Shoulder core forging die for 3T/5T swager

A hammer forging machine and mandrel technology, which can be used in manufacturing tools, forging/pressing/hammering machinery, forging/pressing/hammer devices, etc., and can solve problems such as increasing forging time and increasing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

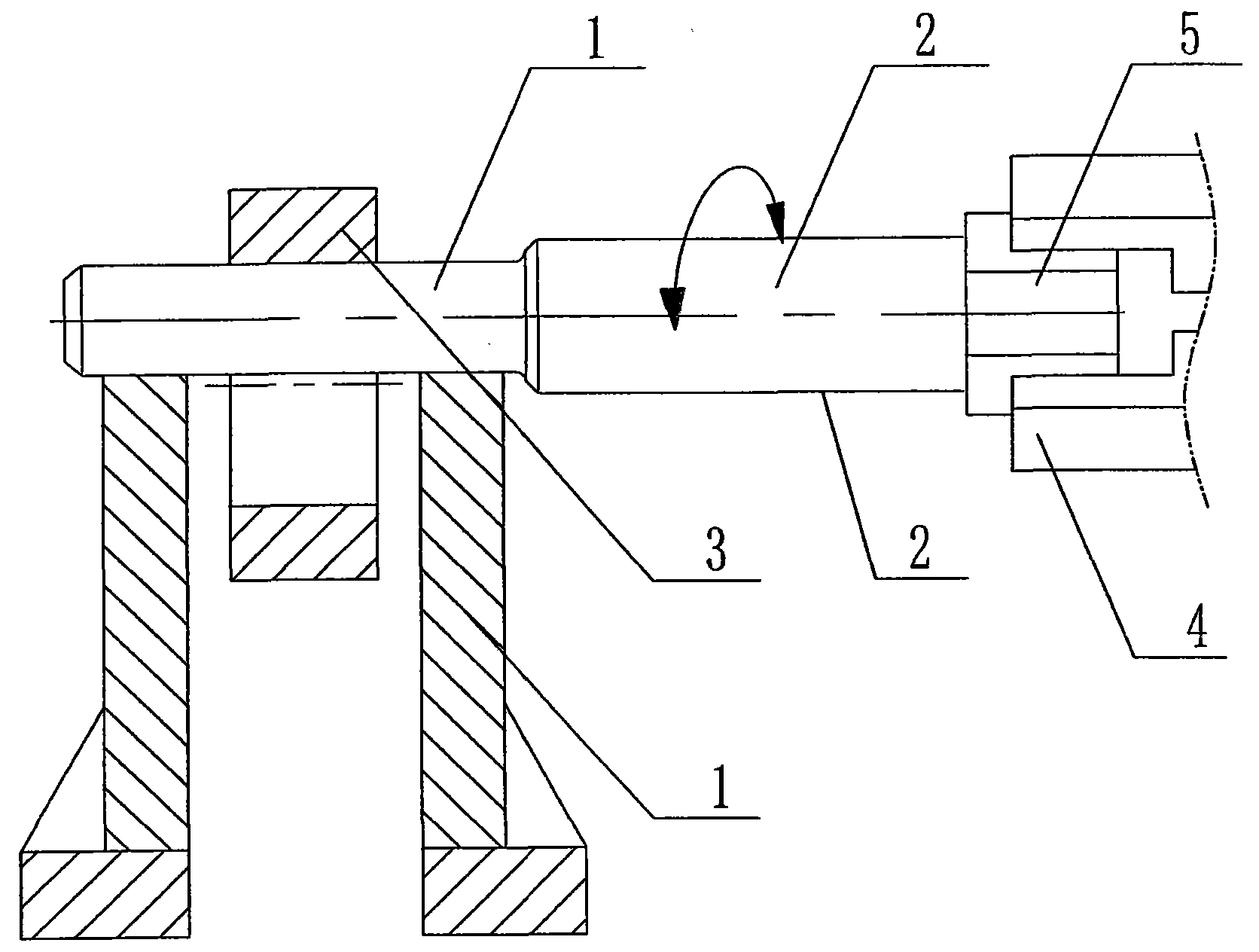

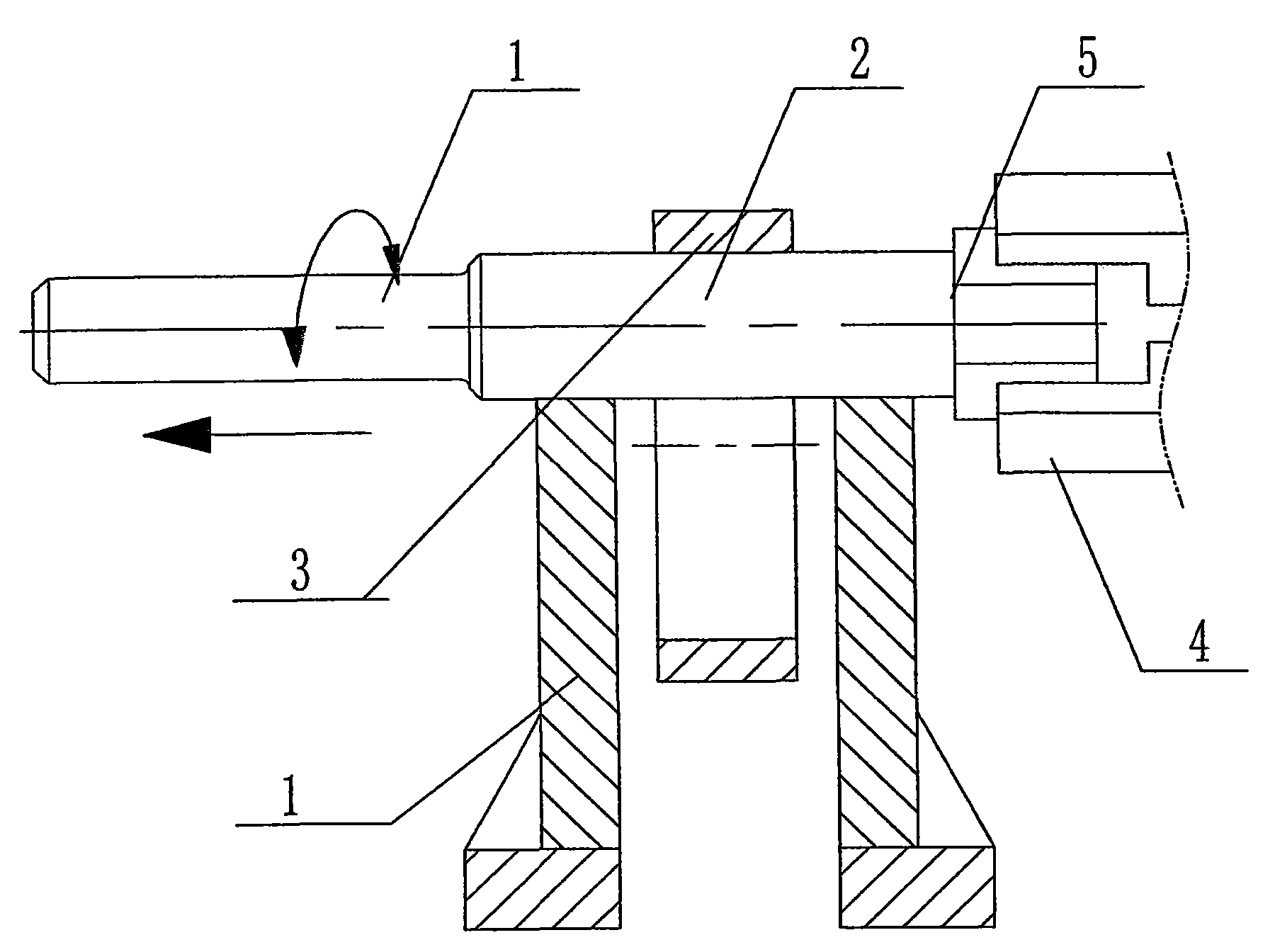

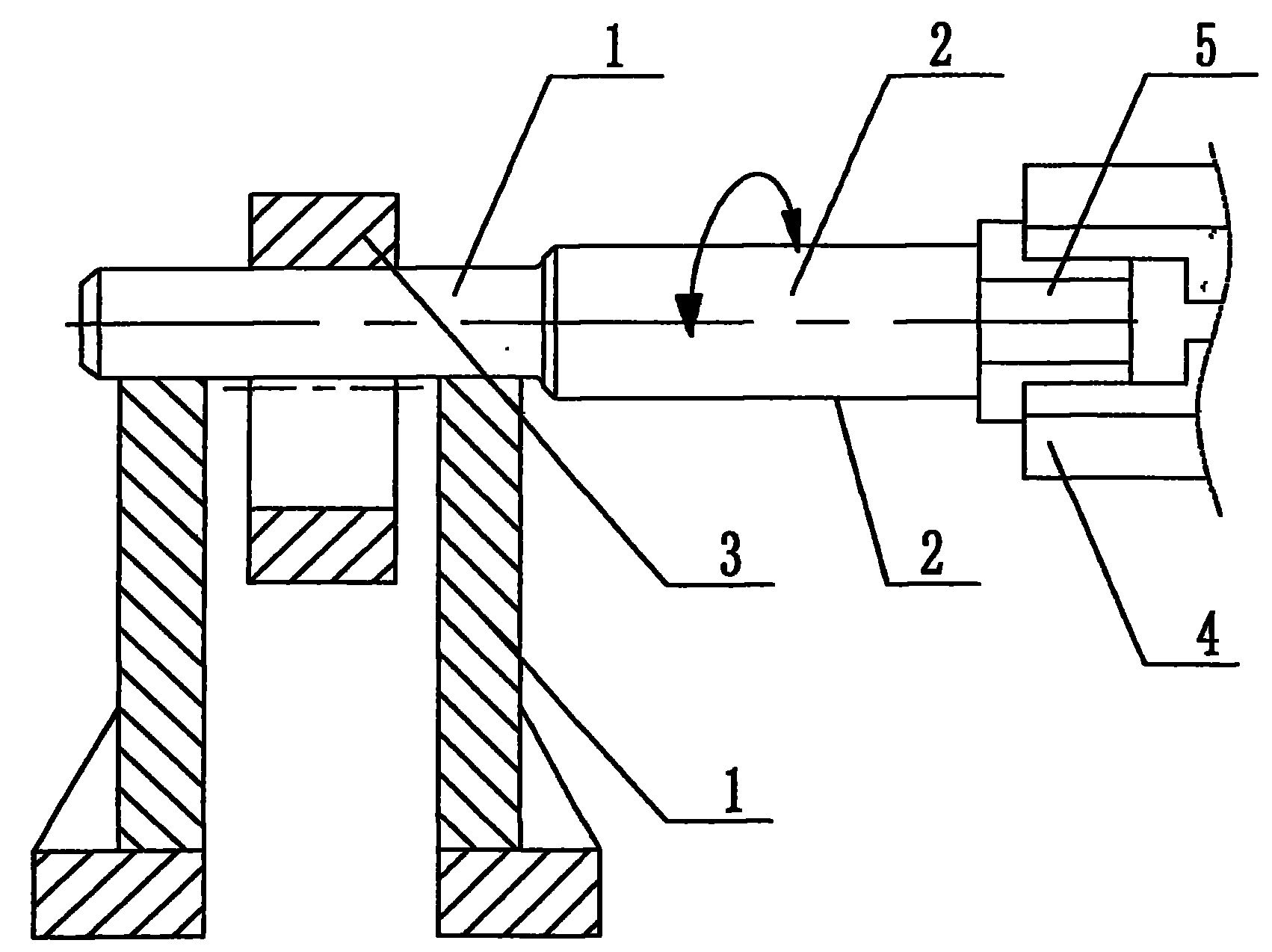

[0009] see Figure 1~2 , The 3T, 5T hammer forging machine step mandrel forging die related to the present invention mainly consists of a horse frame 1, a mandrel 2 and a jaw 4. Described mandrel 2 is divided into two straight sections from front to back along its length direction, and the front one straight section mandrel diameter is smaller, is referred to as small diameter section 2.1, and the back one straight section mandrel diameter is larger, is called large diameter section 2.1. The diameter section 2.2 and the tail of the large diameter section 2.2 are octagonal 5, and the mandrel 2 is horizontally placed on the horse frame 1, and the jaw 4 is placed at the octagonal end of the mandrel 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com