Patents

Literature

55results about How to "Play the role of supporting positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

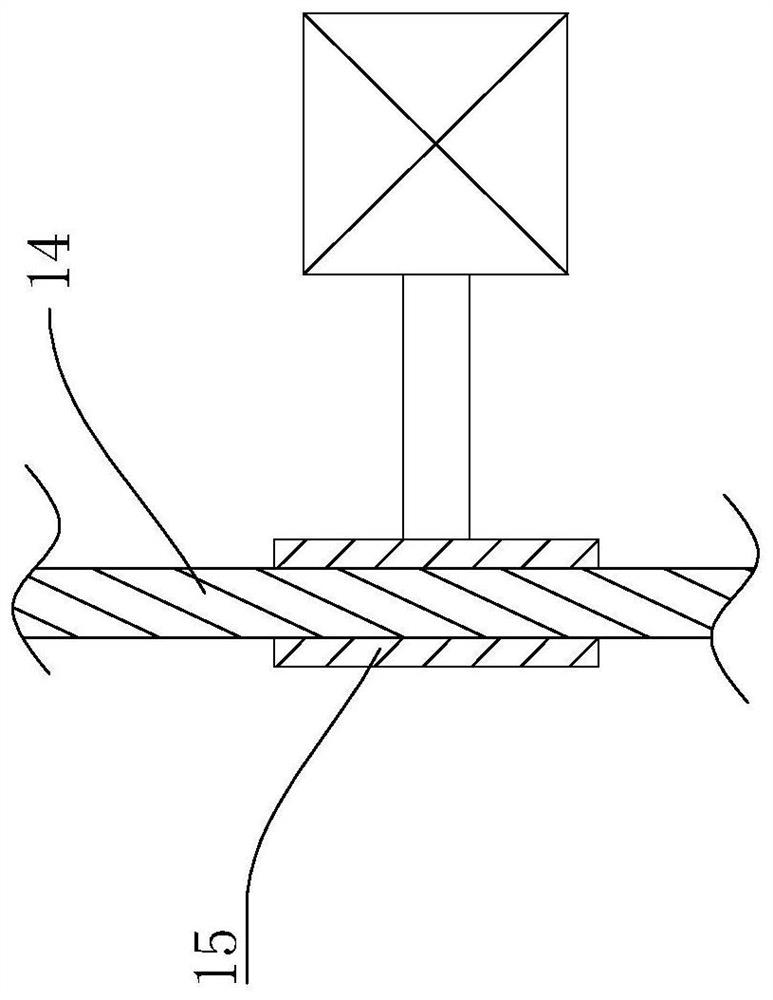

Inventor

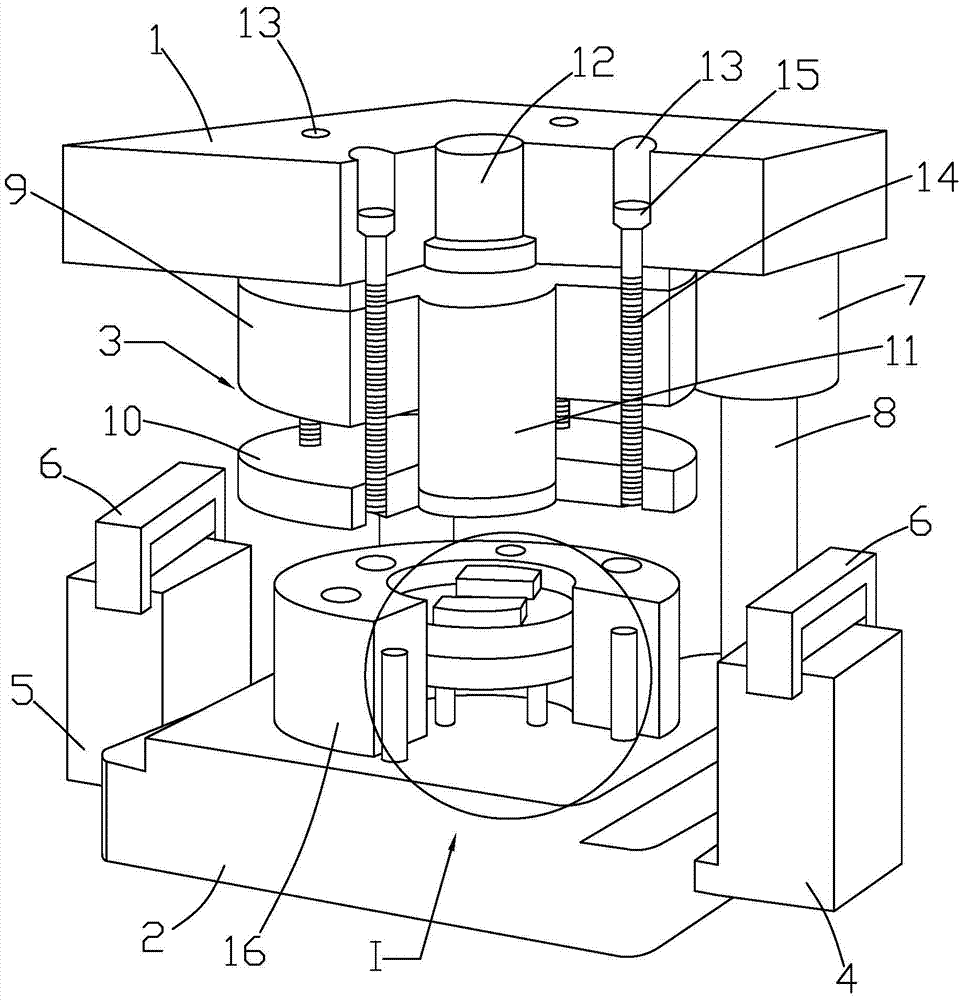

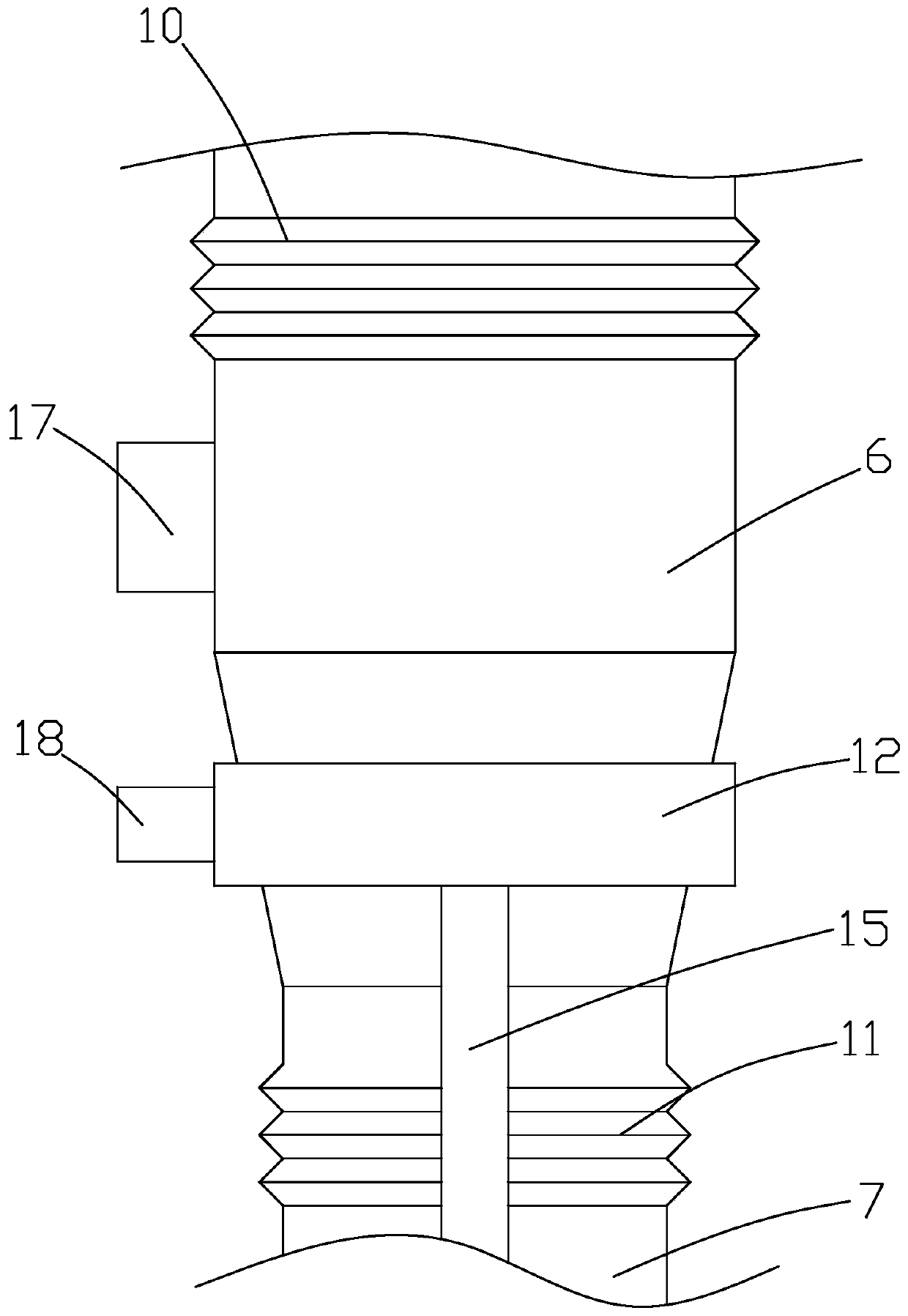

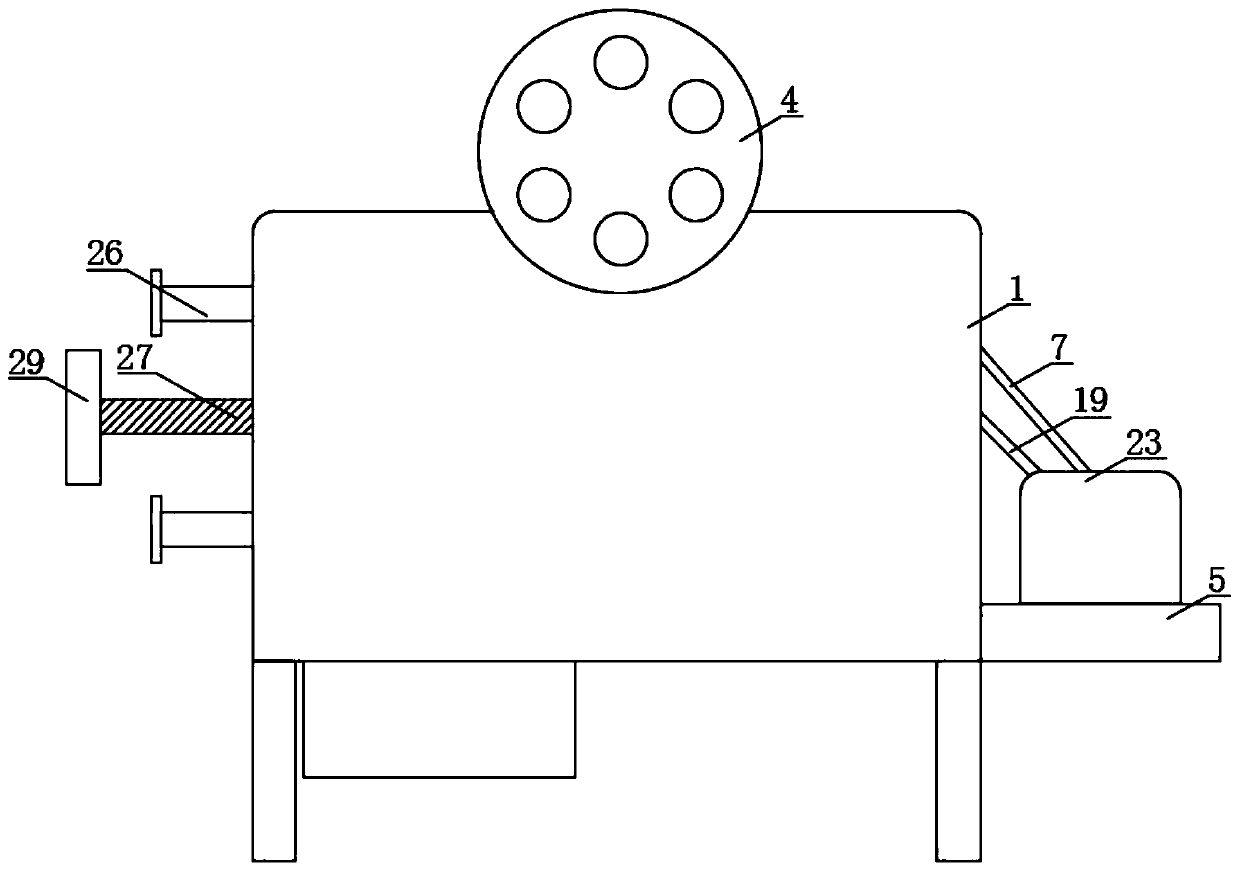

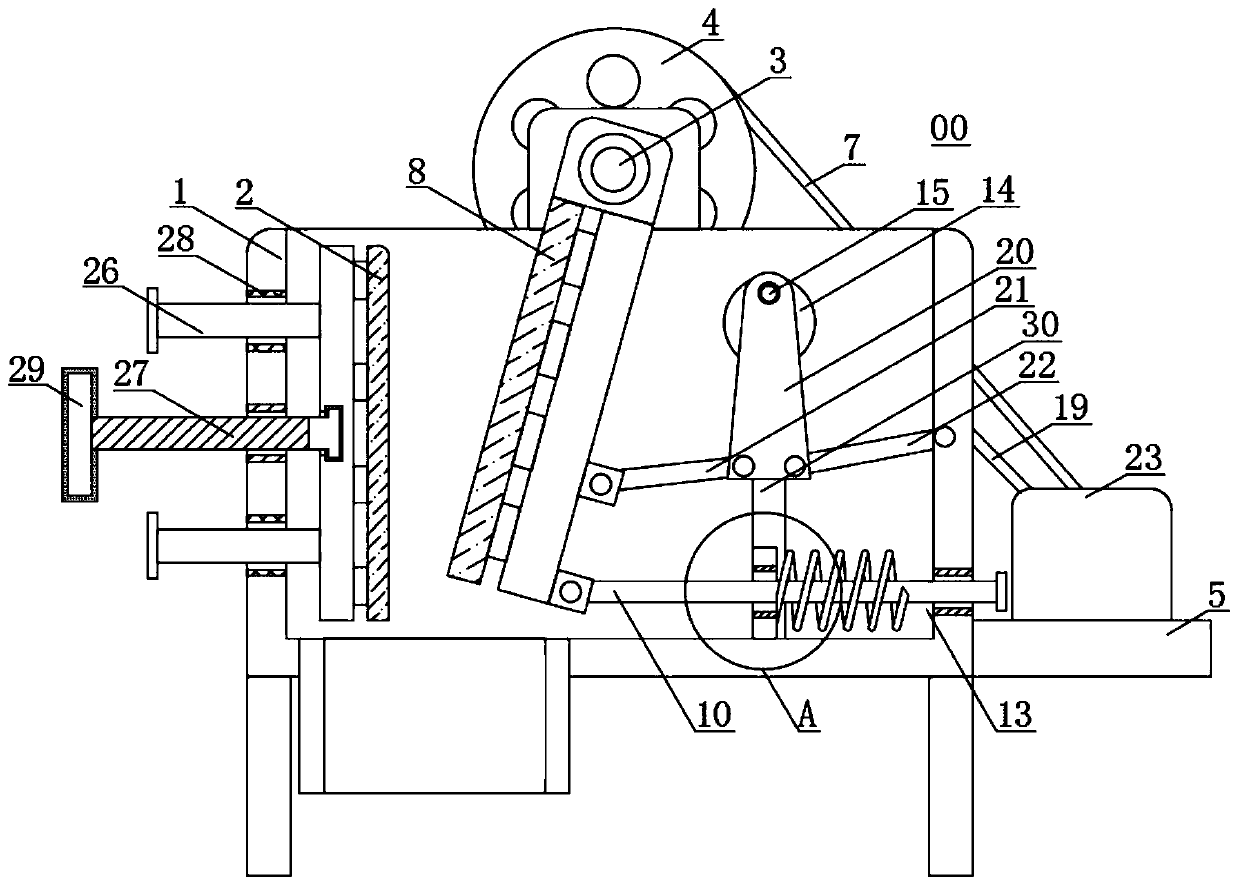

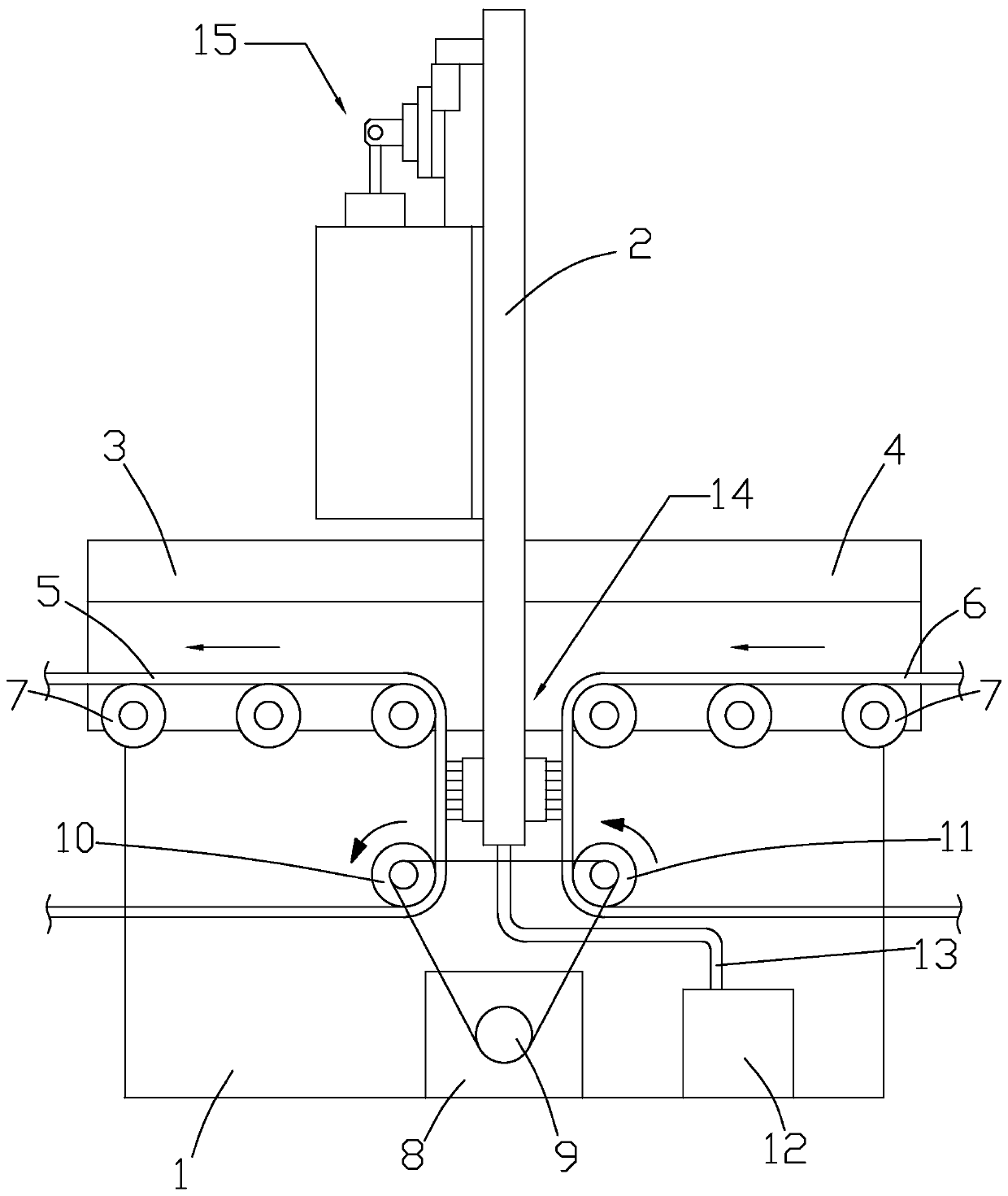

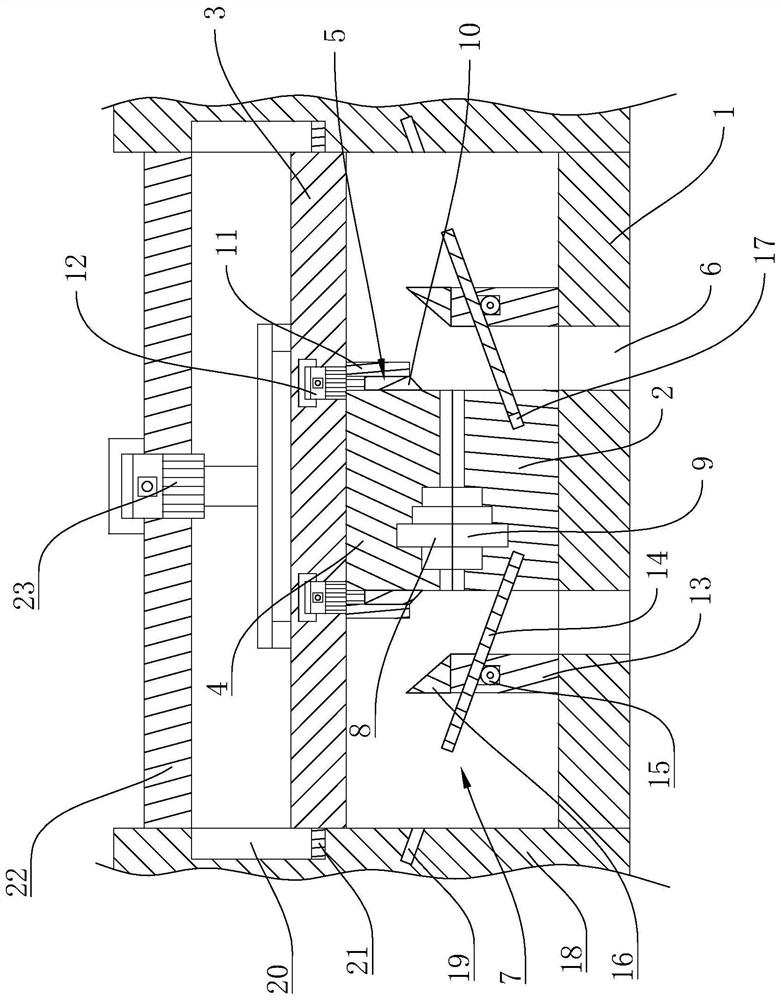

Silicon steel sheet punching machine for production of fan motor rotor

InactiveCN105449946AReduce impactAffect the service lifeMetal-working feeding devicesManufacturing stator/rotor bodiesHydraulic cylinderPunching

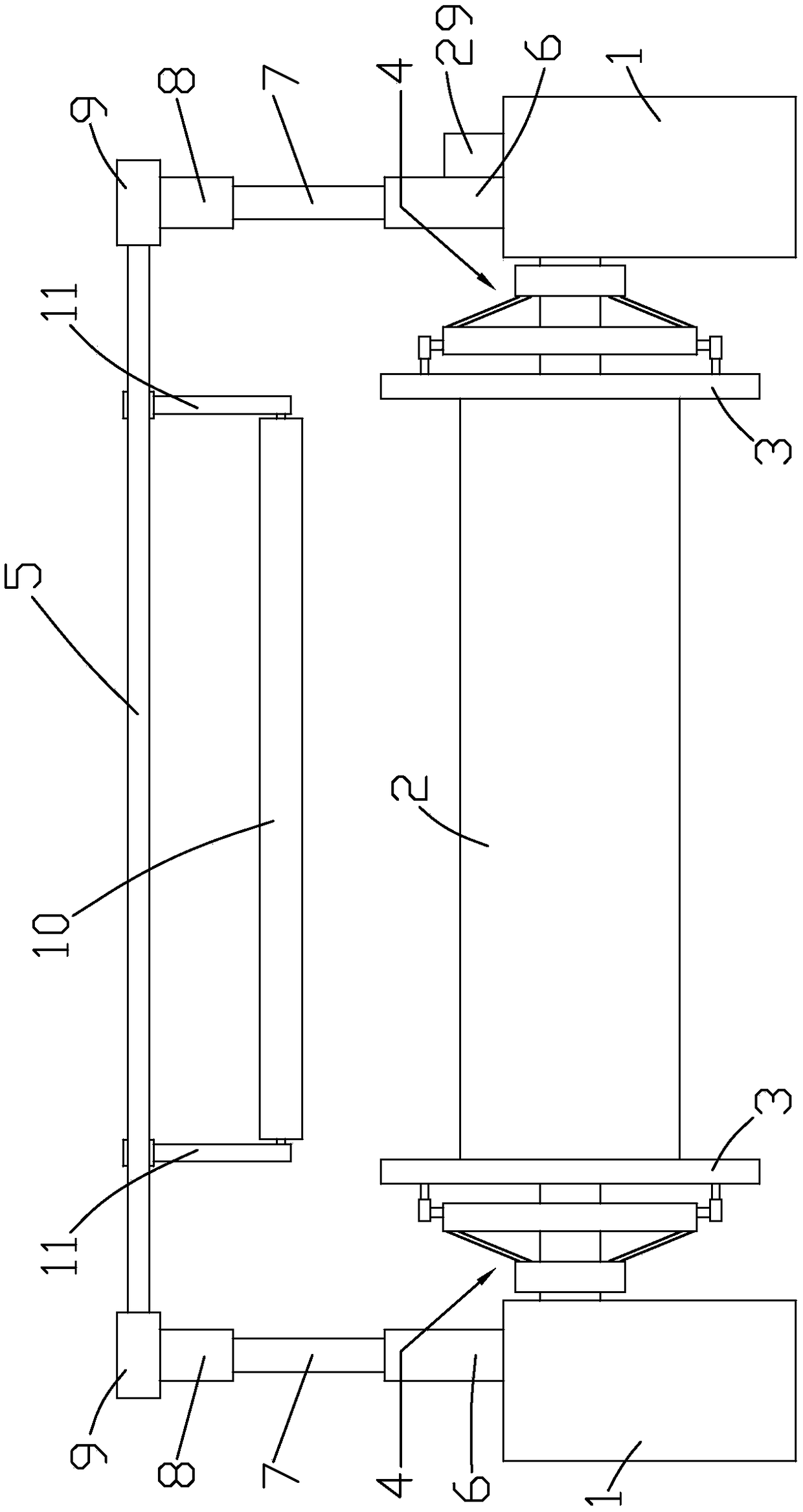

The invention discloses a silicon steel sheet punching machine for production of a fan motor rotor. The silicon steel sheet punching machine comprises an upper top plate, a base, a stamping mechanism, a feeding box body and a discharging box body, wherein a main hydraulic cylinder is arranged on the upper top plate, at least two lifting hydraulic cylinders are arranged on the bottom surface of the upper top plate and connected onto the top surface of the base via a piston rod, a punching processing table is arranged at the center of the top surface of the base and fixedly connected onto the base via a limitation rod, a stamping through hole is formed in the center of the punching processing table, a buffer mechanism is arranged in the stamping through hole, the feeding box body and the discharging box body are respectively arranged at the two sides of the base, and feeding positioning devices are arranged on the top surfaces of the feeding box body and the discharging box body. The silicon steel sheet punching machine is simple in structure and has high practicability, continuous transmission of silicon steel sheets can be fulfilled, and the transmission efficiency of the silicon steel sheets is improved; and moreover, the punching process of the silicon steel sheets with different sizes and types can be met, the silicon steel sheets after being punched are automatically stacked and formed, and the production process of the rotor is simplified.

Owner:SHENGZHOU BEIYULING MOTOR FACTORY

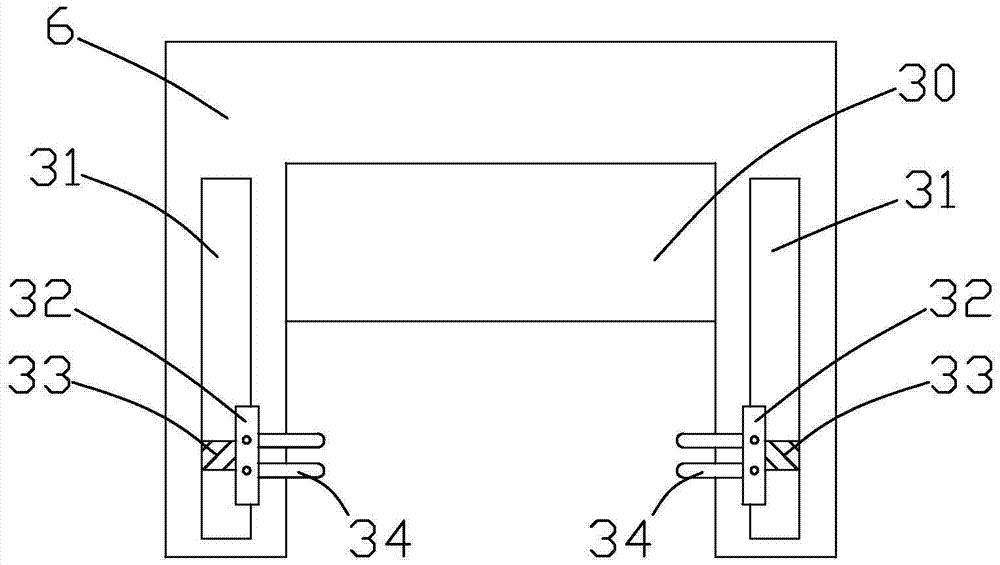

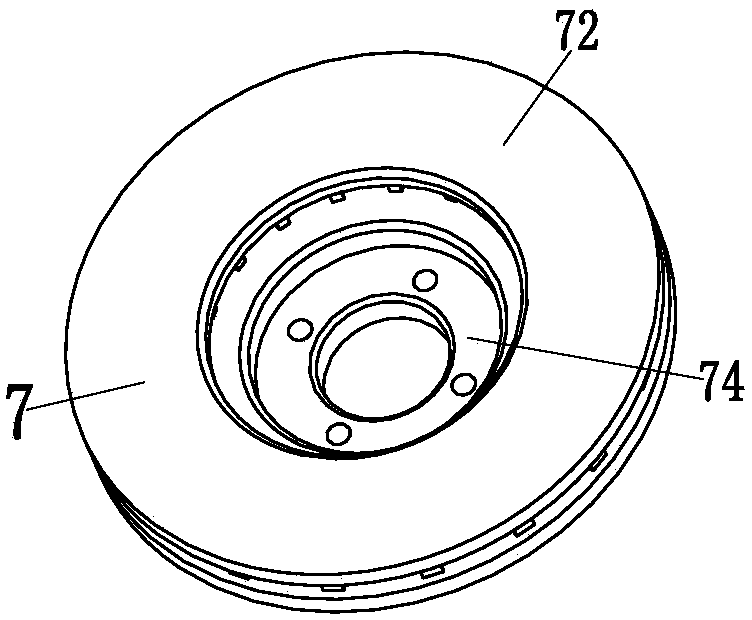

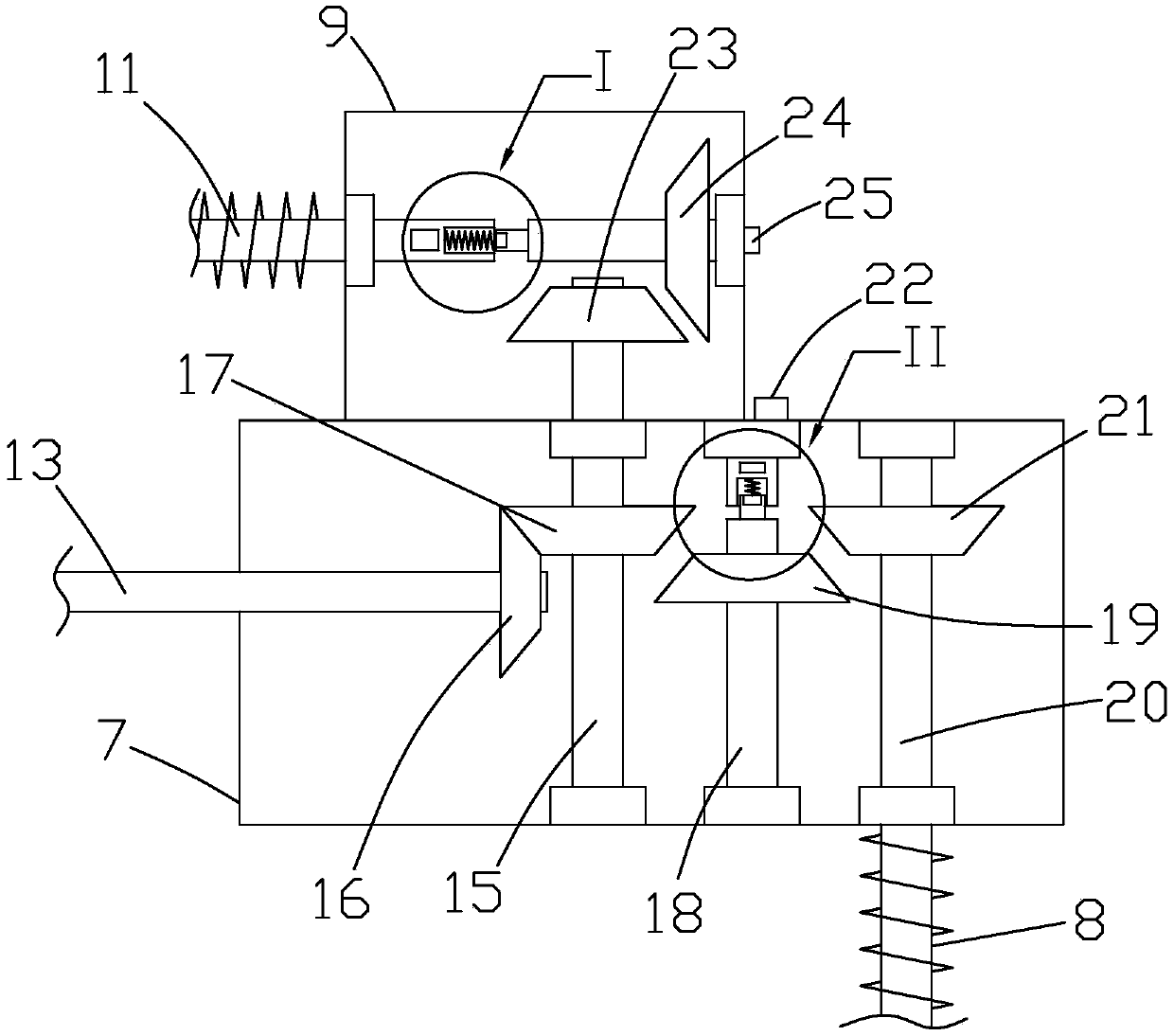

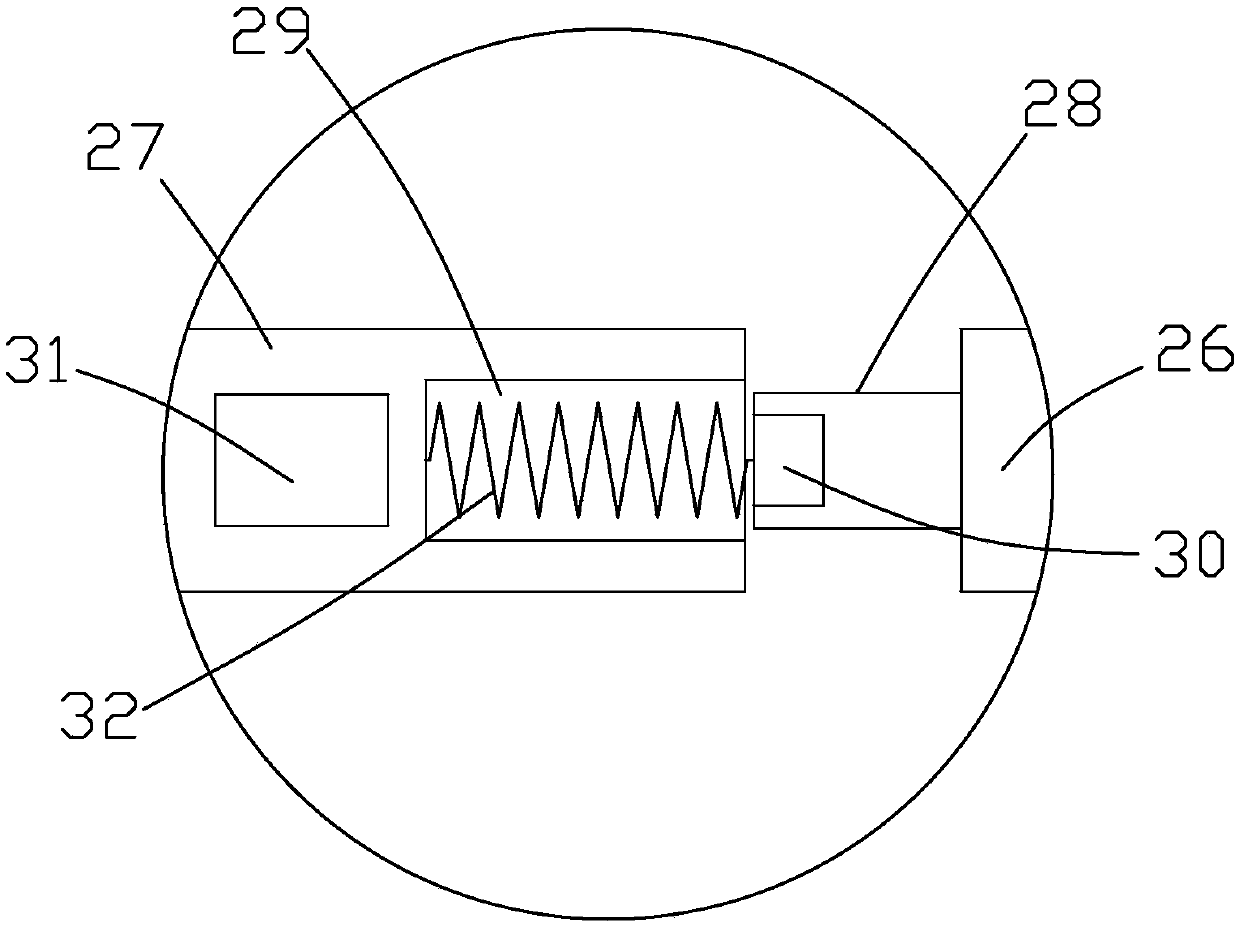

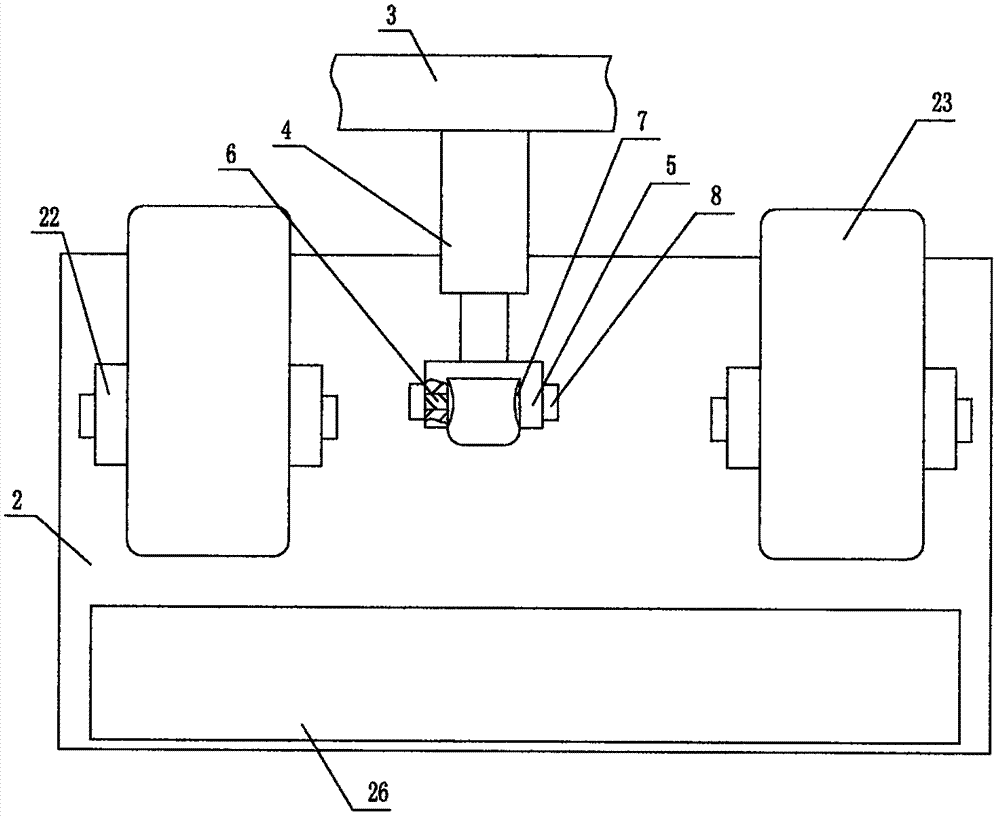

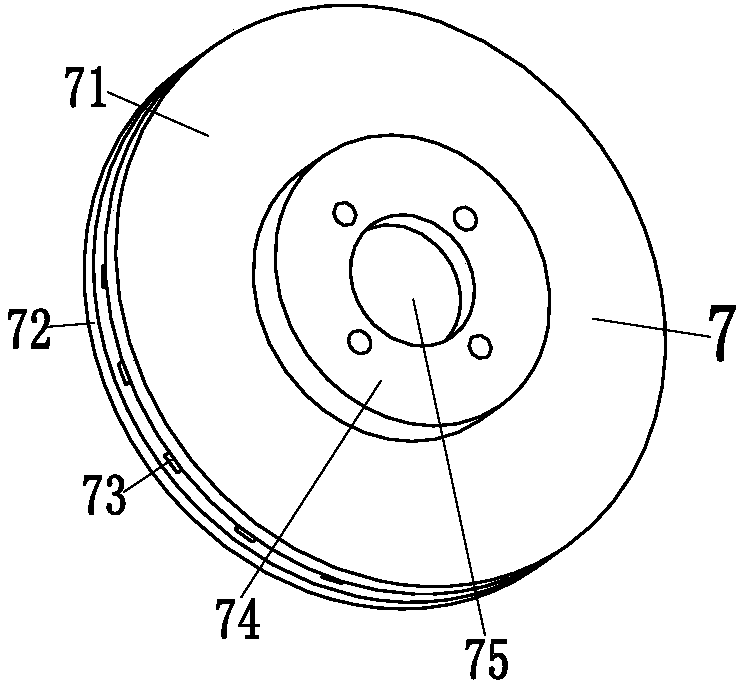

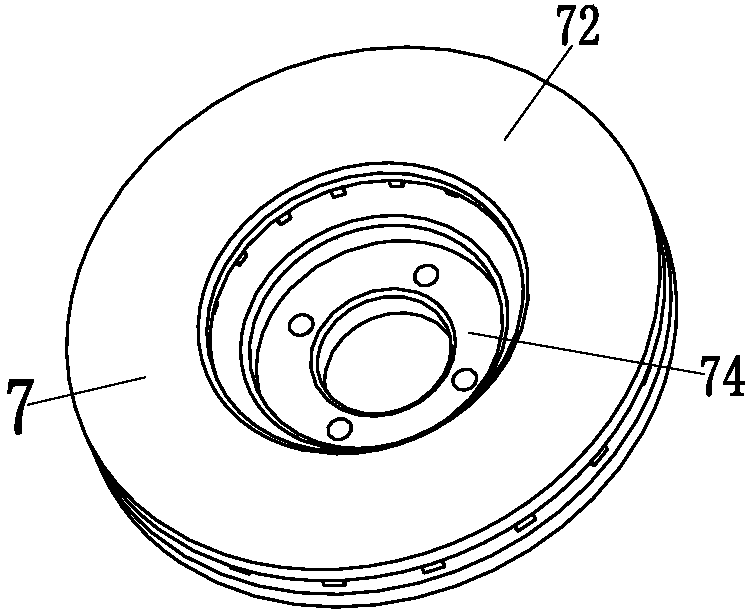

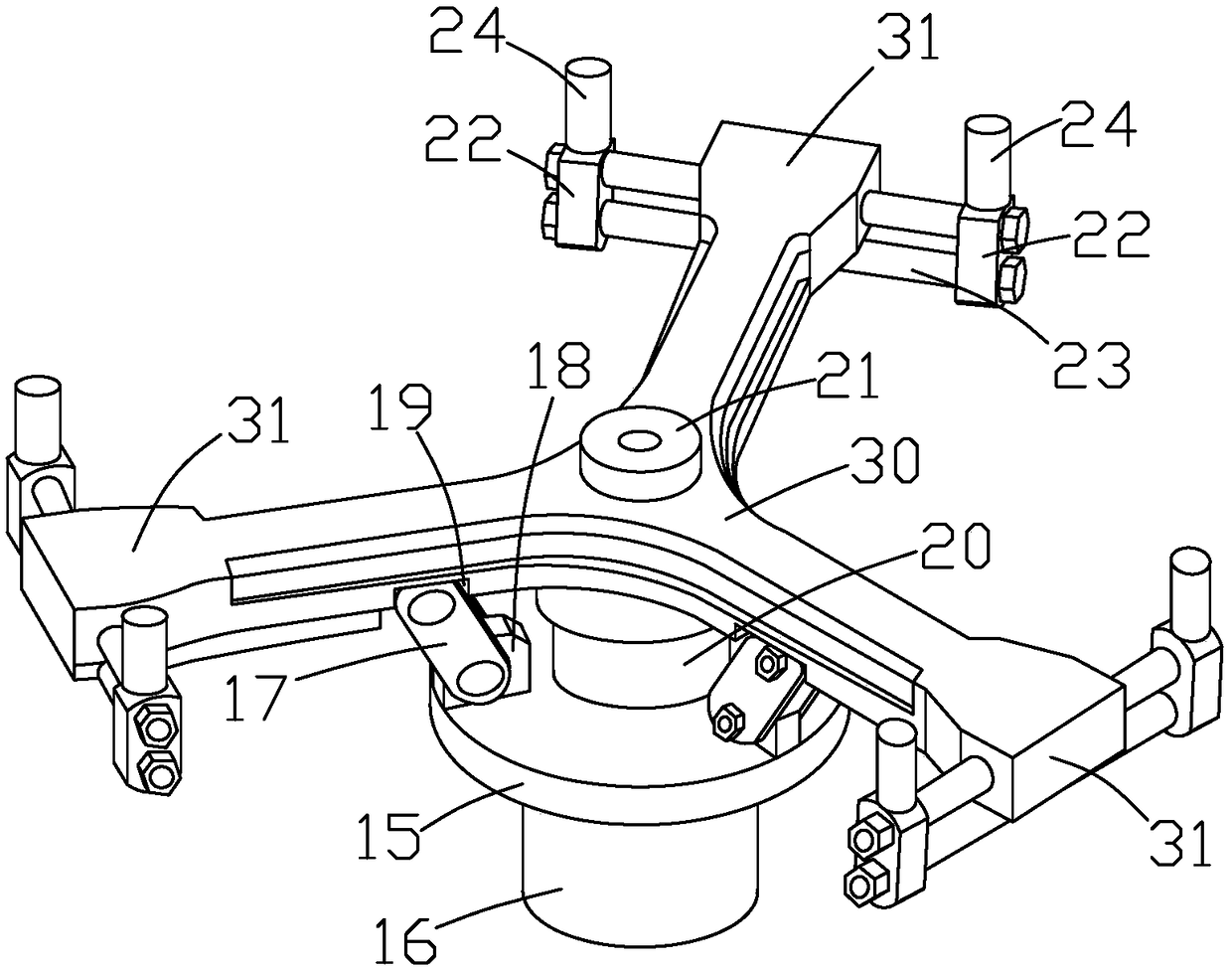

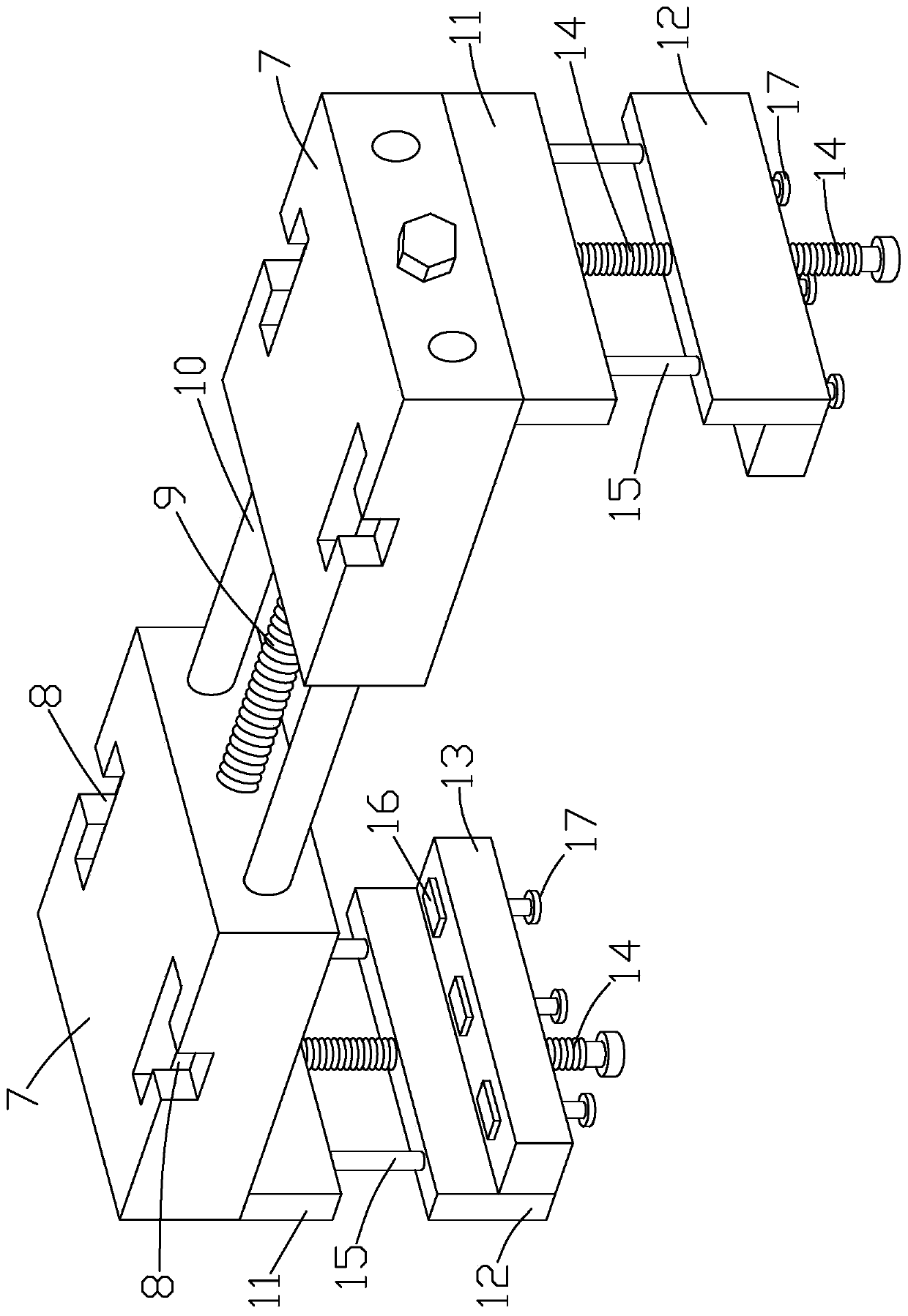

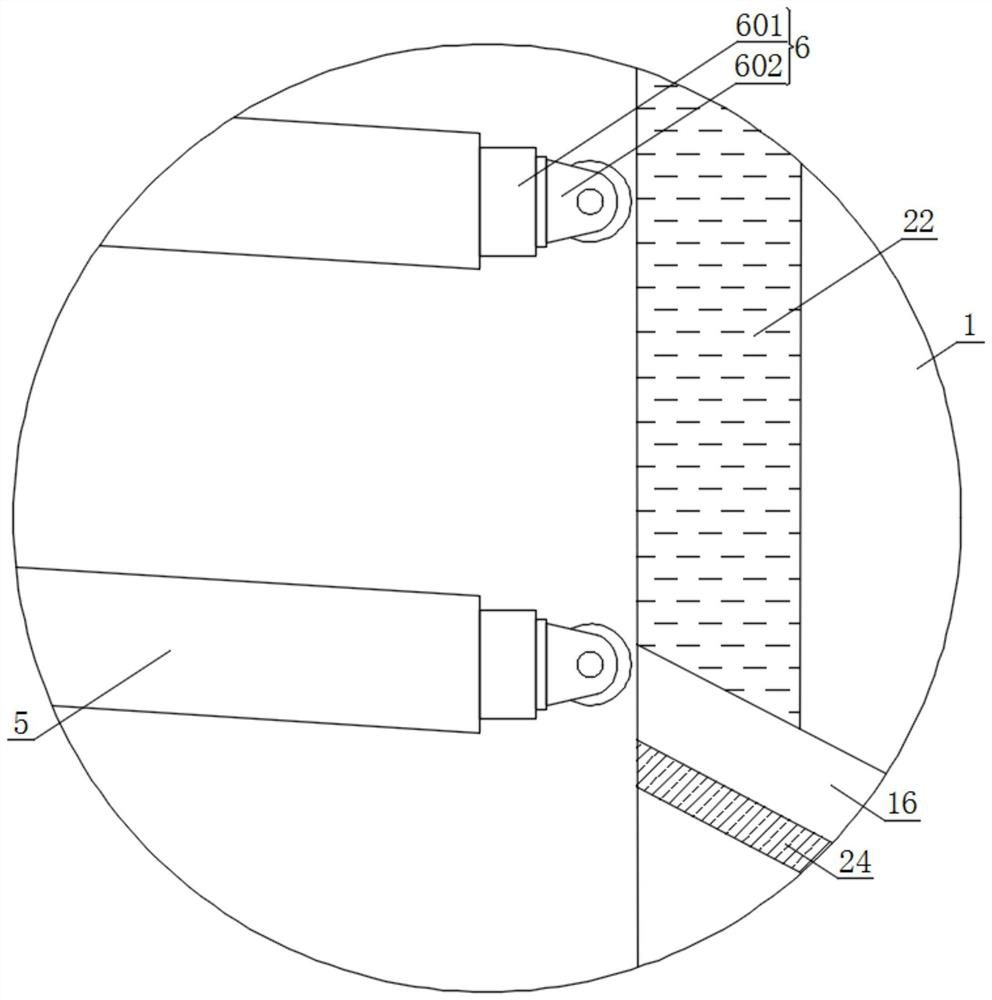

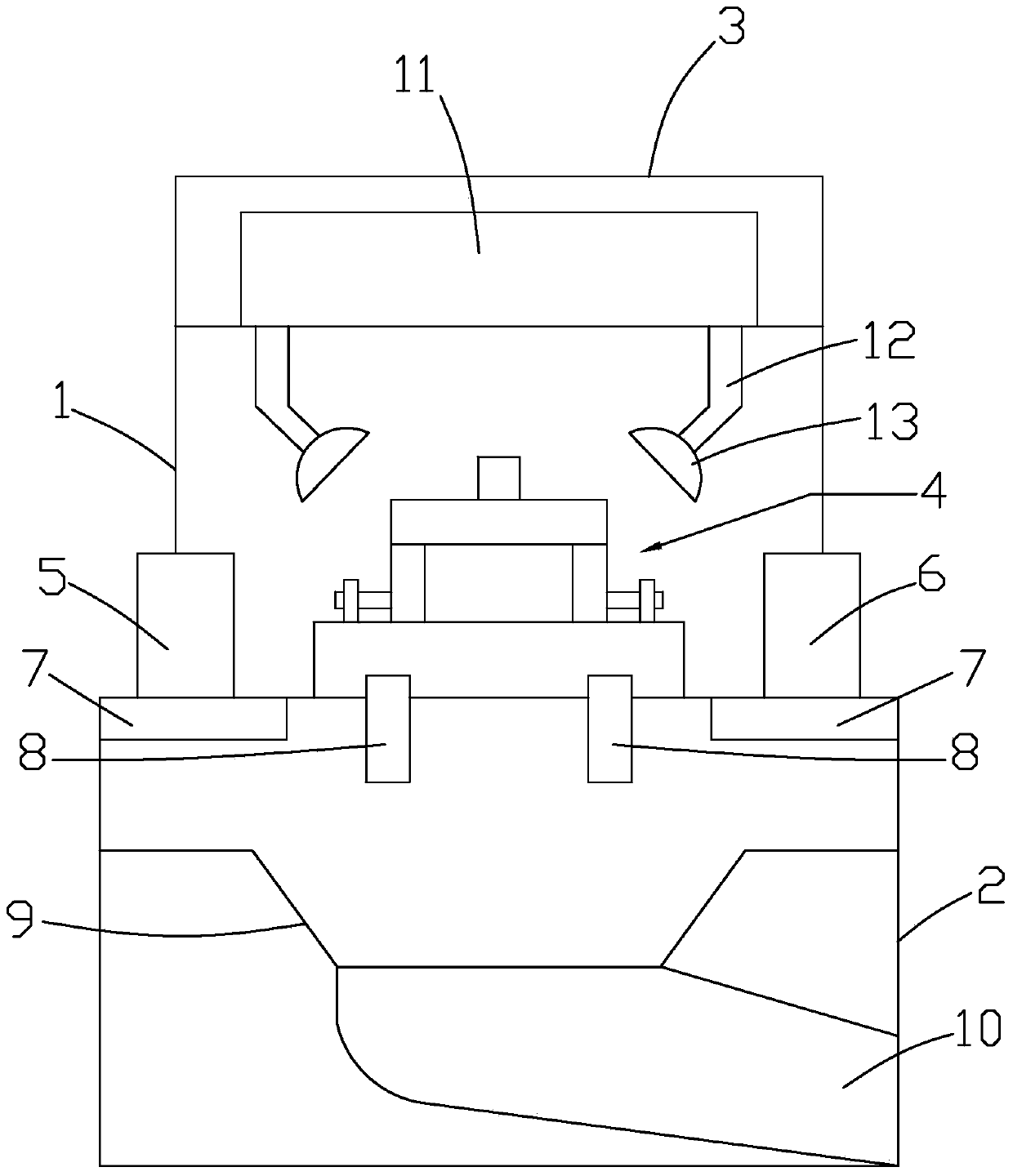

New energy automobile brake disc fixture with stable fixing and automatic position switching functions

InactiveCN108081130AEasy to fixPlay the role of supporting positioningGrinding feedersGrinding work supportsNew energyStable fixation

The invention relates to a new energy automobile brake disc fixture with stable fixing and automatic position switching functions. The new energy automobile brake disc fixture comprises a support bottom plate, a support connecting frame, fixing devices and a position switching device. The support connecting frame is mounted on the top of the left end of the support bottom plate, a circular hole isformed in the middle of the upper end of the support connecting frame, the size of the circular hole formed in the support connecting frame is larger than the sizes of convex discs of brake discs, the convex discs of the brake discs can penetrate the circular hole formed in the support connecting frame when the convex discs face downwardly, the two fixing devices are mounted on the left side andthe right side of the top of the support connecting frame, and the position switching device is positioned on the outer sides of the fixing devices and is connected with the support bottom plate. Thenew energy automobile brake disc fixture has the advantages that the difficult problems of incapability of stably fixing existing brake discs when the existing new energy automobile brake discs are polished in factories, incapability of fixing different models of brake discs, requirements on manually switching the positions of the existing brake discs and the like at present can be solved by the aid of the new energy automobile brake disc fixture; the new energy automobile brake disc fixture has the functions of stably fixing the new energy automobile brake discs and automatically switching the positions of the brake discs.

Owner:吴凡

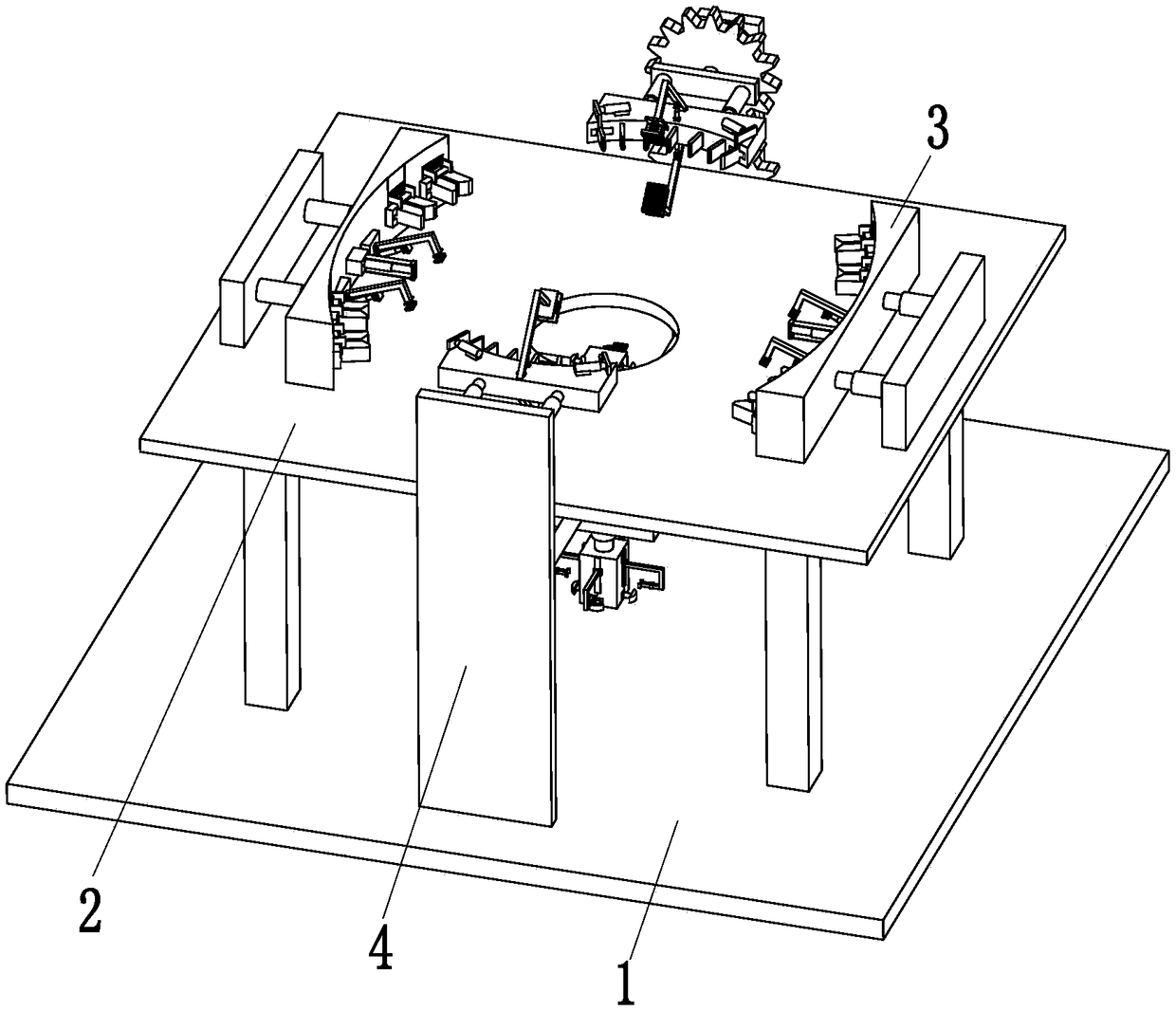

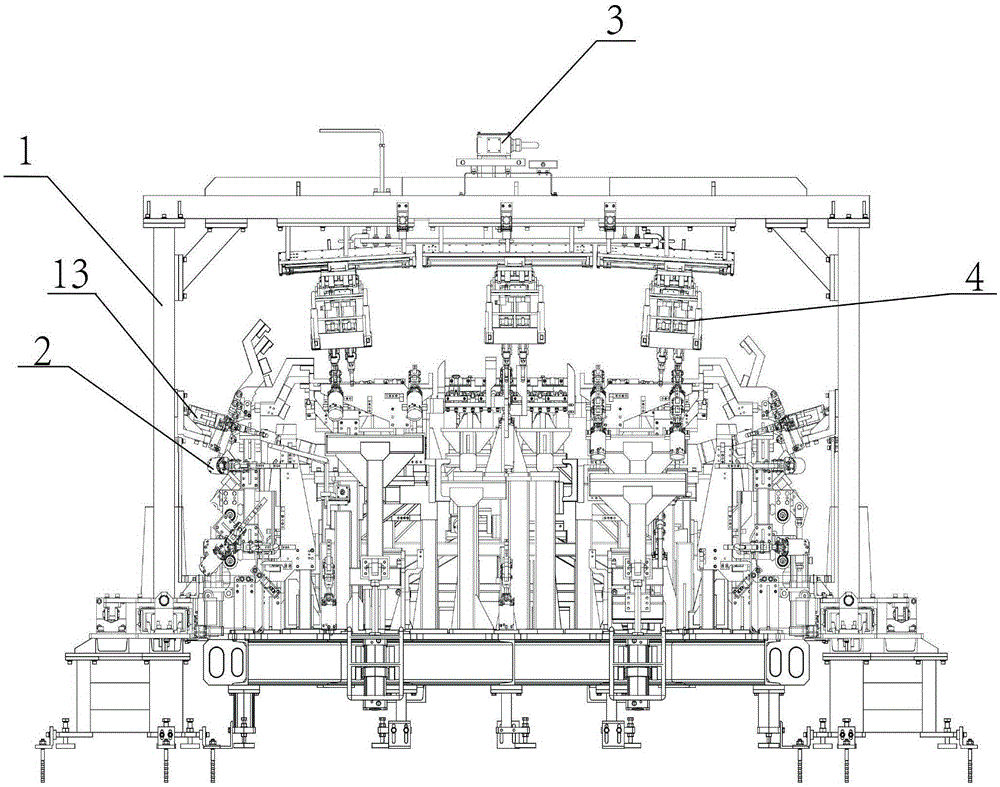

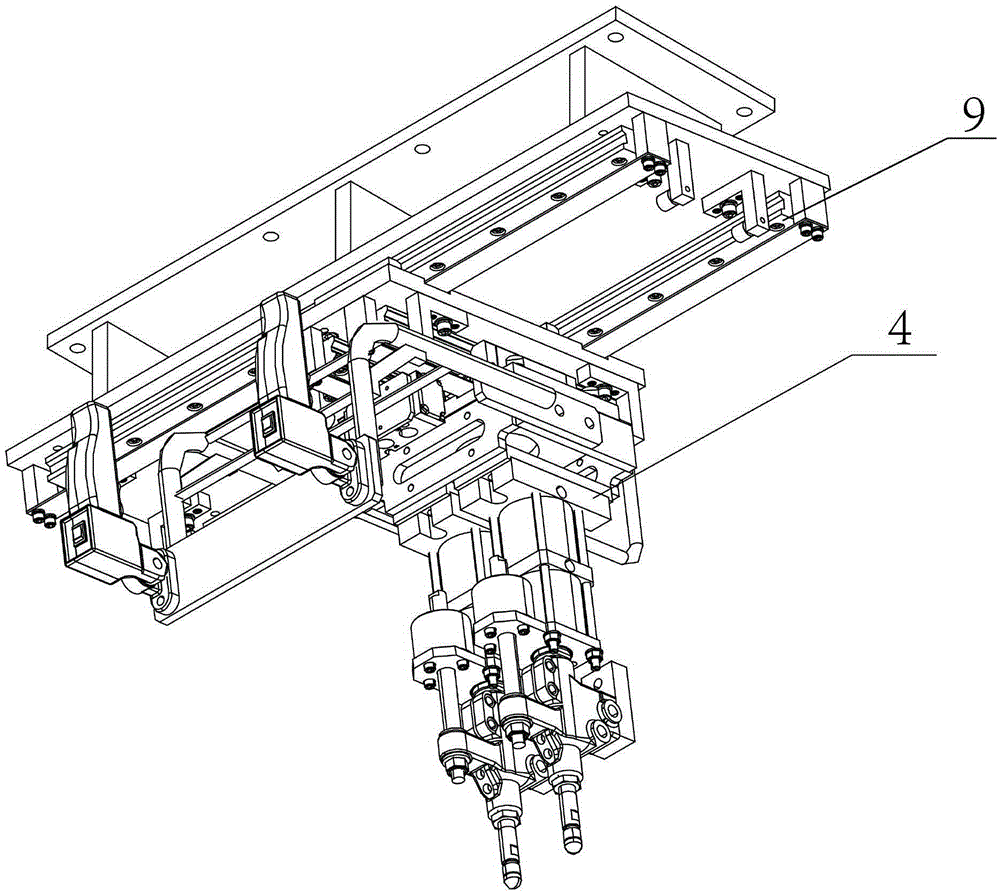

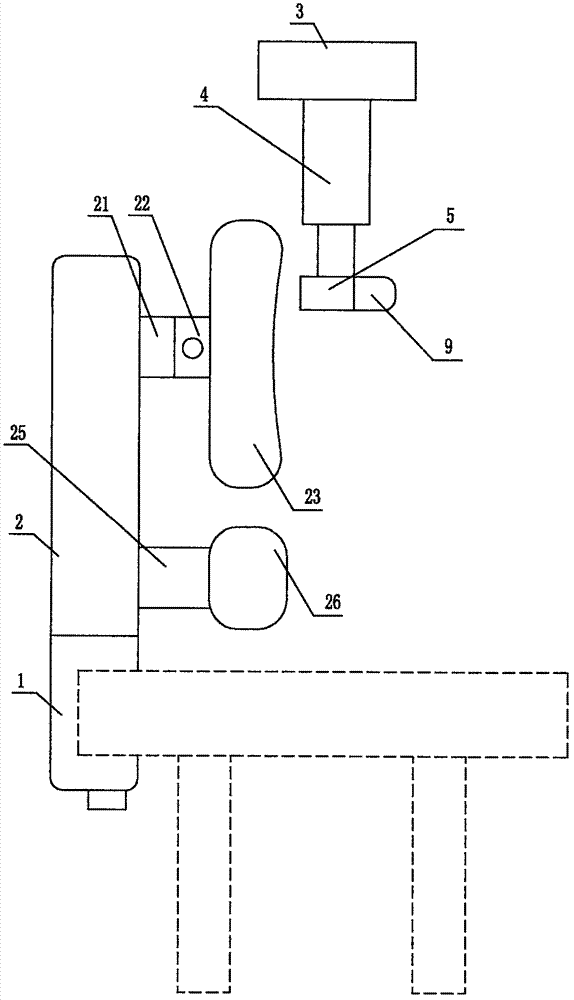

Single-face double-point welding process for automobile

InactiveCN105382393AReduce the difficulty of operationGood welding effectResistance electrode holdersVehicle componentsTransformerFunctional requirement

The invention aims at providing a single-face double-point welding process for an automobile. The process is characterized in that the process involves a special welding machine, automobile welding special clamps, a transformer, single-face double-point welding tongs, single-face double-point welding mechanisms, a gantry steel structure, gantry sliding-out mechanisms, gantry bases, a welding tong welding plane moving structure, upper electrodes, lower electrode islands, conductive bridges and locating connection parts; the transformer and the single-face double-point welding tongs are carried on the special welding machine, single-side double-electrode welding is adopted by the special welding machine, and the transformer is mounted on the top of the special welding machine. The process has the beneficial effects that full manual operation for welding can be achieved, only two workers are needed, and large heavy welding tongs are not used; the welding tongs are fixed to the special welding machine and are light, easy to operate and good in welding effect; on the basis that the functional requirement is met, the investment cost is lowered to a great extent, the operation difficulty of the workers is lowered, and the stability and multi-vehicle-type adapting capacity of equipment are greatly improved.

Owner:天津七所高科技有限公司

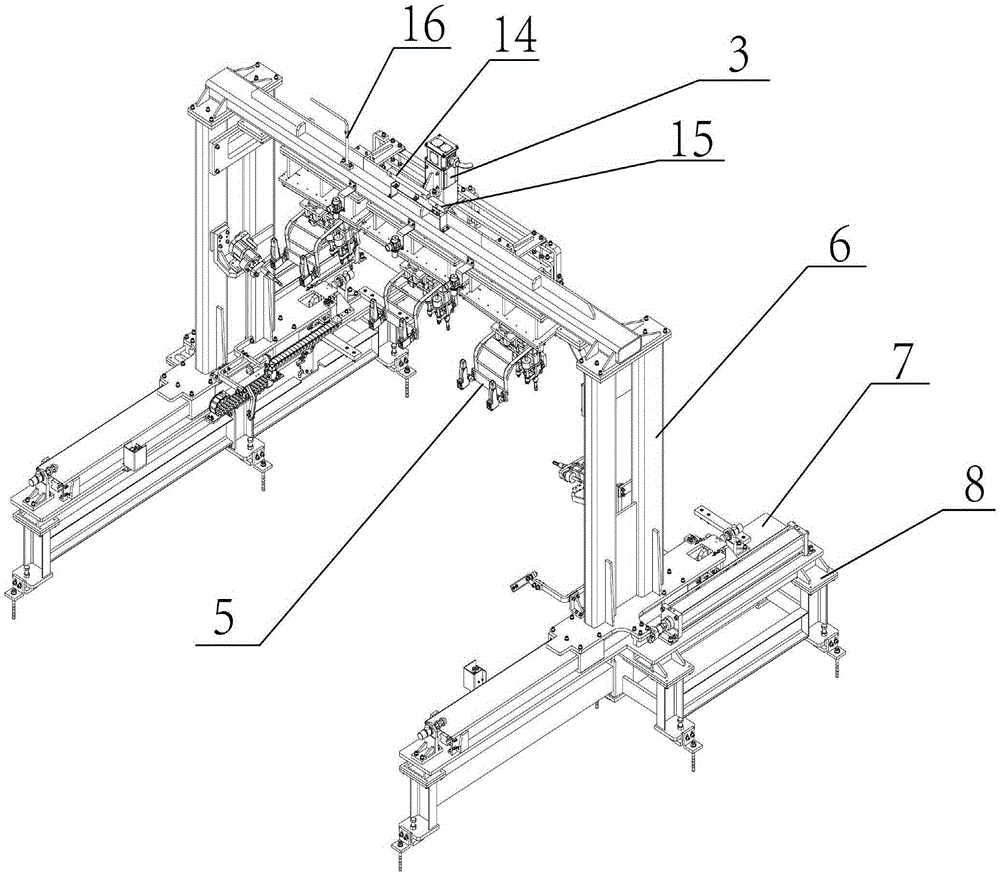

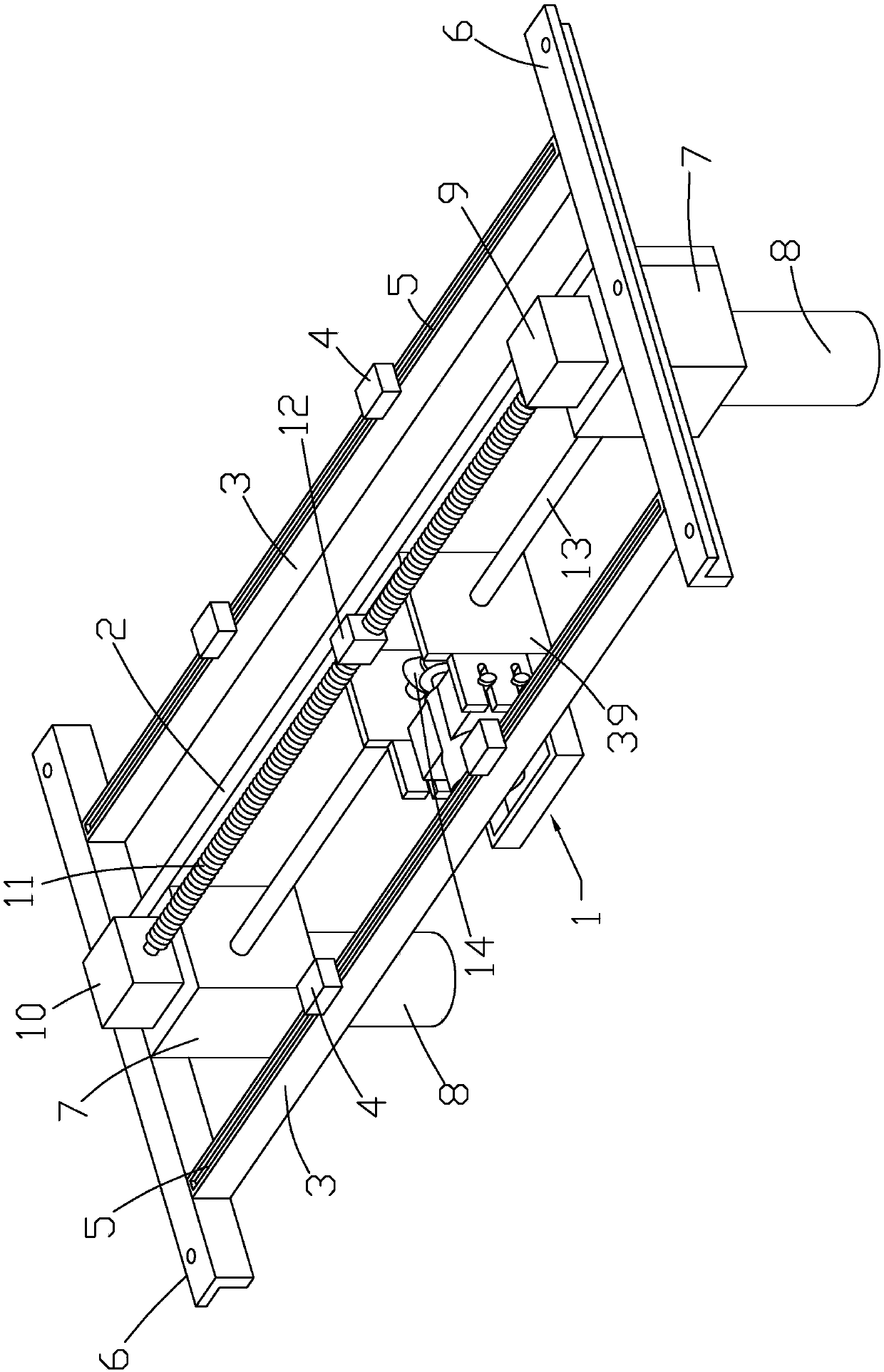

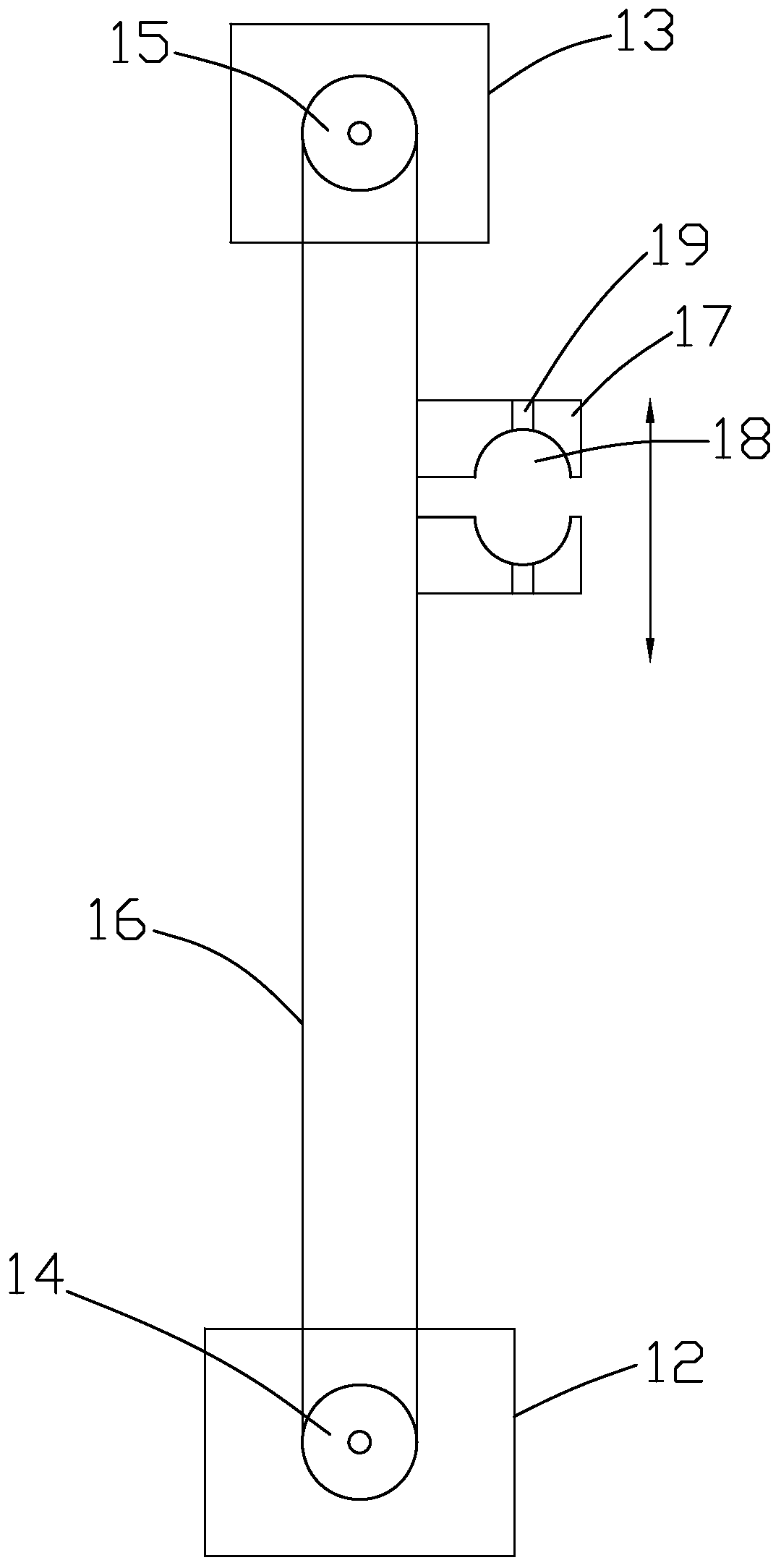

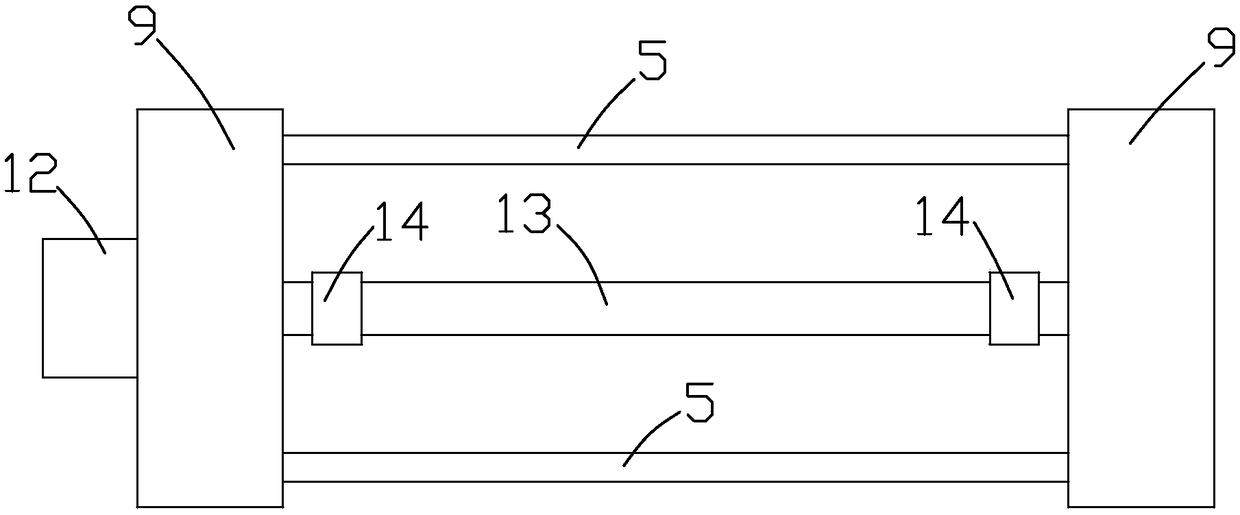

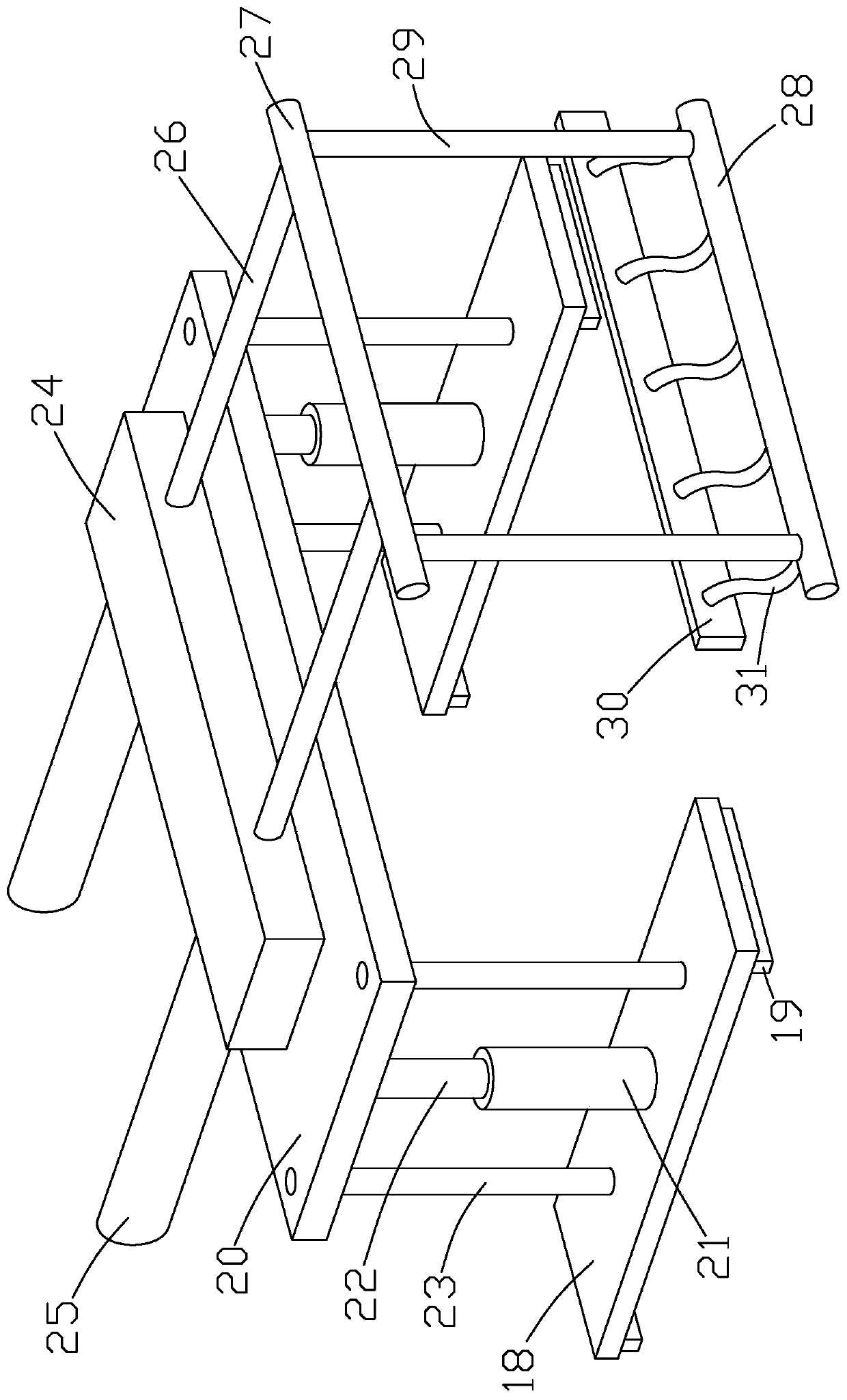

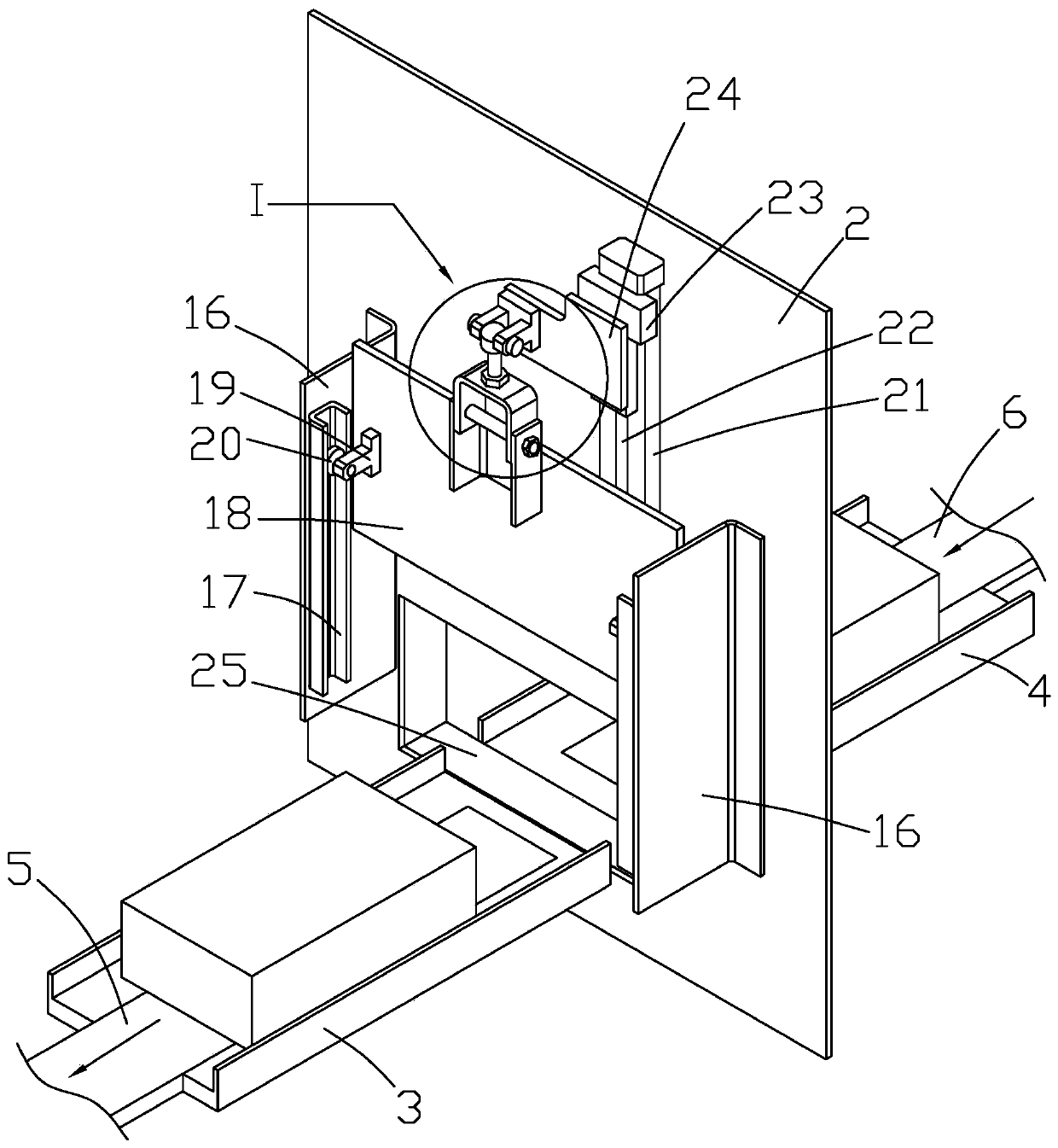

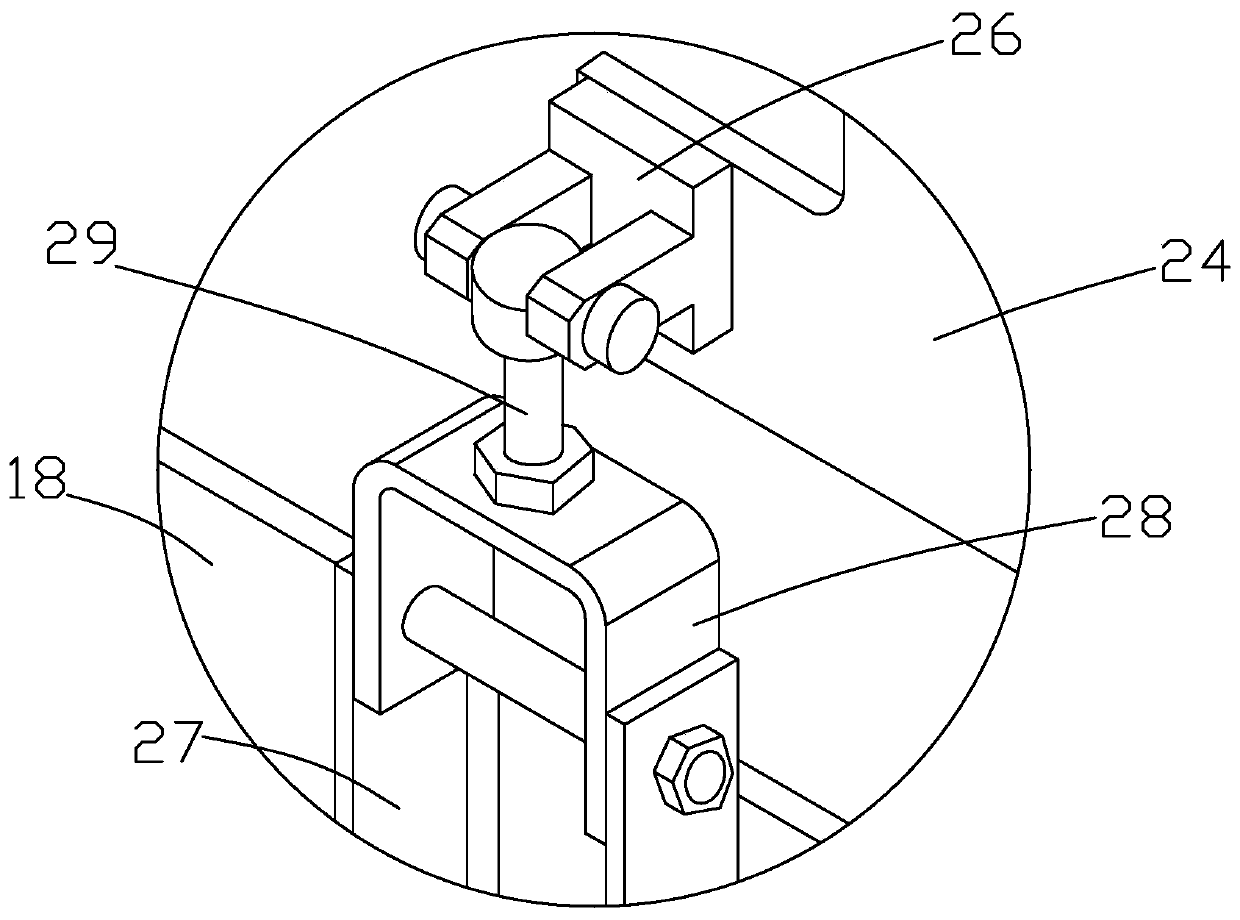

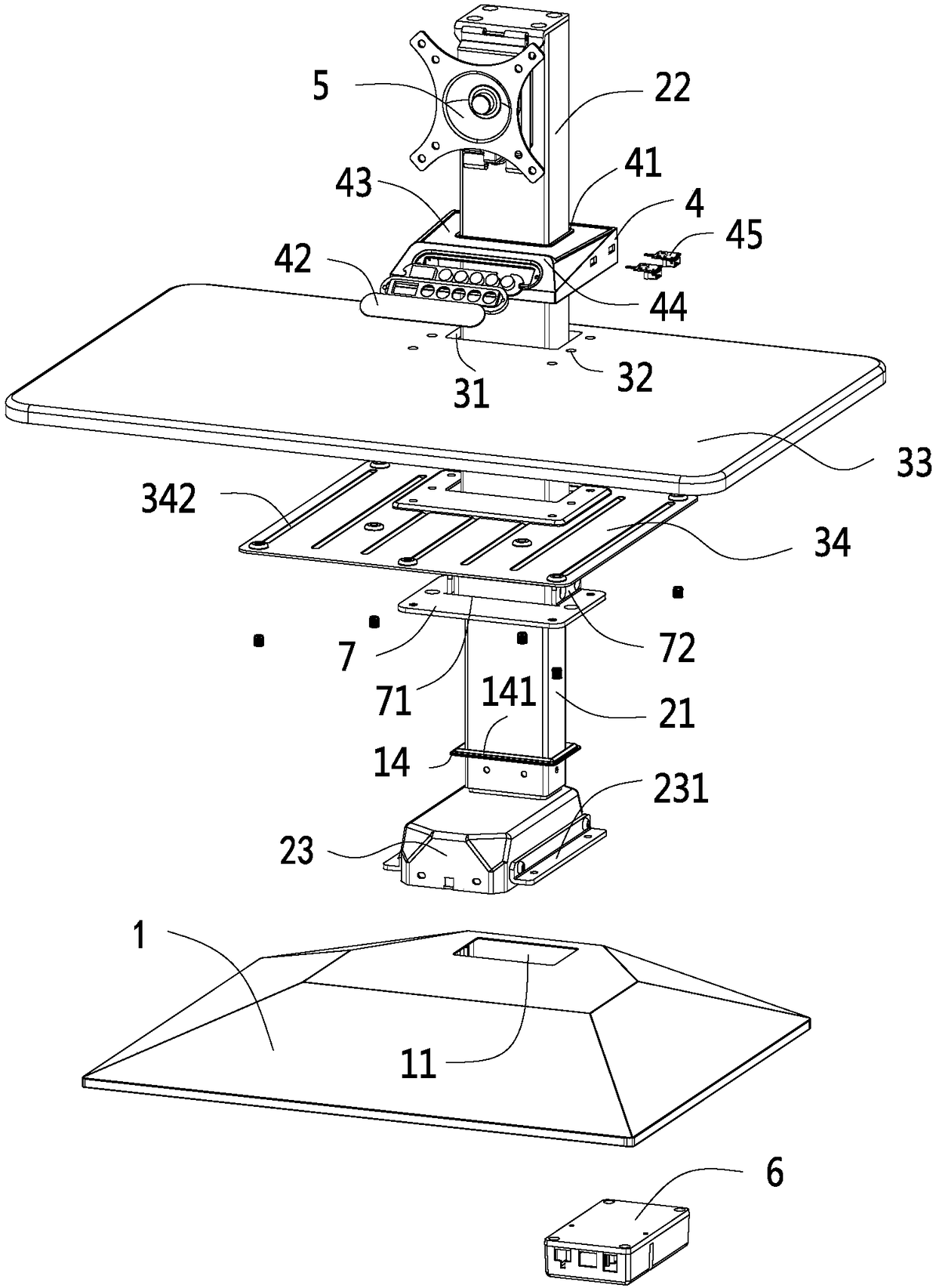

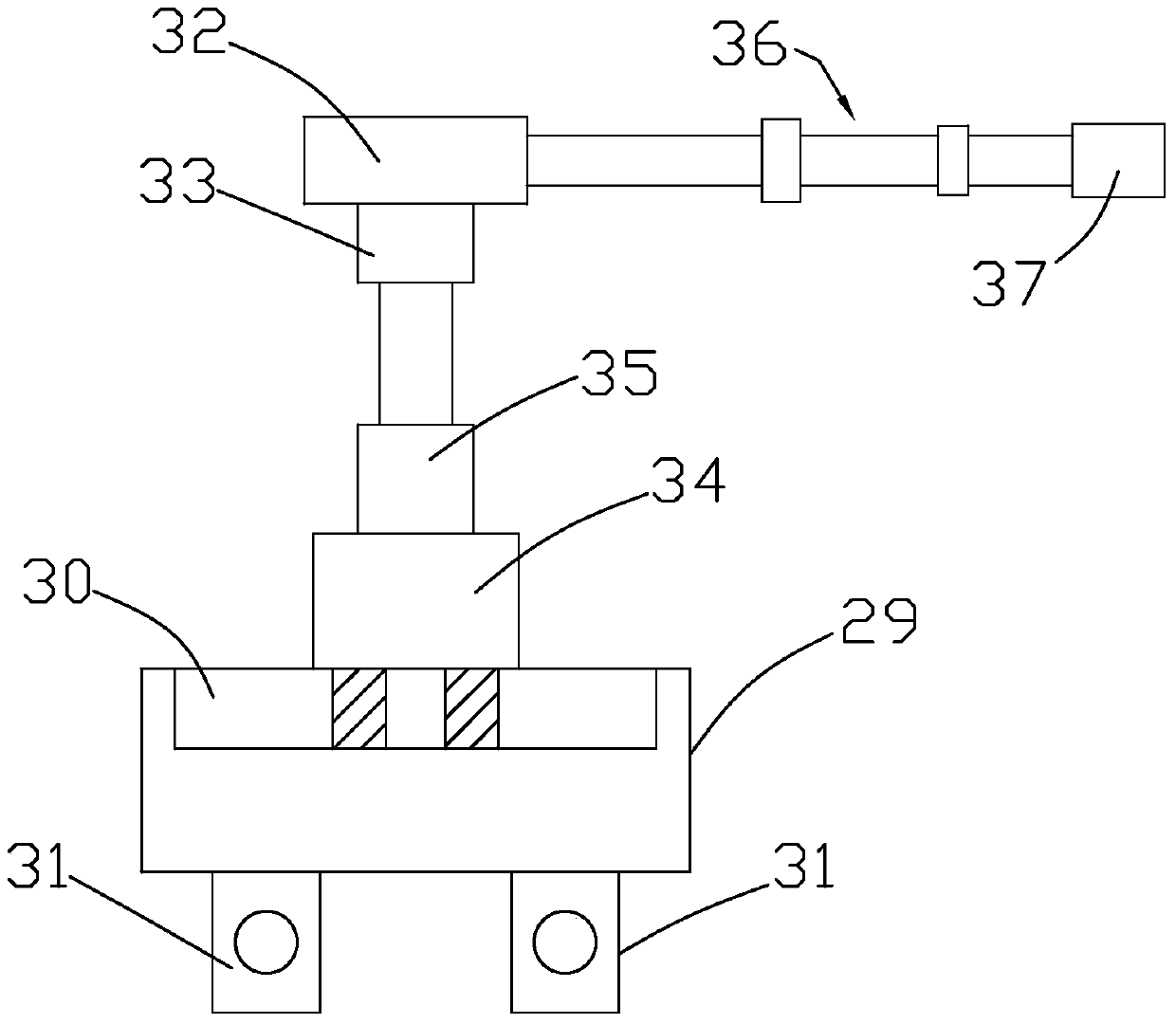

Multipurpose linear driver for electric lifting table and mounting method of multipurpose linear driver

ActiveCN109567386AImprove stabilityImprove reliabilityToothed gearingsMechanical energy handlingElectric machineDrive shaft

The invention discloses a multipurpose linear driver for an electric lifting table and a mounting method of the multipurpose linear driver. The multipurpose linear driver comprises a driving mechanism, a cross beam, a lifting mechanism and a horizontal moving mechanism, wherein boxes are symmetrically arranged on the left side and the right side of the cross beam and connected through a transmission shaft; first power bevel gears are symmetrically arranged at two ends of the transmission shaft, and the horizontal moving mechanism is arranged on the top surfaces of the boxes and connected in the boxes. The mounting method of the multipurpose linear driver comprises the following steps: mounting of the driving mechanism, mounting and positioning of the boxes and the lifting mechanism, mounting of the horizontal moving mechanism, mounting of support bars and operation of the linear driver. Mounting and dismounting of the electric lifting table are facilitated, maintenance is facilitated,and because the electric lifting table is driven by a single drive motor, stability and reliability of the electric lifting table are greatly improved, noise is reduced, transverse movement of the tabletop can be realized, and flexibility of the table in use is enhanced.

Owner:绍兴蒂尔莱特科技有限公司

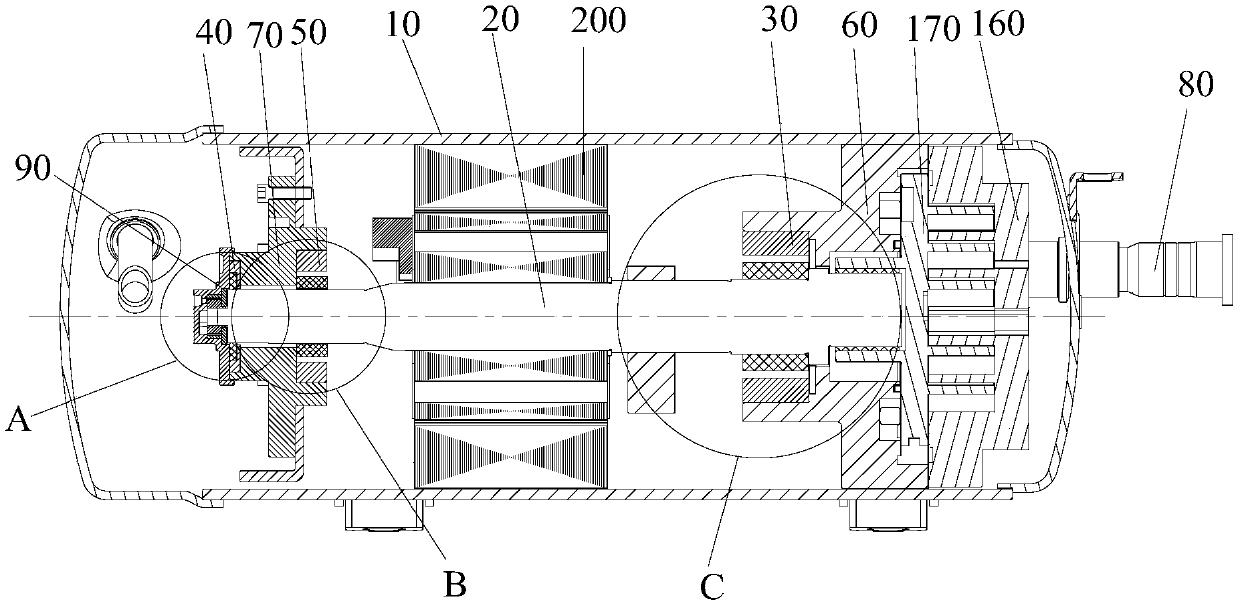

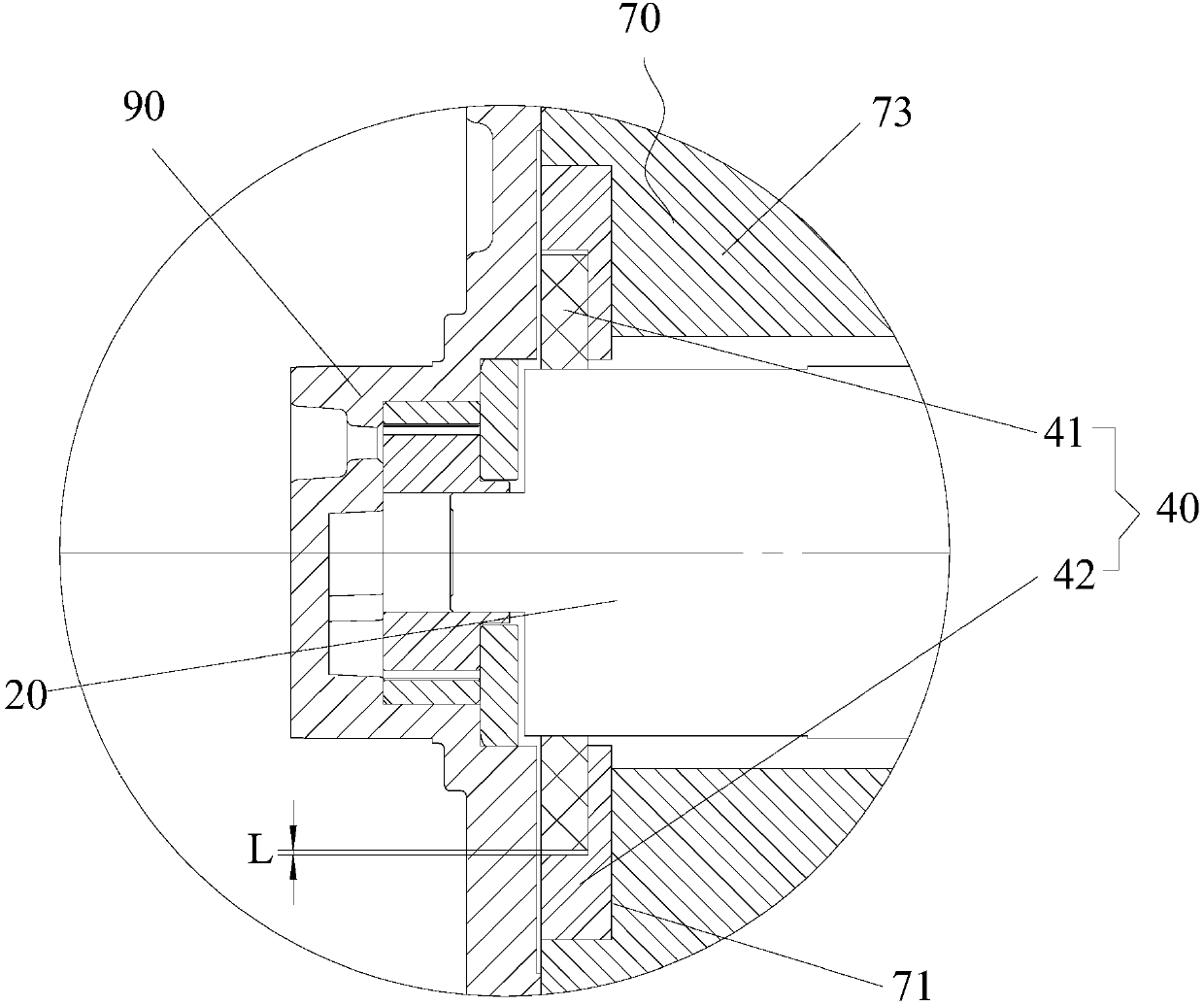

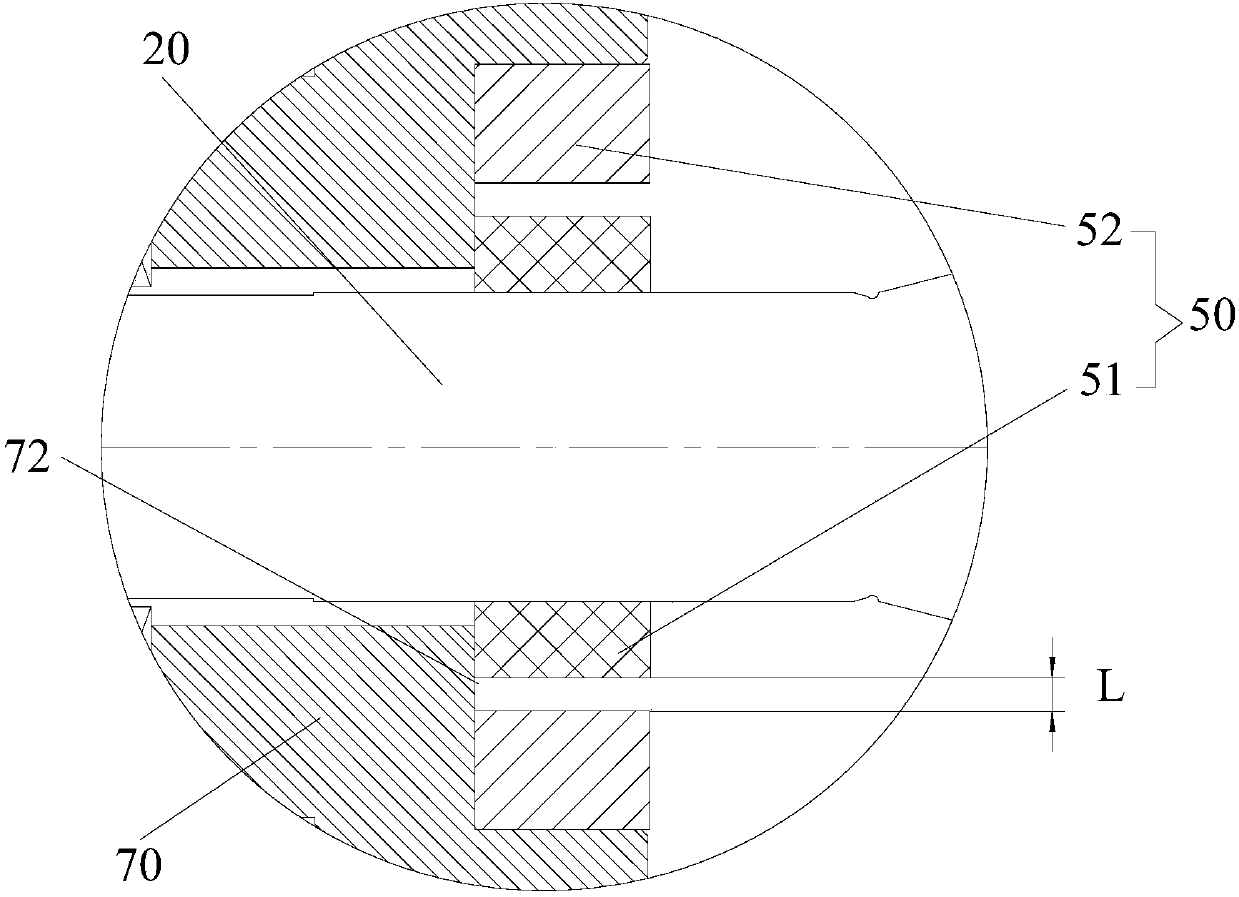

Compressor, compressor parallel system and multi-online heat exchange system

ActiveCN107588005AReduce mechanical wearImprove reliabilityRotary/oscillating piston combinations for elastic fluidsCompressorEngineeringCrankshaft

The invention provides a compressor, a compressor parallel system and a multi-online heat exchange system. The compressor includes a casing and a crankshaft arranged in the shell and also includes a first magnetic suspension bearing arranged in the casing and a second magnetic suspension bearing arranged in the casing, wherein the first magnetic suspension bearing and the second magnetic suspension bearing are respectively arranged at both ends of the crankshaft. The problems that the crankshaft is easy to wear and easily produces noise when the compressor runs at high speed in the prior art are effectively solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Auxiliary turn-over device

InactiveCN107212988APlay the role of supporting positioningImprove stabilityNursing bedsAmbulance serviceMechanical engineeringPatient care

The invention discloses an auxiliary turning device. The upper part of the receiving plate opposite to the inner surface is provided with two sets of supporting and positioning devices arranged at intervals along the length direction of the receiving plate. Contact with the back of the human body, so that the positioning board plays a role of supporting and positioning the human body, and the two positioning boards can improve the stability of the support. Put the towel between the two clamping plates, turn the locking nut to move the clamping plate at the end of the clamping rod relatively inward and clamp and fix the towel, slide the oil cylinder to make the towel face the patient's back along the length of the bed To wipe, start the oil cylinder, make the telescopic rod of the oil cylinder move up and down, and wipe the patient's back up and down. During the wiping process, there may be water flowing down the patient's back, and the flowing water can be absorbed by the absorbent sponge. The invention is convenient for assisting the patient to maintain the side lying state and nursing the patient.

Owner:牟丰英

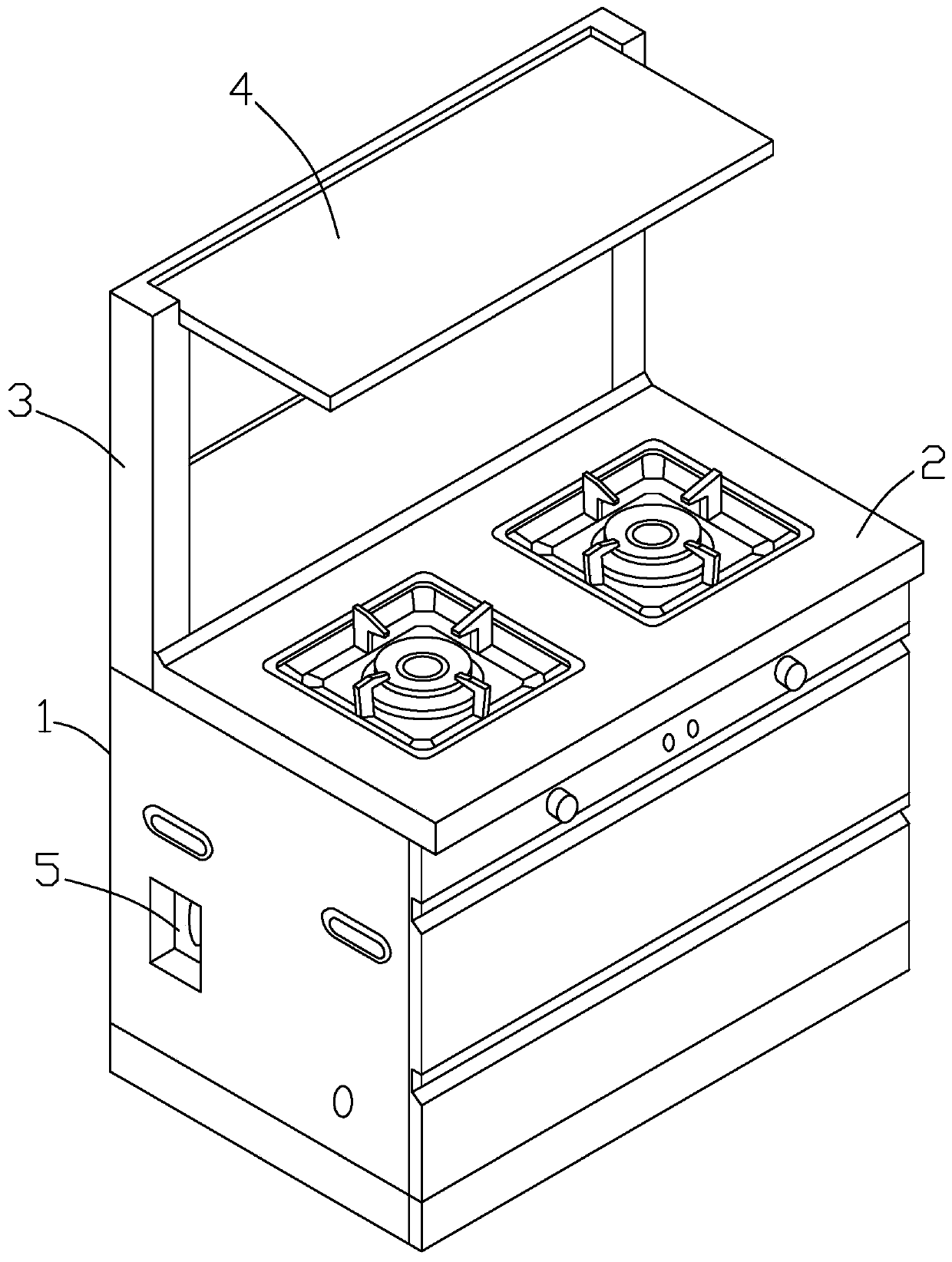

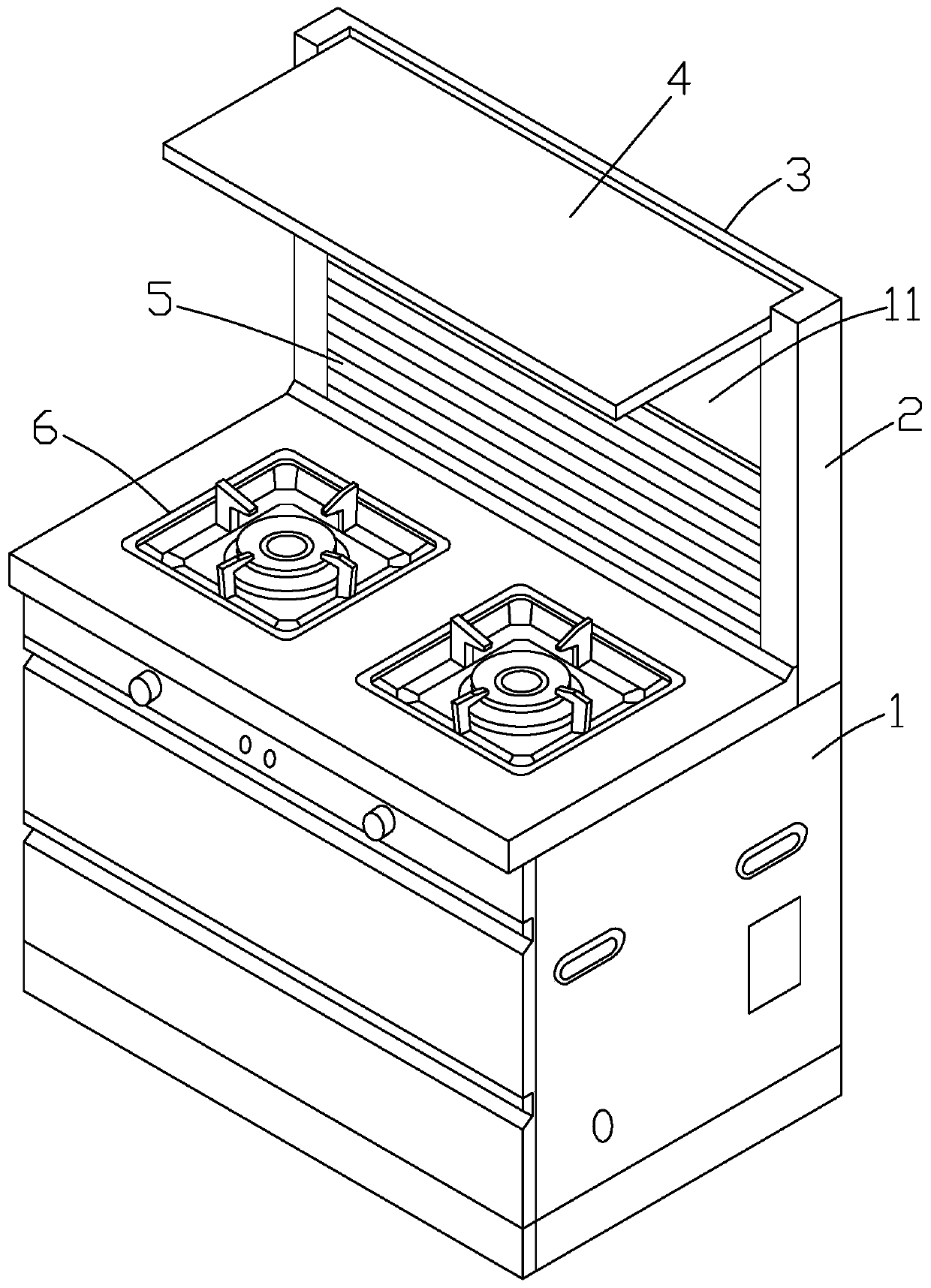

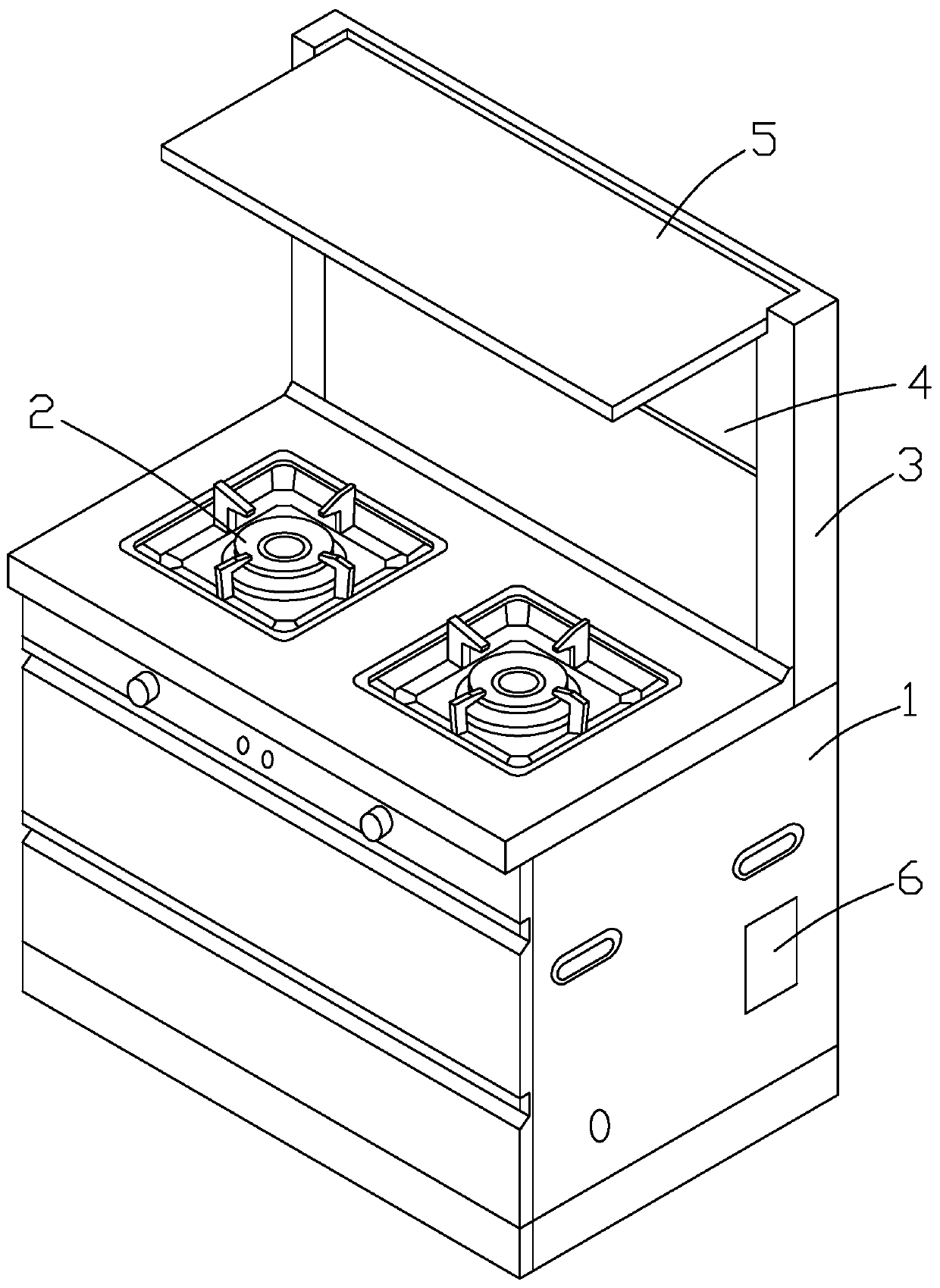

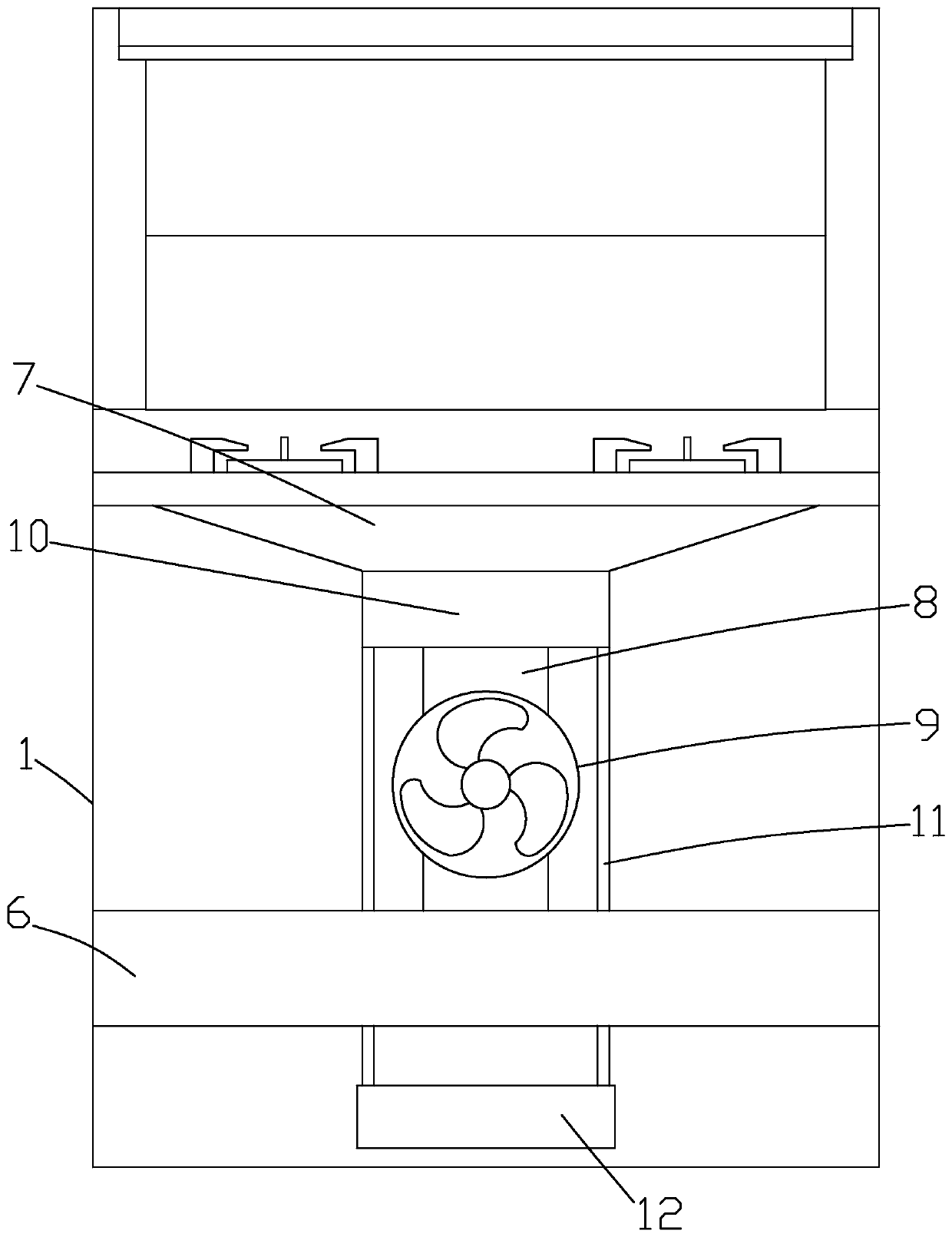

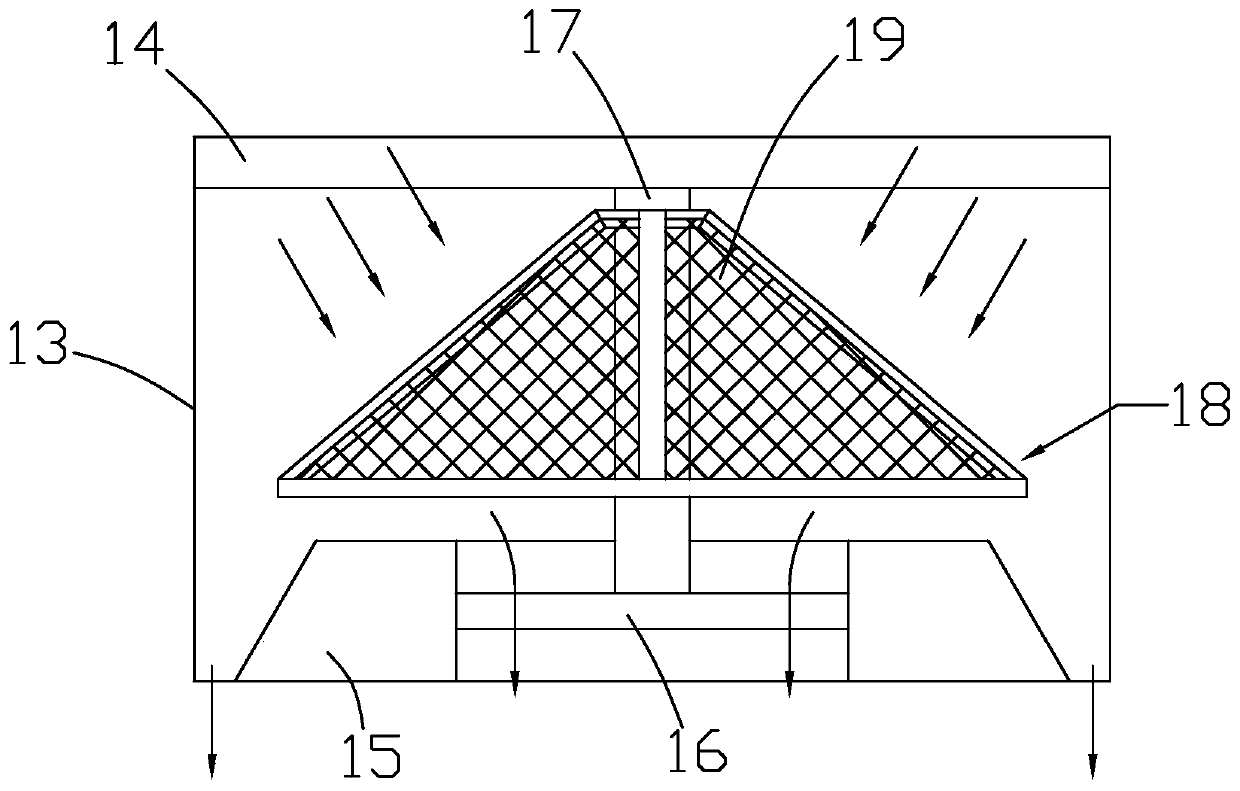

Integration cooker capable of adjusting volume of smoke collection cavity and making method of integration cooker

PendingCN110726164AAdjustable spacingImprove sealingDomestic stoves or rangesPump componentsProcess engineeringWind power

The invention discloses an integration cooker capable of adjusting the volume of a smoke collection cavity and a making method of the integration cooker. The integration cooker comprises an integration cooker body and the adjustable smoke collection cavity, the top of the adjustable smoke collection cavity is communicated with a cooking fume suction groove in the top face of the integration cookerbody, and a supporting mechanism is arranged on the side face of the adjustable smoke collection cavity, and connected with a lifting driving mechanism and a limiting sliding mechanism. The making method of the integration cooker comprises the steps of machining the integration cooker body, machining and installing the adjustable smoke collection cavity, machining and installing the supporting mechanism, installing the lifting driving mechanism, installing the limiting sliding mechanism, and conducting pilot running on the integration cooker. According to the integration cooker, through the design of the adjustable smoke collection cavity, the smoke collection cavity is close to or away from a draught fan, flexible adjustment of wind power in the shifting process of the draught fan is satisfied, and it is avoided that the wind power is suddenly increased or decreased; moreover, up-down floating adjustment on wind power can be made when the draught fan is at different gear positions, the adjustment on the wind power of the integration cooker is diversified, air flow is smoother, and the noise is lowered.

Owner:浙江蓝炬星电器有限公司

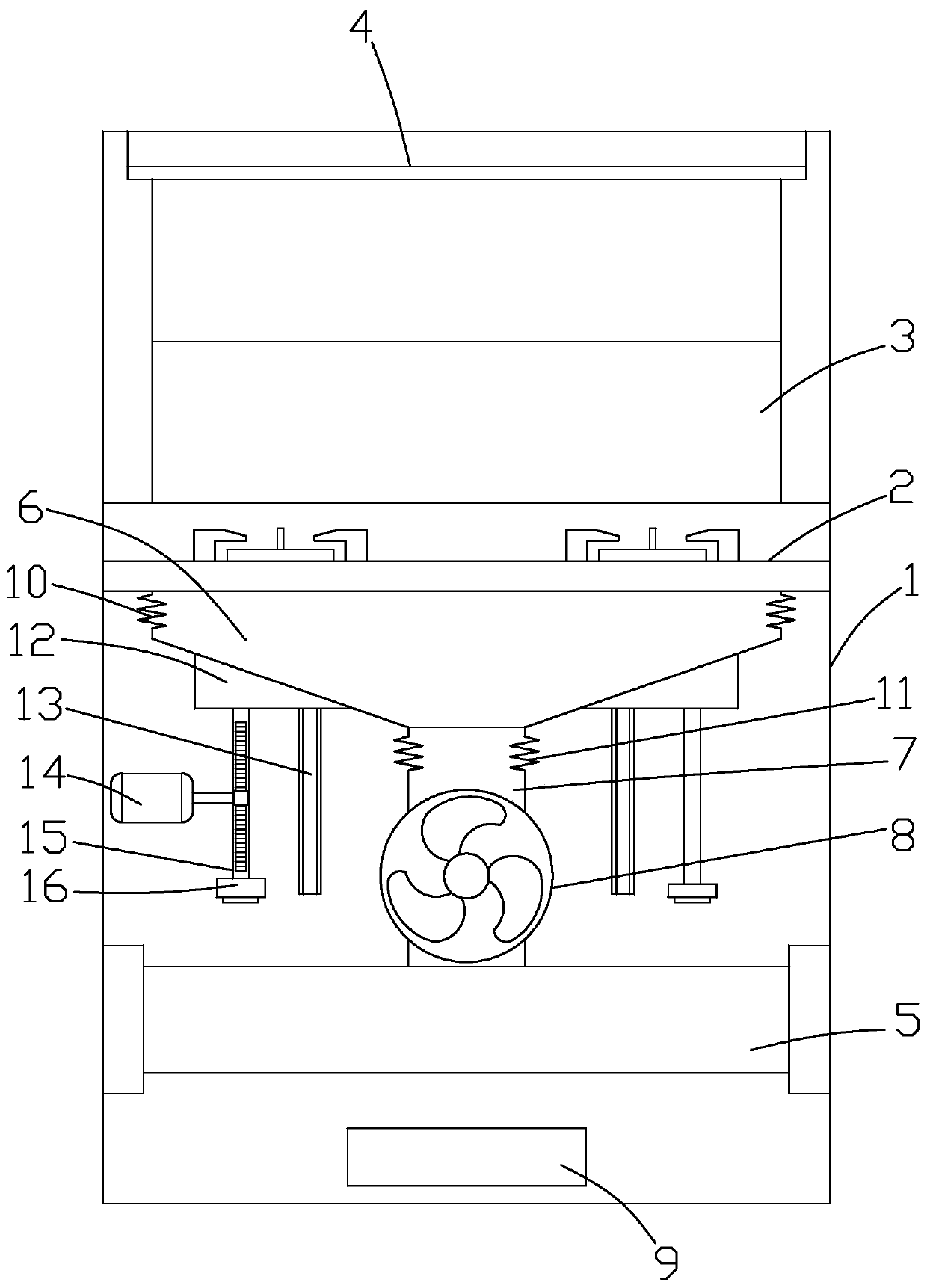

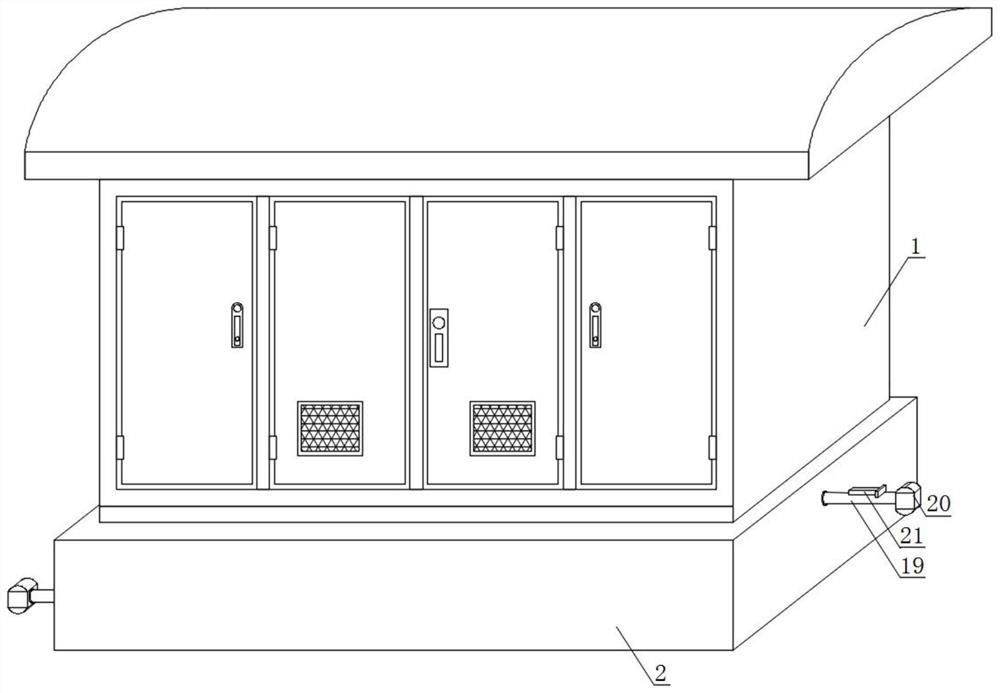

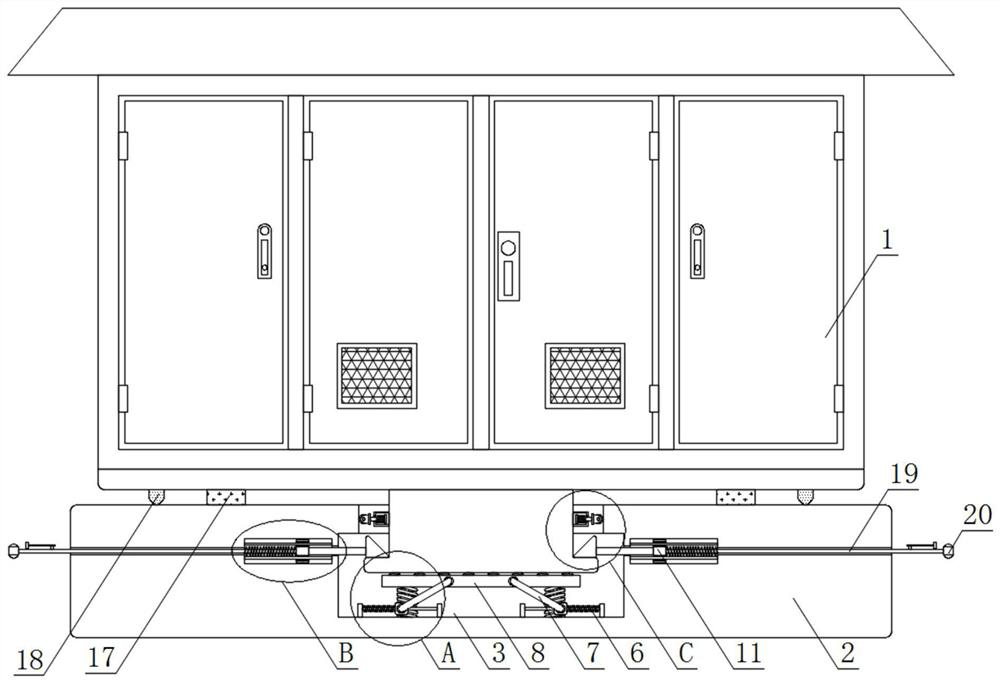

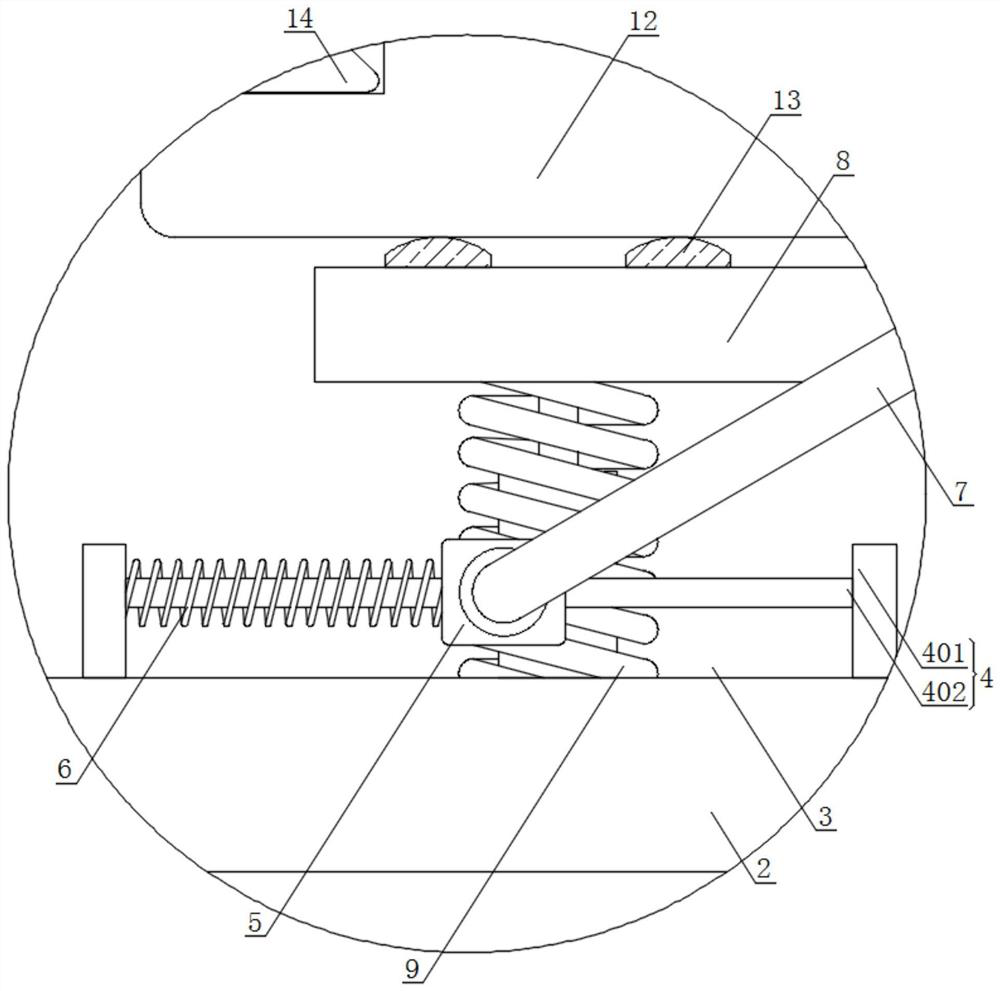

Damping base of prefabricated substation

PendingCN111810772AActs as a shock absorberLess prone to damageNon-rotating vibration suppressionEngine bedsArchitectural engineeringElectric power equipment

The invention discloses a damping base of a prefabricated substation, and belongs to the technical field of power equipment. The damping base comprises a prefabricated substation main body and a mounting base. A mounting groove is formed in the top of the mounting base. Two support frames are fixedly arranged on each of the left and right sides of the bottom of the mounting groove. Adjusting sliders are in sliding connection with the four support frames. Damping springs are fixedly arranged on the opposite sides of every two left-right opposite adjusting sliders. According to the damping baseof the prefabricated substation, when the prefabricated substation main body is hit by a downward impact force, a mounting plate is impacted through a T-shaped mounting base and and elastic blocks, sothat damping support components and the damping springs at the bottom of the mounting plate play the role of damping and buffering, the impact resistance effect of the damping base of the prefabricated substation is relatively good, ultimately the damping effect of the damping base of the prefabricated substation is relatively good. When a substation is impacted, inner electric elements are not prone to being damaged, and the protection effect is relatively good.

Owner:JIANGXI MINGZHENG SUSTION EQUIP

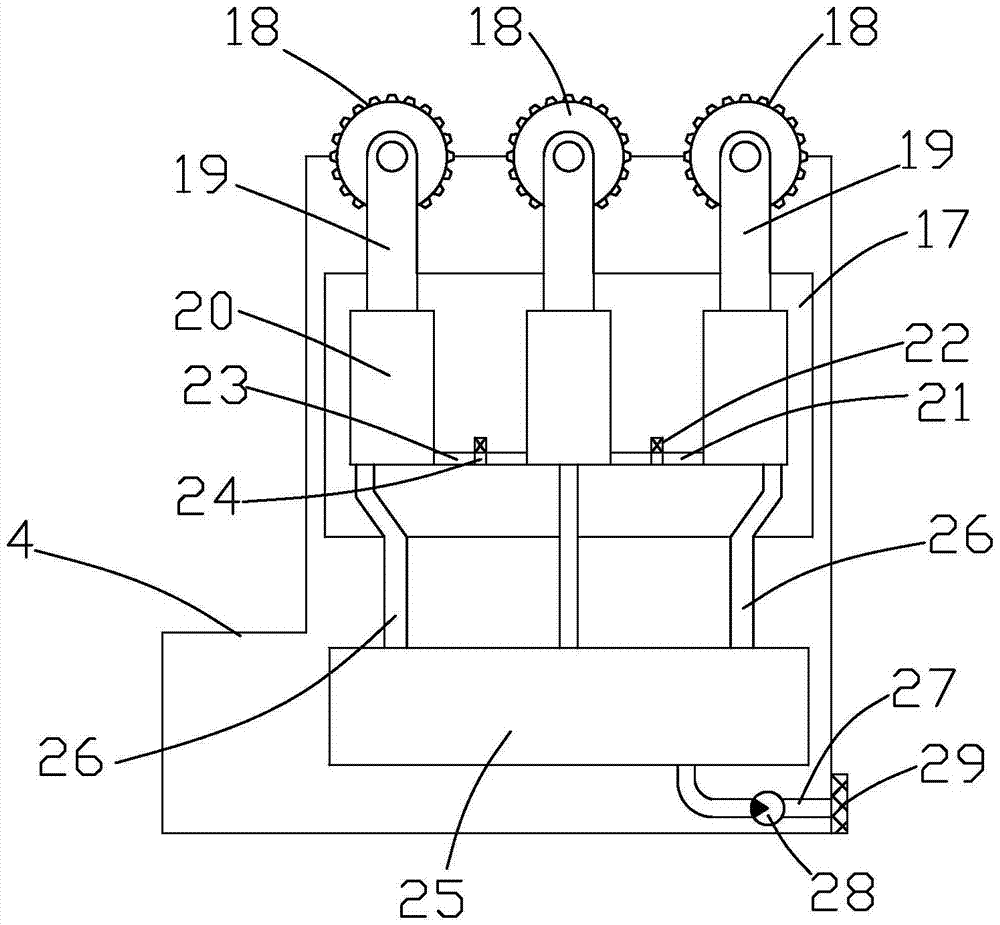

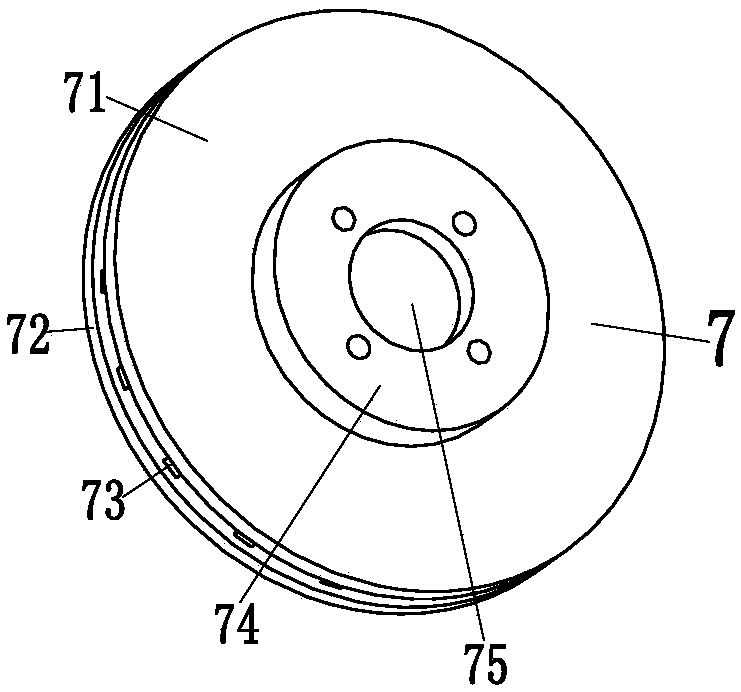

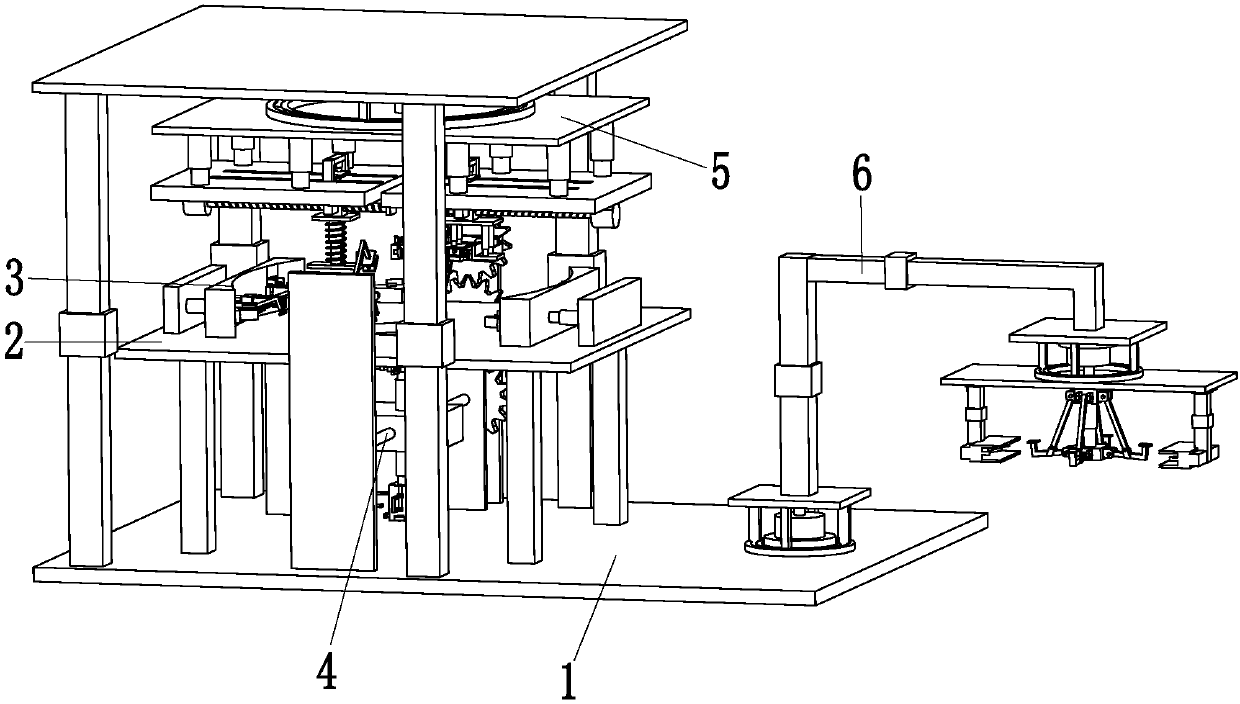

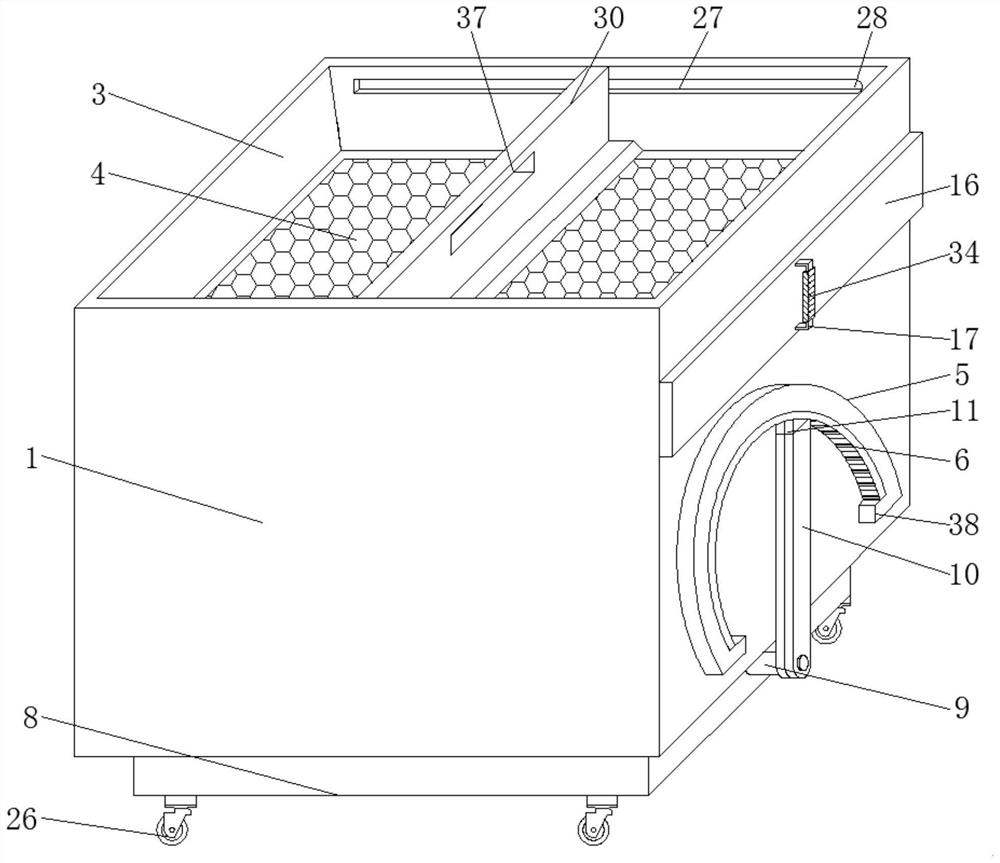

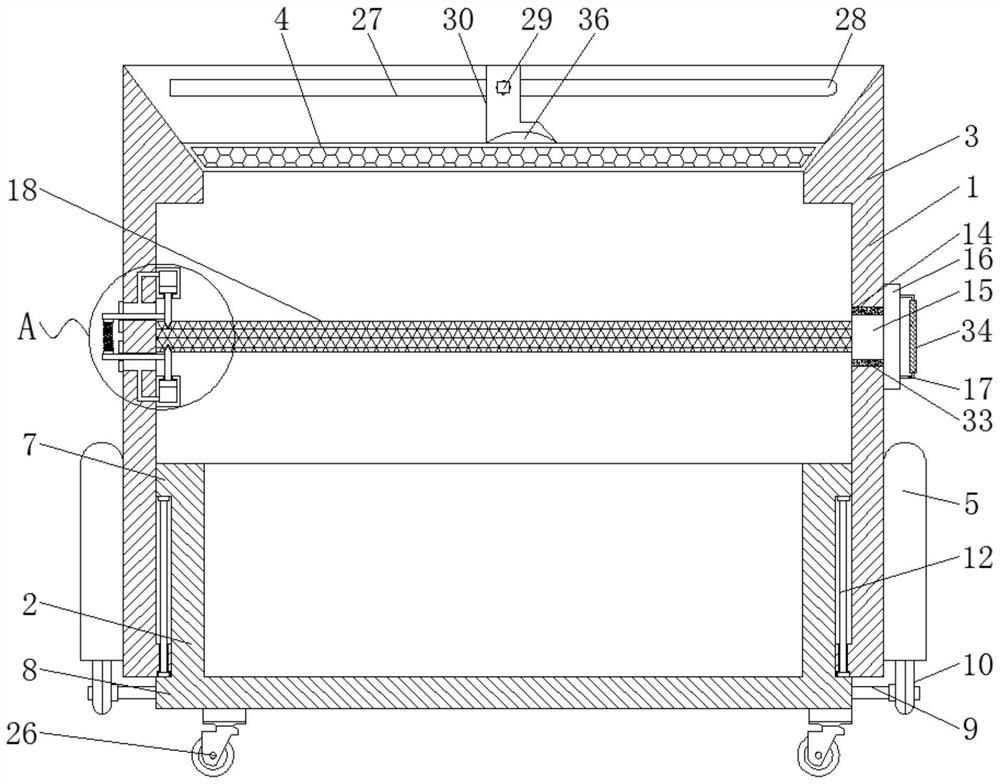

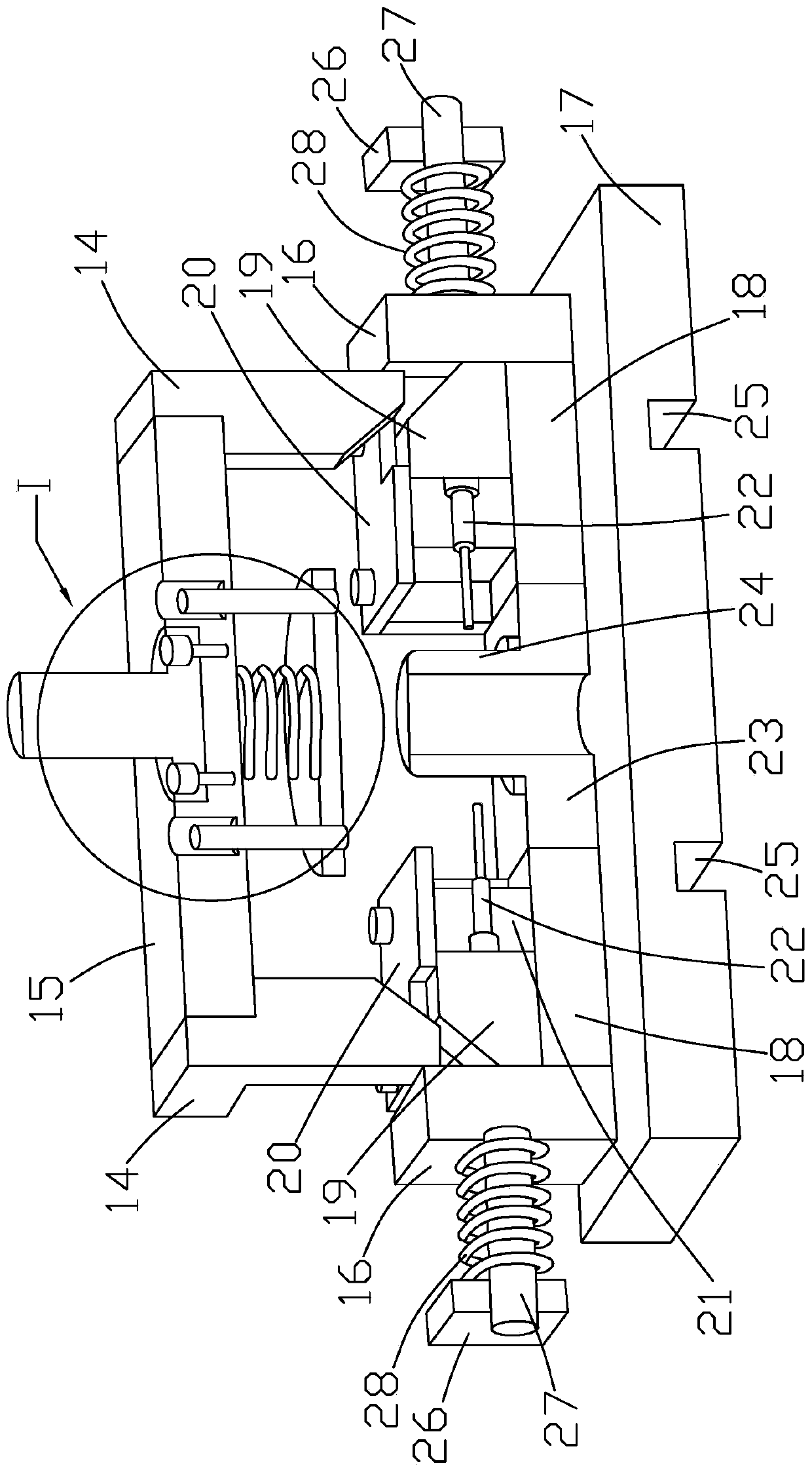

Brake disc machining machine with hoisting, fixing and grinding functions for electric automobile brake system

InactiveCN108098542AGrinding stabilityEasy to fixEdge grinding machinesGrinding carriagesEngineeringMachining

The invention relates to a brake disc machining machine with hoisting, fixing and grinding functions for an electric automobile brake system. The brake disc machining machine comprises a supporting bottom plate, a supporting connecting frame, fixing devices, a transposition device, a grinding device and a hoisting device; the supporting connecting frame is installed on the top part of the left endof the supporting bottom plate; the left side and the right side of the top part of the supporting connecting frame each are provided with one fixing device; the transposition device is located on the outer sides of the fixing devices, and the transposition device is connected with the supporting bottom plate; the grinding device is located above the fixing devices, and the grinding device is installed on the top part of the supporting bottom plate; and the top part of the right end of the supporting bottom plate is provided with the hoisting device. According to the brake disc machining machine, the problems that fixing of a brake disc is not stable, fixing cannot be carried out on different types of brake discs, the brake disc needs to be transposed manually, potential hazards exist when the ground brake disc is taken manually, the grinding effect is poor, and the brake disc needs to be carried manually when the electric automobile brake disc is ground in an existing factory can besolved.

Owner:刘秀娟

Rocking bar structure for adjusting jaw crusher

ActiveCN111468214APlay the role of positioningSmooth crushing processGrain treatmentsReciprocating motionStructural engineering

The invention discloses a rocking bar structure for adjusting a jaw crusher, and belongs to the technical field of jaw crushers. The rocking bar structure for adjusting the jaw crusher comprises a crushing box, a left side fixed jaw plate is arranged on the left side in the crushing box, and the top of the crushing box is rotationally connected with an eccentric driving shaft. A movable block is rotationally connected to the surface of a connecting rod, a movable rocking bar is hinged to the bottom of the left side of the movable block, and a right side fixed jaw plate is hinged to the other side of the movable rocking bar, so that the connecting rod drives the movable rocking bar during reciprocating motion, then the right side fixed jaw plate is driven, a supporting rocking bar is hingedto the right side of the right side fixed jaw plate, and the other side of the supporting rocking bar is hinged to the crushing box, so that the supporting rocking bar can stabilize the movable block, the movable block runs relatively stably, and finally the device has the advantage that the rocking bars can actively drive a crushing jaw so as to enhance the crushing capacity of the device.

Owner:SHANDONG LIANBANG HEAVY IND

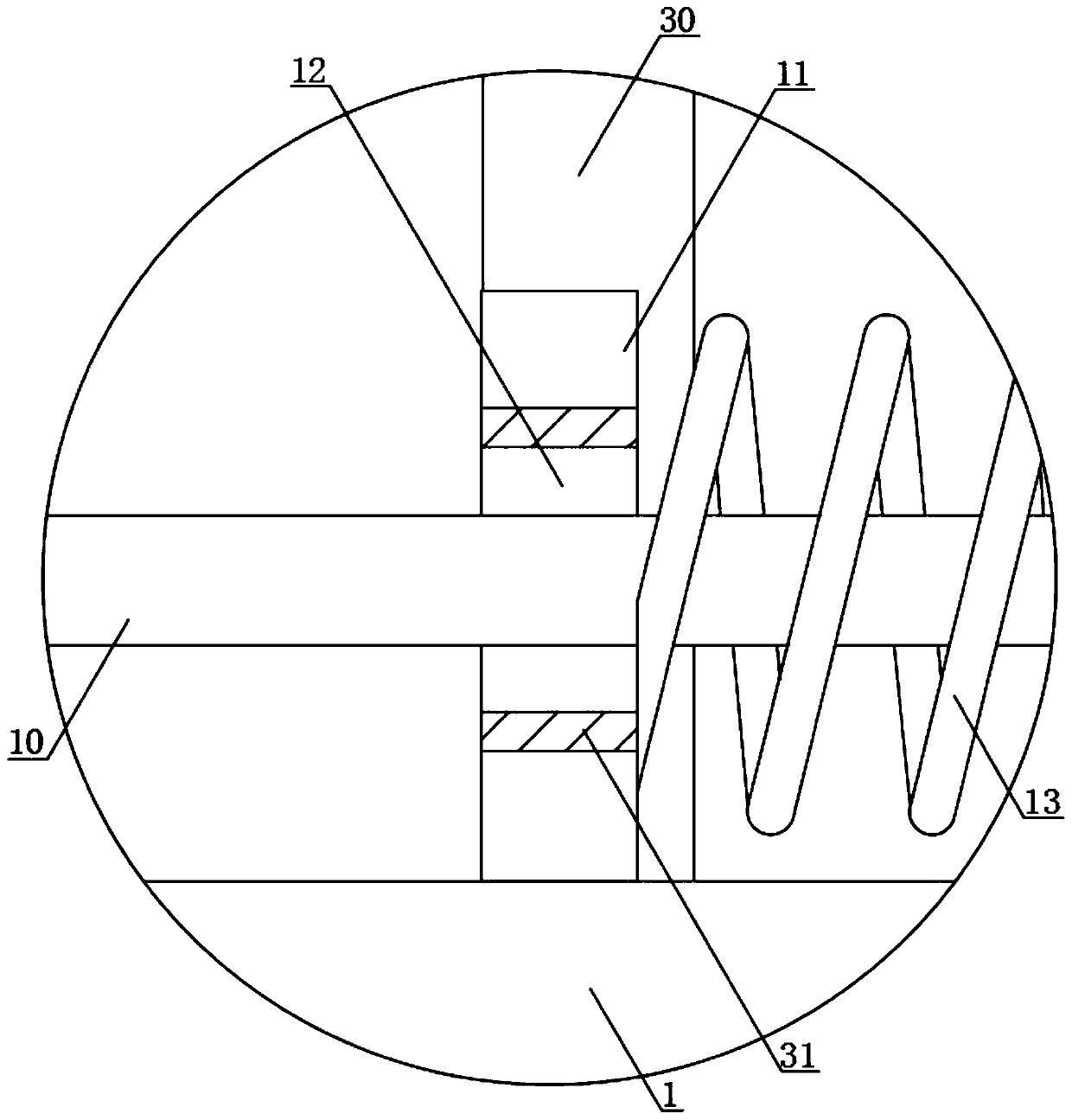

Integrated cooker with lifting type smoke guide plate and manufacturing method thereof

PendingCN110173725AGuaranteed integrityImprove smoke guiding effectDomestic stoves or rangesLighting and heating apparatusInlet channelEngineering

The invention discloses an integrated cooker with a lifting type smoke guide plate and a manufacturing method thereof. The integrated cooker comprises a cooker body, a kitchen range and two parallel supporting columns are arranged on the top surface of the cooker body, the supporting columns are located on the rear side of the kitchen range, the rear side faces of the two supporting columns are insealed connection through a rear side baffle, a top baffle is arranged between the top surfaces of the two supporting columns, the lifting type smoke guide plate is arranged between the inner side surfaces of the two supporting columns, a smoke inlet channel is formed between the lifting type smoke guide plate, the rear side baffle and the two supporting columns, and the smoke inlet channel communicates with the interior of the cooker body. The manufacturing method comprises the following steps of carrying out cooker body machining; carrying out driving mechanism installation; carrying out lifting type smoke guide plate installation; and carrying out integrated cooker pilot run. According to the integrated cooker, the caliber of the smoke inlet channel can be adjusted, the air speed can be adjusted, the adsorption efficiency of the oil fume can be improved, the smoke discharging requirement of pots with different sizes can be met, and meanwhile, the flames are prevented from being directly sucked into the smoke inlet channel due to the fact that the flames do not act on the bottom of the pot so as to reduce the combustion efficiency of the fuel gas and cause the waste of the fuelgas.

Owner:浙江蓝炬星电器有限公司

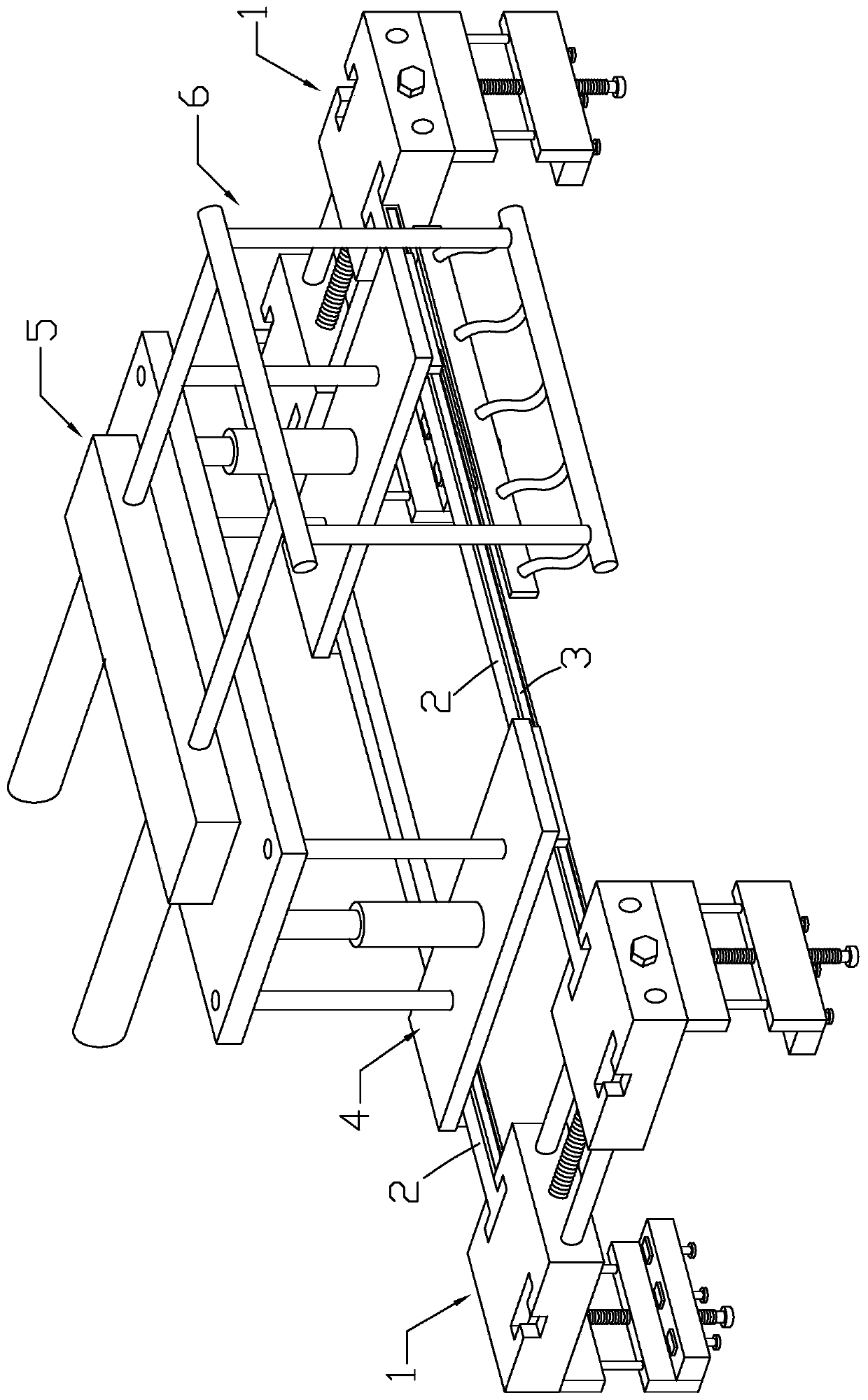

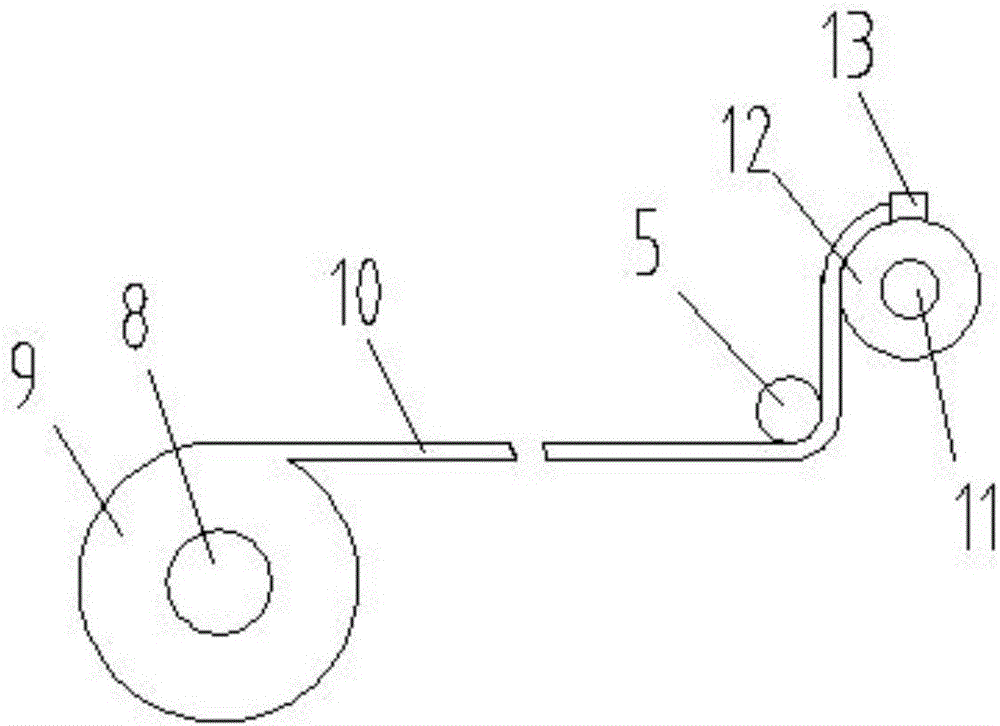

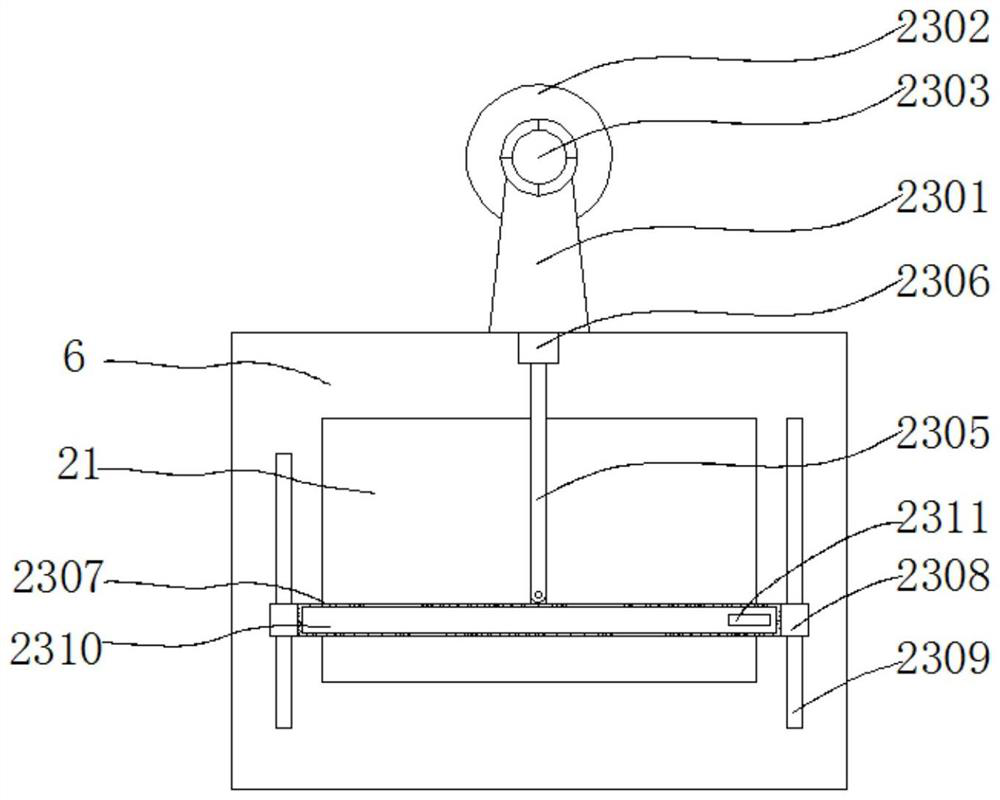

Yarn storage device for textile warping machine

ActiveCN109281027AImprove stabilityImprove reliabilityWarping machinesOther manufacturing equipments/toolsYarnTextile

The invention discloses a yarn storage device for a textile warping machine. The device comprises box bodies, a yarn storage roller, lifting mechanisms and a yarn guiding mechanism, wherein the two ends of the yarn storage roller are fixedly connected with baffles, the side faces of the baffles are provided with concave holes, the baffles are connected to the box bodies through clamping mechanisms, each clamping mechanism comprises a triangular turntable, a positioning plate and a clamping assembly, the three clamping assemblies are located at the ends of the triangular turntables respectively, the top faces of the triangular turntables are provided with limiting columns, the bottom faces of the triangular turntables are connected with the positioning plates through shaft sleeves and limiting mechanisms, the positioning plates are connected with second rotating shafts, the box bodies are internally provided with driving mechanisms, the driving mechanisms are connected with second rotating shafts, the lifting mechanisms are located above the box bodies, and the yarn guiding mechanism is arranged between the two lifting mechanisms. The yarn storage device for the textile warping machine has the advantages that the structure is simple, the practicability is strong, not only is the precision during yarn storage improved, thereby providing convenience for directly winding the yarn on the yarn storage roller, but also the tensile force when the yarn is winded on the yarn storage roller is adjusted through the yarn guiding mechanism according to the elasticity of different types of yarn.

Owner:SHENGZHOU WENDA TEXTILE CO LTD

Flashing construction device and method of room surface parapet

The invention discloses a flashing construction device and method of a room surface parapet. The flashing construction device comprises a lifting mechanism, a horizontally moving mechanism, a positioning mechanism and two symmetrically-arranged clamping mechanisms. Two parallel guiding rails are arranged between the two clamping mechanisms, T-shaped racks are symmetrically arranged at the two endsof the guiding rails, sliding grooves are formed on the side surfaces of the guiding rails, two lifting mechanisms are movably connected on the top surfaces of the two guiding rails, the two liftingmechanisms are arranged in parallel, the top ends of the lifting mechanisms are connected with the horizontally moving mechanism, and the positioning mechanism is fixedly connected to the front end ofthe horizontally moving mechanism. The construction method comprises the steps that substrate treatment is conducted, a flashing construction device is installed, waterproof construction is conducted, wall plastering is conducted, flashing construction in the connecting position of flashing surfaces, and flashing brushing asphalt paint. According to the flashing construction method of the room surface parapet, the step is simple, requirements of the flashing construction of the parapets with different sizes are met, the construction step is greatly simplified, the labor intensity of the manual operation is reduced, and the quality and accuracy of the flashing construction are improved.

Owner:CHENGLONG CONSTR GROUP

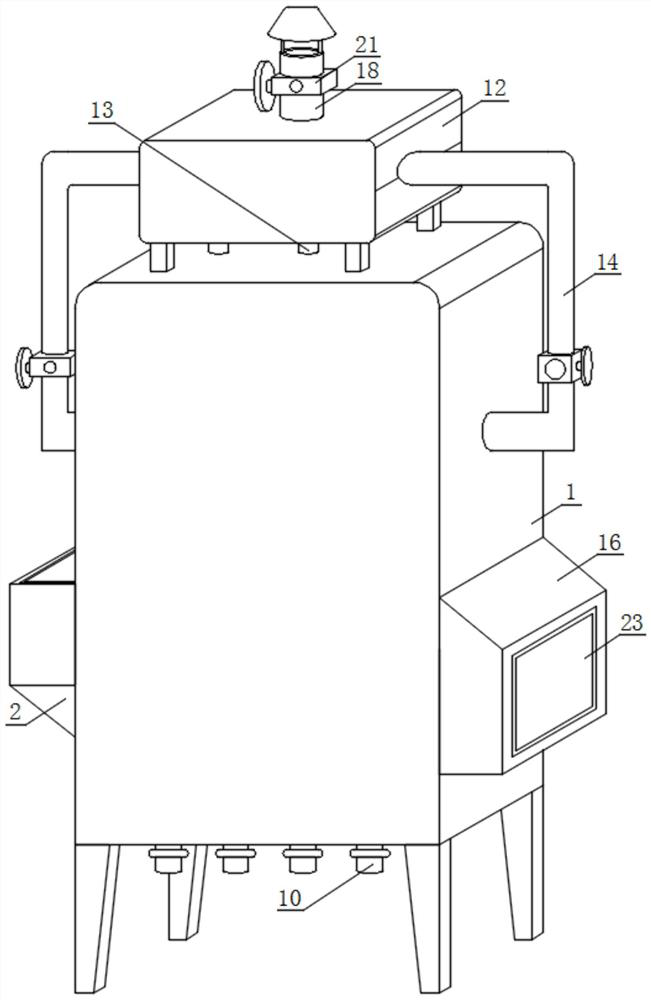

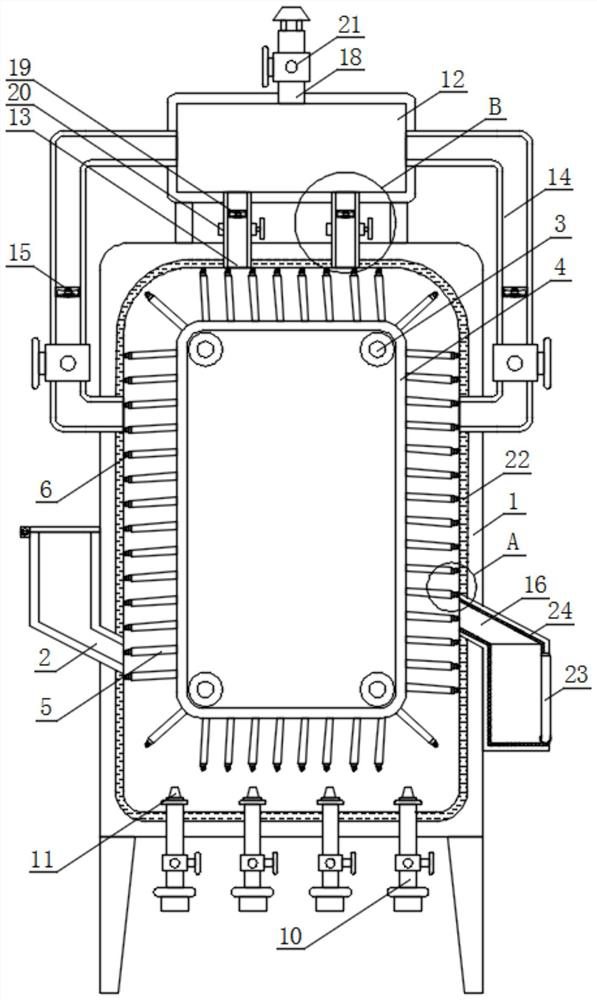

Heating furnace for aluminum rod production

InactiveCN111854427AHeating evenlyHeating evenly and efficientlyCharge composition/stateFurnace typesFlue gasExhaust fumes

The invention discloses a heating furnace for aluminum rod production, and belongs to the technical field of aluminum rod production. The heating furnace comprises an aluminum rod heating furnace, wherein a feeding hopper communicating with the aluminum rod heating furnace is fixedly mounted on the right side of the aluminum rod heating furnace, four transmission rollers are rotationally connectedinside the aluminum rod heating furnace, and an integrated high-temperature-resistant transmission belt is in transmission connection with the exteriors of the four transmission rollers. According tothe heating furnace for aluminum rod production, by operating an electric motor, the high-temperature-resistant transmission belt and heat-resistant placement plates can be driven by the transmissionrollers, aluminum rods can be driven by the high-temperature-resistant transmission belt for transmission, and the aluminum rods inside the aluminum rod heating furnace can be uniformly heated at high temperature through heating burners at the tops of fuel gas outer pipes, so that the heating of the aluminum rods is relatively efficient and uniform; and high-temperature waste gas after heating ofthe aluminum rod heating furnace is re-conducted to the interior of the aluminum rod heating furnace through lower air pipes on the two sides of a waste heat recovery furnace, so that the heating quality and efficiency of the aluminum rods in the aluminum rod heating device are relatively high, and the waste heat recovery effect on the fuel-gas flue gas is good.

Owner:恒吉集团实业有限公司

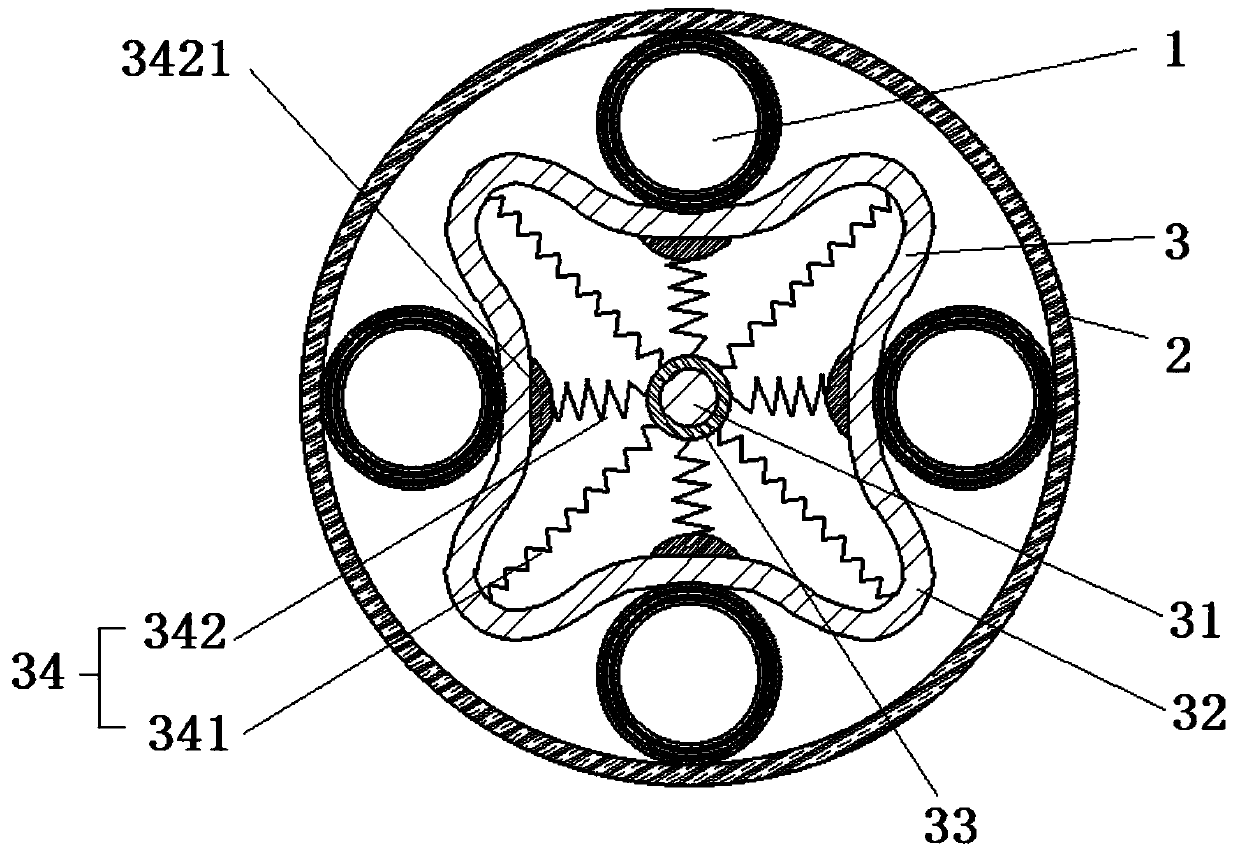

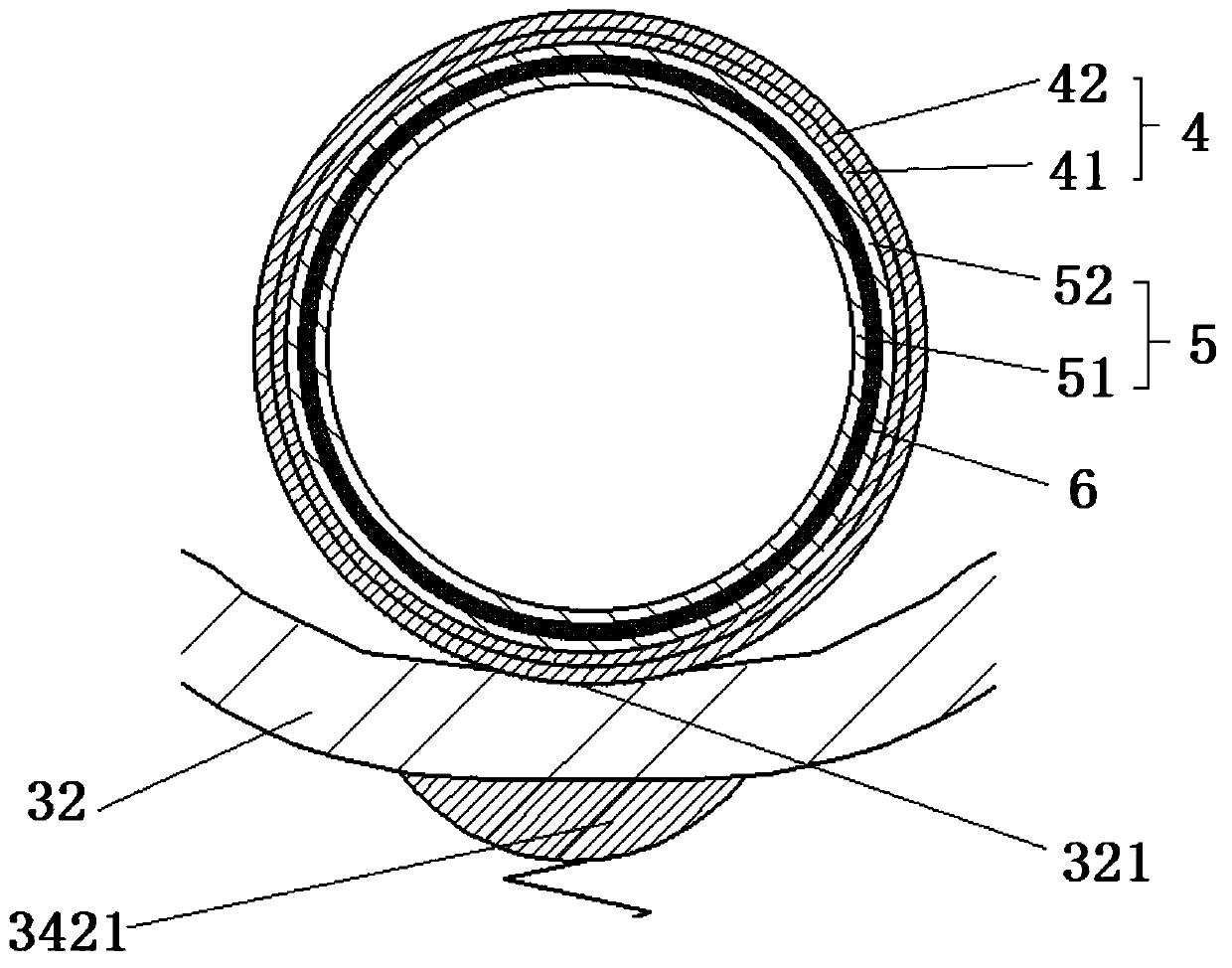

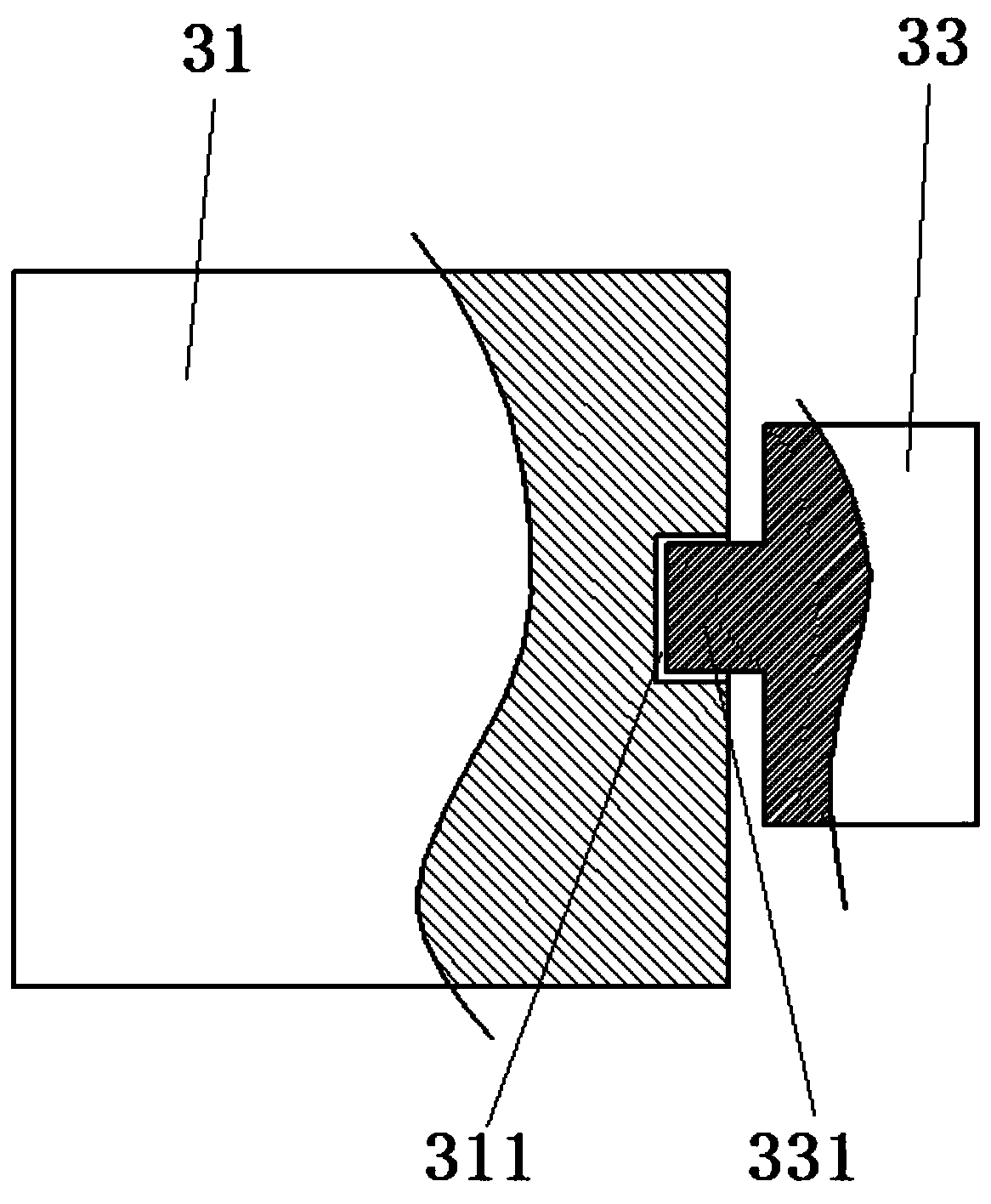

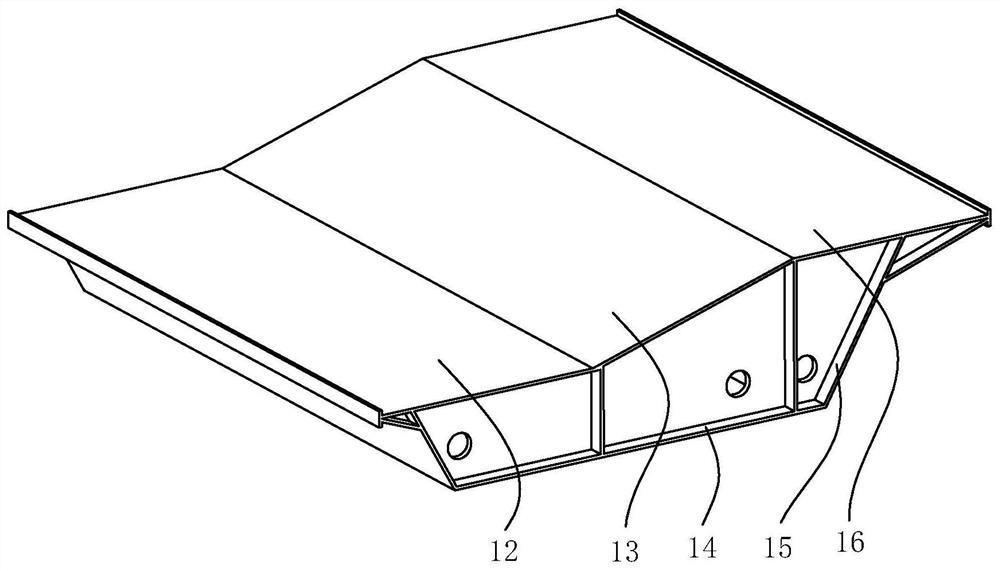

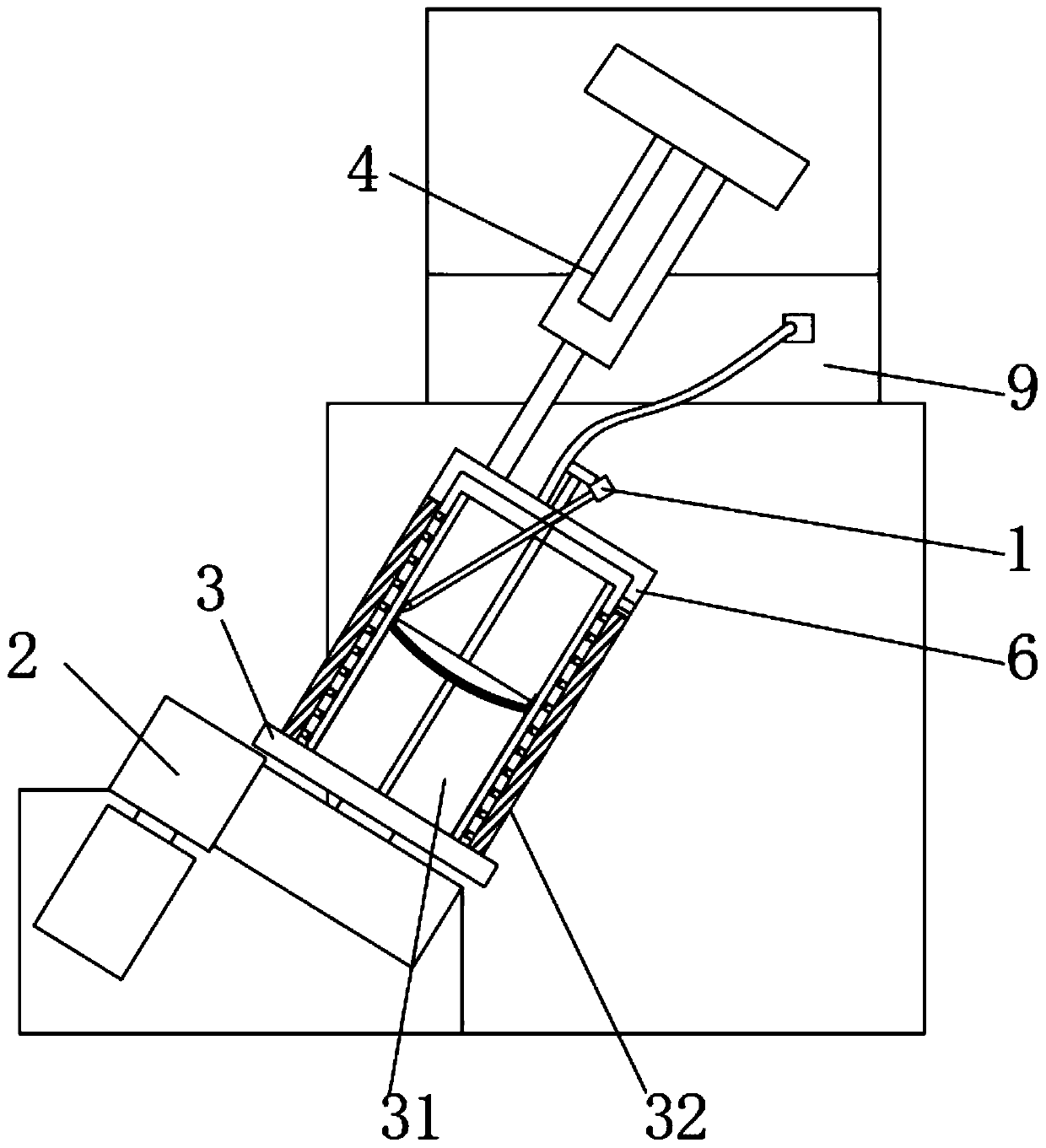

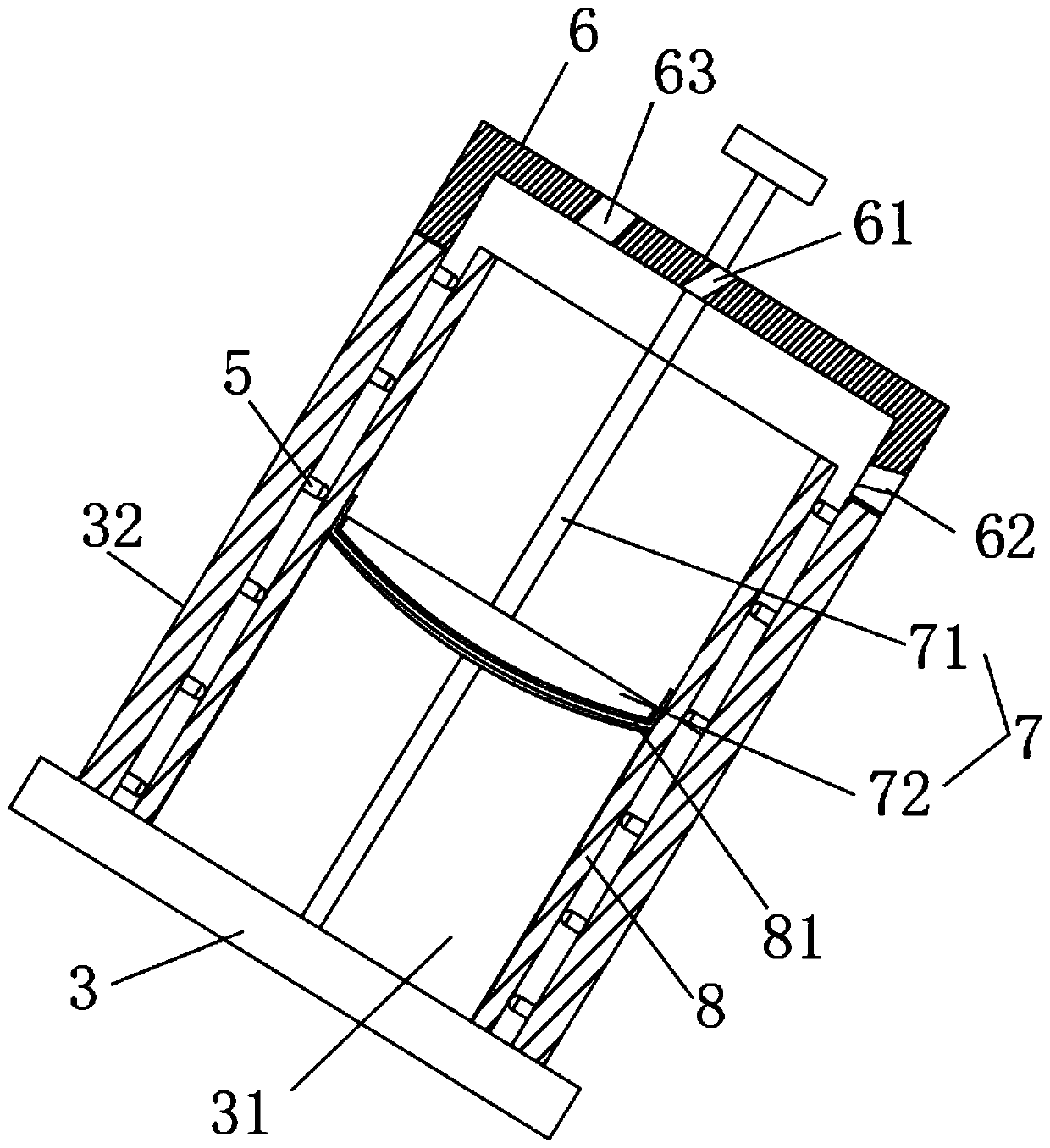

Tensile fireproof flame-retardant cable

ActiveCN111210934AGood flexibilitySignificant technical effect: this scheme uses aramid yarn to increase flexibilityClimate change adaptationInsulated cablesYarnEngineering

The invention relates to the field of cables and discloses a tensile fireproof flame-retardant cable. The cable comprises a wire core (1), a protective sleeve (2) sleeving the wire core (1), and an installation framework (3) arranged in the protective sleeve (2).A reinforcing layer (4), fireproof layers (5) and a waterproof layer (6) wrap the wire core (1), the installation framework (3) comprisesa central rod (31) and a rubber soft sleeve (32), and the wire core (1) is installed outside the rubber soft sleeve. In the invention, an aramid yarn is adopted to increase flexibility of the cable;and the cable is not easy to crack due to tension, use safety is ensured, fireproof performance of the cable is improved through the two fireproof layers, an inorganic silicate fireproof coating can effectively isolate a heat conduction effect between a heat source and each cable layer, good fireproof and flame-retardant effects are improved, a fireproof function of the cable is realized, and a service life of the cable is prolonged.

Owner:浙江元通线缆制造有限公司

Automatic polishing chamfering machine of table board

ActiveCN106670933AAvoid slack strap situationsEnsure consistencyGrinding drivesBelt grinding machinesDistribution controlEngineering

The invention relates to an automatic polishing chamfering machine of a table board. The automatic polishing chamfering machine comprises a rack and a distribution control box. The rack is uniformly provided with polishing chamfering devices, each polishing chamfering device comprises an abrasive belt which is arranged on the rack and is upwards inclined from front to back, and a feeding mechanism matched with the table board and making the table board be fed in a front-rear horizontal manner is arranged in a gap between every two adjacent abrasive belts; and each feeding mechanism comprises a feeding device arranged on the rack and being capable of performing front-rear feeding, each feeding device is provided with a feeding clamper matched with the table board, and the feeding devices and the feeding clampers are connected to the distribution control box. According to the automatic polishing chamfering machine of the table board, the abrasive belts which are arranged in an inclined manner are adopted as the polishing chamfering devices in cooperation with the feeding mechanisms capable of making the table board be fed in a horizontal front-rear manner to achieve fixed-angle chamfering of the table board, chamfering efficiency is improved, the situation that abrasive belts are loose is avoided, and consistency of polishing chamfering is guaranteed.

Owner:广东顺德恒丽宝商用厨具有限公司

Feeding device of numerical control machine tool and mounting method thereof

PendingCN110480398AEasy to connectImprove work efficiencyMetal working apparatusMaintainance and safety accessoriesNumerical controlUltimate tensile strength

The invention provides a feeding device of a numerical control machine tool and a mounting method thereof. The feeding device comprises a box body, a supporting plate, a first feeding frame and a second feeding frame, wherein the first feeding frame and the second feeding frame are respectively provided with a first conveying belt and a second conveying belt through carrier rollers, the first conveying belt and the second conveying belt are connected through a driving mechanism, a cleaning mechanism is arranged at the bottom of the supporting plate, and a blocking mechanism is arranged on oneside of the supporting plate. The mounting method comprises the steps of machining of the box body, mounting of the first conveying belt and the second conveying belt, machining and mounting of the supporting plate, mounting of the cleaning mechanism, mounting of the blocking mechanism and trial operation of the feeding device. According to the mounting method, materials can be blocked at intervals according to actual feeding requirements, and the materials can be prevented from falling off the conveying belts; and the mounting method is simple in steps, not only can realize automatic intelligent feeding, but also improve the stability and the reliability of feeding, greatly reduces the labor intensity of manual operation, and further improves the bearing capacity of the conveying belts.

Owner:新昌卡戎机械科技有限公司

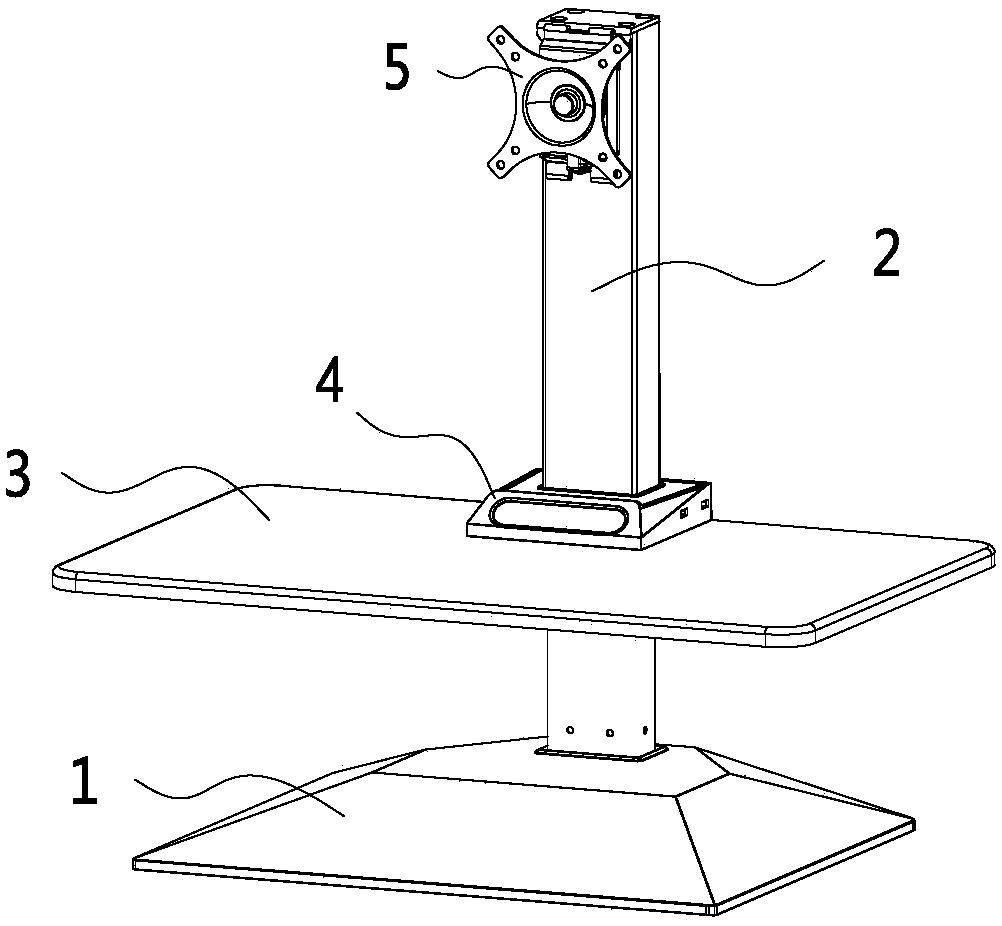

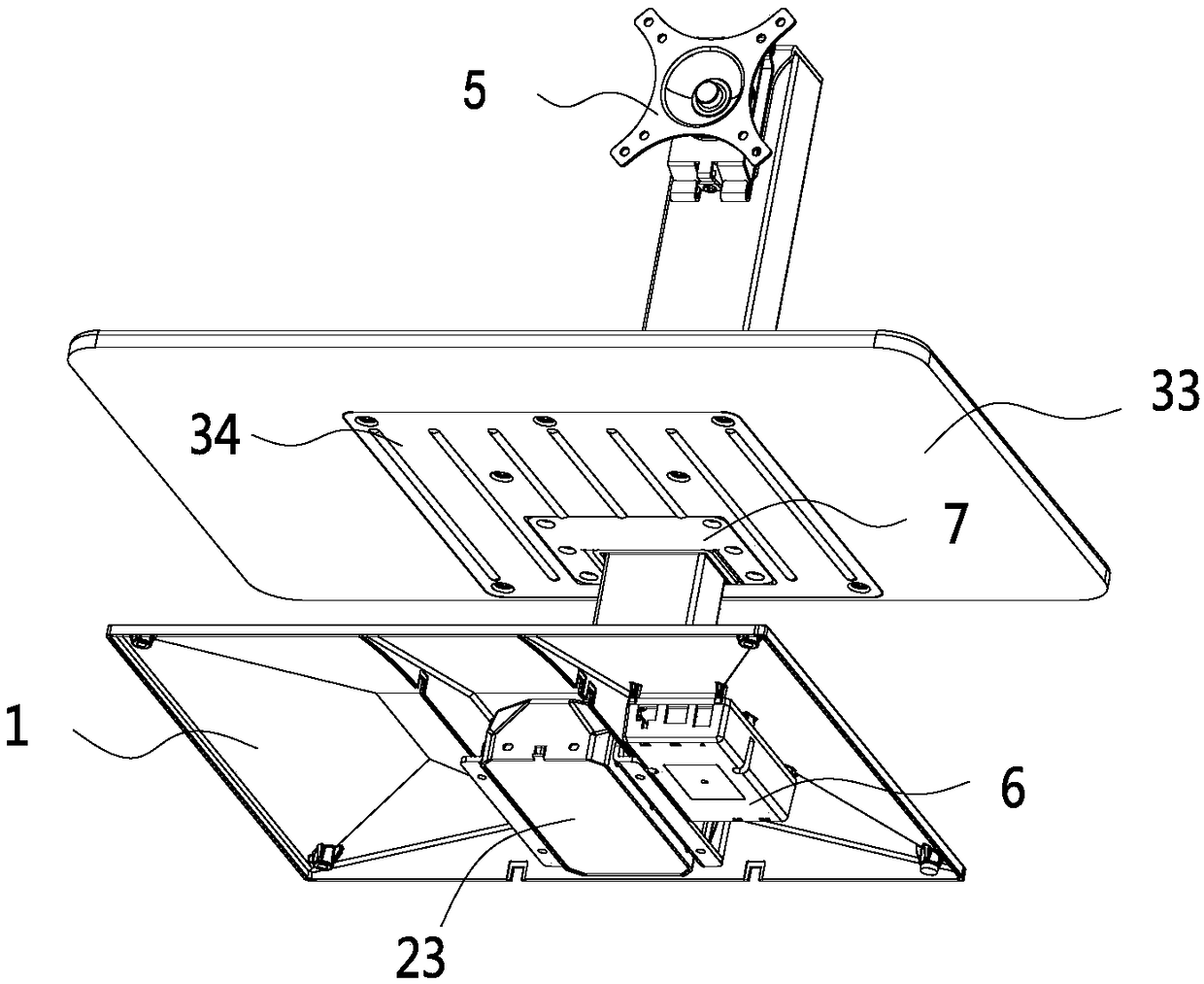

Electric lifting platform on table

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

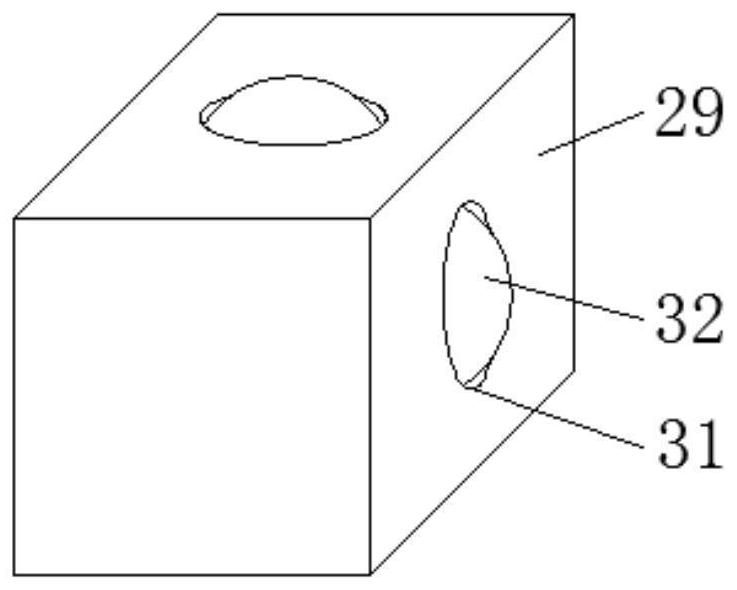

Packing case for assembly packing

InactiveCN105346868APlay the role of supporting positioningPlay a buffer rolePackaging vehiclesContainers for machinesEngineeringAirplane

The invention provides a packing case for assembly packing. The packing case for assembly packing comprises a supporting base built to be a cube structure, a left side wall, a right side wall, a top cover, a front wall and a rear wall; end part supporting blocks corresponding in left and right are arranged at the left end part and the right end part of the supporting base, middle part supporting blocks corresponding in left and right are arranged in the middle part of the supporting base, end part separating and limiting slots are formed in the end part supporting blocks, middle part separating and limiting slots are formed in the middle part supporting blocks, and the slot openings of the end part separating and limiting slots transversely correspond to the slot openings of the middle part separating and limiting slots; sponge limiting strips are arranged on the left side wall and the right side wall, separating bulges distributed at intervals are arranged on the sponge limiting strips, and the protruding parts of the separating bulges correspond to the slots openings of the end part separating and limiting slots; and metal supporting rods and top limiting rods are arranged between the front wall and the rear wall. The packing case for assembly packing, provided by the invention, has the benefits as follows: the packing case can be fit with the appearance of an aircraft component required to be packaged, the packing support is firm, a plurality of components can be accommodated at the same time, the limiting and the separating are clear, the buffering is in place, the self weight is light, and the transportation is convenient.

Owner:赛维(天津)供应链管理有限公司

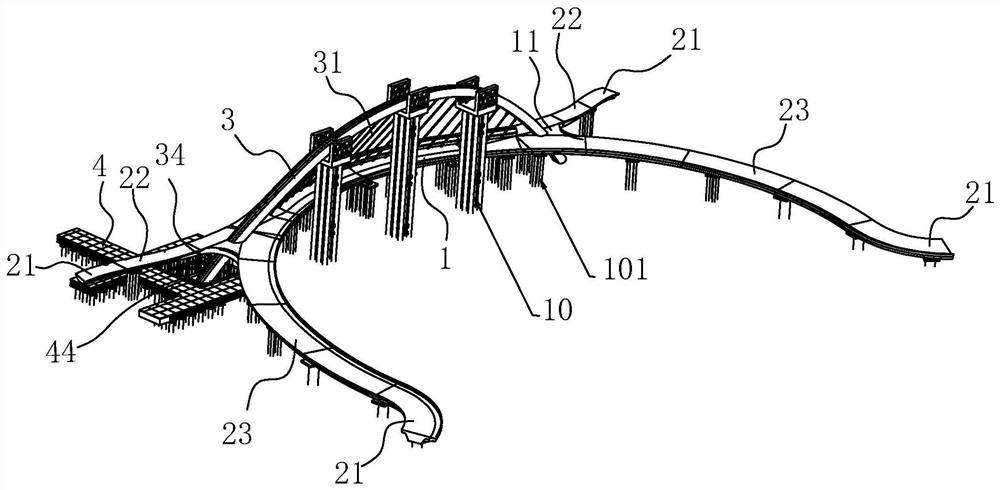

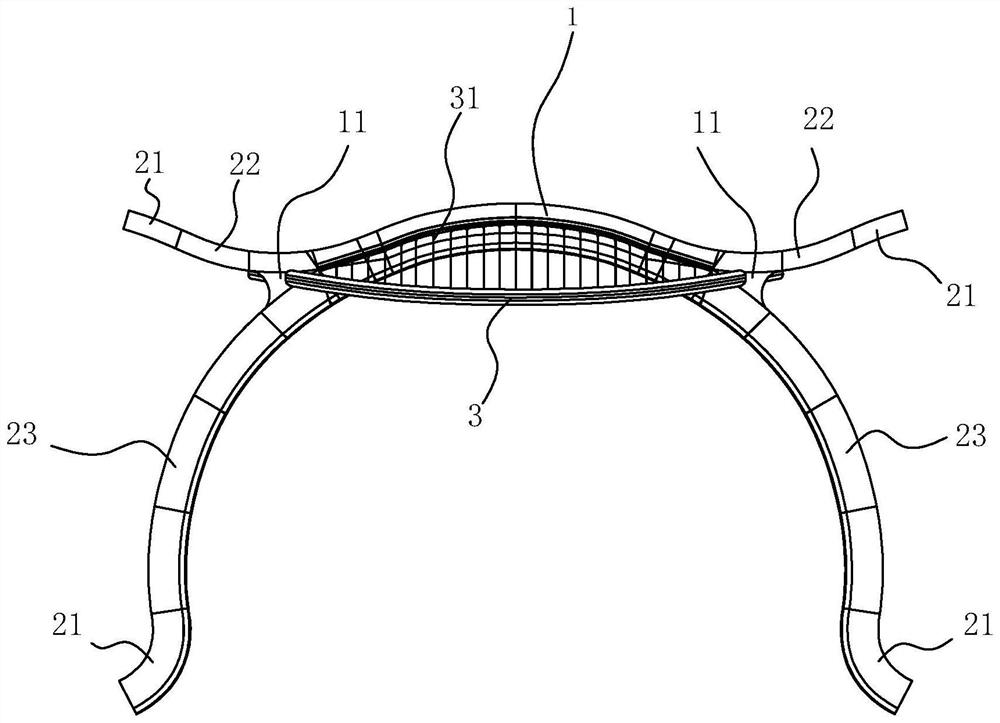

Special-shaped pedestrian landscape bridge structure and construction method thereof

PendingCN113106833APlay a water blocking effectPlay the role of supporting positioningBridge structural detailsFoundation engineeringPierPedestrian

The invention relates to a special-shaped pedestrian landscape bridge structure and a construction method thereof. The special-shaped pedestrian landscape bridge structure comprises an arc-shaped main bridge and an arch rib body, the arc-shaped main bridge is provided with two ends, and each end of the arc-shaped main bridge communicates with a first arc-shaped branch bridge and a second arc-shaped branch bridge which are used for being connected with the shoreside; the two first arc-shaped branch bridges are externally tangent to the outer arc of the arc-shaped main bridge, the two second arc-shaped branch bridges are internally tangent to the inner arc of the arc-shaped main bridge, and bridge body construction is completed through the construction steps of main pier pile foundation construction, main pier bearing platform cofferdam construction, main pier bearing platform construction, steel beam and arch rib support erection, arch beam erection, suspender cable tensioning, support dismantling and landscape greening and brightening engineering construction. The construction has the effect of facilitating connection of walking bridges in all areas of the two banks.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

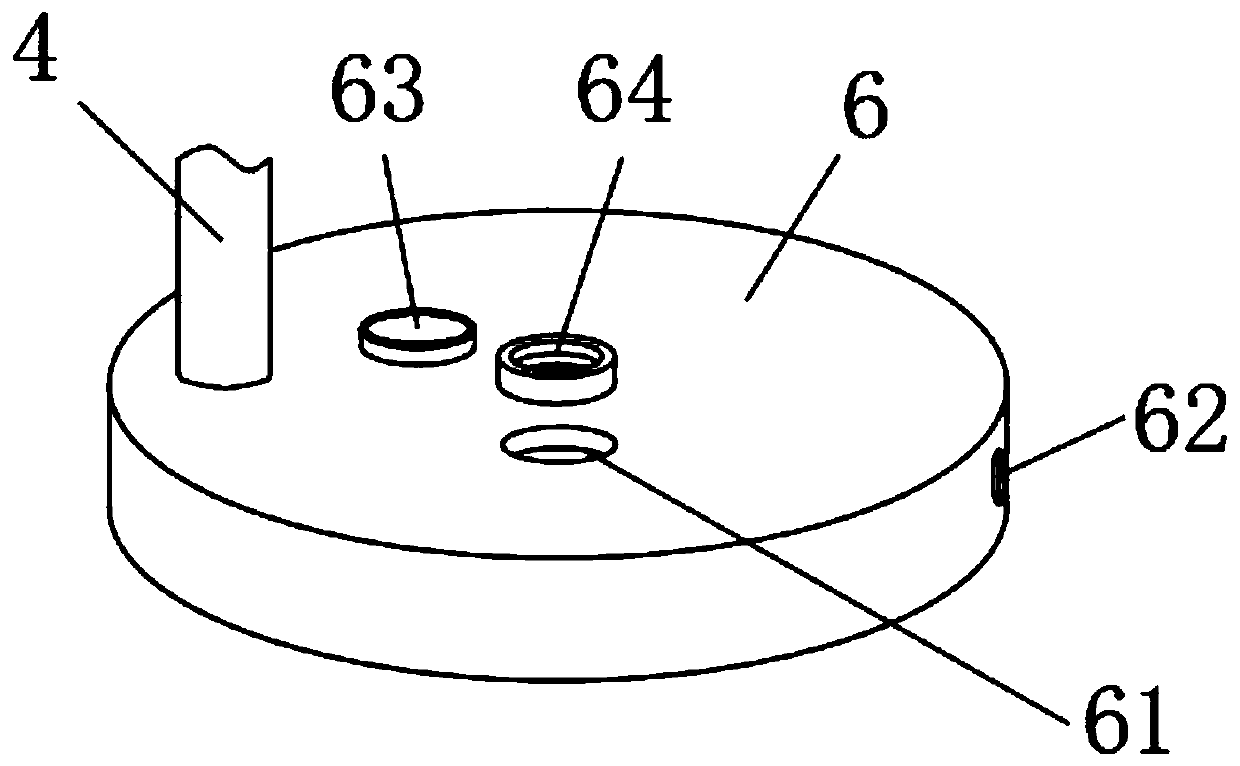

Multi-chamber magnesium-aluminum alloy parking air reservoir processing device and method

ActiveCN111571052AGuaranteed placement stabilityAvoid offsetWelding/cutting auxillary devicesAuxillary welding devicesElectric machineStructural engineering

The invention provides a multi-chamber magnesium-aluminum alloy parking air reservoir. The multi-chamber magnesium-aluminum alloy parking air reservoir comprises a rotating motor; the rotating motor is obliquely arranged; an output end of the rotating motor is equipped with a bottom plate; an inner positioning seat and an outer positioning tube are installed at the center of the surface of the bottom plate; the inner top of a reservoir body is equipped with a setting mechanism; the setting mechanism is slidably attached to the top surface of a partition cover; the setting mechanism is used forcompressing the partition cover at the top; the setting mechanism is assembled at the center of the inner wall of a transparent seal cover; and the top surface of the transparent seal cover is fixedly connected with a pneumatic rod. According to the multi-chamber magnesium-aluminum alloy parking air reservoir provided by the invention, the placement stability of the reservoir body can be ensuredthrough the inner positioning seat and the outer positioning tube, the offset of the reservoir body during welding is avoided, and the welding precision is improved; and the inner positioning seat canstop and limit the partition cover, so that the installation of the partition cover is simpler and more convenient, and the installation position is more accurate.

Owner:合肥丰华汽车零部件有限公司

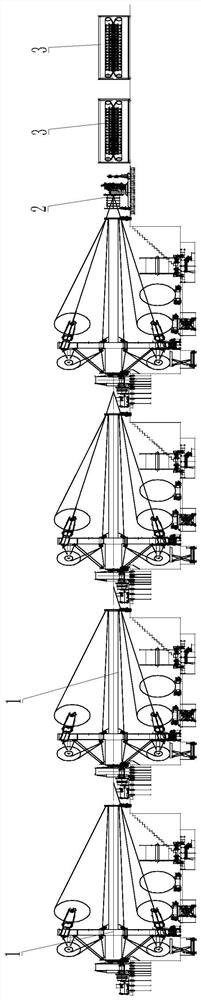

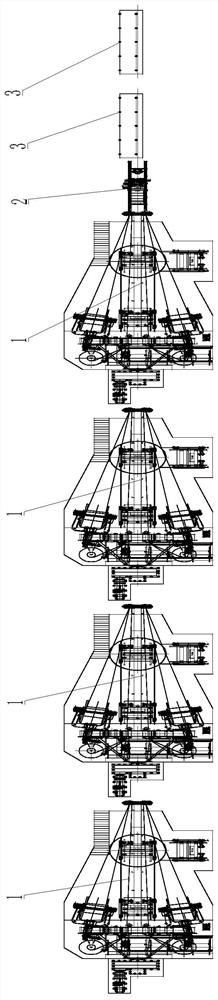

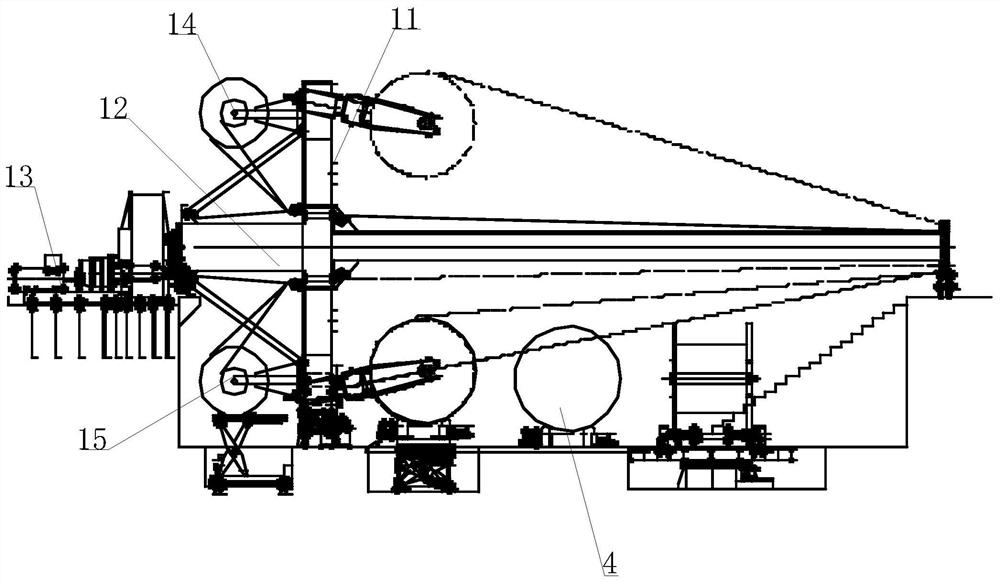

Working method of horizontal cabling production line

ActiveCN112289513AGuaranteed normal outputEnsuring stranding process efficiencyCable/conductor manufactureStructural engineeringManufacturing line

The invention discloses a working method for a horizontal cabling production line, and the method specifically comprises the following steps: 1, enabling the cores of a cable to be twisted through cable twisting bodies, enabling each group of cable twisting bodies to be twisted with a plurality of groups of cores, and enabling a plurality of groups of cable twisting bodies to be horizontally arranged side by side in a series connection mode, adjusting the serial number of the cable twisting bodies according to the number of the cable cores, wherein the cable twisting bodies are used for twisting the cable groups; and 2, enabling the cable stranded bodies located on the rear side to further conduct stranding machining on the cable stranded by the former set of cable stranded bodies, feedinga cable feeding disc into a disc to be conveyed through a disc conveying trolley, and enabling a wrapping die holder to wrap the stranded cable. The cable cores of the cable are stranded through thecable stranding bodies, the multiple sets of cable stranding bodies are horizontally arranged side by side in a series connection mode, different types of cables can be machined according to the number specification of actual cable cores, and the series connection number of the cable stranding bodies is adjusted according to the number of the cable cores.

Owner:HEFEI SMARTER TECH GROUP CORP

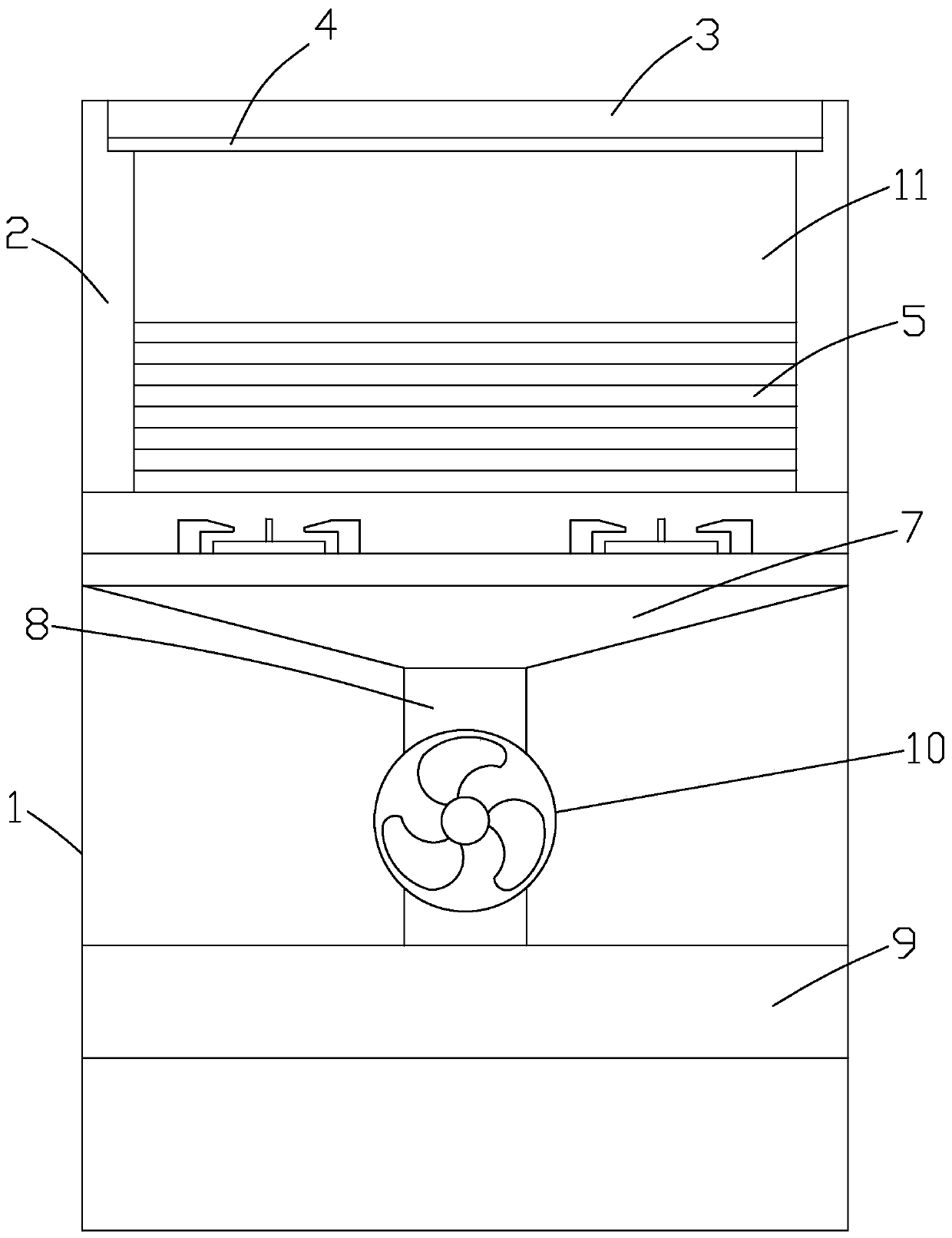

Integrated kitchen with oil stain separation device, and processing method for same

PendingCN110260379AImprove work efficiencyResidue reductionDomestic stoves or rangesLighting and heating apparatusEngineeringPetroleum engineering

The invention discloses an integrated kitchen with an oil stain separation device, and a processing method for the same. The integrated kitchen comprises an integrated kitchen body and also comprises the oil stain separation device, wherein the oil stain separation device is fixedly connected to the bottom of a smoke collection cavity; the oil stain separation device is connected to a smoke discharge pipe via a conveying pipe; the smoke discharge pipe is horizontally disposed inside the integrated kitchen body; and a fan is disposed on the conveying pipe. The processing method comprises the steps including processing of the integrated kitchen body, processing of an air conveying pipeline, installation of the oil stain separation device, installation of an oil collection box and trial operation of the integrated kitchen. The integrated kitchen and the processing method disclosed by the invention have the beneficial effects that through design of the oil stain separation device, oil molecules in oil smoke can be quickly separated, and environmental pollution can be reduced; accumulation of oil stains in the fan and inside the conveying pipe and the smoke discharge pipe can be reduced, and the service life of the fan is prolonged; difficulty is cleaning is reduced; and noise generated during work of the integrated kitchen is reduced.

Owner:浙江蓝炬星电器有限公司

Gearbox shaft forge piece machining equipment and machining method thereof

PendingCN113560476AShorten forging timeImprove mechanical propertiesForging/hammering/pressing machinesForging press detailsMachiningIndustrial engineering

The invention belongs to the technical field of shaft forge piece forging, and particularly relates to gearbox shaft forge piece machining equipment and a machining method thereof. The gearbox shaft forge piece machining equipment comprises a machining base, the machining base is provided with a thermal correction shaft forging piece lower die, an upper die fixing plate capable of doing reciprocating rectilinear motion in the vertical direction is arranged above the thermal correction shaft forging piece lower die, and a thermal correction shaft forging piece upper die is arranged at the bottom of the upper die fixing plate. Through the arrangement of a flash removal cutter, a cutter limiting plate and a rim charge blocking and communicating plate, the shaft forging piece is subjected to thermal correction, meanwhile, flash of the shaft forging piece is automatically cut off through the flash removal cutter, the forging time of the shaft forging piece is shortened, the mechanical performance of the shaft forging piece is improved, and the service life of the shaft forging piece is prolonged; and through moving the rim charge blocking and communicating plate, the flash on the edge blocking and communicating plate can enter a discharging groove, the flash is automatically discharged through the discharging groove, the flash does not need to be manually cleaned, operation is easy and convenient, and the automation degree and the production efficiency are high.

Owner:ZHEJIANG JIAJIE AUTOMOBILE DESIGN CO LTD

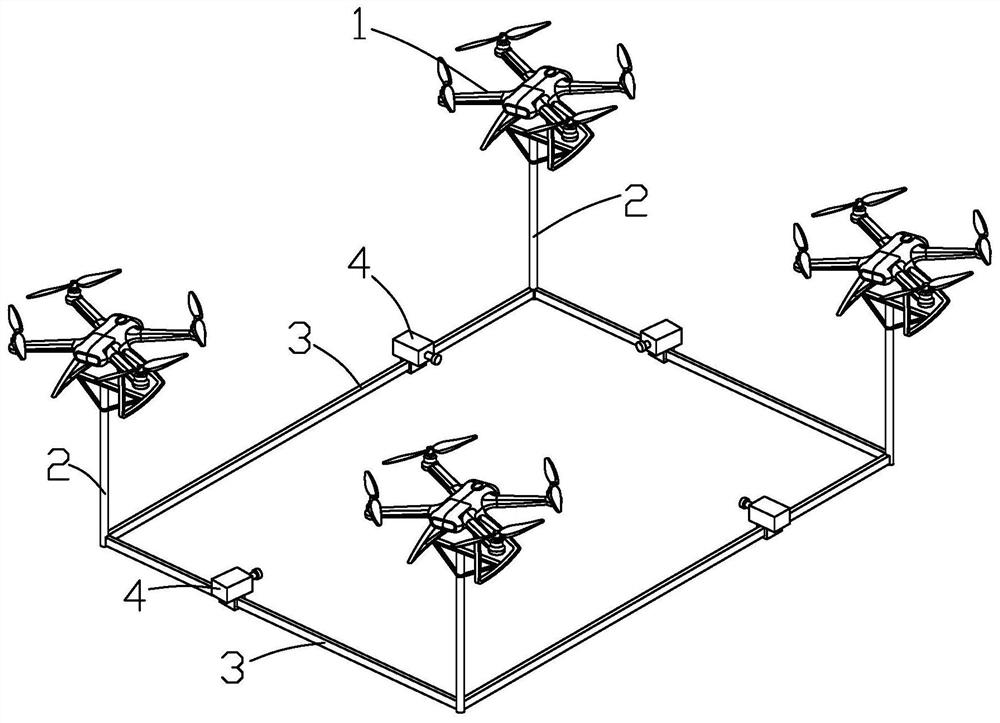

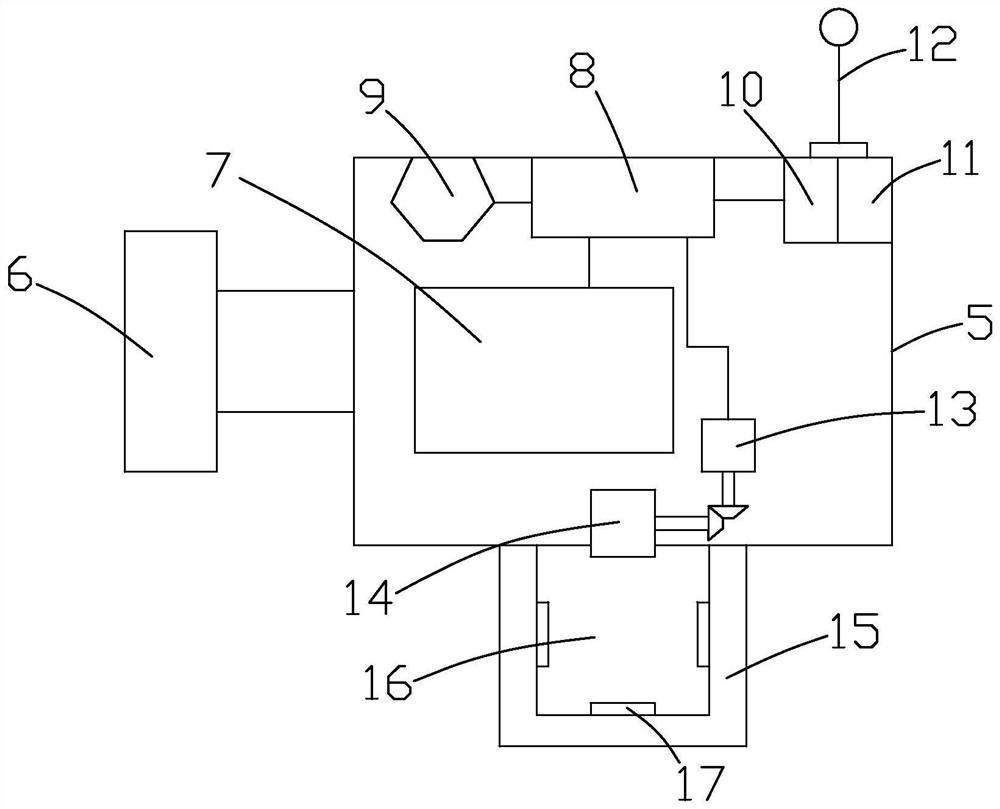

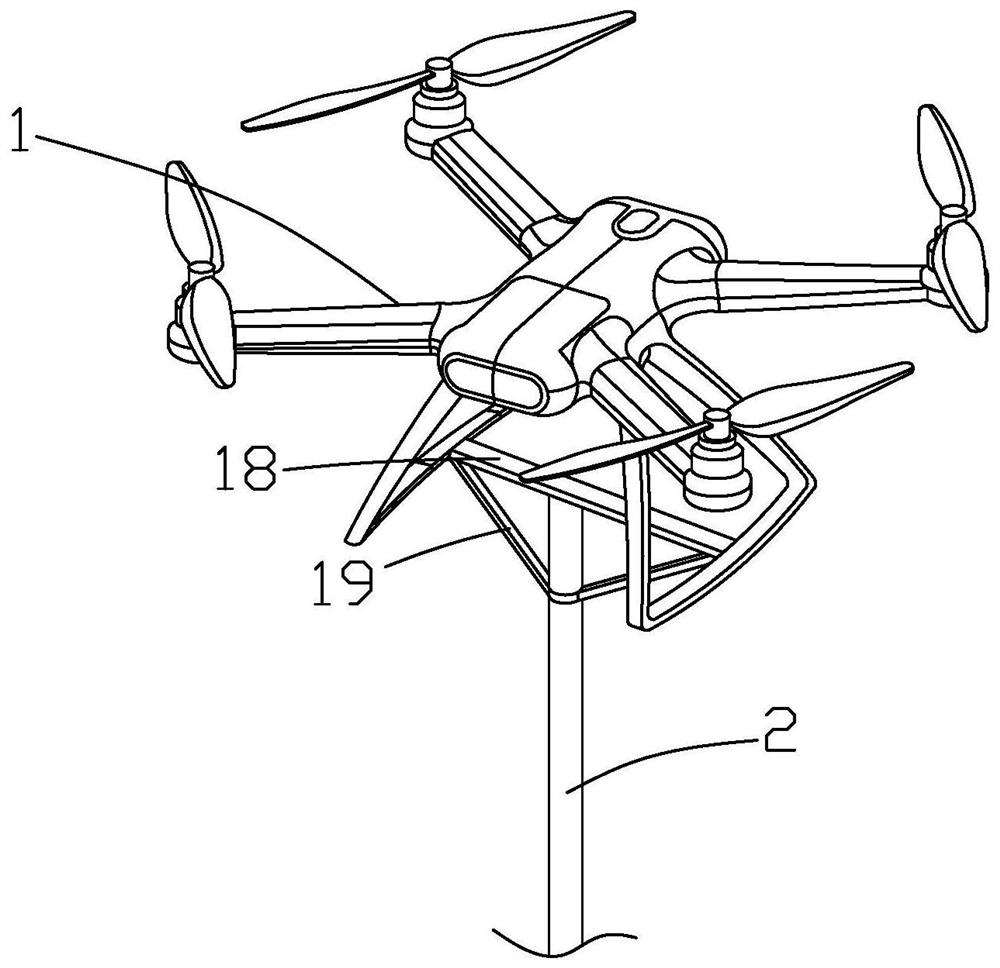

A UAV forestry resource survey method

ActiveCN110579774BSimple stepsPracticalPicture taking arrangementsElectromagnetic wave reradiationForest industrySoil science

Owner:ZHEJIANG FORESTRY UNIVERSITY

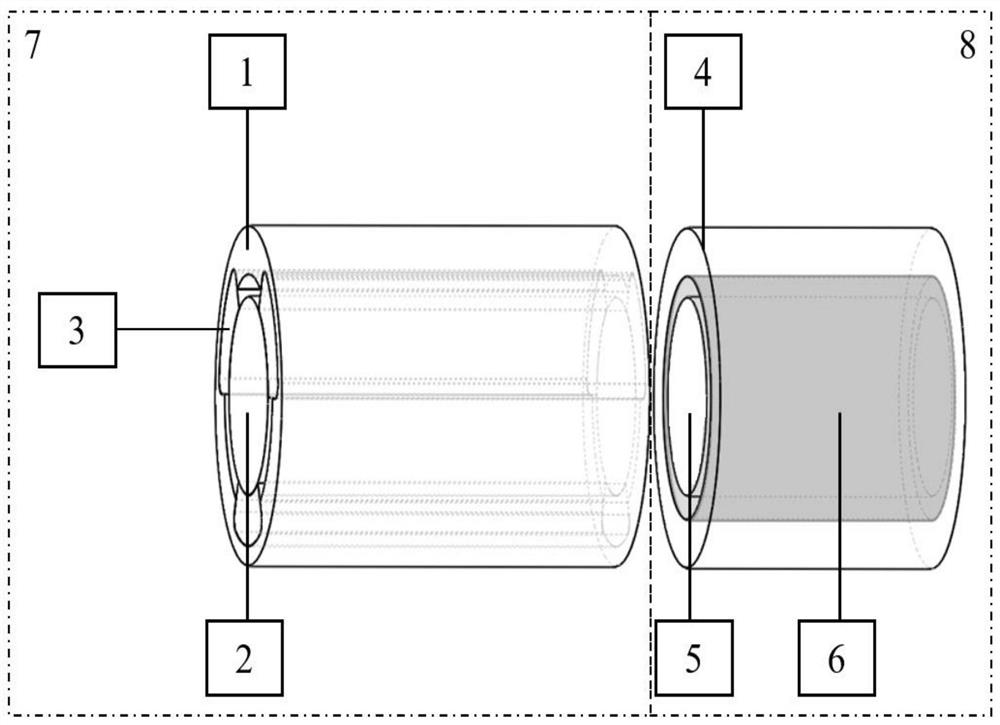

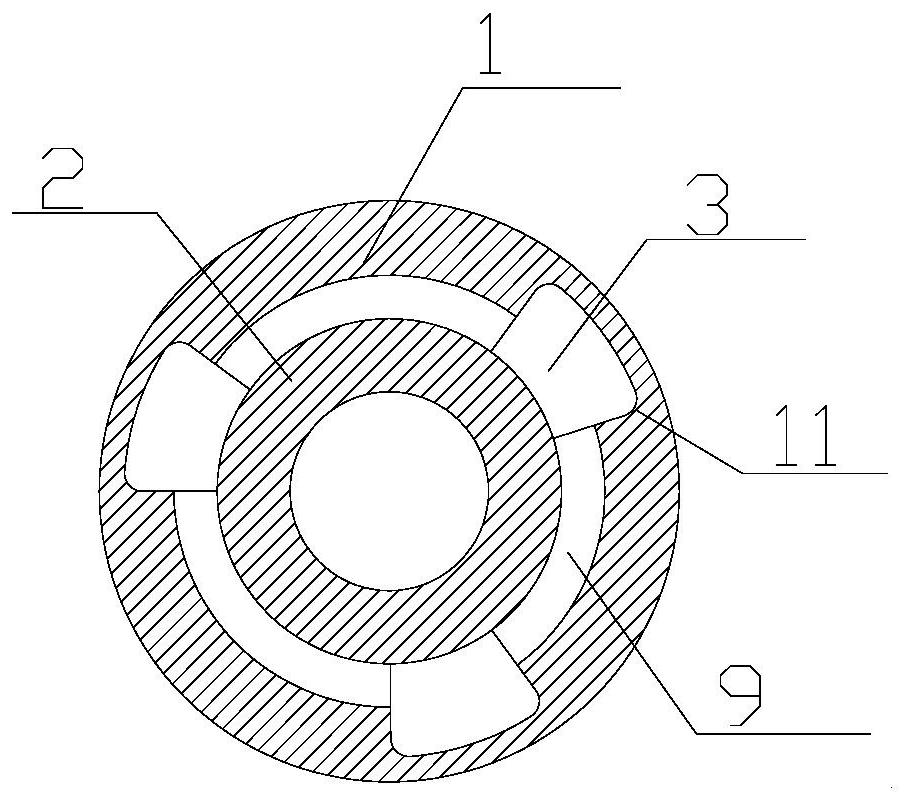

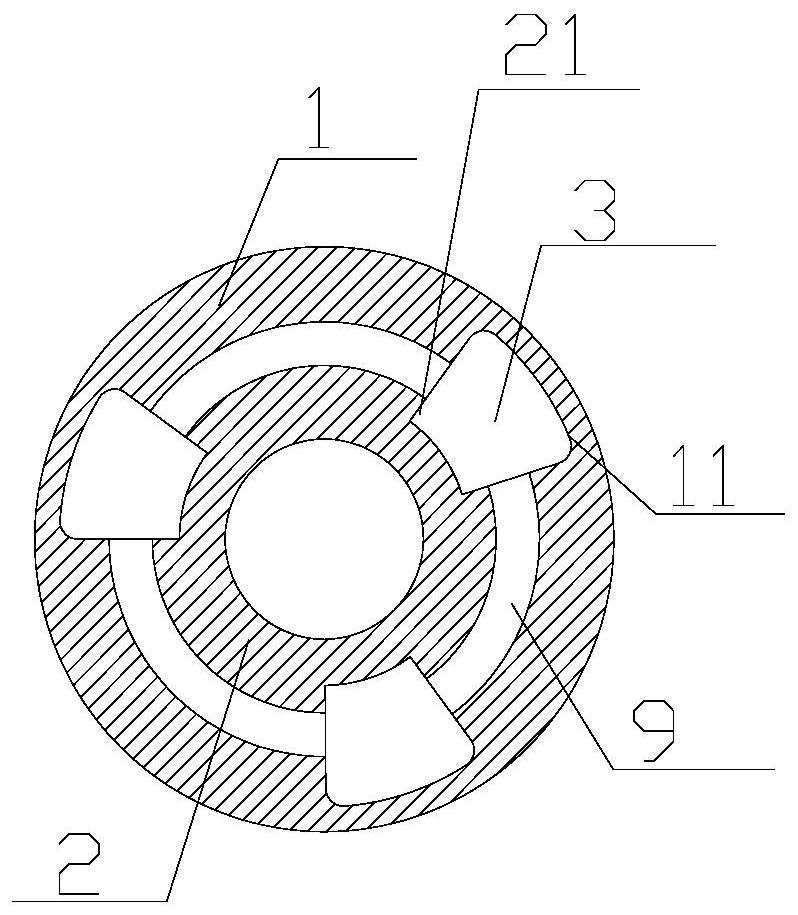

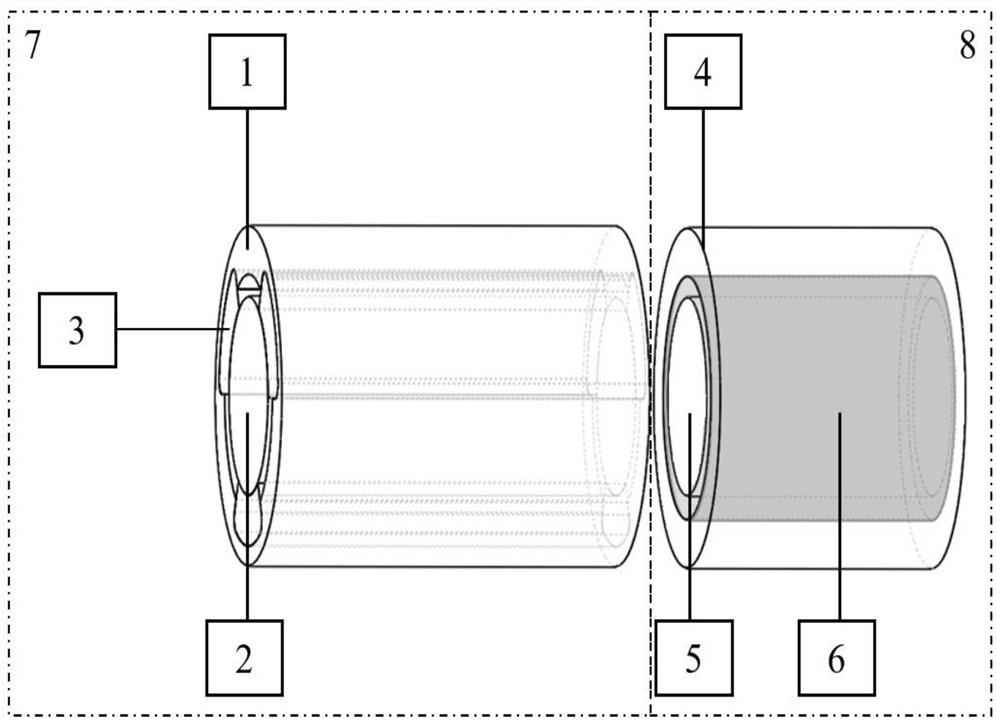

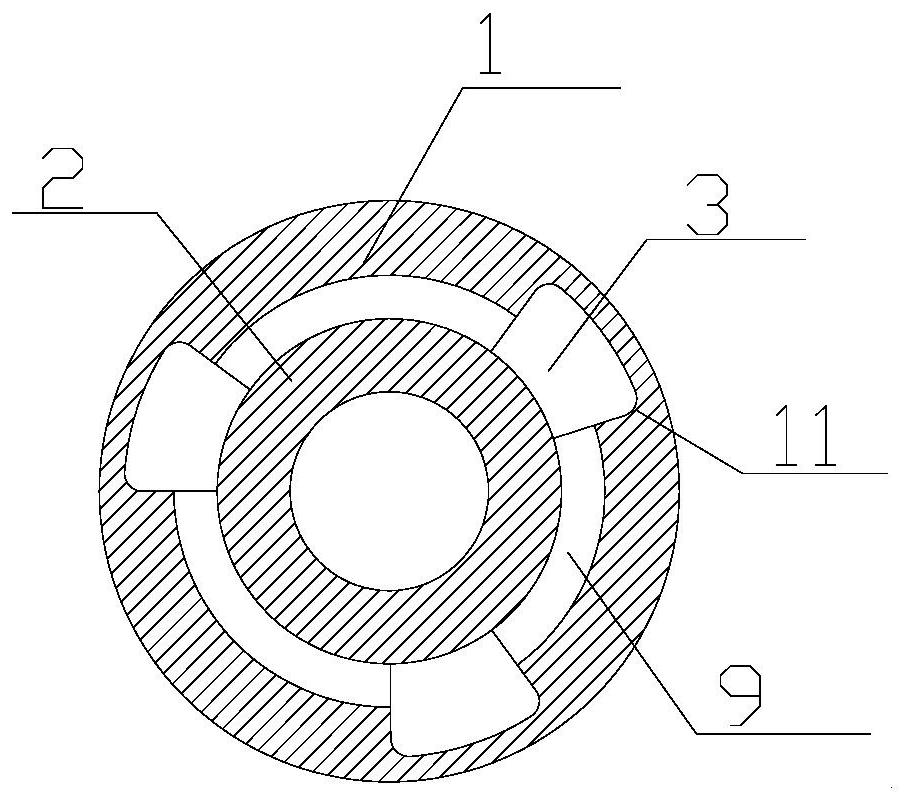

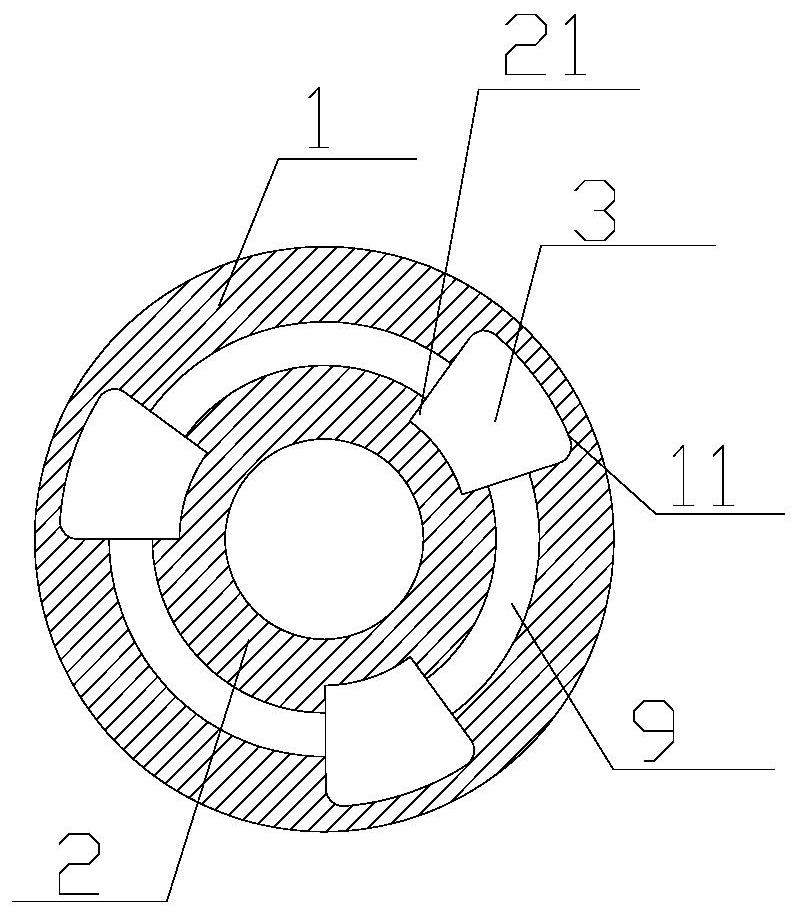

Multi-channel high-field asymmetric waveform ion migration tube

ActiveCN112687516AReduce lossesImprove resolutionElectron/ion optical arrangementsPhysicsAsymmetric waveform

The invention provides a multi-channel high-field asymmetric waveform ion migration tube. The multi-channel high-field asymmetric waveform ion migration tube comprises a migration region and a detection region arranged at the output end of the migration region, wherein the migration region comprises a columnar inner electrode and an annular outer electrode, the columnar inner electrode is sleeved with the annular outer electrode, and an electrode gap is formed between the annular outer electrode and the columnar inner electrode; a through type isolation column is arranged in the electrode gap, and the through type isolation column divides the electrode gap into at least one migration channel; and moreover, the columnar inner electrode and the annular outer electrode are coaxially arranged through the through type isolation column. By utilizing the invention, the problems of large gap between the inner electrode and the outer electrode, weaker ion signals and difficulty in guaranteeing the coaxiality of the inner electrode and the outer electrode of the existing cylindrical migration tube can be solved.

Owner:TSINGHUA UNIV

Glass processing device capable of conveniently observing internal processing conditions

InactiveCN113321408AEnable recyclingRealize purificationWaste water treatment from ceramic industriesTreatment involving filtrationWater vaporEngineering

The invention discloses a glass processing device capable of conveniently observing internal processing conditions, and relates to the field of glass processing. The glass processing device comprises a bottom plate and a frame body, an observation window is fixedly connected to one end of the frame body, and a rocker assembly is arranged at the top of the frame body; and the rocker assembly comprises a rocker assembly body, a kidney-shaped plate, a rotary disc, a servo motor, a first connecting rod, a second connecting rod, a first sliding block, a concave shell, a second sliding block, a sliding rail, a clamping strip, a fastener and a convex cleaning block. According to the glass processing device capable of conveniently observing the internal processing conditions, water vapor on the surface of an observation window can be cleaned in time, observation is convenient, water obtained after glass products are cooled is recycled, the cooling efficiency is high, high-temperature water vapor generated during cooling can be treated, stable limiting can be conducted on glass products in the conveying process, and purification treatment can be conducted on a cooled water body.

Owner:刘贤东

Rainwater recycling device for landscape gardens

PendingCN113952773APlay a filtering roleNot easy to dropGeneral water supply conservationStationary filtering element filtersStructural engineeringMechanical engineering

Owner:张保雷

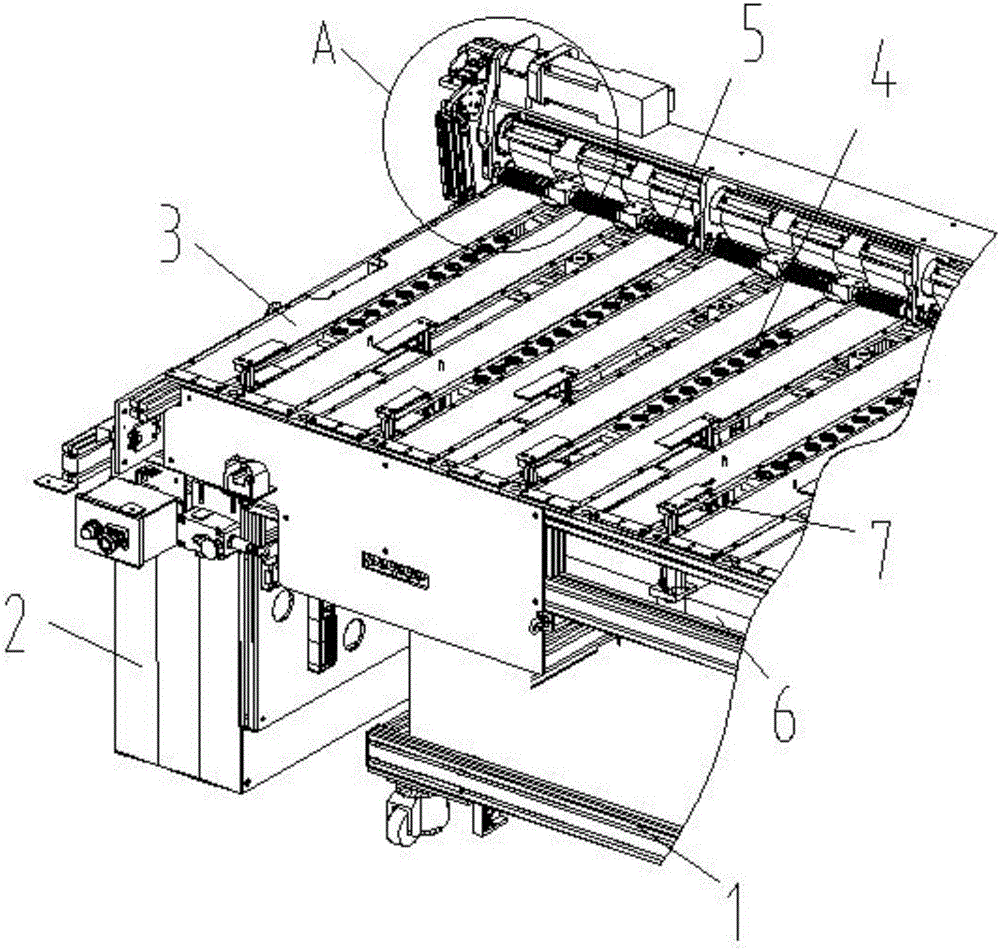

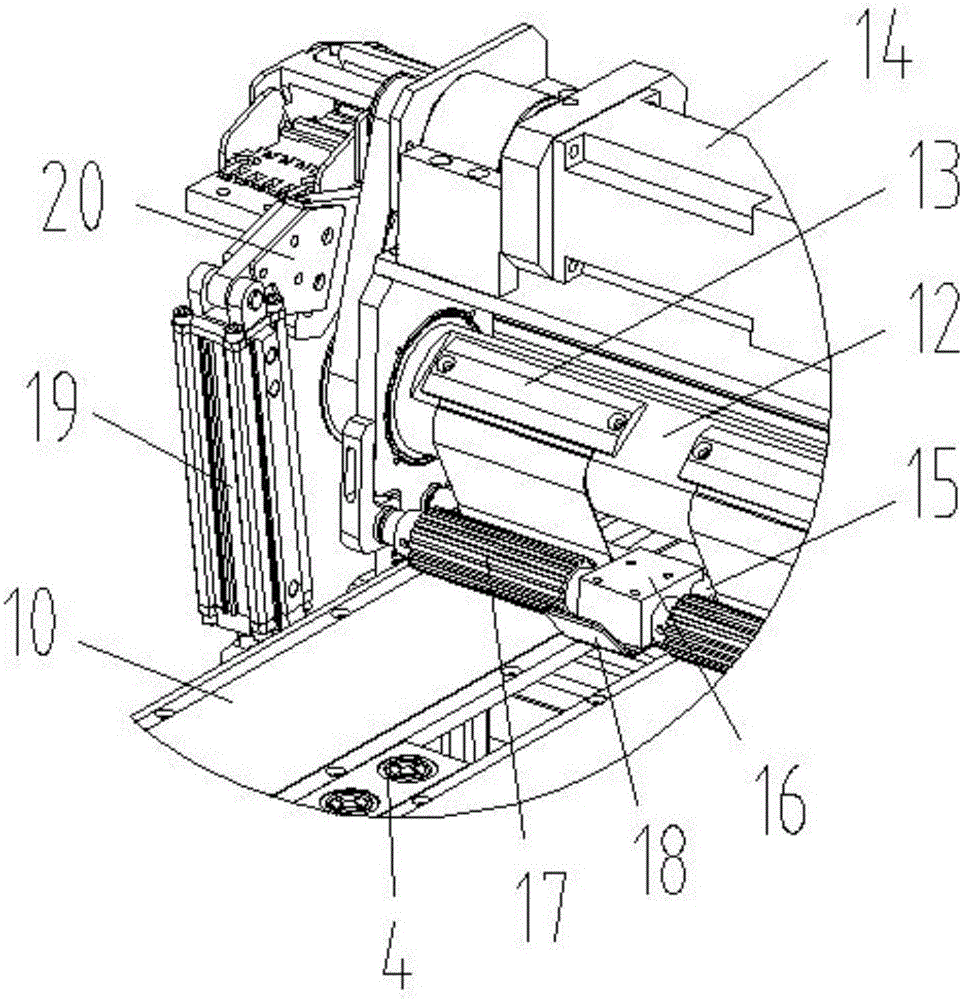

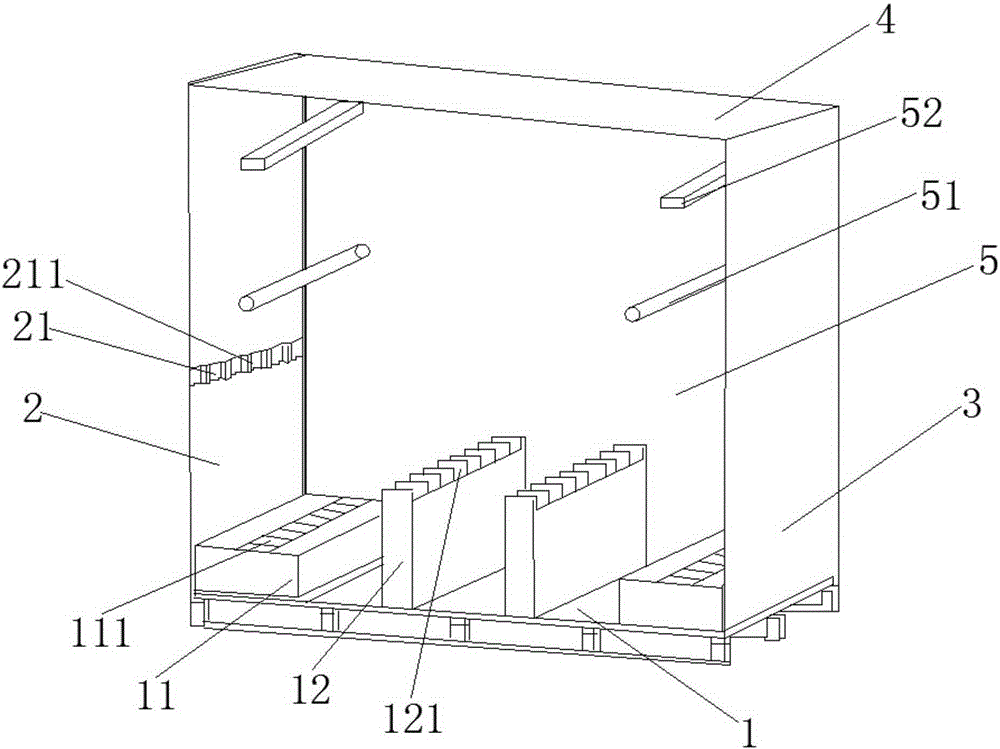

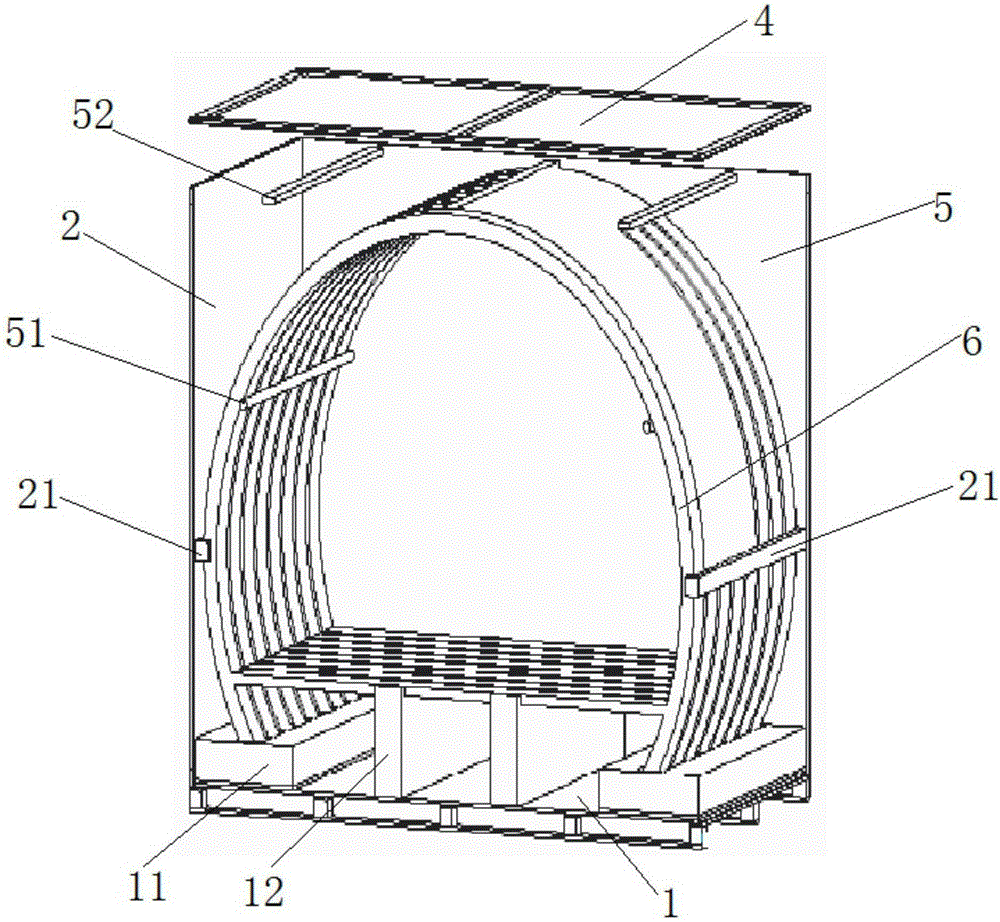

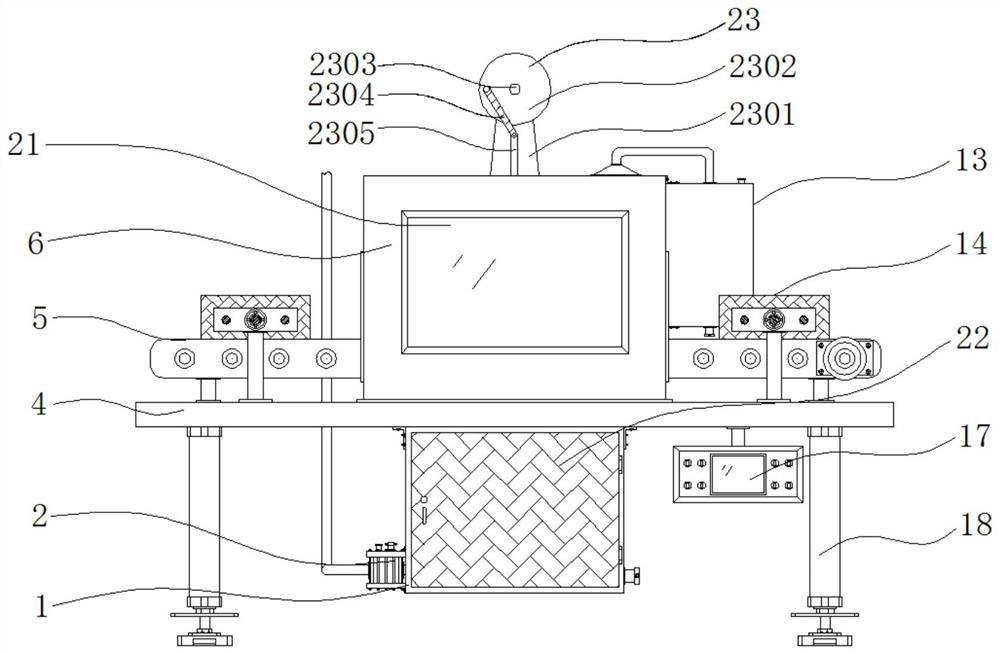

A stator processing equipment for producing air conditioner motors

ActiveCN105414600BImprove processing qualityImprove mobile flexibilityDirt cleaningLarge fixed membersDraining tubeSolid particle

The invention discloses stator processing equipment for producing an air conditioner motor. The stator processing equipment comprises a box body, a base and a top plate, wherein the box body is located at the top of the base; the top plate is fixedly connected to the top of the box body; a suction box is arranged in the top plate; a stator processing device is arranged in the box body and movably connected to the top of the base by guide rails; a feeding device and a discharging device are respectively arranged at the left side and the right side of the stator processing device; first limit slots are formed in the top of the base; the feeding device and the discharging device are respectively limited in the first limit slots; a collection hopper is arranged in the base; and a drain tube is arranged at the bottom of the collection hopper. The stator processing equipment is simple in structure and high in practicability, and can not only realize quick feeding and discharging of stators but also effectively collect and eliminate dust impurities and solid particles, which are produced during stator processing, thereby reducing pollution to the processing environment and improving the stator processing precision and quality.

Owner:WUHAN XINGLI PLASTIC CO LTD

Multi-channel high-field asymmetric waveform ion transfer tube

ActiveCN112687516BReduce lossesImprove resolutionElectron/ion optical arrangementsWave shapeIon transfer

A multi-channel high-field asymmetric waveform ion transfer tube provided by the present invention includes a transfer region and a detection region arranged at the output end of the transfer region; the transfer region includes a columnar inner electrode and a ring-shaped outer electrode, and the ring The ring-shaped outer electrode is sleeved outside the columnar inner electrode, and an electrode gap is formed between the ring-shaped outer electrode and the columnar inner electrode; wherein, a penetrating isolation column is arranged in the electrode gap, and the penetrating type The spacer divides the electrode gap into at least one migration channel; and the columnar inner electrode and the ring-shaped outer electrode are arranged coaxially through the penetrating spacer. The above-mentioned invention can solve the problems that the existing cylindrical transfer tube has a large gap between the inner and outer electrodes, weak ion signals, and it is difficult to guarantee the coaxiality of the inner and outer electrodes.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com