Method for forging by using tilting gear and manipulation trolley instead of sleeve for turning steel ingot

A technology for turning a steel turning machine and an operating car is applied in the field of metallurgical forging, which can solve the problems of wasting time, difficult to control the forging process, slow work, etc., and achieves the effect of easy operation, saving forging time, and large clamping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

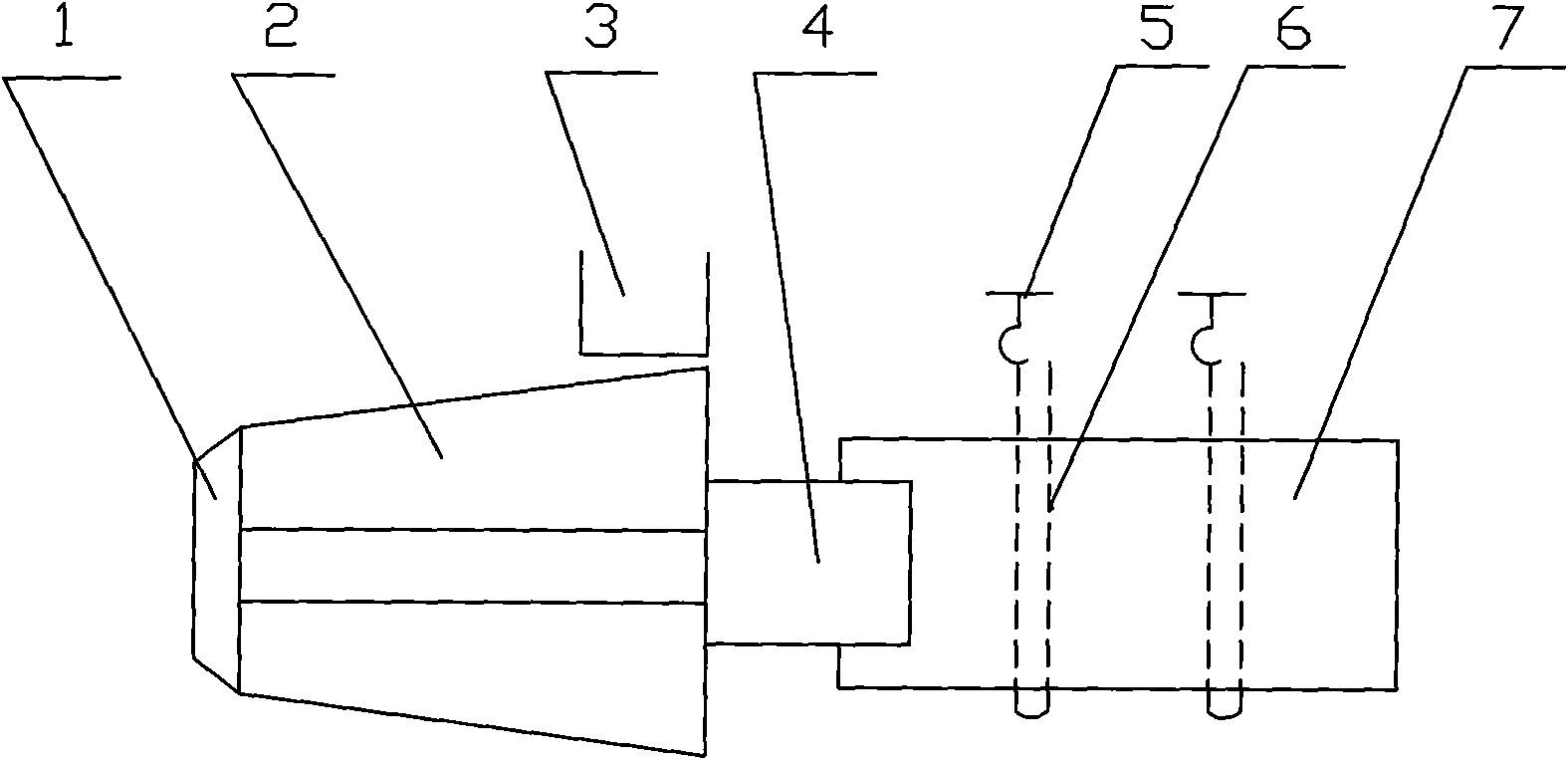

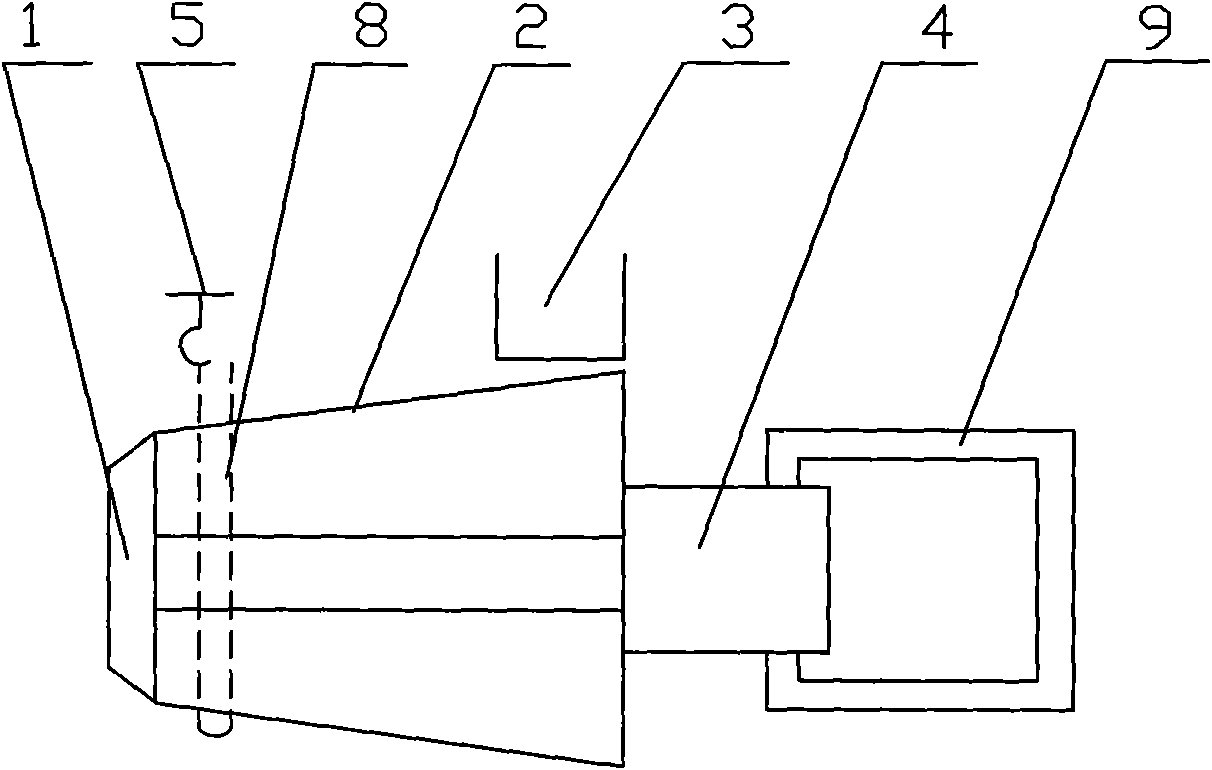

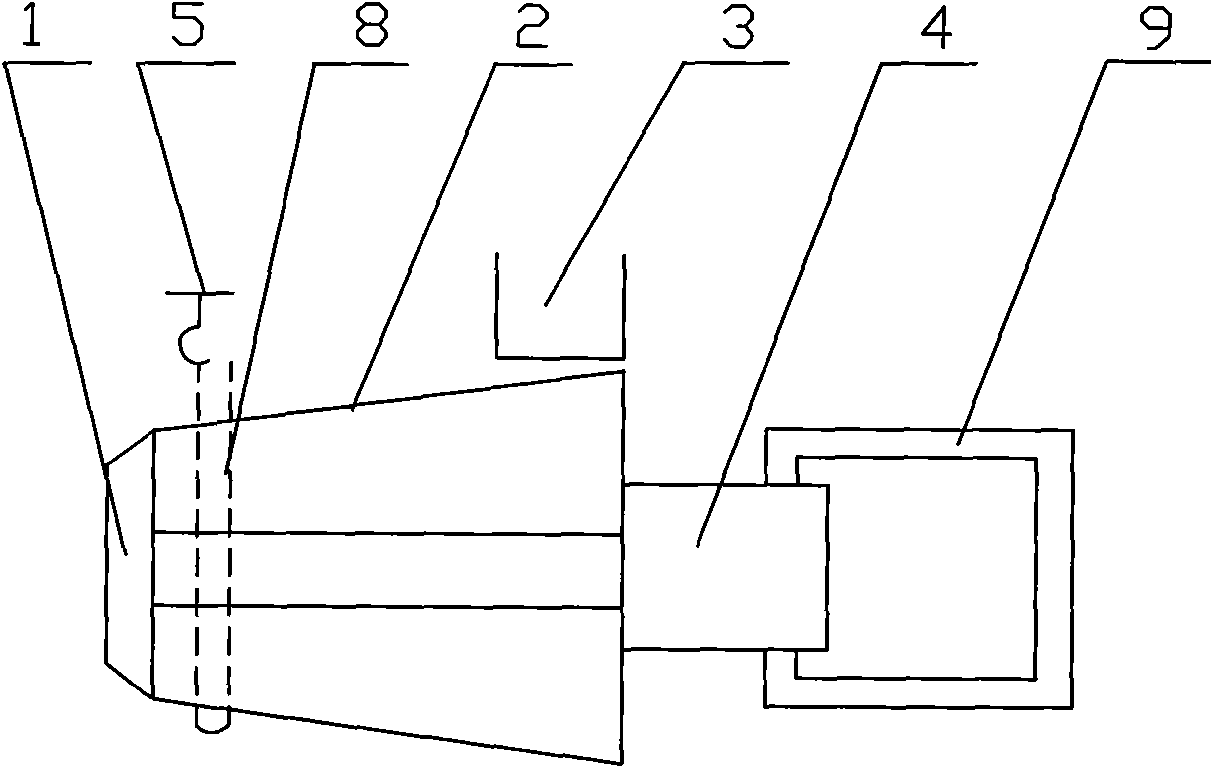

[0012] See figure 2 A method for forging a steel ingot by using a turning machine and an operating car to replace a sleeve to turn over a steel ingot, the method includes the following steps:

[0013] 1) The steel turning machine 8 is arranged on the top of the steel ingot 2, and the cap mouth 4 of the head of the steel ingot 2 is clamped by the manipulator 9 of the operating vehicle; the steel turning machine 8 is used to trap the manipulator 9 of the operating vehicle;

[0014] 2) The steel turning machine 5 is hung on the main hook of the crown block 5, so that the steel turning machine 8 and the manipulator 9 of the operating vehicle turn over the steel ingot at the same time, and the steel ingot is forged by the hydraulic press 3.

[0015] The invention adopts a crown block, uses a steel turning machine and an operating vehicle manipulator to cooperate with turning over the steel ingot, has a good clamping effect on the steel ingot, is easy to control the process, is eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com