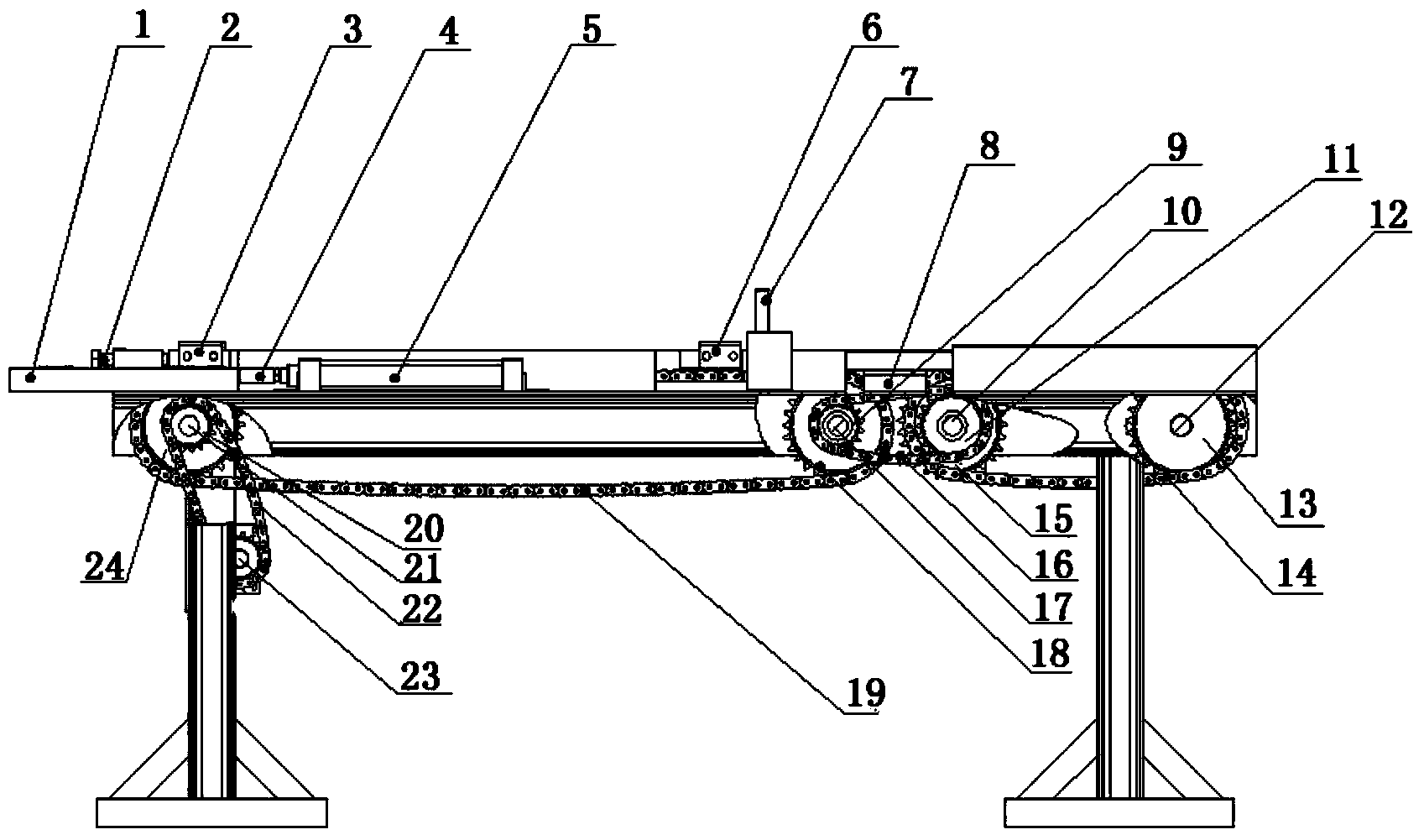

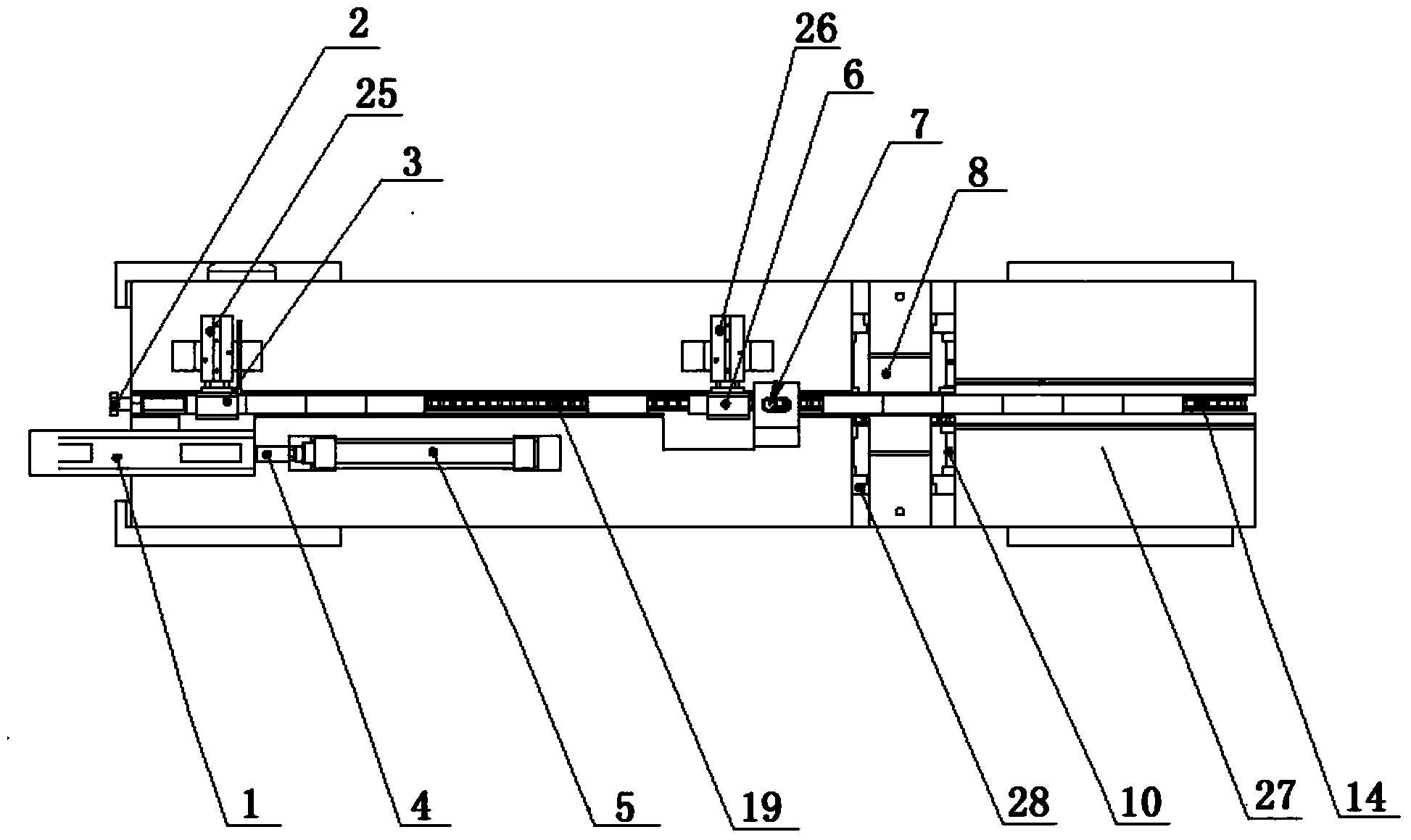

[0016] by figure 2 The one shown on the right is the front for description, such as figure 1 , figure 2 with image 3 As shown, the present invention comprises support 27, material rail 1, motor driving wheel 20, motor driving wheel 23, transmission chain-22, longitudinal cylinder 5, primary driven wheel 13, secondary driving wheel 24, transmission shaft-12, transmission Shaft four 21 and bearing seat 28, the material rail 1 is arranged on the support 27, the motor driving wheel 20 and the motor driving wheel 23 are connected by the transmission chain one 22, and the longitudinal cylinder 5 is arranged in front of the material rail 1 and is in the same position as it. On the axis, the longitudinal cylinder push plate 4 is fixed on the extended end of the longitudinal cylinder 5, and the transmission shaft one 12 and the transmission shaft four 21 are installed on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com