Gearbox shaft forge piece machining equipment and machining method thereof

A technology for processing equipment and gearboxes, which is applied in the field of shaft forgings, can solve the problems affecting the service life of shaft forgings' mechanical properties, low automation and production efficiency, and inability to perform thermal correction at the same time, so as to improve mechanical performance and service life. High degree of automation and production efficiency, the effect of shortening the forging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

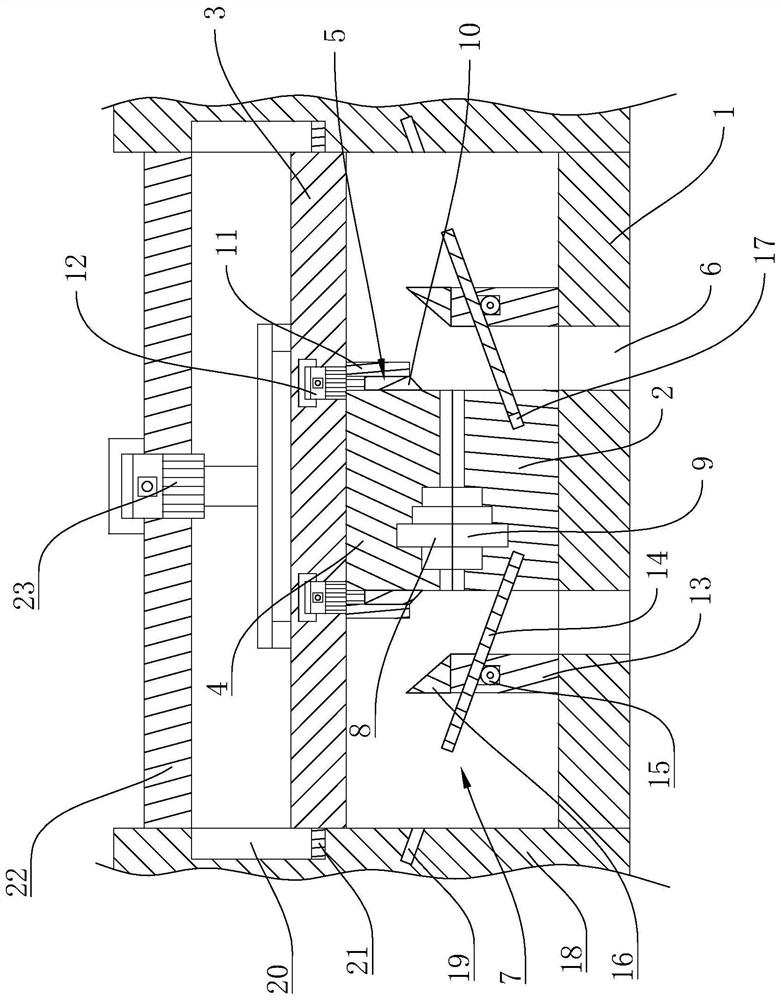

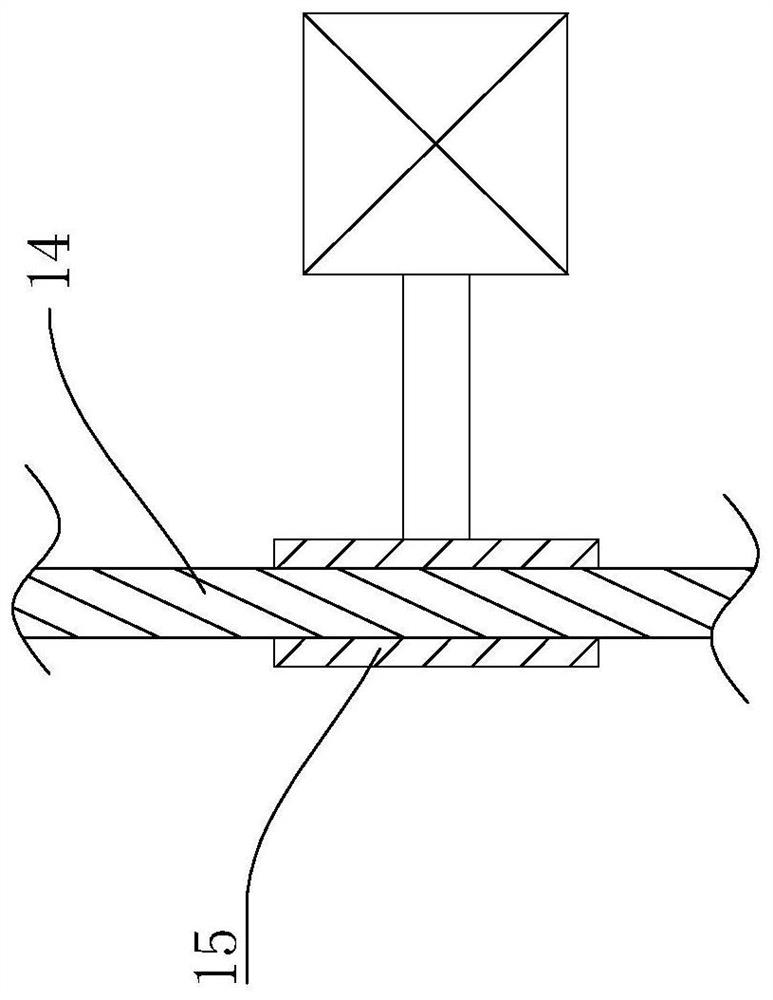

[0027] Such as Figure 1-2 As shown, a gearbox shaft forging processing equipment includes a processing base 1. The processing base 1 is provided with a thermally corrected shaft forging lower die 2. Above the thermally corrected shaft forging lower die 2 is a The upper mold fixed plate 3 that reciprocates linearly in the vertical direction, the bottom of the upper mold fixed plate 3 is provided with a heat correction shaft forging upper mold 4, and the bottom of the upper mold fixed plate 3 is also provided with a number of upper mold fixed plates 3 An automatic flash cutting assembly 5 symmetrical to the center line. The automatic flash cutting assembly 5 is slidably matched with the upper die 4 of the heat-corrected shaft forging. The material chute 6 , between the said material falling chute 6 and the automatic flash cutting assembly 5 , there is an edge material baffle member 7 which can reciprocate along a straight line.

[0028] In this embodiment, the upper die fixing...

Embodiment 2

[0048] Based on the transmission shaft forging processing equipment provided in Example 1, this embodiment provides a processing method using the transmission shaft forging processing equipment, including the following steps: S1: Place the shaft forging to be processed on the lower mold of the thermally corrected shaft forging In step 2, the upper die 4 of the thermally corrected shaft forging is brought closer to one end of the lower die 2 of the thermally corrected shaft forging, so that the lower die 2 of the thermally corrected shaft forging and the upper die 4 of the thermally corrected shaft forging are closely pressed together to perform thermal correction; S2: Move the automatic flash cutting assembly 5 downwards, automatically cut the flash of the shaft forging through the automatic flash cutting assembly 5, and the cut flash material falls on the edge material blocking plate 7; S3: complete the flash cutting Finally, by moving the edge material baffle plate 7, the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com