Intelligent plastic forming process method and intelligent plastic forming equipment used for same

A technology of plastic forming and process method, which is applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of low product rate, insufficient precision, long manufacturing cycle, etc., and achieve surplus materials and dressing materials. Less, ensure the internal quality, the effect of high forging accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

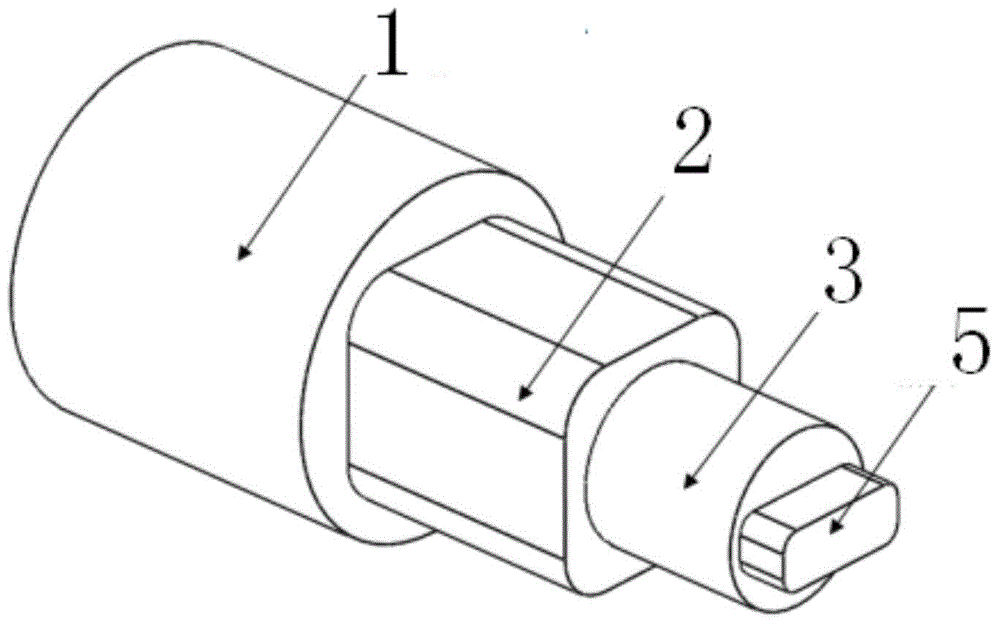

[0045] Embodiment: an intelligent plastic forming process, the specific steps are as follows:

[0046] Step 1: Carry out three-dimensional modeling on the forging 11 and use finite element analysis software to digitally simulate the plastic deformation of the model, wherein the three-dimensional software can be CAD software;

[0047] Step 2: According to the simulation results, an automatic program design system with machine learning function (intelligent concept design system based on machine learning) is used to complete the analysis and programming of the forging 11 forming steps (on-line or off-line);

[0048] Step 3: Steel ingot heating: heating according to design requirements;

[0049] Step 4: Closed upsetting: Put the heated steel ingot into the upsetting cylinder, and perform closed upsetting on the steel ingot on the intelligent plastic forming hydraulic press (not on the free forging hydraulic press) to form a blank. The heat and force process of forging eliminates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com