Intelligent new textile material cutting device for textiles

A new material and cutting technology, which is applied in the cutting of textile materials, textiles and papermaking, mechanical cleaning, etc., can solve the problems of uneven cutting by machines and low efficiency of manual cutting, so as to improve work efficiency, reduce costs and low investment , the effect of increased practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

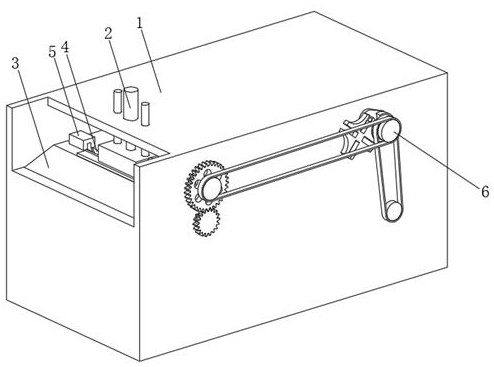

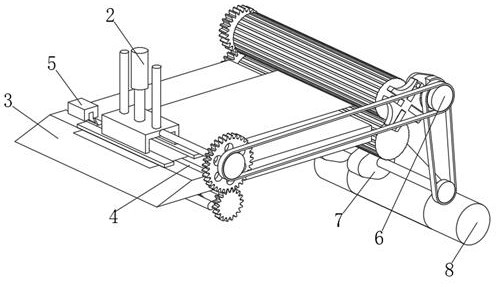

[0036] A kind of smart textile new material cutting device for textile, such as Figure 1-Figure 8 As shown, it includes a box body 1, the top of the box body 1 is provided with a fixing mechanism 2, the inner wall of the box body 1 is provided with a support plate 3, the top of the support plate 3 is provided with a chute 4, and the inner wall of the chute 4 is provided with a cutting Mechanism 5, a transmission mechanism 6 is provided on the right side of the box body 1, a dust removal mechanism 7 is provided inside the box body 1, a reel 8 is provided on the inner wall of the box body 1, and the reel 8 is located at the rear of the support plate 3;

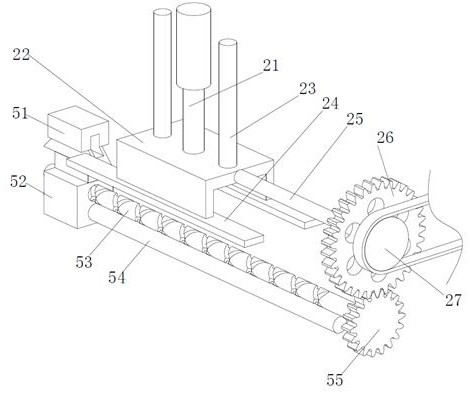

[0037] The fixing mechanism 2 includes an electric push rod 21, the output end of the electric push rod 21 is provided with a mounting plate 22, the top of the mounting plate 22 is provided with a connecting column 23, and the bottom of the mounting plate 22 is provided with two pressing plates 24, and the mounting plate 22 The...

Embodiment 2

[0045] Such as Figure 1-Figure 6 As shown, the surface of the slide block 51 is movably connected with the inner wall of the chute 4, the top of the mounting block 52 is fixedly connected with the bottom of the slide block 51, and the surfaces of the screw rod 53 and the guide post 54 are all movably connected with the inner wall of the mounting block 52, The left end of pinion 55 is fixedly connected with the right end of screw rod 53, and the surface of pinion 55 and the surface of bull gear 26 mesh with each other, and the two ends of blade 56 are fixedly connected with the inner wall of slide block 51, and the surface of screw rod 53 and casing The inner wall of 1 is rotationally connected, and the two ends of the guide post 54 are fixedly connected with the inner wall of the box body 1. The inner wall of the mounting block 52 is provided with a block, and the block is in the spiral groove on the surface of the screw rod 53, so the rotation of the screw rod 53 will The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com