Non-woven fabric cutting leftover material recycling and smashing device

A technology of scrap recycling and crushing equipment, applied in metal processing, grain processing, etc., can solve the problems of poor recycling and cleaning, waste of scraps, etc., and achieve the effect of convenient transportation, accelerated crushing effect, and uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

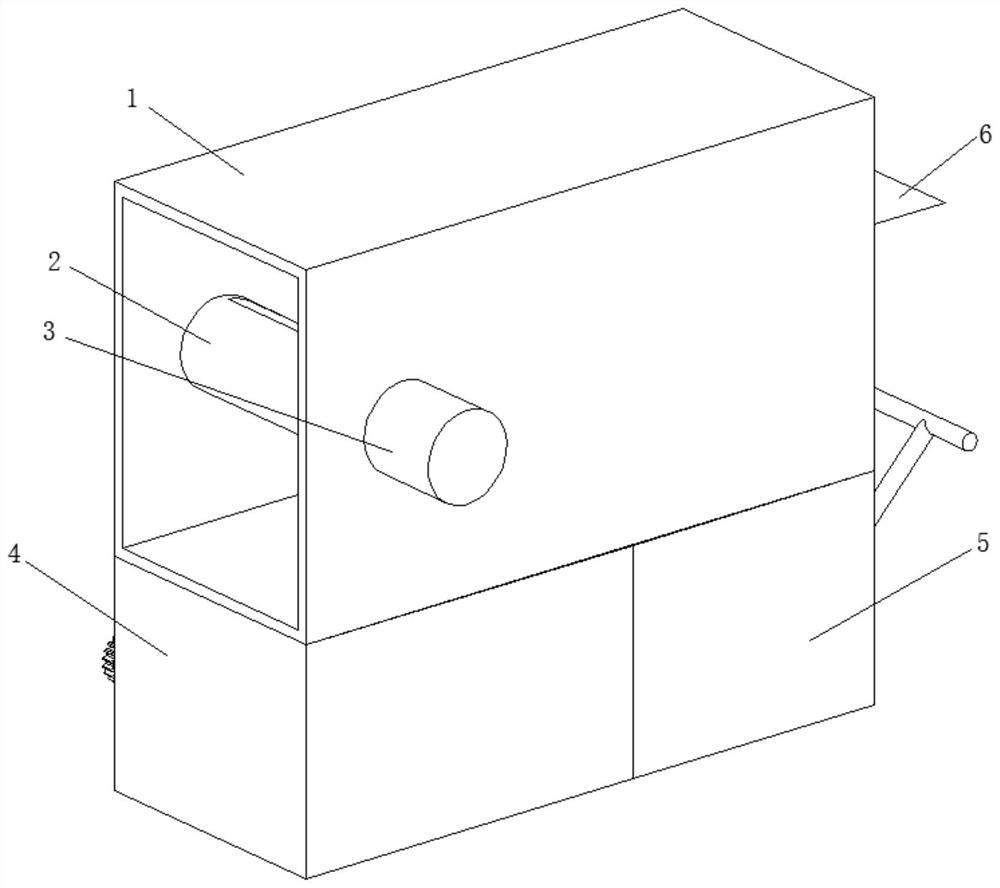

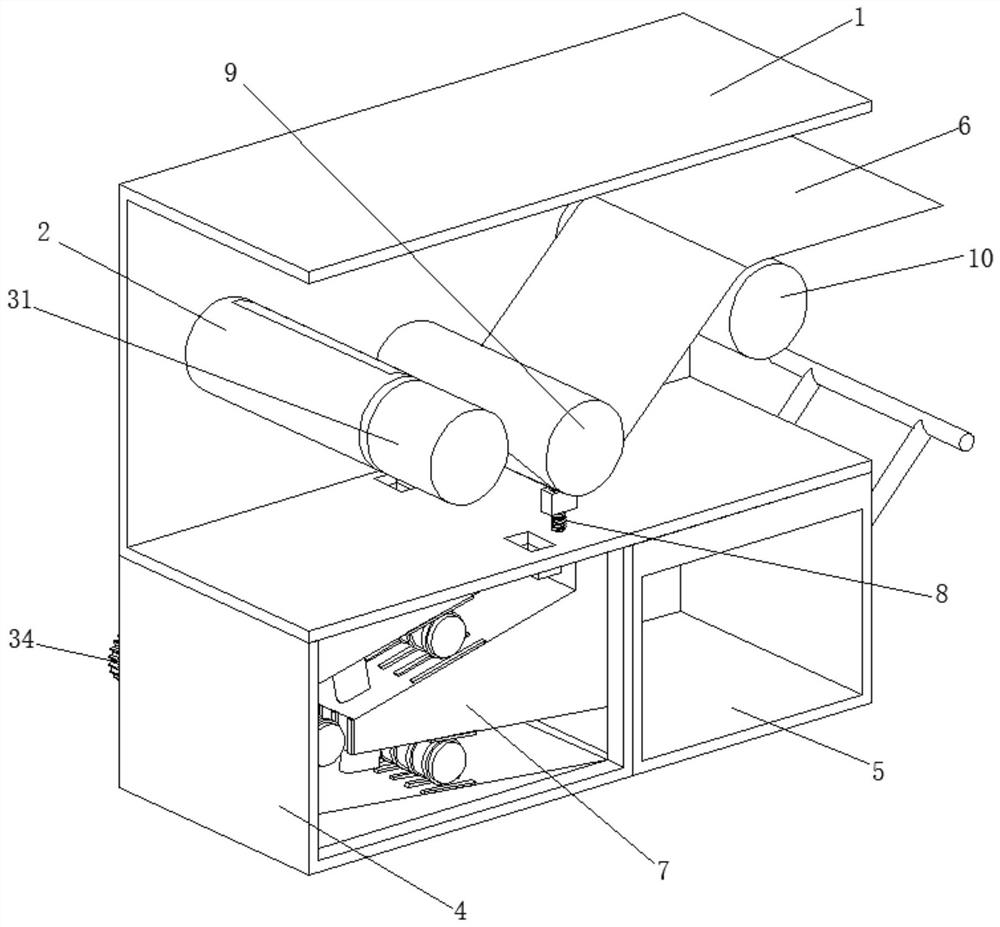

[0030] A kind of equipment for recycling and crushing non-woven fabric trimmings, such as Figure 1-Figure 6 As shown, the box body 1 is included, and the inner wall of the box body 1 is respectively connected with the reel 2, the transmission drum 9 and the guide drum 10, and the transmission drum 9 is located between the reel 2 and the guide drum 10, and the right side of the box body 1 A transmission mechanism 3 is provided, a recovery box 4 is welded on the bottom of the box body 1, and a collection box 5 is slidably connected to the bottom of the box body 1, and the collection box 5 is located at the rear of the recovery box 4, and the reel 2, the transmission roller 9 and the guide The surface of the drum 10 is movably connected with a cloth 6 , the inside of the recovery box 4 is provided with a crushing mechanism 7 , and the bottom wall inside the box body 1 is provided with an edge trimming mechanism 8 .

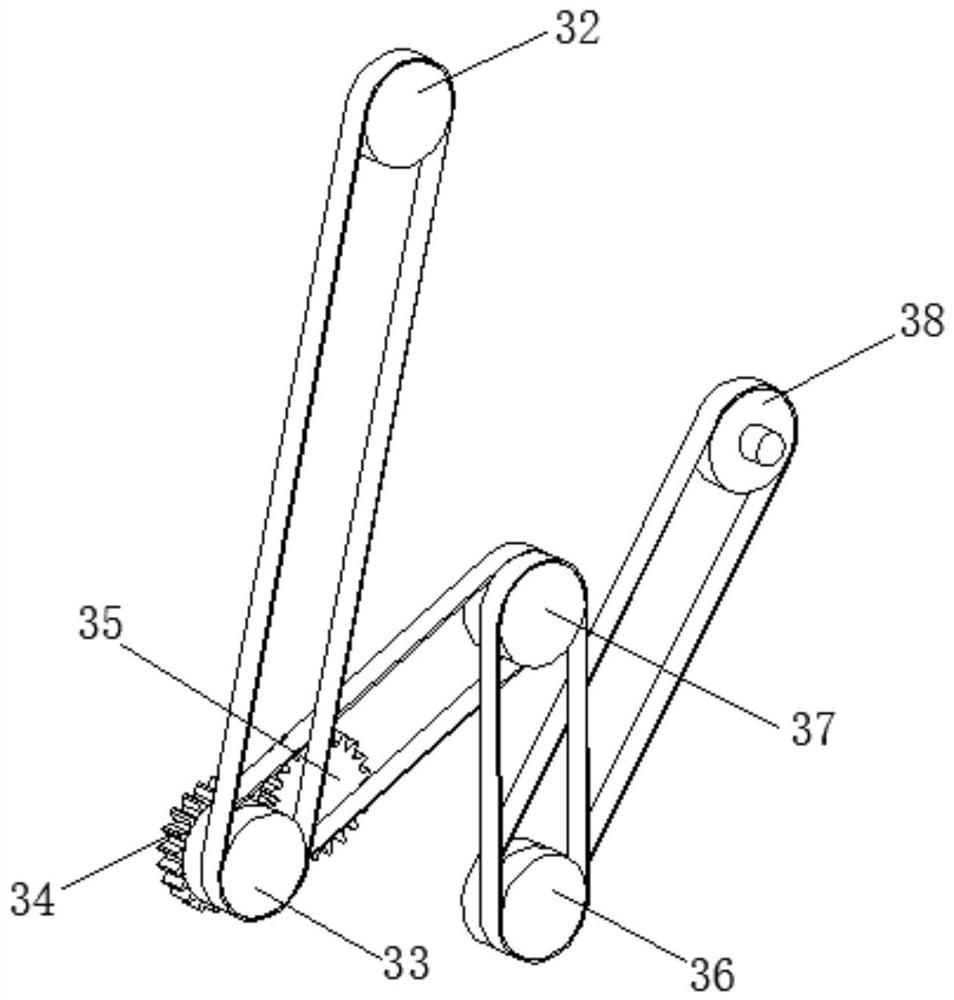

[0031] In this embodiment, the transmission mechanism 3 includ...

Embodiment 2

[0041] Such as Figure 6-Figure 7 As shown, on the basis of Embodiment 1, in this embodiment, the top of the lower scraper 721 and the bottom of the upper scraper 725 are rotatably connected with the surface of the bump 71, the connecting shaft 729, the transmission shaft 7211, the connecting rod 722 and the surface of the transmission rod 724 are rotatably connected with the inner wall of the projection 71, and the axis of the second bevel gear 7213 is clipped and fixed with the axis of the second gear 35 through the connecting rod.

[0042] Through the opposite rotation of the two lower scrapers 721 and the two upper scrapers 725, the crushed leftovers can be moved to make them more evenly dispersed, so that the crushing roller 74 can be crushed more evenly, which is more convenient for the subsequent process to recycle.

[0043] It is worth noting that the trimming mechanism 8 includes a fixed block 81 , the inner wall of the fixed block 81 is engaged with a cutting blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com