Forging process of nearly-isotropic, high-strength and high-plasticity Mg-Gd-Y-Zr alloy material

An isotropic, alloy material technology, applied in metal processing equipment and other directions, can solve the problems of low production efficiency, poor comprehensive mechanical properties, high cost, and achieve the effects of convenient operation, comprehensive mechanical properties improvement, and heat loss reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

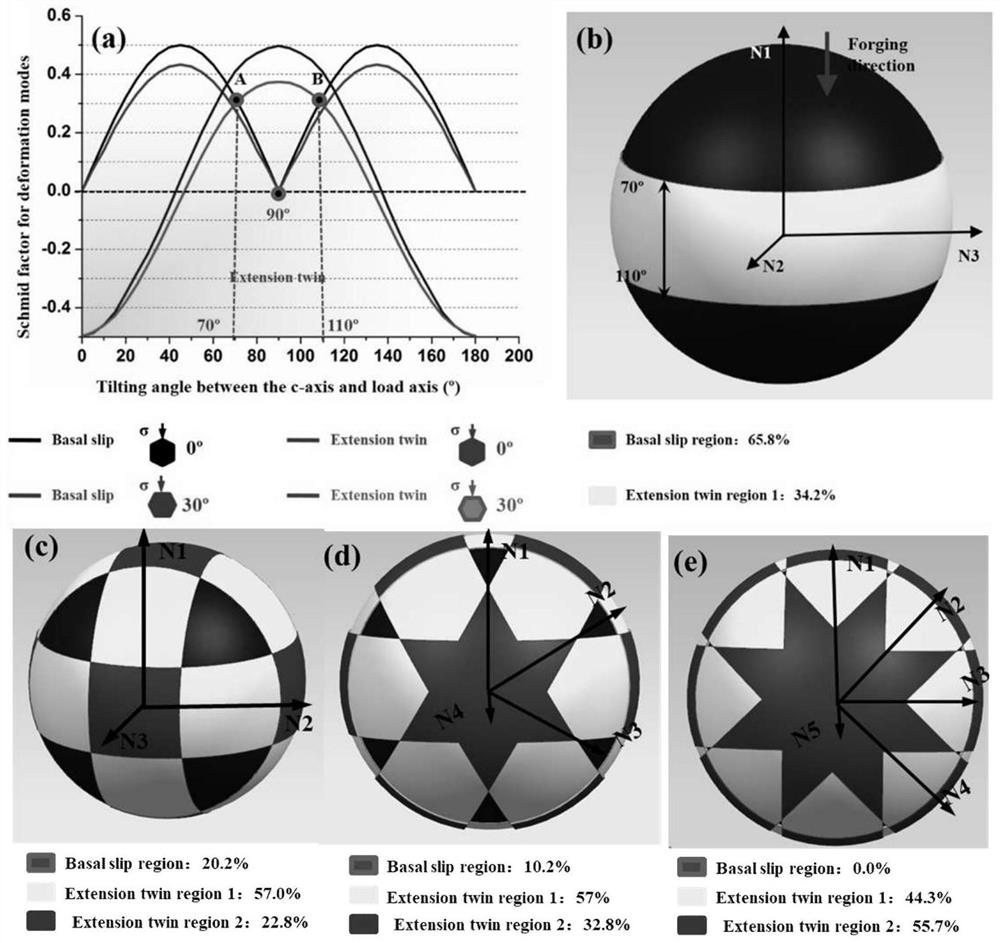

Method used

Image

Examples

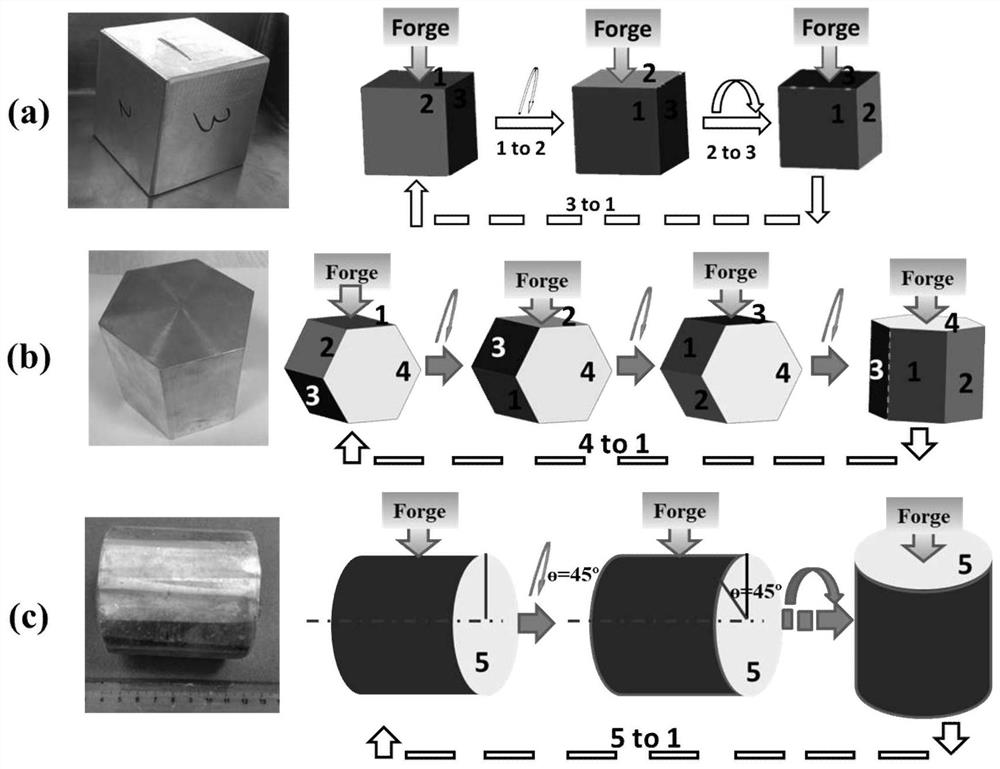

Embodiment 1

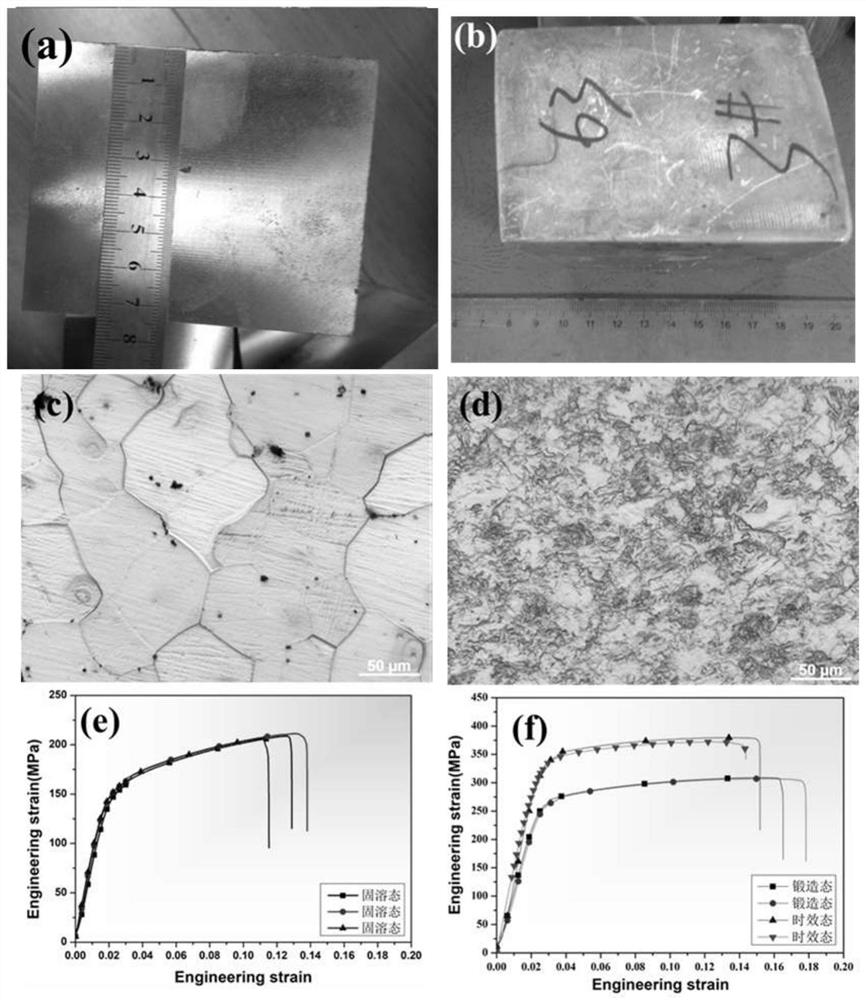

[0042] This embodiment adopts Mg-6.0Gd-3.0Y-0.5Zr (GW63K) alloy, the weight percentage of the alloy composition is Gd: 6.0%, Y: 3.0%, Zr: 0.5%, and the magnesium content is the balance balance, which is abbreviated as GW63K. Cut out two 70×70×70mm cube block materials from the GW63K alloy ingot, solid solution at 480°C for 8h and air-cool, keep at 420°C for 60min, and then perform multi-directional hammer forging on an industrial air hammer, that is, 1. 2, 3 three directions of cyclic loading, block sample 2 hammer forging 160 (70+70+20) passes, the symbol "+" means short-term annealing ~ 5min during the forging process, the entire process takes about 15min, and the forging is over The temperature is 300-350°C, and the final sample is air-cooled. There is no defect on the surface sample after hammer forging, and the difference between the size of the sample in three directions and the size of the original sample is not more than 20%, such as image 3 (a) and 3(b), image 3(c...

Embodiment 2

[0046] This embodiment adopts Mg-5.0Gd-2.0Y-0.5Zr (GW52K) alloy, the weight percentage of the alloy composition is Gd: 4.96%, Y: 2.44%, Zr: 0.43%, the magnesium content is the balance balance, abbreviated as GW52K. Five 70×70×70mm cube samples were cut out from the GW52K magnesium alloy ingot, and were solid solutioned at 480°C for 8h and air-cooled. Before forging, the sample was kept at 430°C for 60 minutes, and then multi-directional hammer forging was performed on an industrial air hammer. The cubic sample 2 was hammered for 170 (70+70+30) passes, and the symbol "+" represented short-term forging during forging. Annealing ~ 5 minutes, block sample 4 hammer forging 200 passes, block samples 3 and 5 hammer forging 200 (100+100) passes, the whole process takes about 15 minutes, the forging end temperature is 300-350 ° C, the surface of the sample is intact , no cracks, such as Figure 5 shown. After hammer forging, the grain size is reduced from 100 μm before processing to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com