Disinfection and classification equipment for anesthesiology department and use method thereof

A classification equipment and technology of anesthesiology, applied in the field of medical anesthesia, can solve the problems of manual cleaning and inability to automatically classify, and achieve the effect of increasing efficiency, increasing disinfection cost, and preventing ozone leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

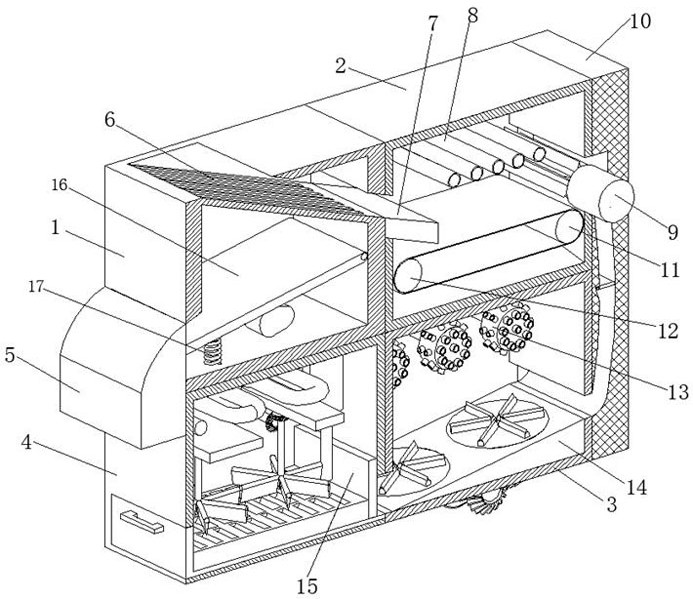

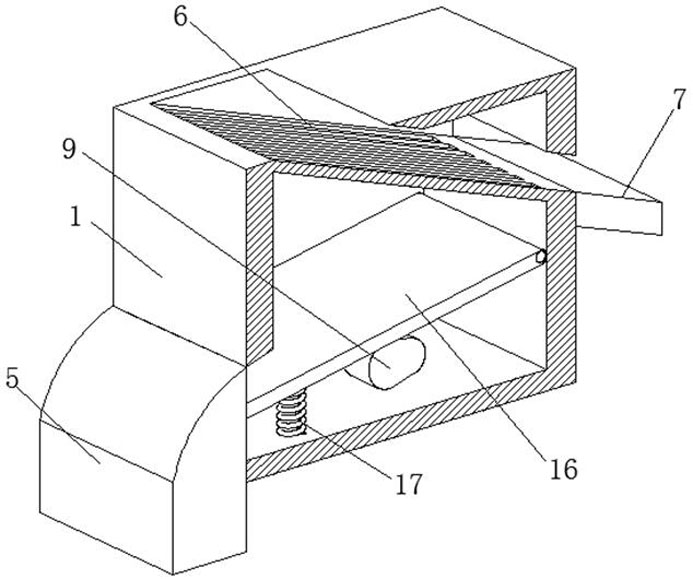

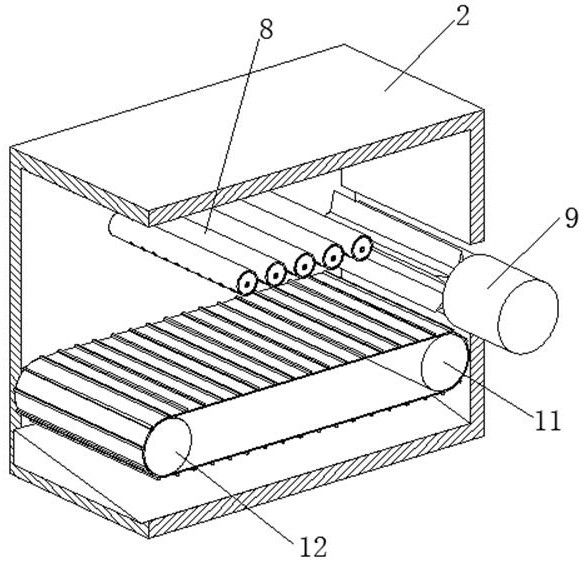

[0039] A kind of disinfection classification equipment for anesthesiology department, such as Figure 1-Figure 7 As shown, the sorting box 1 is included, the rear part of the sorting box 1 is connected with the cleaning box 2 by bolts, the bottoms of the sorting box 1 and the cleaning box 2 are respectively connected with the drying box 4 and the disinfection box 3 by bolts, the front of the sorting box 1 A waste bin 5 is clamped at the top, and several support plates 6 are plugged into the inner wall of the sorting box 1. The rear part of the sorting box 1 is welded with a sloping plate 7, and the sloping plate 7 is located inside the cleaning box 2, and the inside of the cleaning box 2 There are five outlet pipes 8 in communication, the front of the cleaning box 2 is provided with a transmission mechanism 9, the rear of the cleaning box 2 and the disinfection box 3 are all provided with a connecting mechanism 10, and the inside of the drying box 4 is provided with a drying me...

Embodiment 2

[0046] like Figure 7-Figure 9 As shown, the left side of the connection block 101 is respectively connected to the rear of the cleaning box 2 and the disinfection box 3 by bolts, and the two ends of the torsion spring 103 are fixedly engaged with the baffle plate 102 and the inner wall of the connection block 101 respectively, and the torsion spring 103 The baffle 102 can be supported. When a syringe falls, the baffle 102 will drive the torsion spring 103 to rotate and contract. Leakage from the connection block 101 causes the ozone concentration in the disinfection box 3 to be substandard, which in turn affects the disinfection effect and additionally increases the disinfection cost.

[0047] It is worth noting that the drying mechanism 15 includes a cylinder 151, the output end of the cylinder 151 is welded with a slide plate 152, the inner wall of the drying box 4 is plugged with a heating pipe 153, and the bottom wall inside the drying box 4 is slidably connected with a p...

Embodiment 3

[0050] A method for using disinfection and classification equipment in the anesthesiology department, comprising the following steps:

[0051] S1, sorting, the medical personnel will put used medical appliances such as needles and syringes into the sorting box 1, the needles will fall from the gap of the support plate 6 to the bottom of the sorting box 1, driven by the cam 98, The rotating plate 16 will vibrate back and forth, so that the needle head slides into the waste box 5, but the needle cylinder cannot pass through the gap between the support plates 6, and will slide down to the conveyor belt inside the cleaning box 2;

[0052] S2. Cleaning. The syringes dropped on the conveyor belt will be cleaned under the action of water sprayed from the outlet pipe 8. The cleaning time is about 30 seconds to one minute. At the end of the conveyor belt, the driving roller 92 will clean the needle The cylinder is dialed into the connection block 101, and then enters the disinfection b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com