Textile device capable of conveniently flattening and rolling textile fabric

A textile fabric, leveling technology, applied in textiles and papermaking, fabric surface trimming, winding strips, etc., can solve problems such as dust and cloth folds, and achieve the effect of reducing investment, preventing dirt, and maximizing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

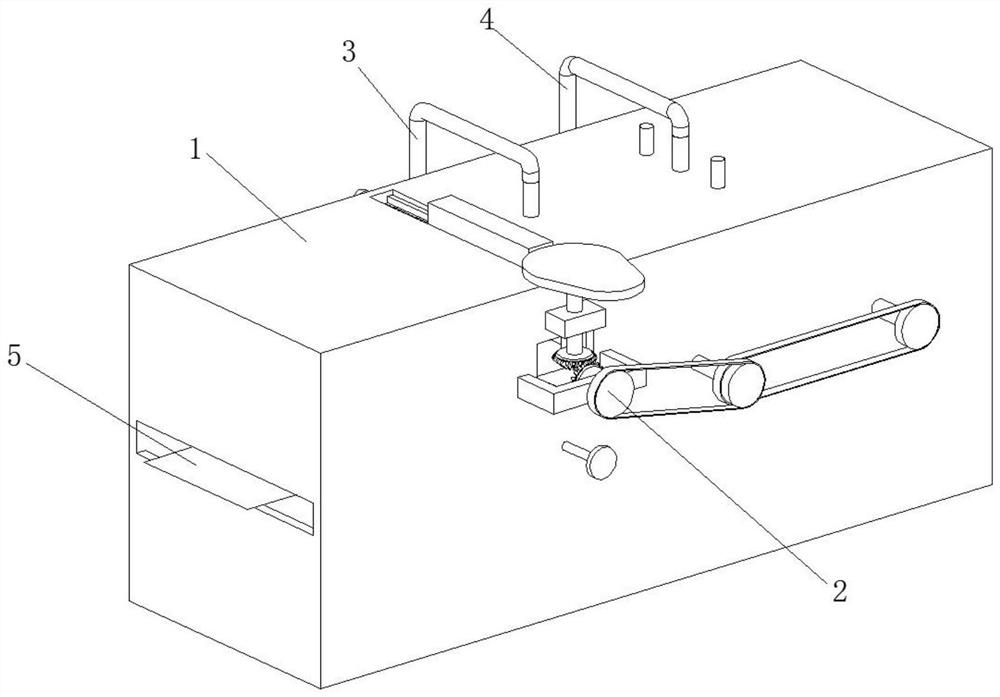

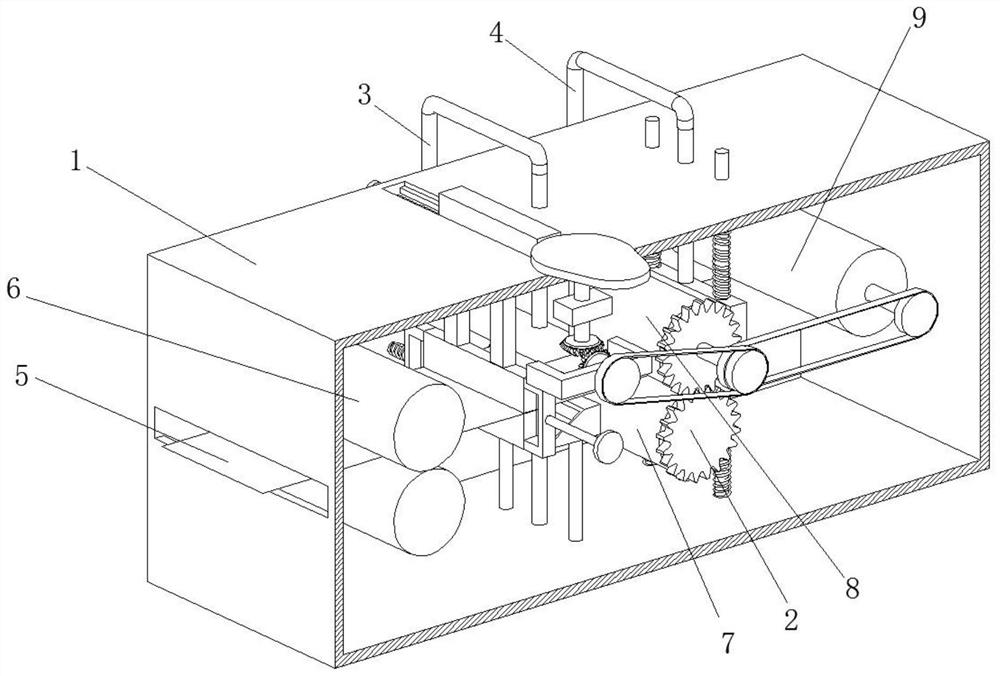

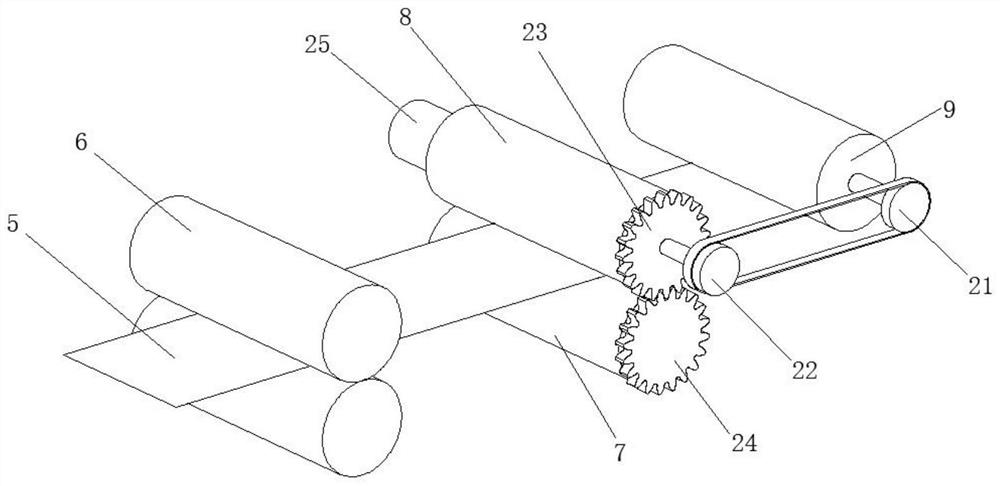

[0030] A textile device that facilitates flat winding of textile fabrics, such as Figure 1-Figure 6 As shown, it includes a box body 1, a transmission mechanism 2 is provided on the right side of the box body 1, a dust suction mechanism 3 and an ironing mechanism 4 are respectively arranged on the left side of the box body 1, and the dust suction mechanism 3 is located at the side of the ironing mechanism 4. In the front, the inner wall of the box body 1 is respectively connected with the driving drum 6, the lower drum 7, the upper drum 8 and the winding drum 9, and the winding drum 9 is located behind the driving drum 6, and the lower drum 7 and the upper drum 8 are located at the transmission Between the cylinder 6 and the winding cylinder 9, and the top of the upper cylinder 8 and the lower cylinder 7, the surfaces of the transmission cylinder 6, the lower cylinder 7, the upper cylinder 8 and the winding cylinder 9 are all movably connected with cloth 5.

[0031] In this e...

Embodiment 2

[0037] like Figure 6-Figure 7 As shown, on the basis of Embodiment 1, in this embodiment, the right side of the collection box 31 is connected to the left side of the casing 1 by bolts, and the upper surface of the suction head 34 communicates with the bottom end of the suction pipe 33, The left side of the suction head 34 is set as an inclined plane, so that the area for absorbing dust on the left side increases, and then the dust brushed by the front brush plate 297 can be sucked into the suction head 34 in time to prevent dust from being sucked into the suction head 34 in time , and cause the dust to fall on the cloth 5 again, causing the cloth 5 to be unqualified after winding.

[0038] Further, the ironing mechanism 4 includes an ironing board 41, the top of the ironing board 41 is connected with a connecting pipe 42, the top of the ironing board 41 is welded with two guide posts 43, and the surface of the guide posts 43 is sleeved with a No. 3 spring 44, The No. 3 spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com