All-hydraulic die forging hammer

A die forging hammer, full hydraulic technology, applied in the direction of forging/pressing/hammer device, forging press, forging press, etc., can solve the problem of difficult precision die forging, increasing the gap between the slider and the bed, affecting the working accuracy of the whole machine, issues of reliability and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

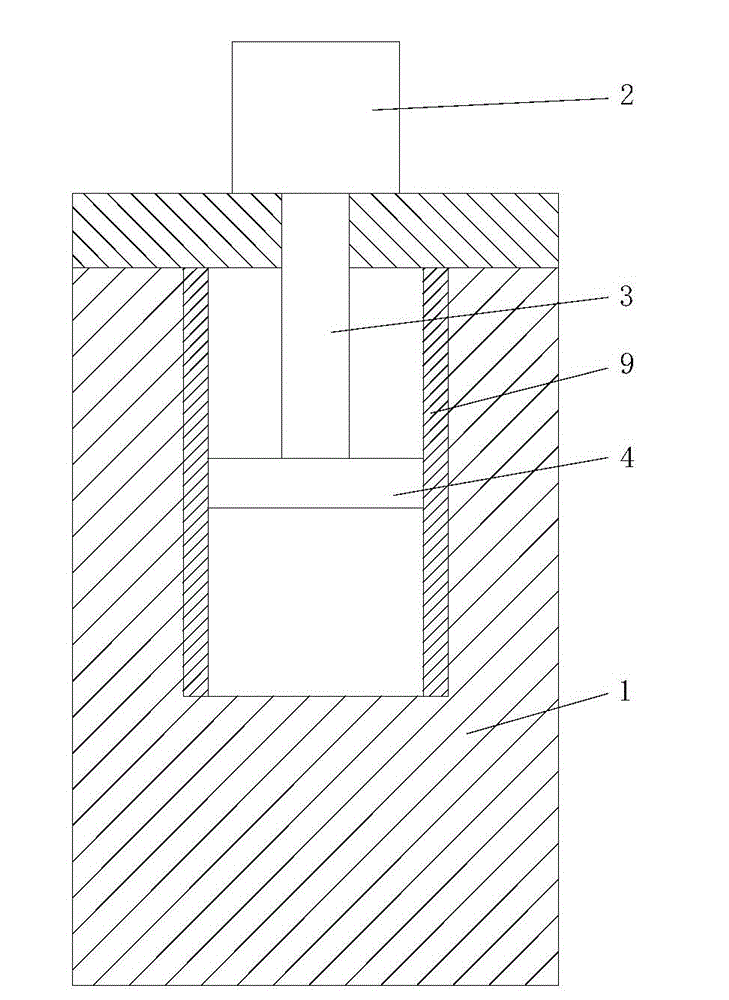

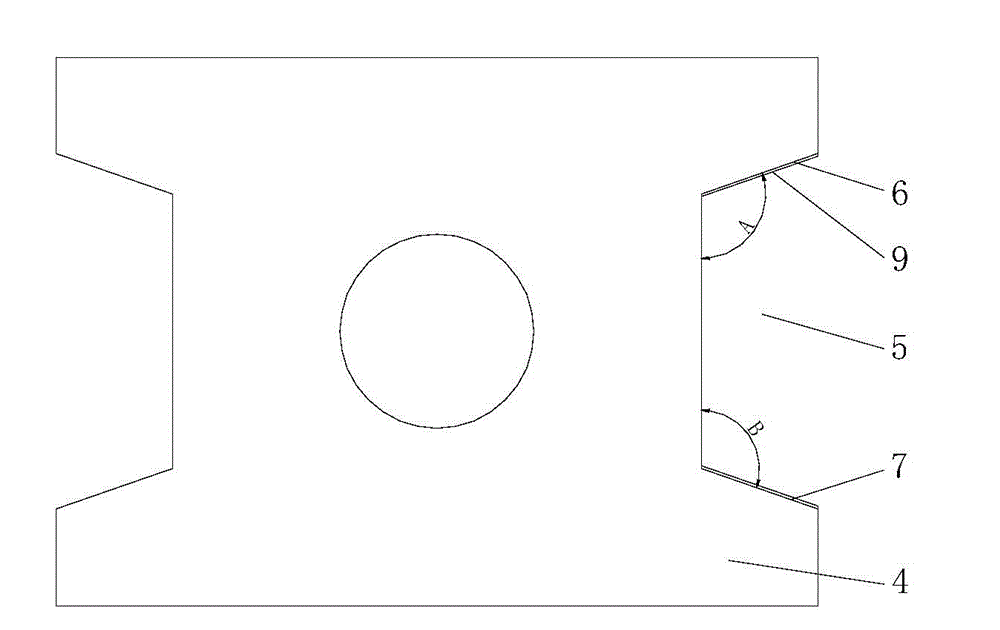

[0016] refer to figure 1 and figure 2 , the full hydraulic die forging hammer of the present invention includes a U-shaped bed 1, a full hydraulic power head is arranged on the U-shaped bed, the full hydraulic power head includes a working cylinder 2, a hammer rod 3 is housed in the working cylinder 2, and the hammer The lower end of the rod is connected to the slider 4, and the first side and the second side of the slider 4 in contact with the bed are respectively provided with guide grooves 5, and each guide groove has a groove bottom and a first guide surface located at the bottom of the groove 6 and the second guide surface 7, wherein the first guide surface 6 and the second guide surface 7 are inclined surfaces, the angle A formed between the first guide surface and the bottom surface of the groove is 120-135 degrees, and the angle A is preferably is 120 degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com