Mining machinery wheel shaft deflection measurement device

A measurement device and mechanical technology, applied in the field of deflection measurement, can solve the problems of low installation and fixation strength, limited scope of application, and only small-weight axles can be installed, so as to reduce the number of placements, increase the scope of application, and reduce costs input effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

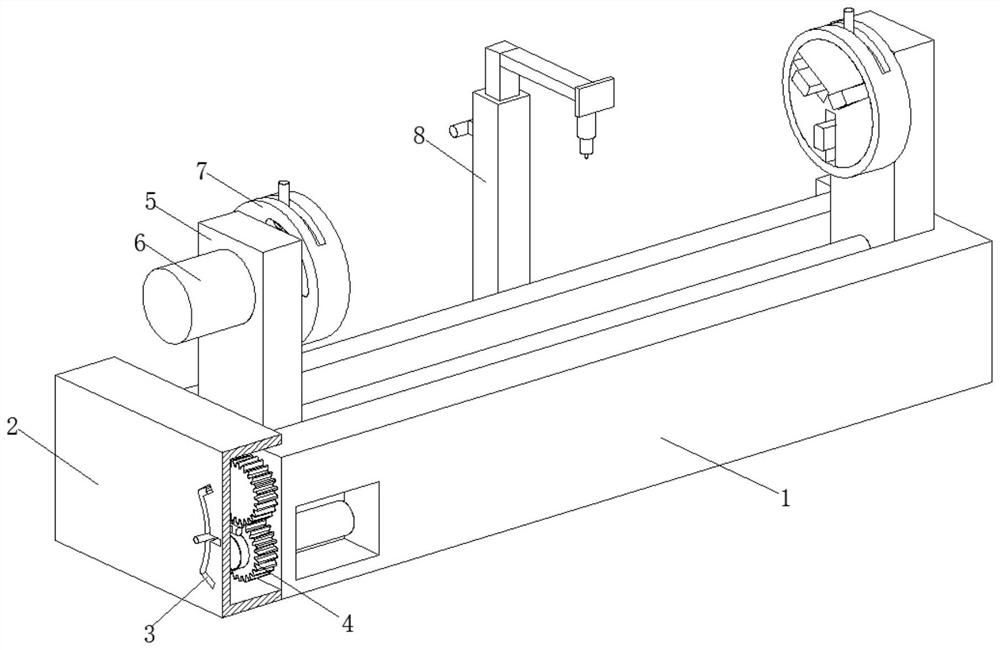

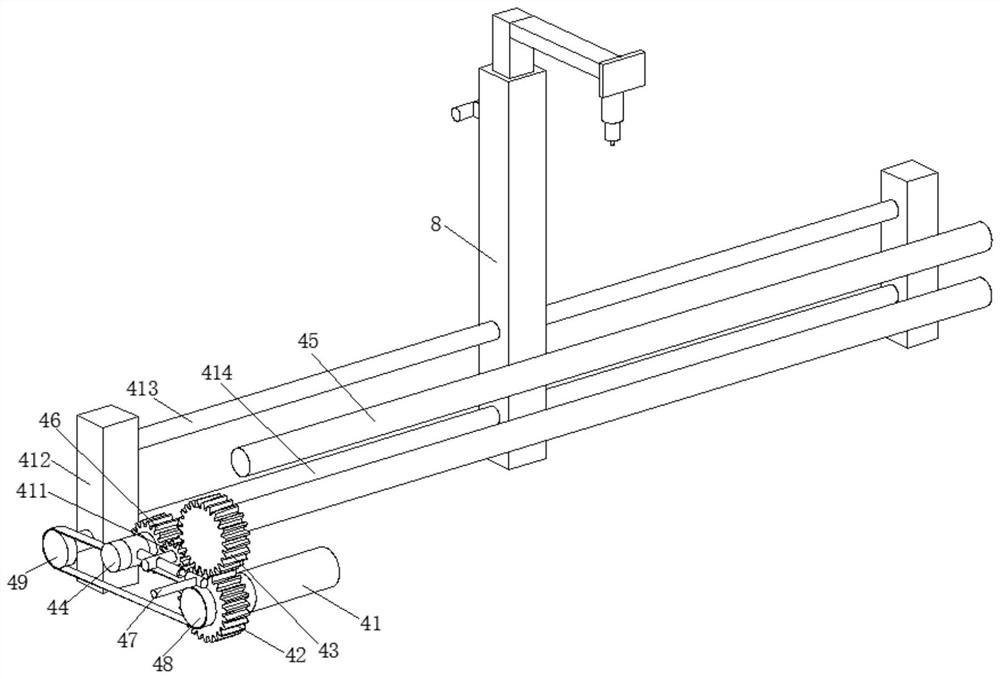

[0030] A deflection measuring device for a mining machinery wheel shaft, such as Figure 1-Figure 6 As shown, it includes a workbench 1, the front of the workbench 1 is connected with a protective box 2 by bolts, the front of the protective box 2 is provided with a card slot 3, the inside of the protective box 2 is provided with a transmission mechanism 4, and the inner wall of the workbench 1 Two support blocks 5 are slidingly connected, the front of the support block 5 is connected with a motor 6 by bolts, the rear of the support block 5 is provided with a clamping mechanism 7 , and the left side of the workbench 1 is provided with a detection mechanism 8 .

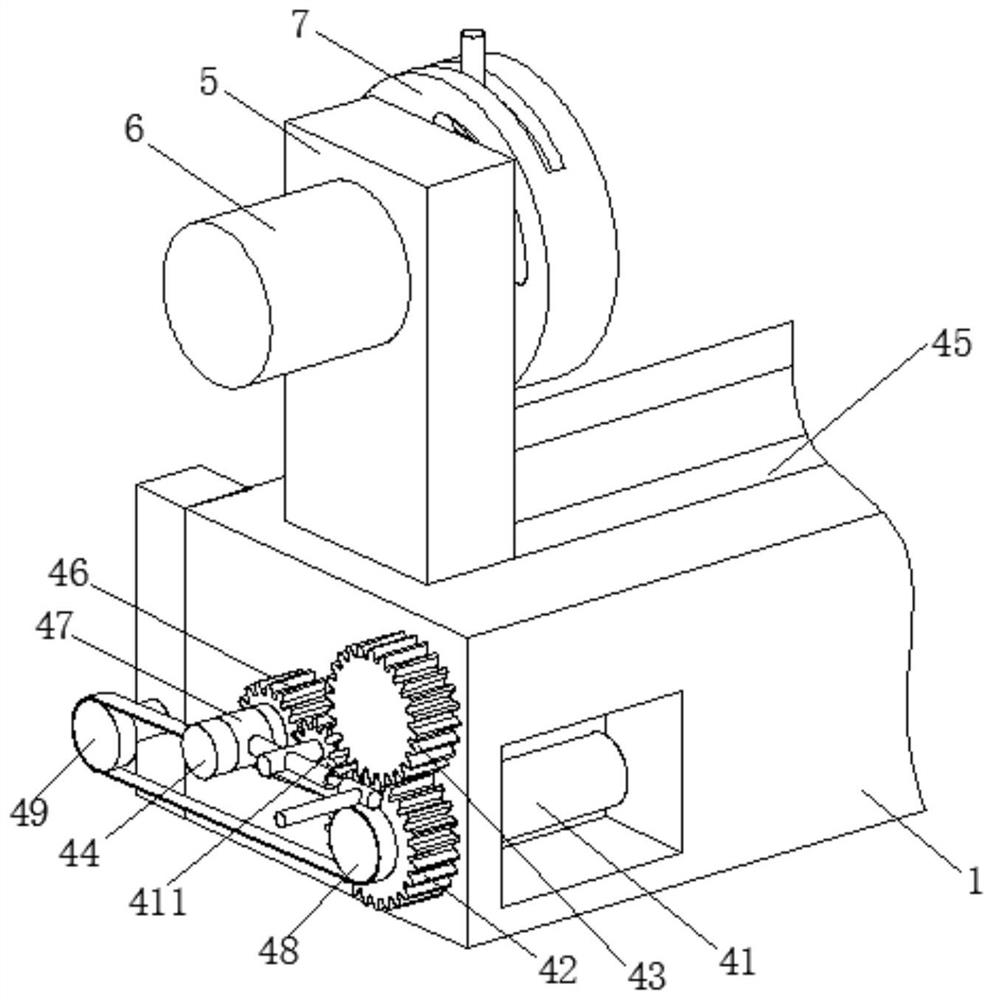

[0031] In this embodiment, the transmission mechanism 4 includes a motor 41, the output end of the motor 41 is clipped to a No. 1 gear 42, the surface of the No. 1 gear 42 is meshed with a No. 2 gear 43, and the inner wall of the workbench 1 is rotatably connected to a two-way screw 44; The inner wall of the workbench 1...

Embodiment 2

[0041] Such as Figure 6-Figure 7 As shown, on the basis of Embodiment 1, in this embodiment, the axis of the fixed disk 71 is clamped and fixed with the output end of the motor 6, the surface of the slider 76 is slidably connected with the inner wall of the limit disk 73, and the push rod The surface of 77 is movably connected with the inwall of fixed disk 71, and fixed disk 71 is provided with arc-shaped slide rail, and push rod 77 is slid on its inner wall, prevents because the inner wall of fixed disk 71 is threadedly connected with the surface of inner disk 72, causes straight line The slide rail of the push rod 77 is blocked, and then the inner disk 72 cannot be continued to rotate, so that the moving range of the slide block 76 is limited, and the axles with different diameters cannot be clamped, and the practicability is greatly reduced.

[0042] It is worth noting that the detection mechanism 8 includes a support column 81, the inner wall of the support column 81 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com