A stator processing equipment for producing air conditioner motors

A processing equipment and stator technology, applied in the direction of metal processing equipment, metal processing, drilling/drilling equipment, etc., can solve the problems of operating environment pollution, inability to realize automatic feeding and discharging, and inability to clean dust and impurities, etc., to achieve The effect of simplifying connection methods, improving mobile flexibility, and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

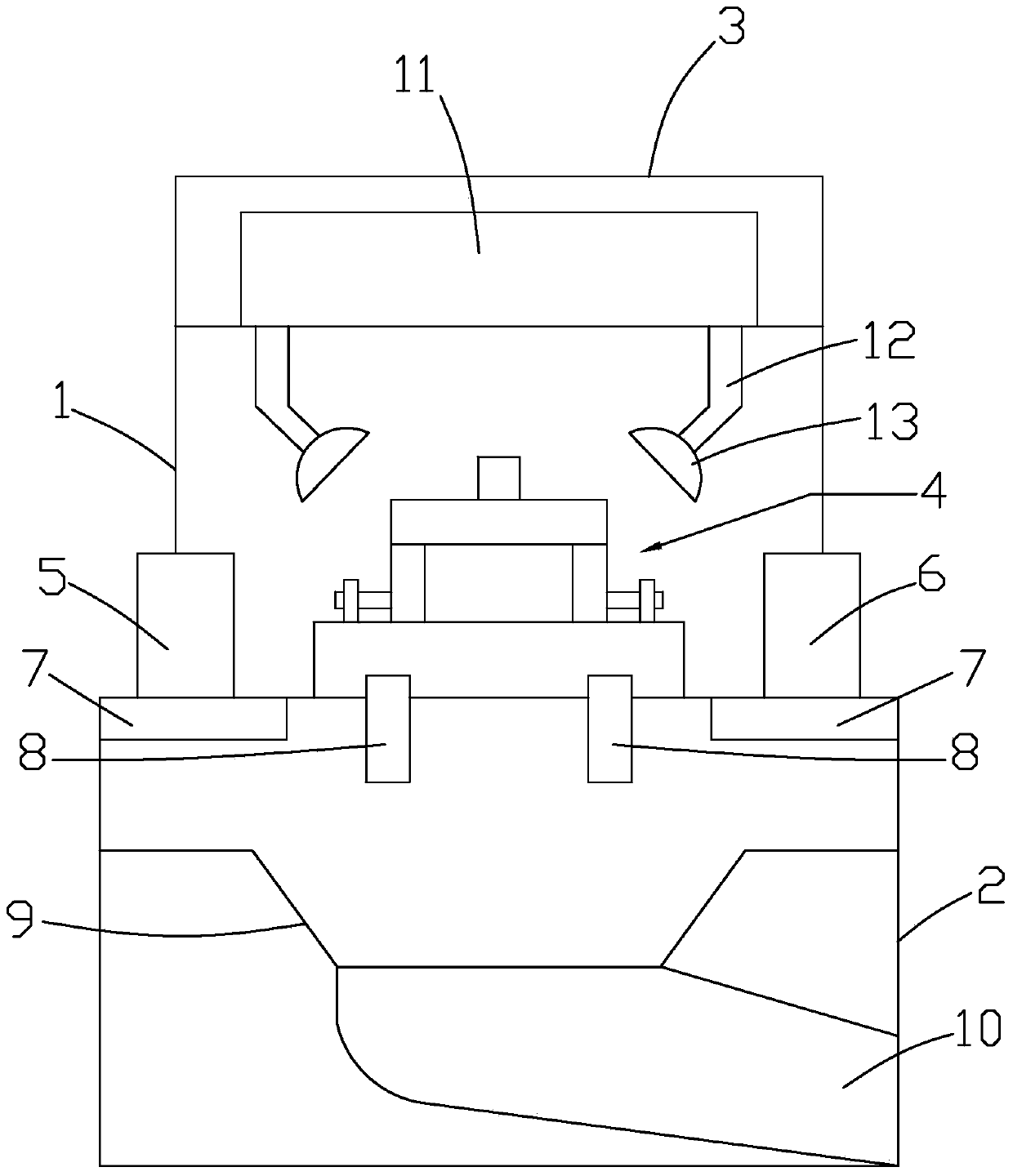

[0029] Such as Figure 1 to Figure 5 As shown, it is a stator processing equipment for producing air conditioner motors according to the present invention, which includes a box body 1, a base 2 and a top plate 3, the box body 1 is located on the top surface of the base 2, and the top plate 3 is fixedly connected to the top of the box body 1 On the surface, a dust collection box 11 is arranged in the top plate 3, and a group of mechanical ducts 12 are arranged symmetrically on the bottom of the top plate 3. The end of the mechanical ducts 12 is provided with a dust collection cover 13, and the dust collection cover 13 can be adjusted by the mechanical duct 12 and the stator. The distance between the processing devices 4 improves the dust collection efficiency and facilitates the cleaning of the dust collection cover 13 at the same time.

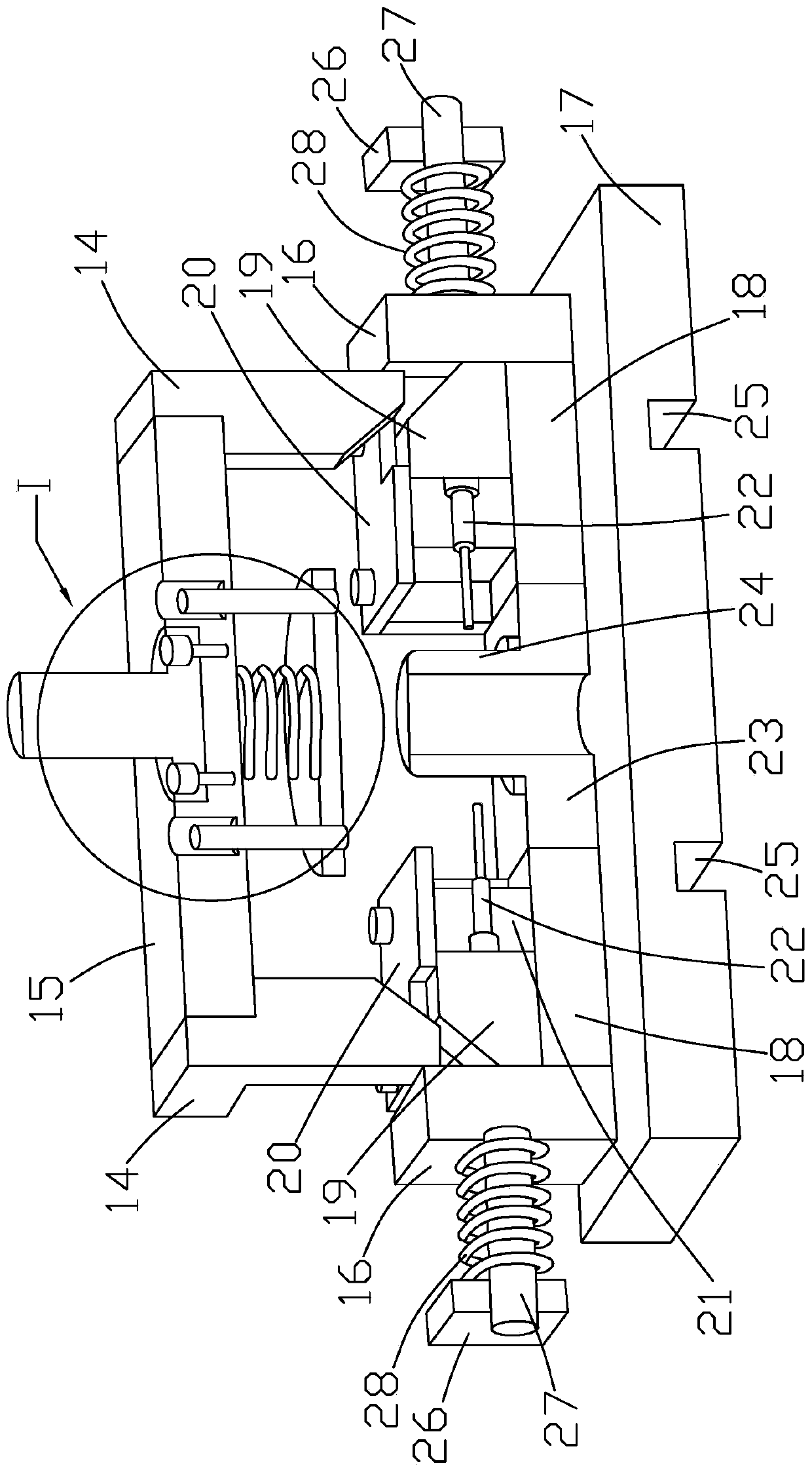

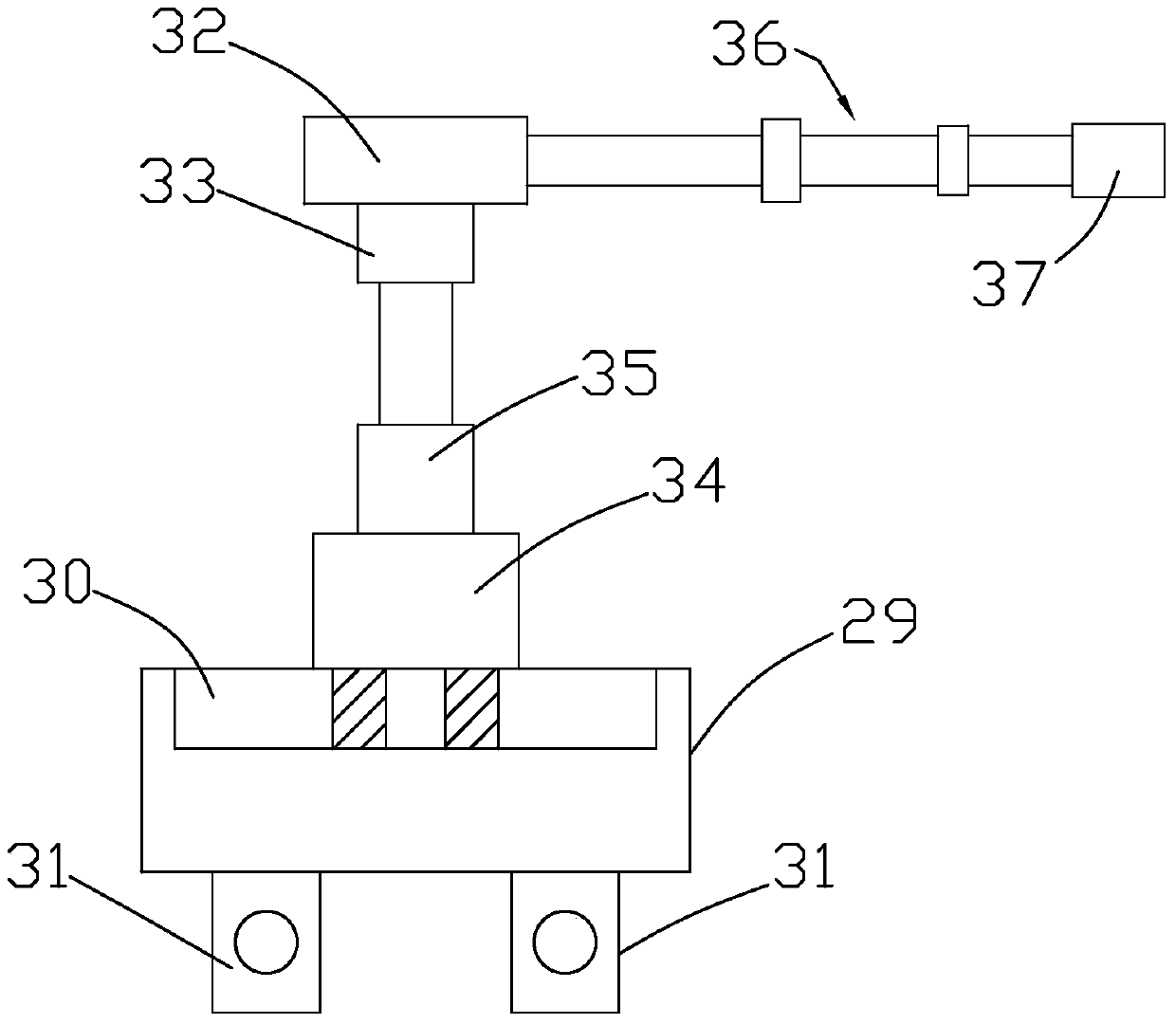

[0030]A stator processing device 4 is arranged inside the box body 1, and the stator processing device 4 is moved and connected to the top su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com