Tensile fireproof flame-retardant cable

A fire-resistant, flame-retardant and tensile-resistant technology, which is applied in the direction of insulating cables, cables, circuits, etc., can solve problems such as insufficient tensile strength, achieve the effects of improving fire prevention and flame retardancy, realizing fire prevention functions, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

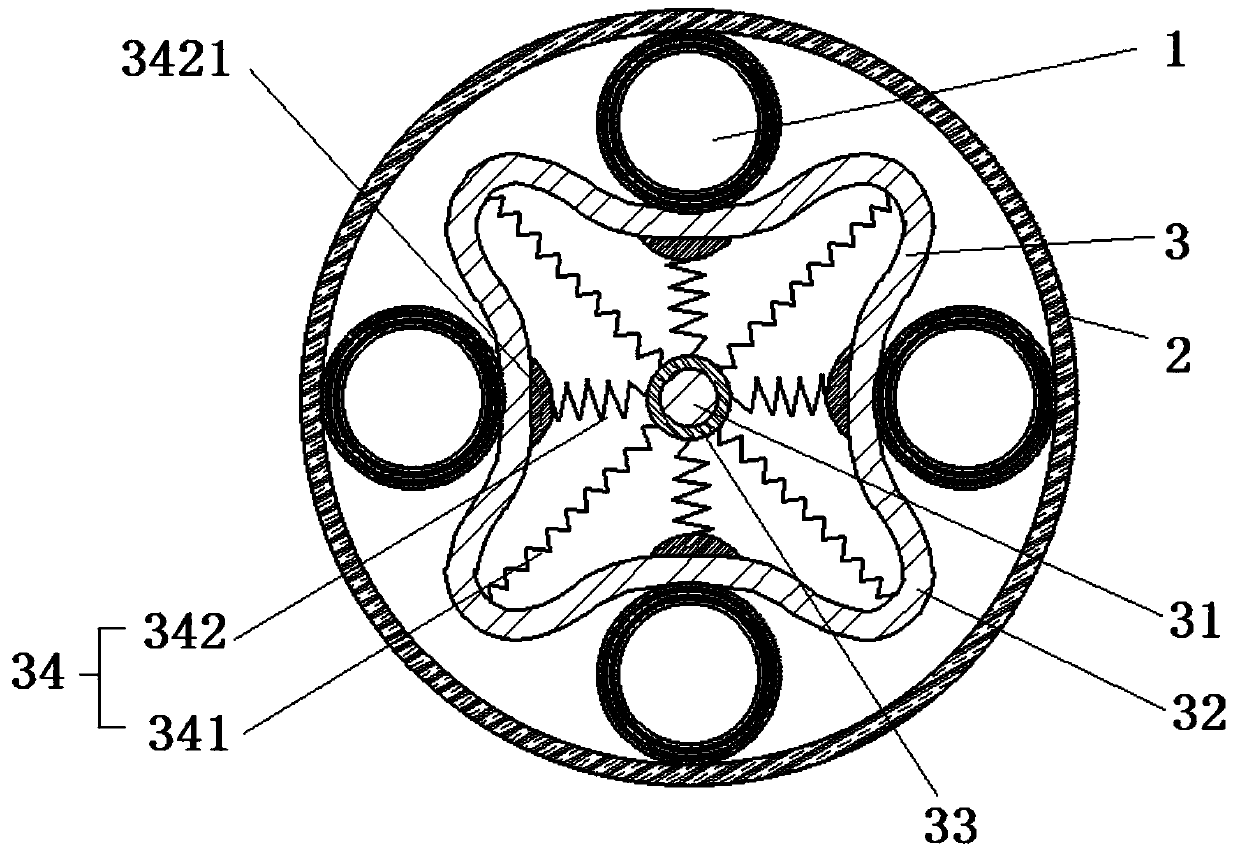

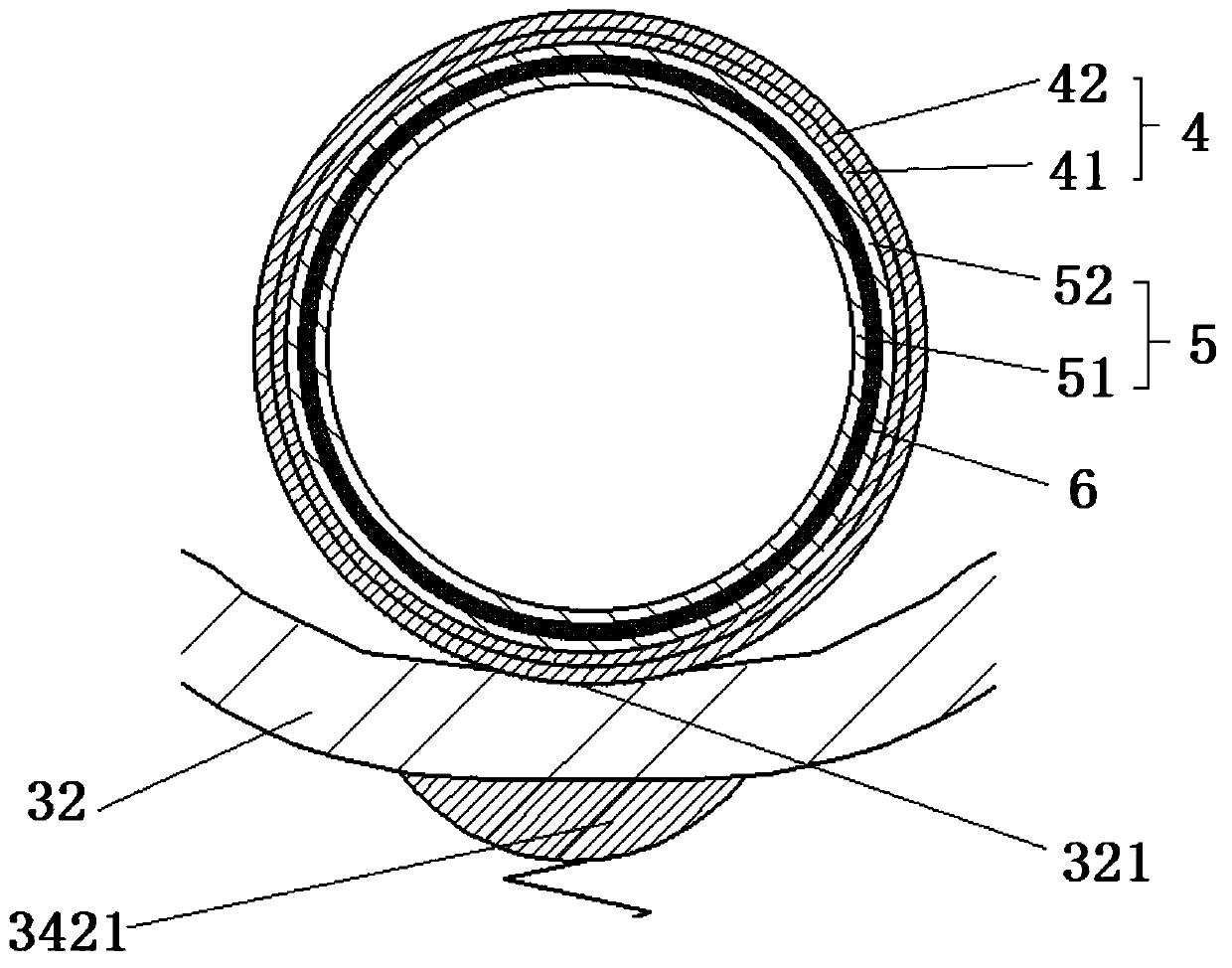

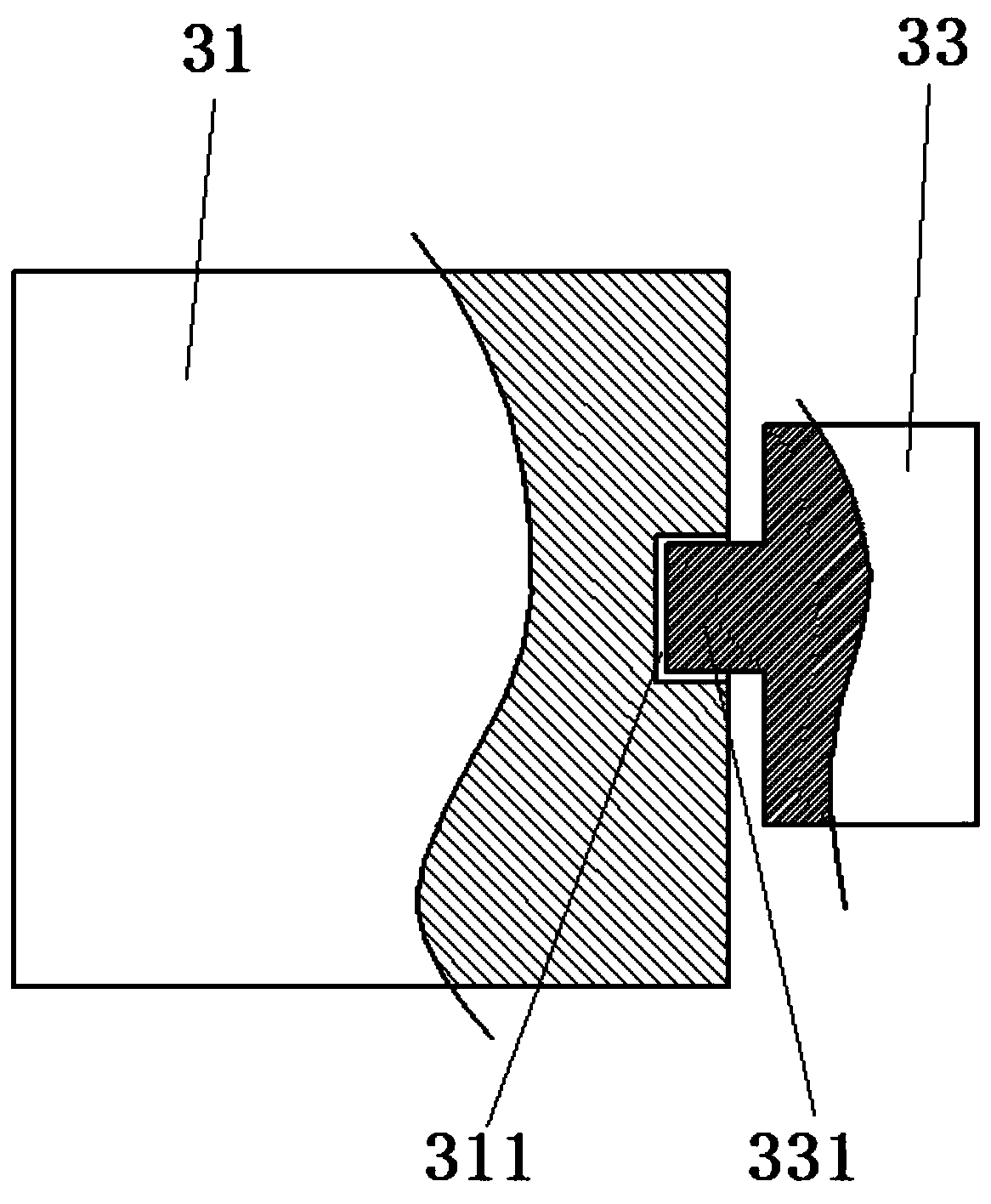

[0022] Tensile fire-resistant and flame-retardant cables, as shown in the figure, include a wire core 1 and a protective sheath 2 set outside the wire core 1. The wire core 1 is wrapped with a reinforcement layer 4, a fireproof layer 5 and a waterproof layer 6. Including the installation frame 3 arranged in the protective cover 2, the installation frame 3 includes a central rod 31 and a rubber soft cover 32 sleeved outside the central rod 31, a plurality of rotating rings 33 are installed on the central rod 31, and the rotating rings 33 and rubber The soft covers 32 are connected by a spring 34 , and the core 1 is installed outside the soft rubber cover 32 , and the soft rubber cover 32 is stretched outward by the force of the spring 34 and the core 1 is pressed against the inner wall of the protective cover 2 .

[0023] The center rod 31 is a rubber rod, the center rod 31 can be bent along with the wire core, the outer surface of the center rod 31 is provided with a plurality ...

Embodiment 2

[0031] Same as embodiment 1, the difference is that the thickness of the rubber soft cover 32 is 0.37mm.

Embodiment 3

[0033] Same as embodiment 1, the difference is that the thickness of the soft rubber cover 32 is 0.3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com