Forging method for magnesium-alloy automobile hub

An automobile wheel and magnesium alloy technology, which is applied in the field of magnesium alloy automobile wheel forging, can solve the problems of insufficient compact structure, low mechanical strength, and insufficient uniform composition of magnesium alloy automobile wheel hubs, and achieves improved thermal insulation effect, safety, and high mechanical strength. , convenient and practical effect of transposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

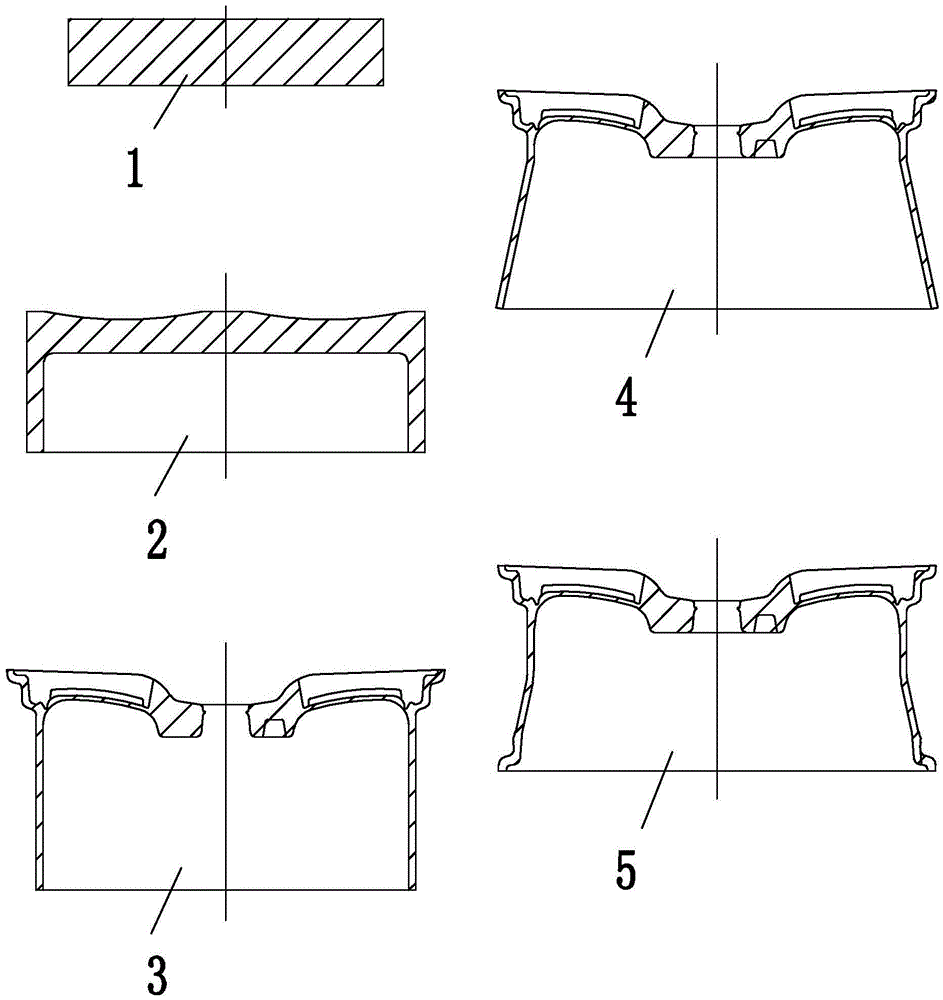

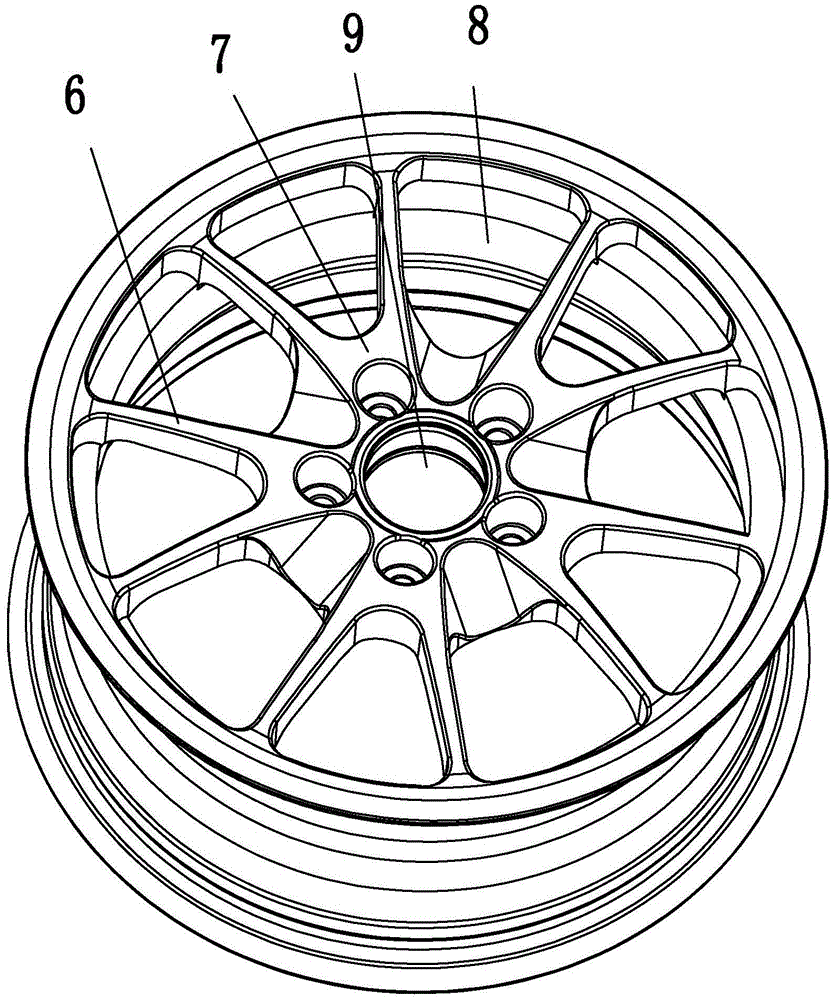

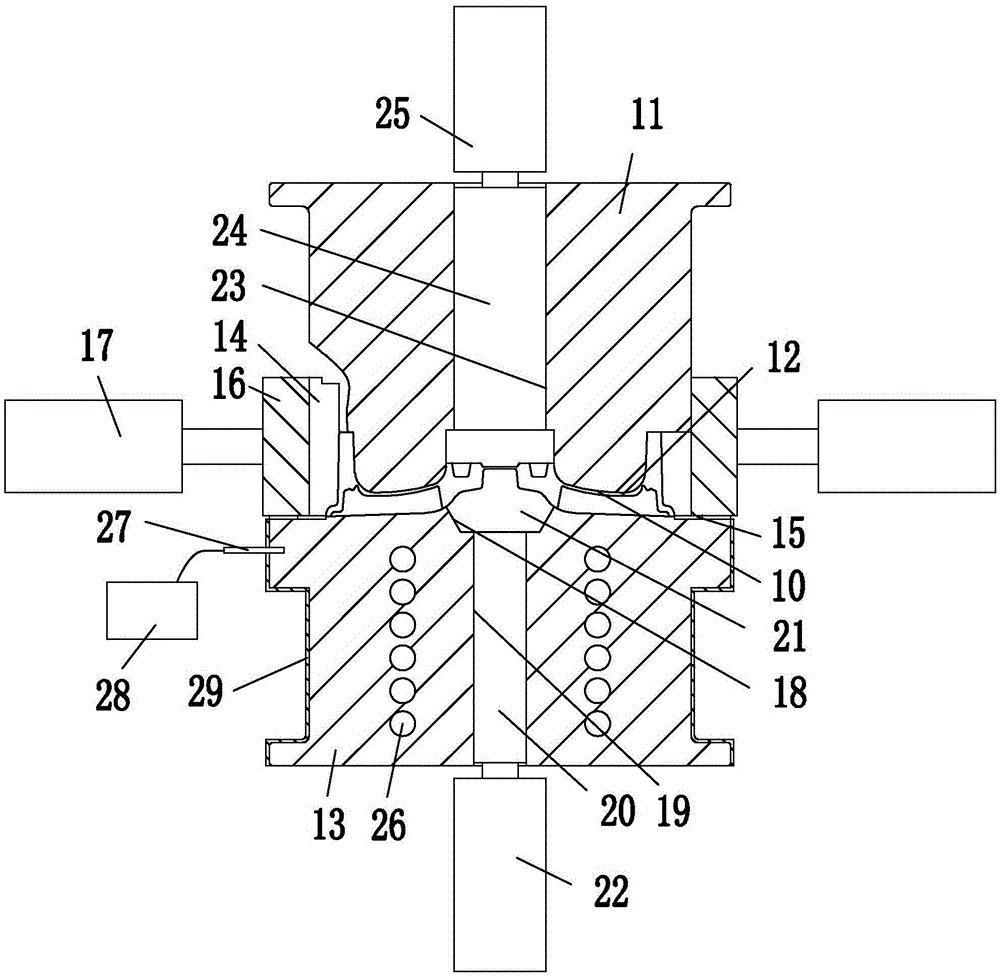

[0022] as attached figure 1 Shown: a magnesium alloy automobile wheel forging method, step 1, heating the magnesium alloy bar in a heating furnace, the heating temperature is controlled at 390 ° C to 420 ° C; step 2, pre-forging the magnesium alloy bar, magnesium The alloy bar is taken out from the heating furnace and indexed into the pre-forging die through the indexing device, and the first hydraulic forging machine is started to forge the magnesium alloy bar into a disc-shaped billet 1; step 3, the disc-shaped billet is forged for the initial shape , the disc-shaped blank is indexed into the primary forming die by the indexing device for heating, the heating temperature is controlled at 390°C to 420°C, and the second hydraulic forging machine is started to forge the disc-shaped blank into the primary forming wheel hub 2; step 4, to Preliminary wheel hubs are subjec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com