Patents

Literature

41results about How to "Avoid absorbing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

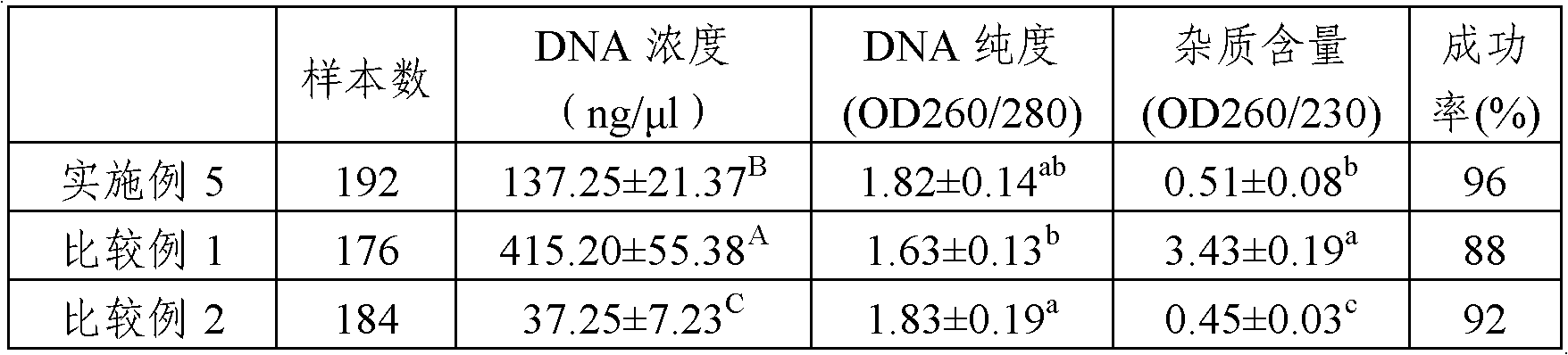

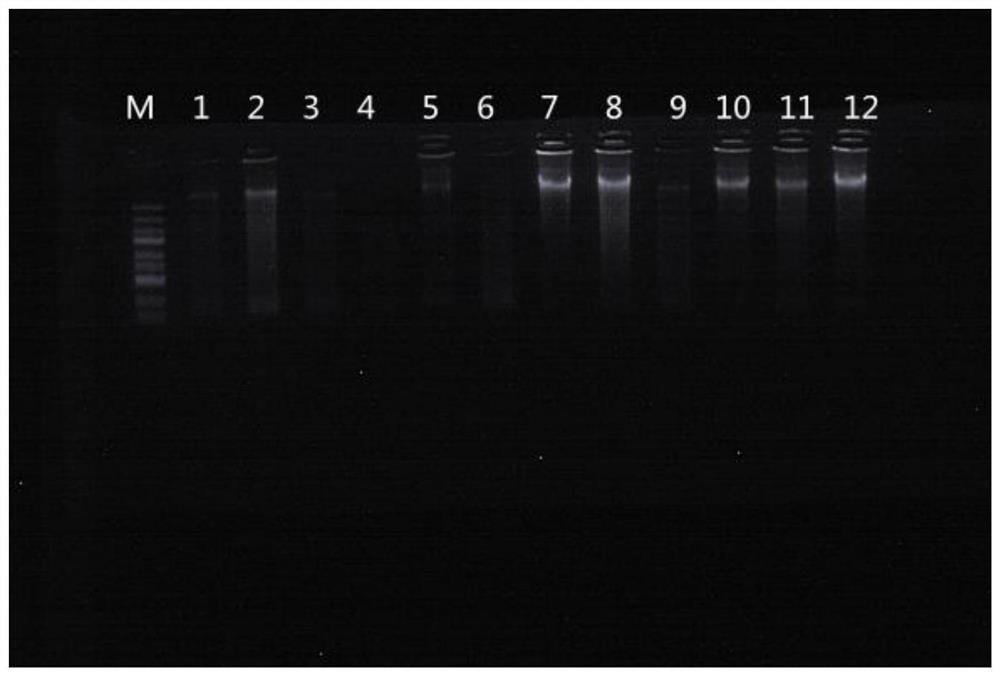

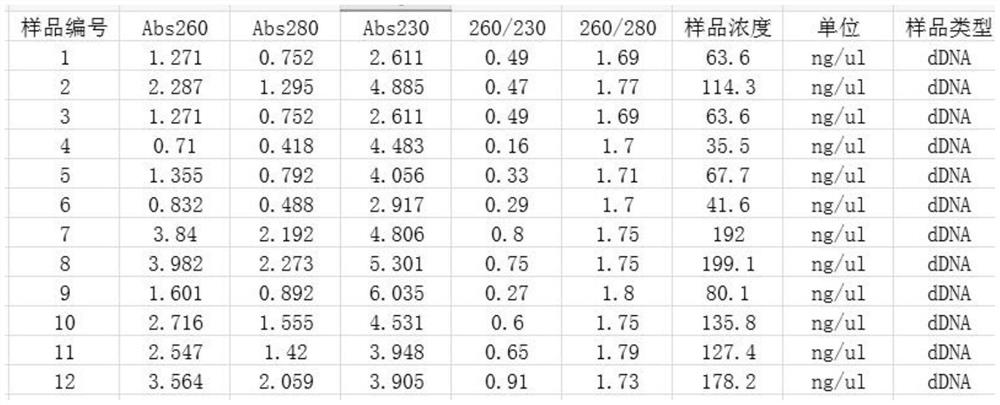

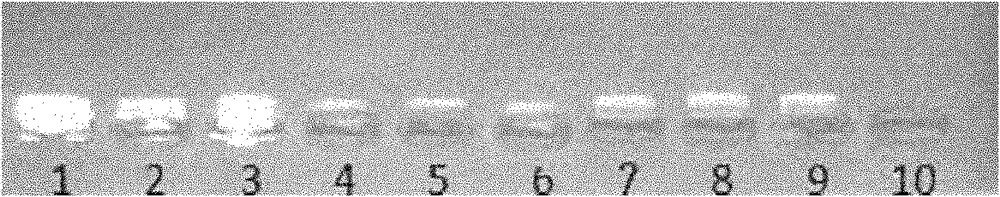

Cell lysis solution for extracting animal DNA, kit and method

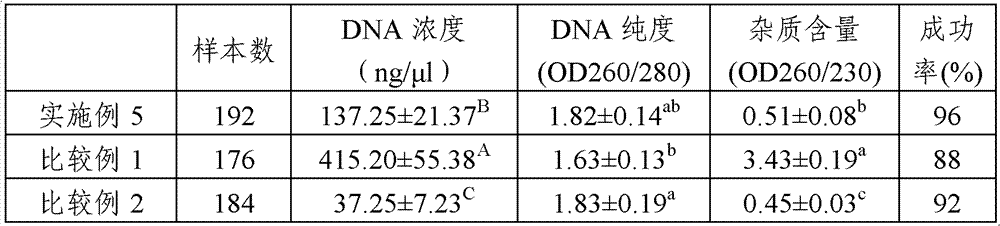

The invention provides cell lysis solution for extracting animal DNA, a kit containing the lysis solution and a method for extracting animal DNA by using the kit. The cell lysis solution provided by the invention comprises Tris-base at a concentration of 20 to 30g / L, ethylene diamine tetraacetic acid (EDTA) at a concentration of 0.5 to 1.0g / L, sodium dodecyl sulfonate (SDS) at a concentration of 20 to 30g / L, NaCl at a concentration of 5 to 10g / L, urea at a concentration of 100 to 150g / L and the balance of sterile water, and the pH value of the cell lysis solution is regulated by NaOH to 8.0 to 9.0. When the animal DNA extraction kit provided by the invention is used, the extraction time is reduced by at least half hour compared with that in the prior art, the use of chloroform with strong toxic odor is avoided, the damage to the health of operators in an operation process is relieved, and the extracted DNA is high in yield and purity. The method provided by the invention is quick, simple, convenient, efficient and very repeatable. In the invention, the result is very stable, the success rate is high, extraction cost is reduced and large-scale extraction of DNA is easy.

Owner:SICHUAN AGRI UNIV

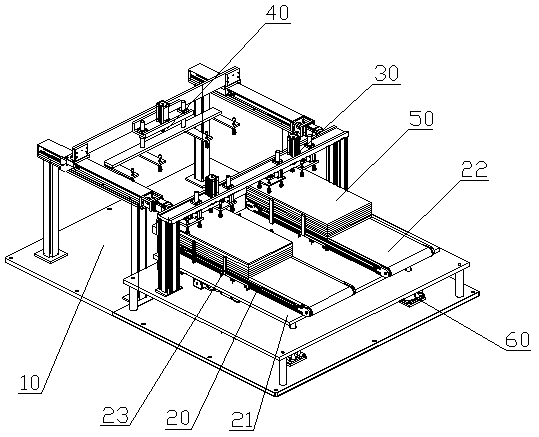

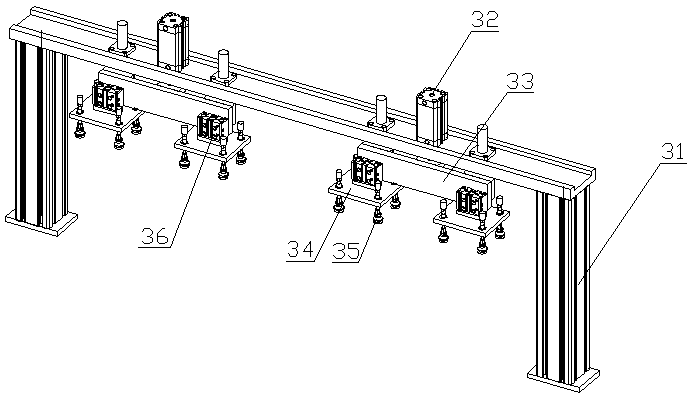

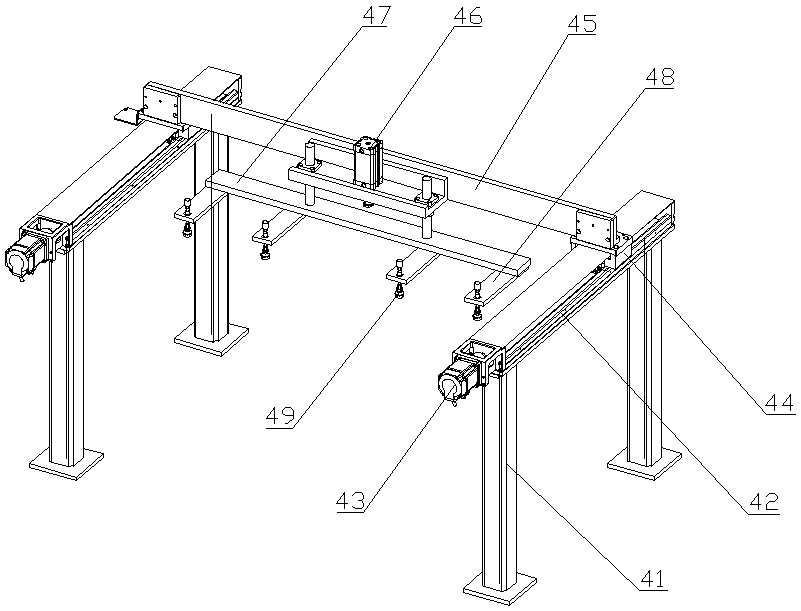

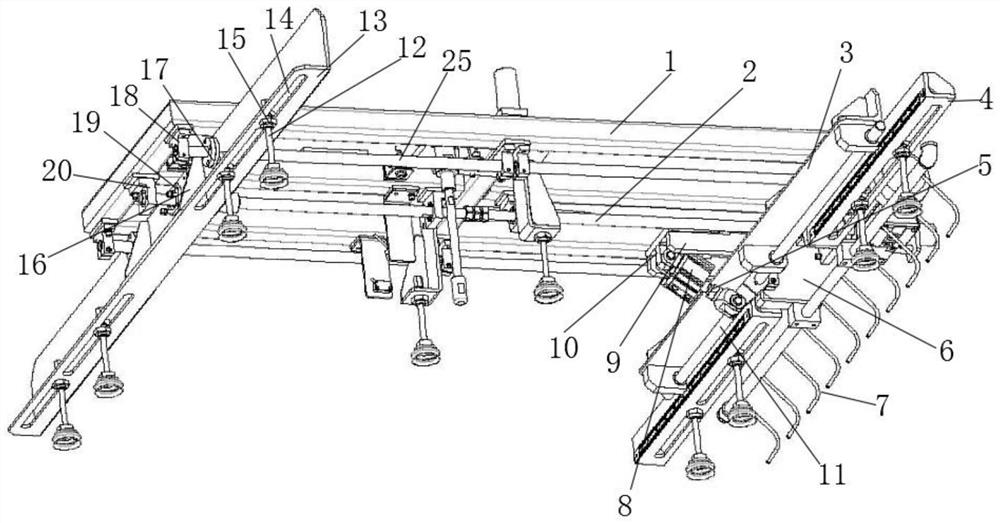

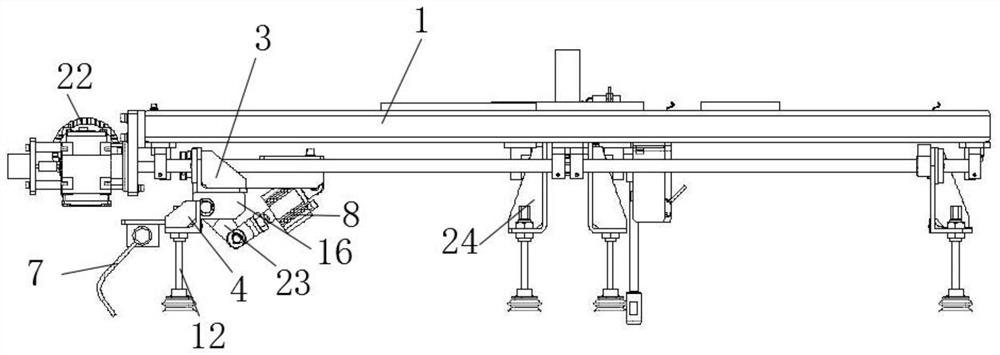

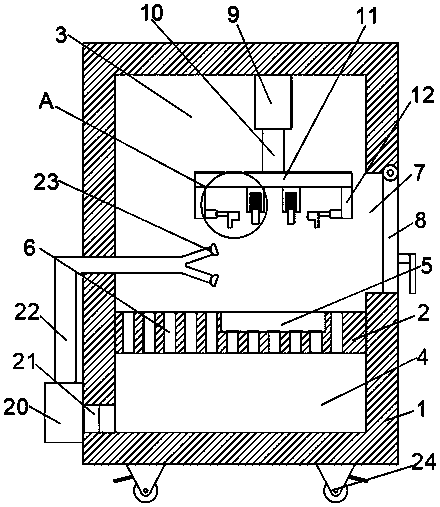

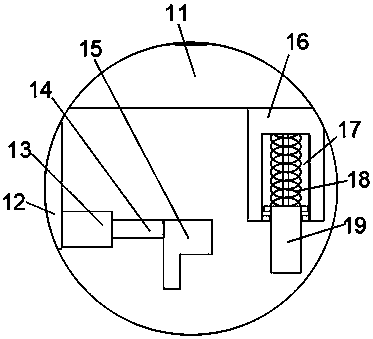

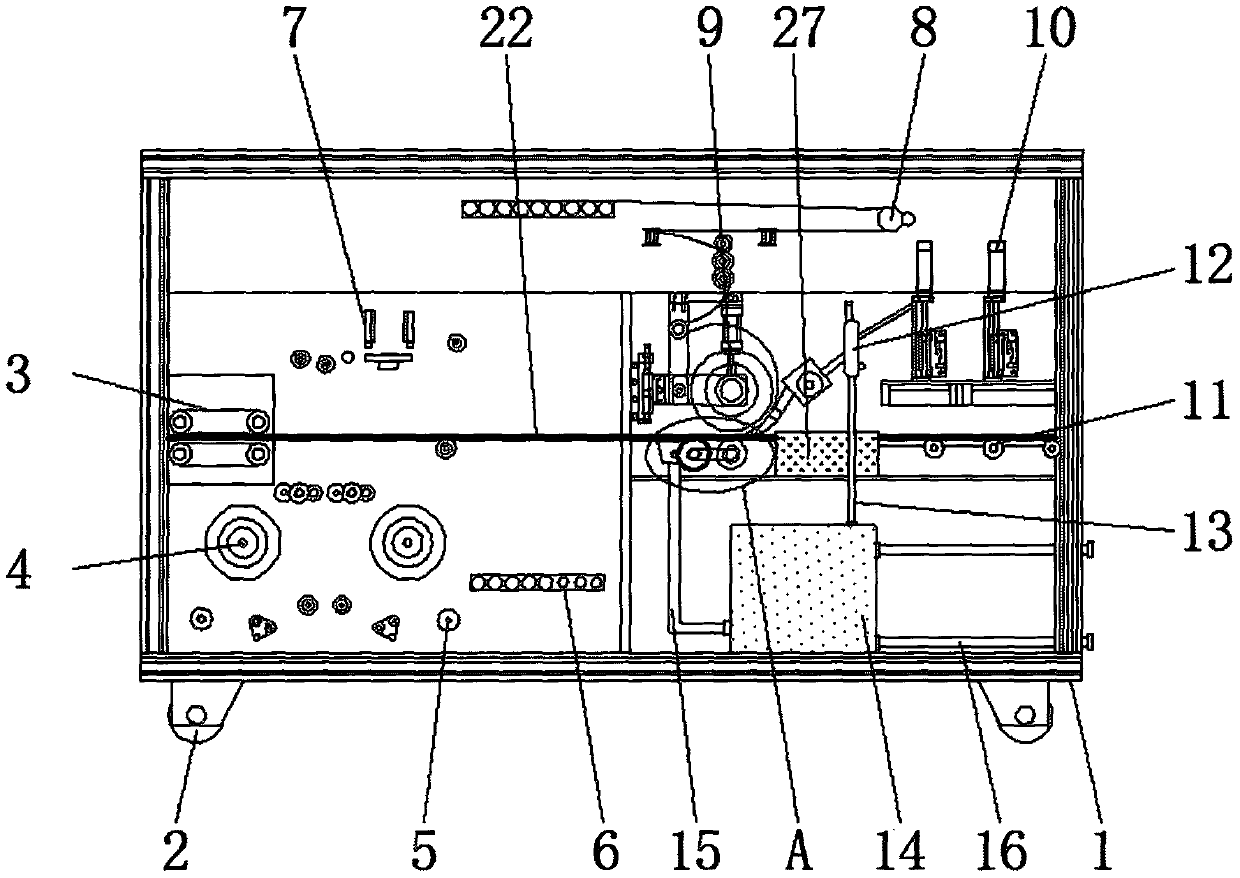

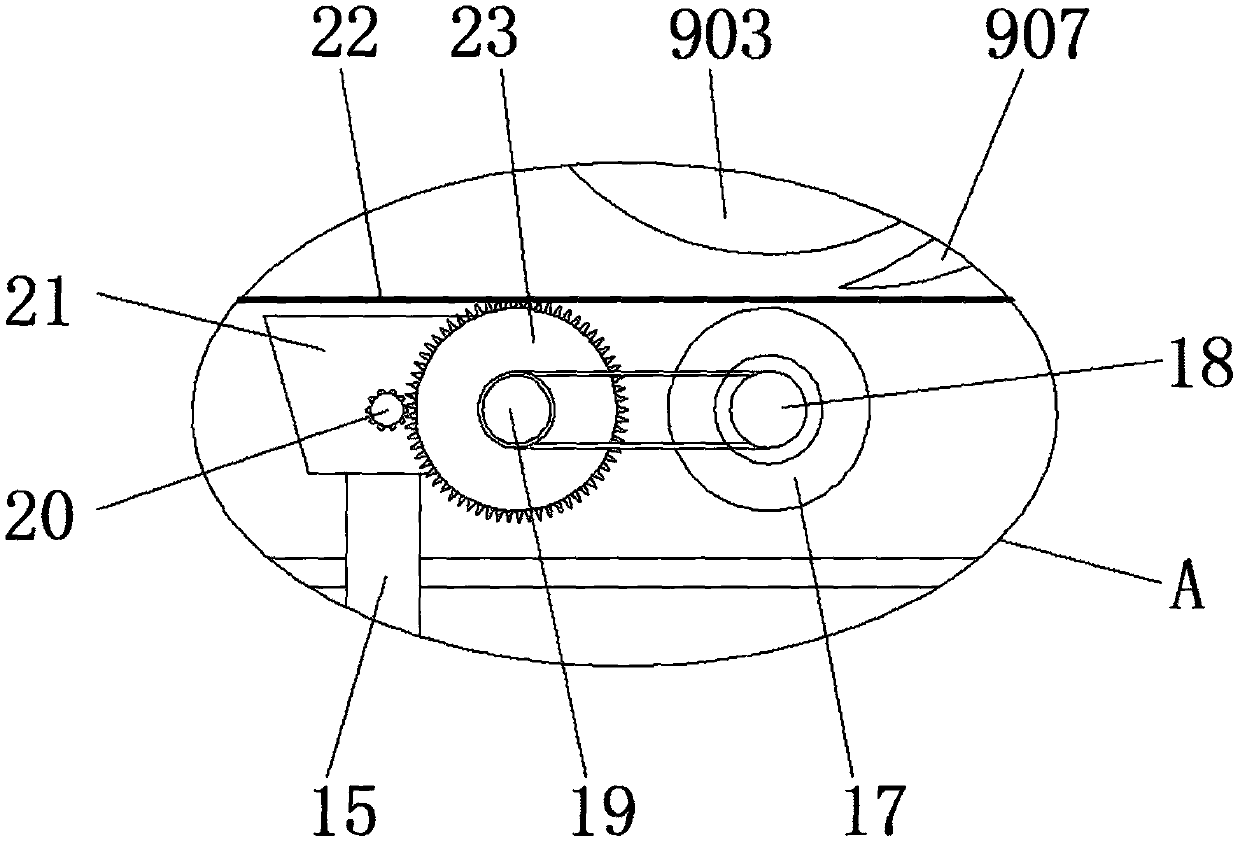

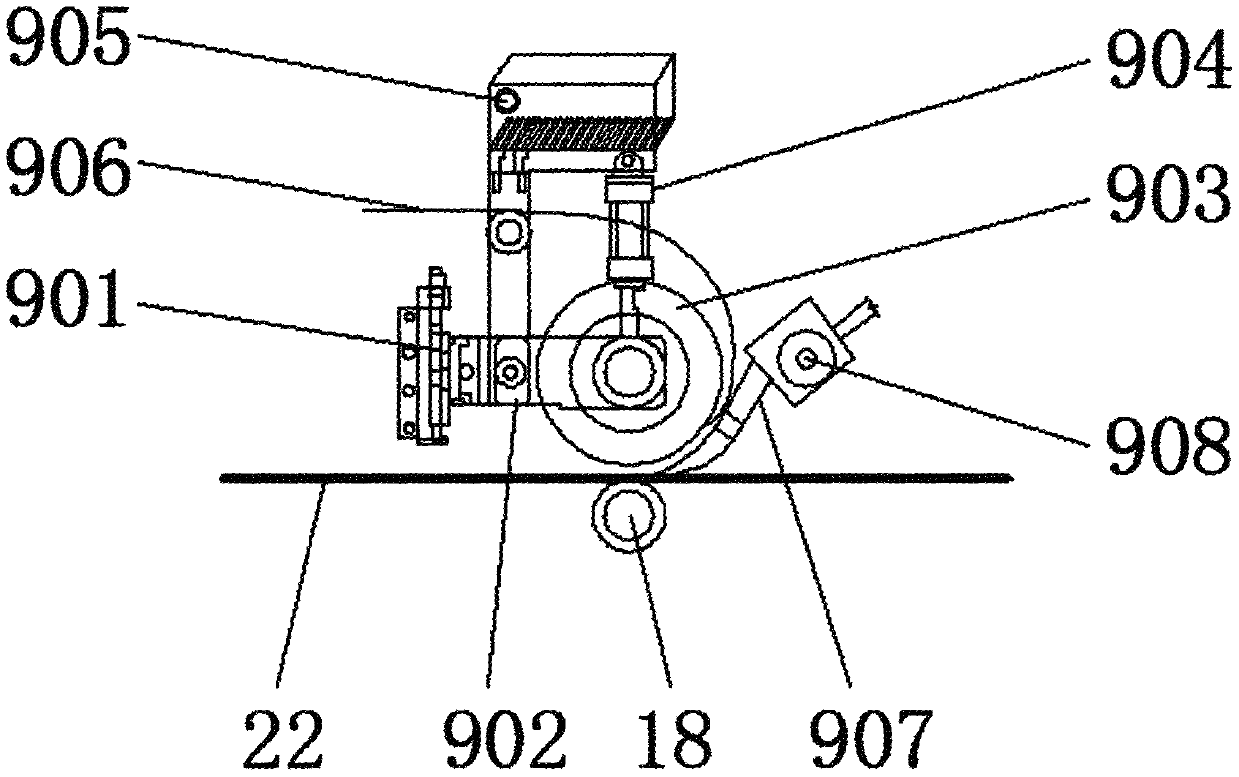

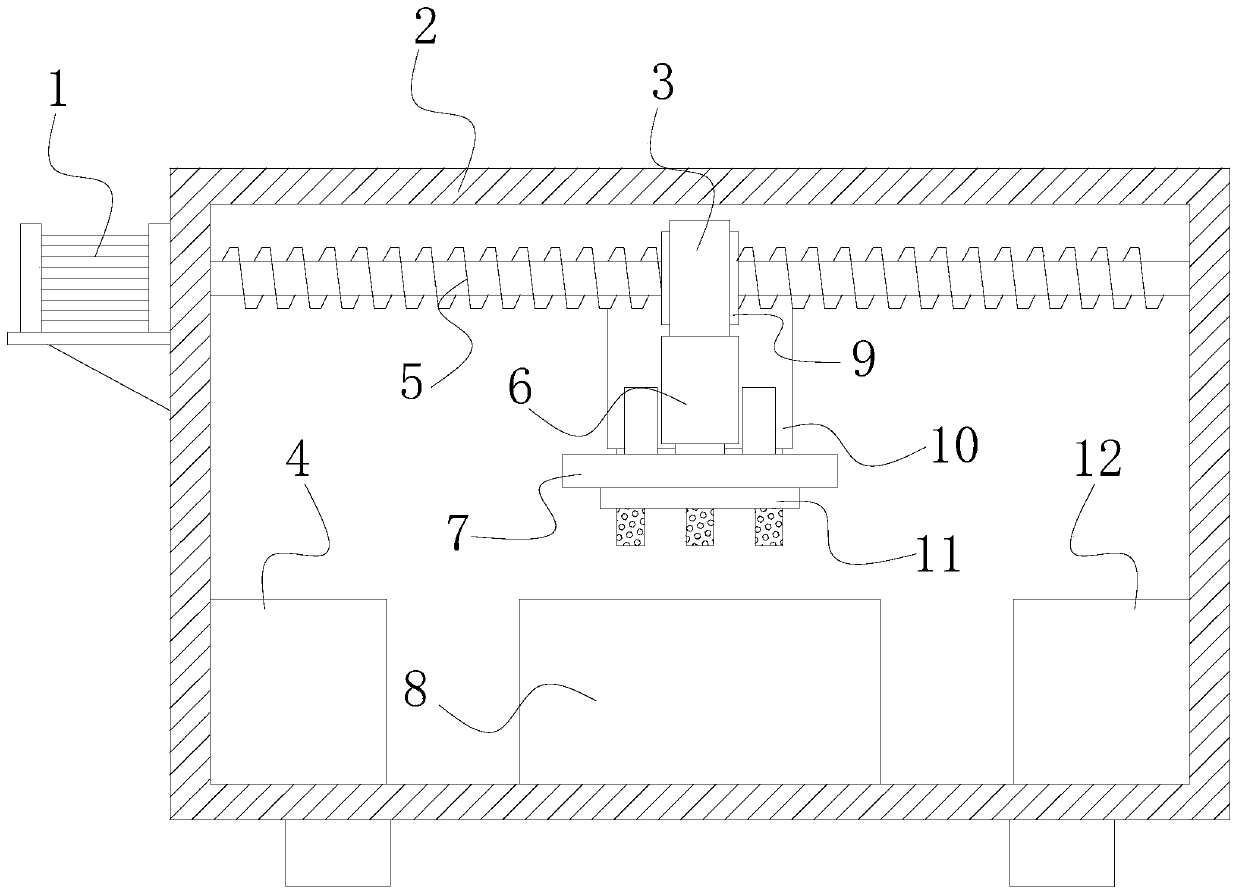

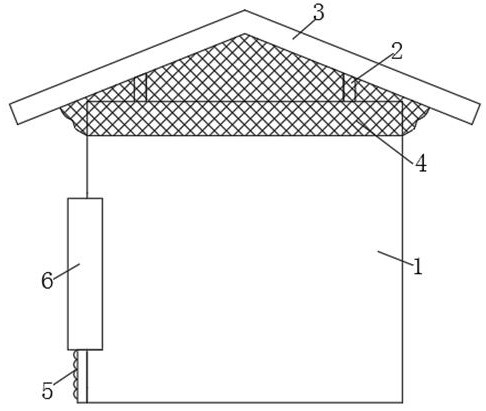

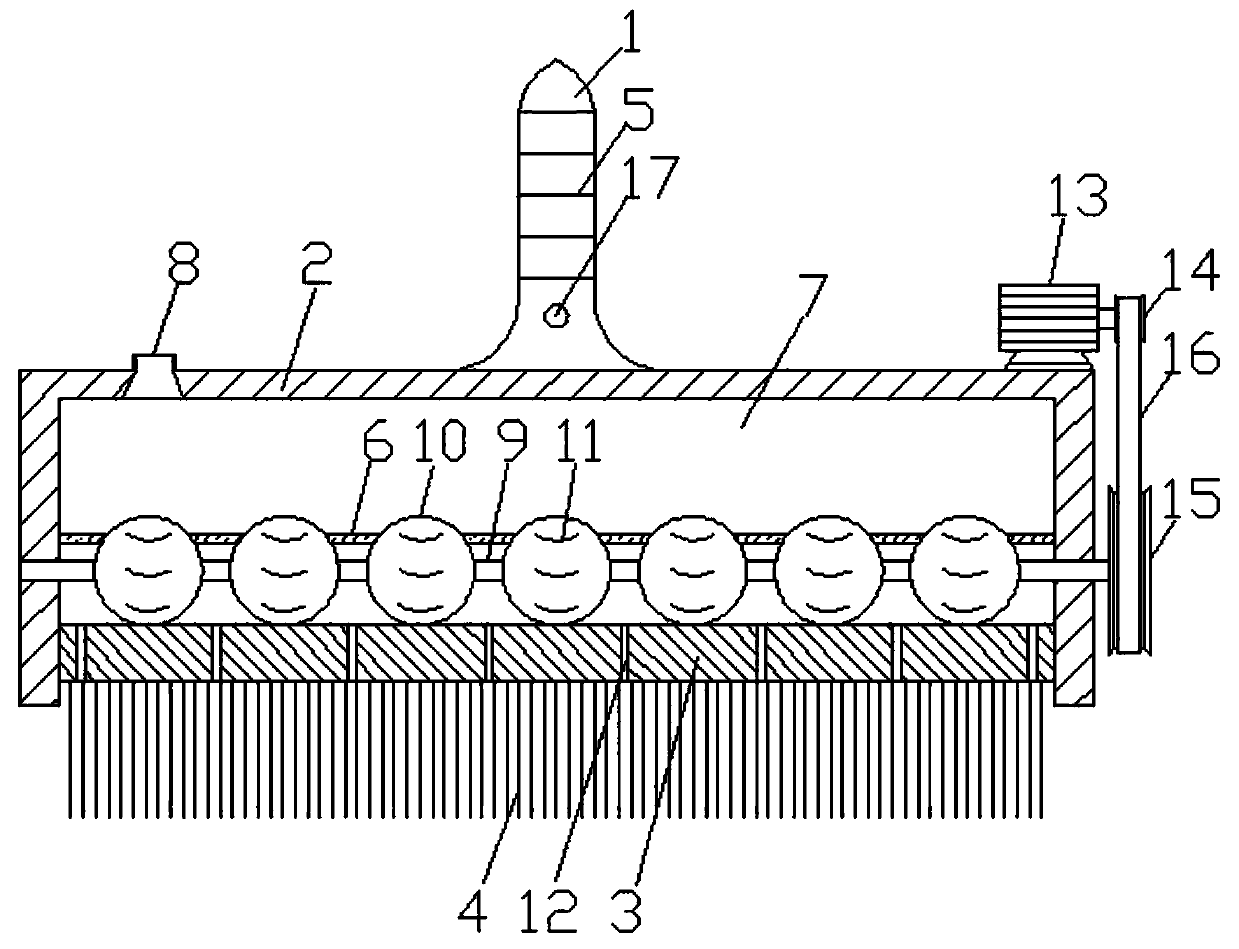

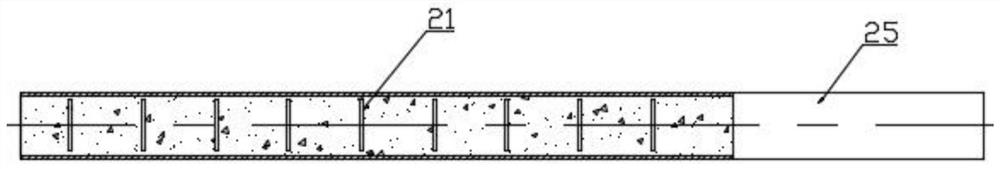

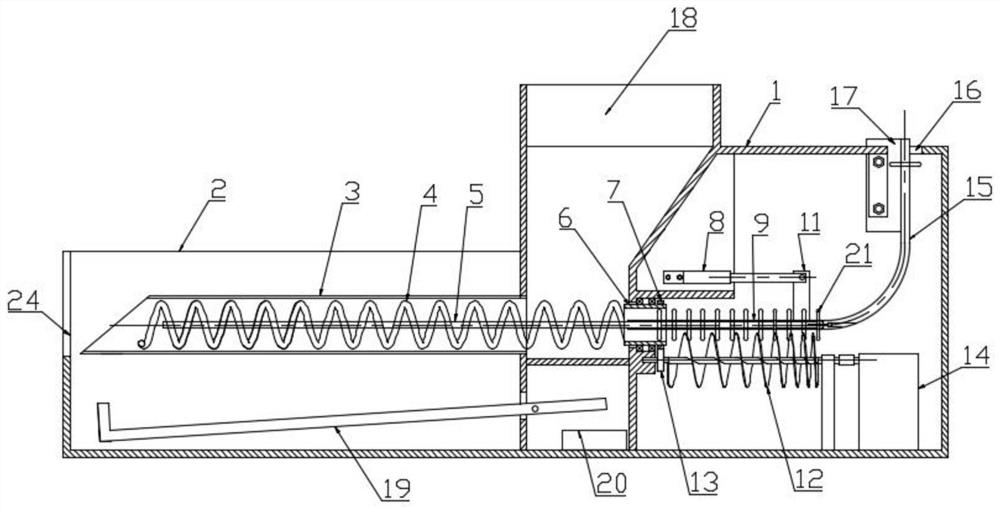

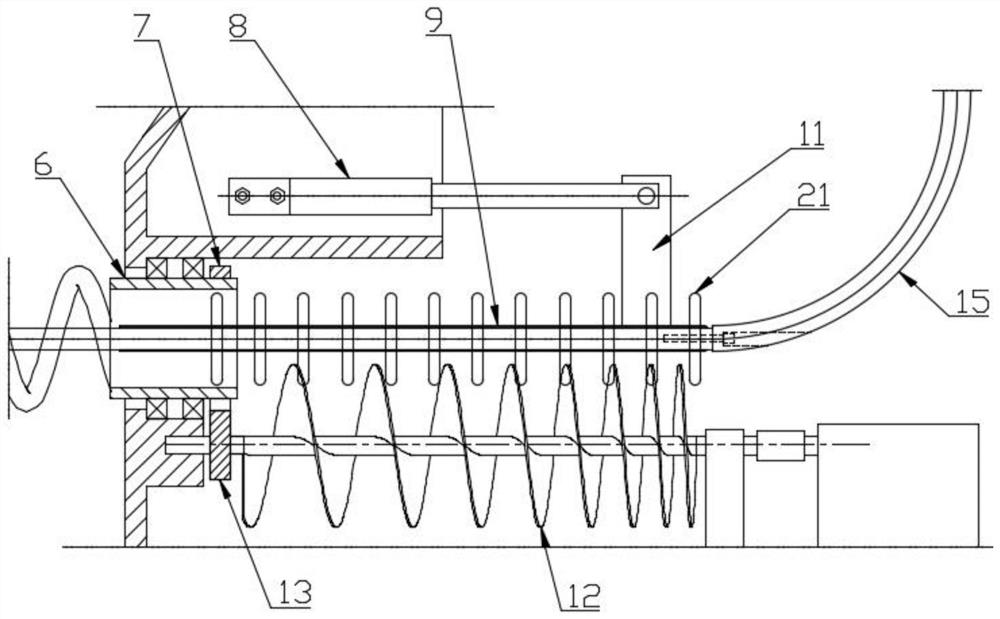

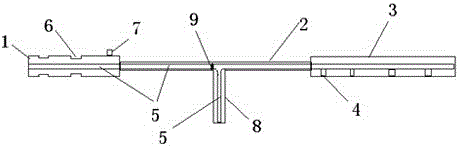

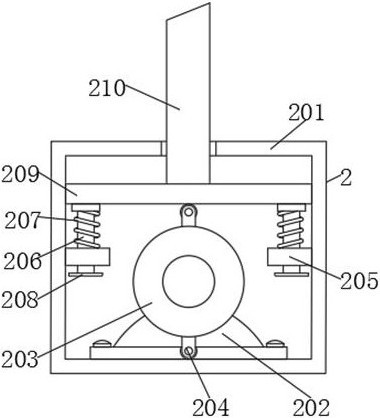

Large-size optical film automatic feeding device

PendingCN107697670AAvoid absorbingDraw reliableArticle feedersArticle separationEngineeringAssembly line

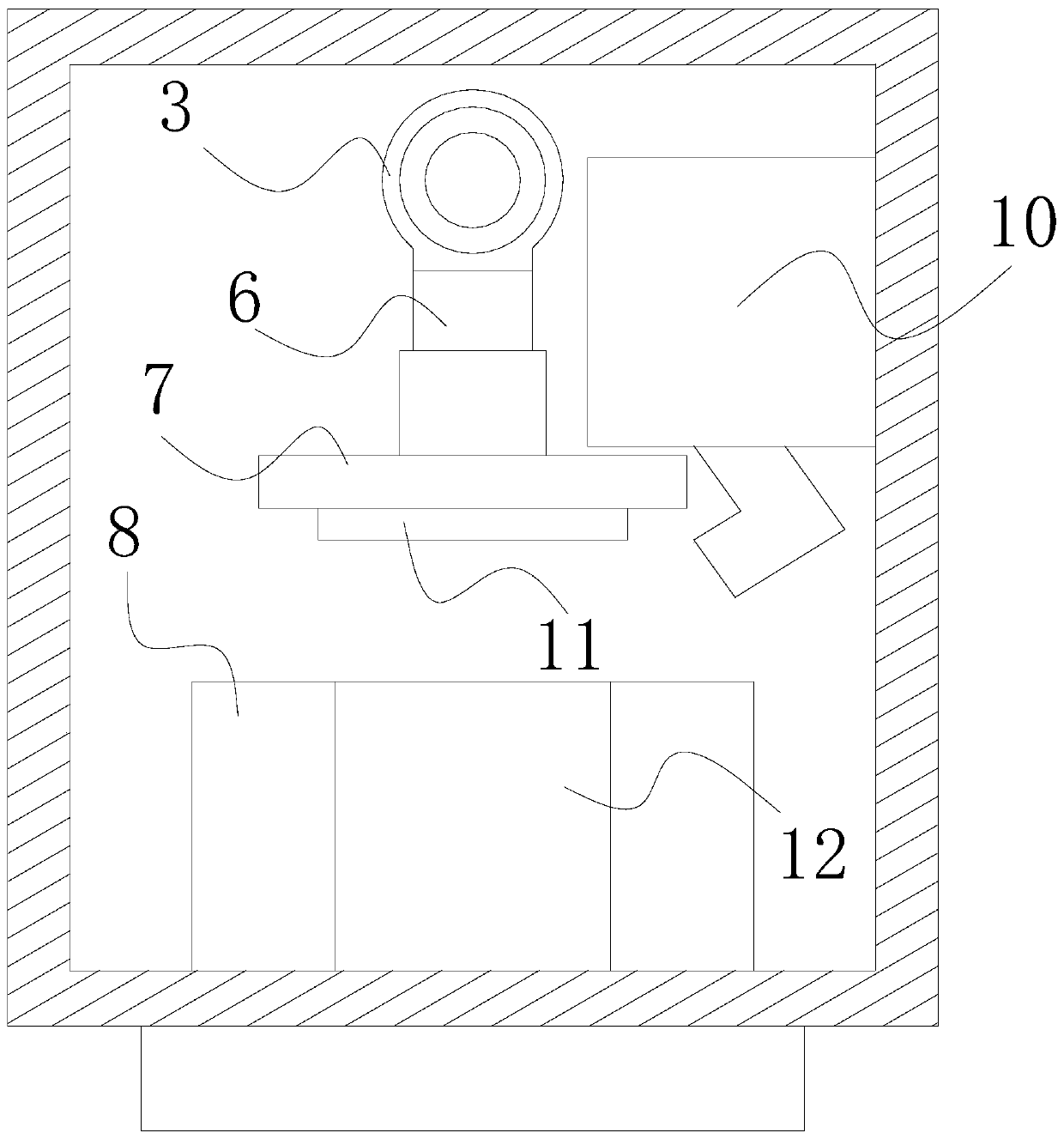

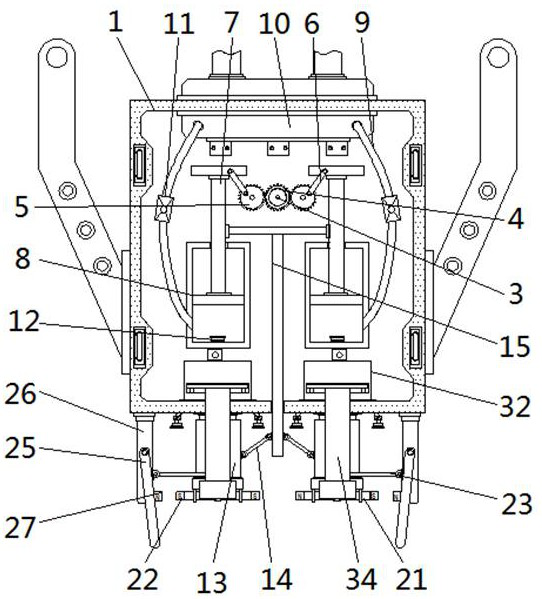

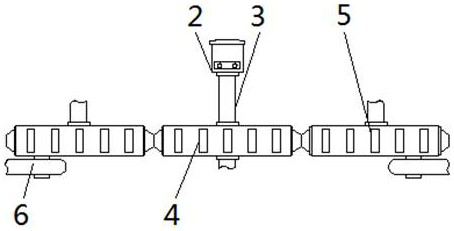

The invention belongs to the field of optical automation test and especially relates to a large-size optical film automatic feeding device which comprises a base, a feeding mechanism, an absorbing mechanism, a transporting mechanism and a control mechanism. The base is used for carrying the feeding mechanism above the base, and the feeding mechanism is arranged on the base so as to carry optical films and transmit the optical films to a first working station. The absorbing mechanism which can move up and down is arranged above the first working station so as to absorb the optical films in thefeeding mechanism and transmit the absorbed optical films to a second working station. The transporting mechanism which can move up and down is arranged at the rear end of the absorbing mechanism so as to absorb the optical films on the second working station and transmit the absorbed optical films to a third working station. The control mechanism is electrically connected with the feeding mechanism, the absorbing mechanism and the transporting mechanism respectively. When in use, operators only need to place stacked optical films on the feeding mechanism, bath feeding can be easily realized.The large-size optical film automatic feeding device is time-saving and labor-saving, high in working efficiency and smooth in operating process, and can be applied to assembly line work environment and has a broad market prospect.

Owner:SHENZHEN JINGCHUANG TECH CO LTD

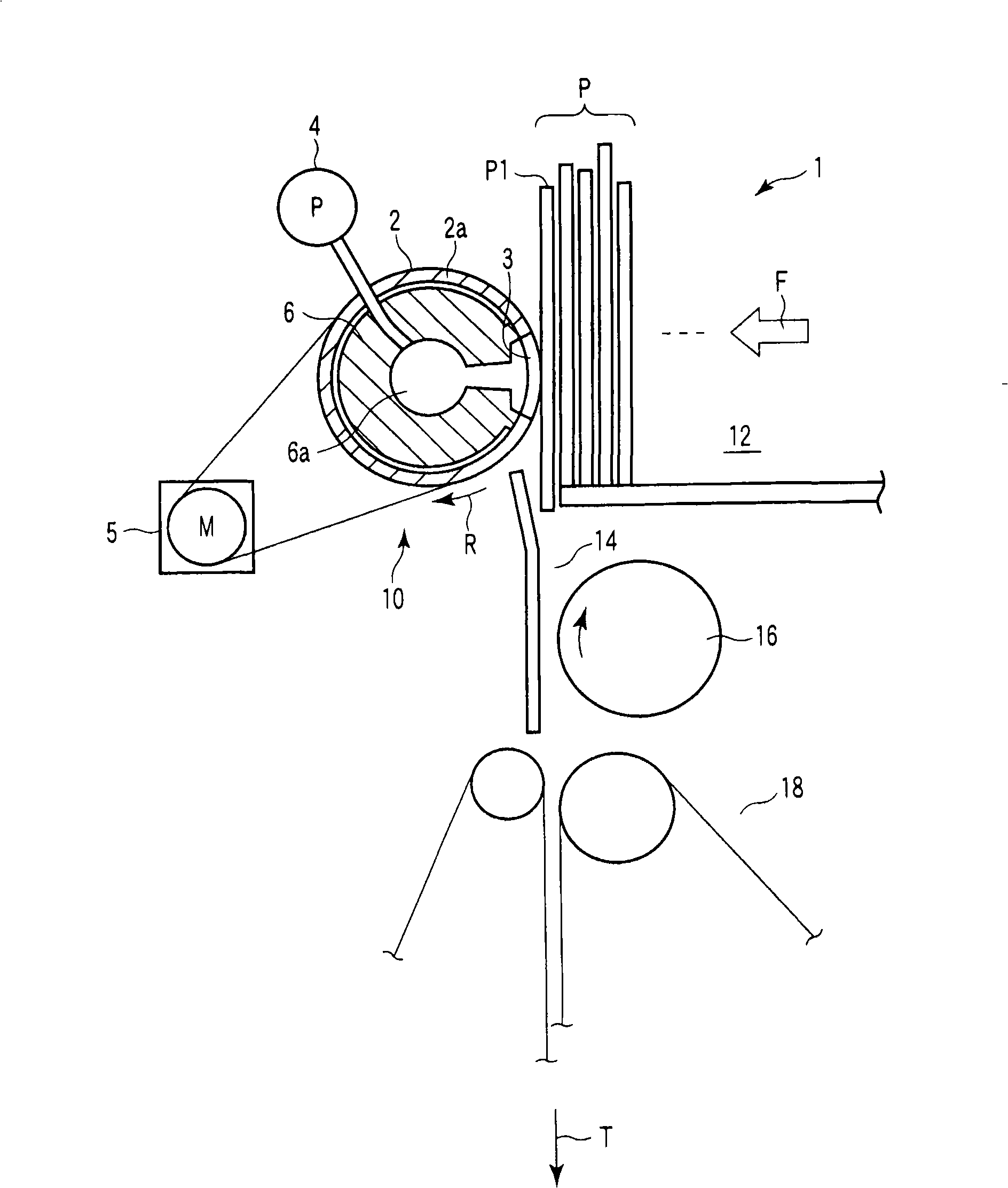

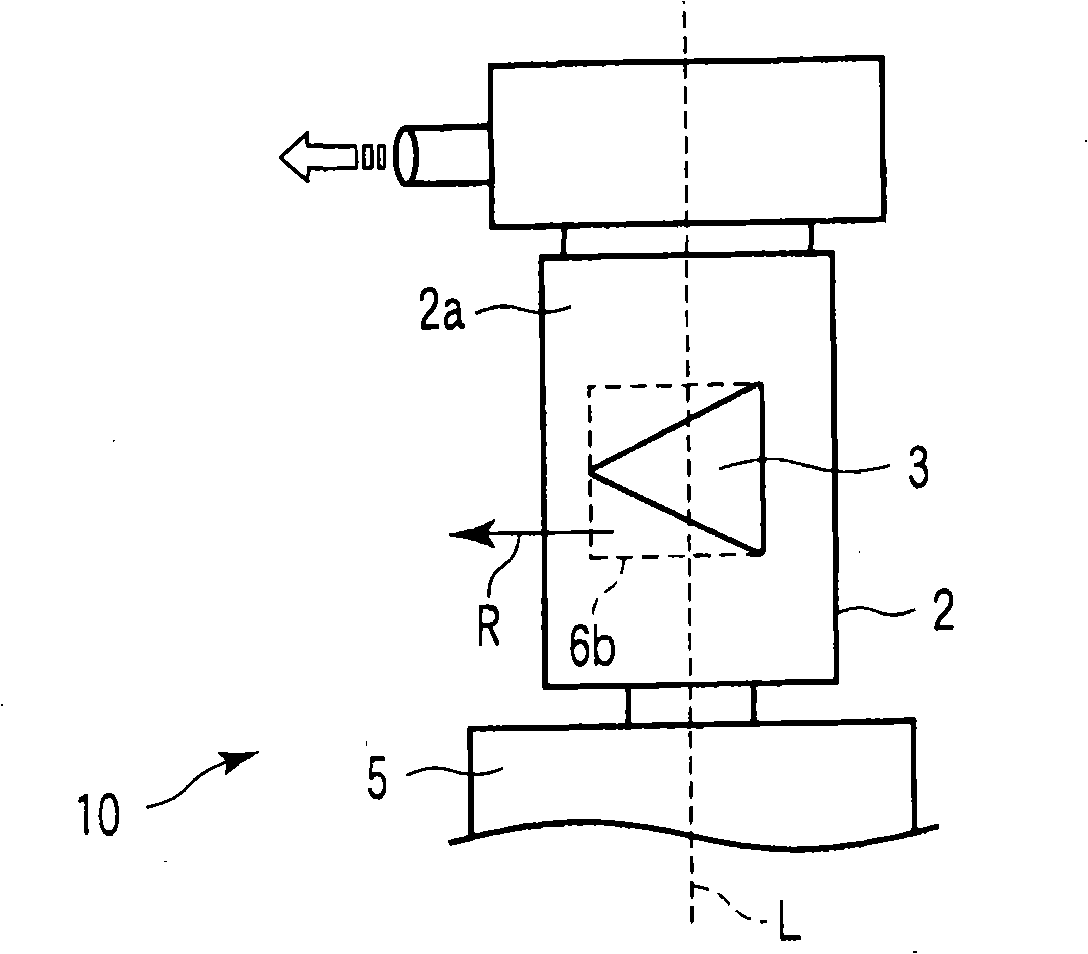

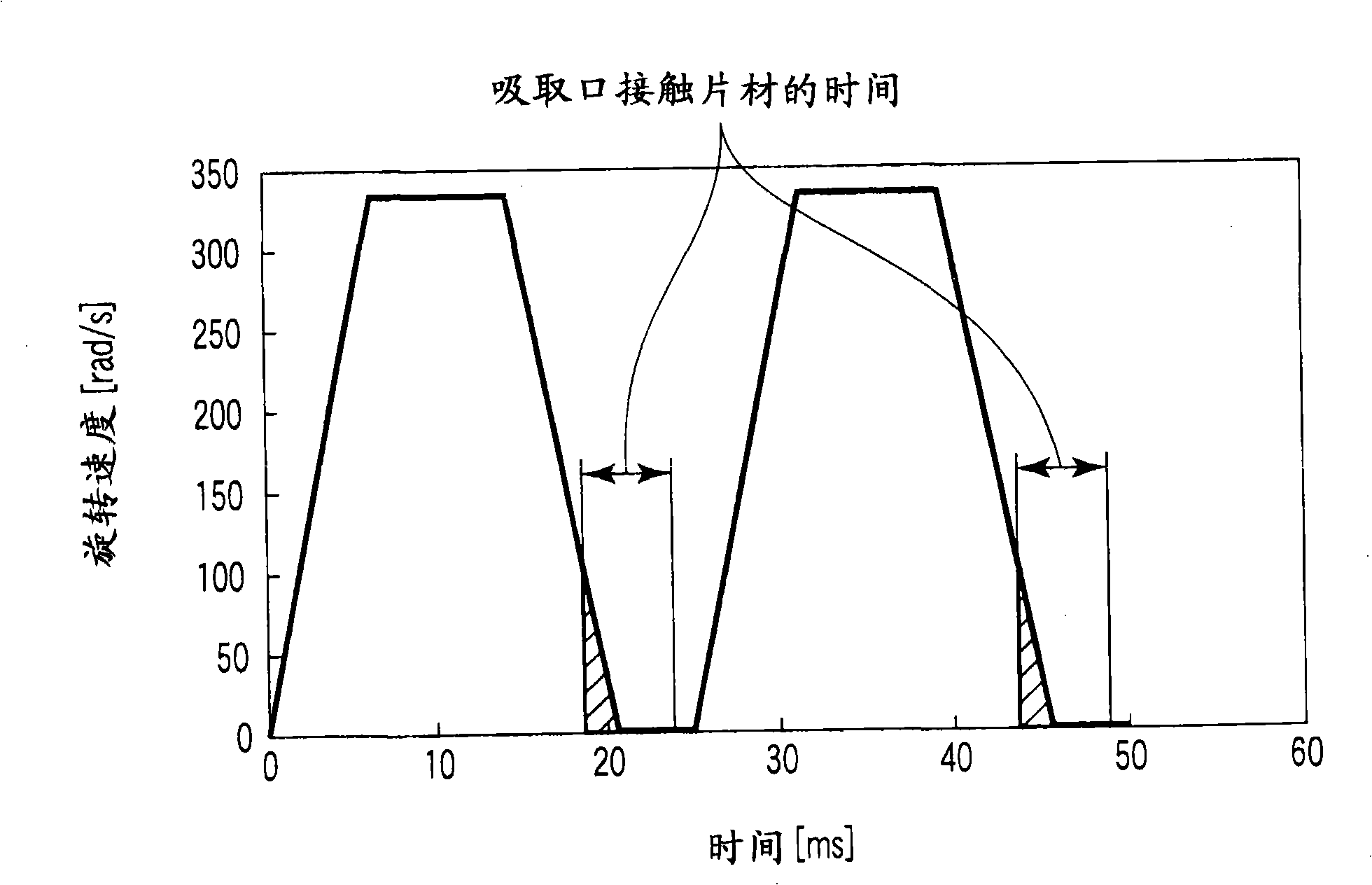

Sheet takeout device

A sheet takeout mechanism (10) has a takeout roller (2) that rotates in contact with a sheet located at a takeout position, and a motor (5) that intermittently rotates the takeout roller (2). A triangular suction port (3) is formed on a suction surface (2a) of the takeout roller (2) and has a vertex located downstream in a rotation direction (R) of the takeout roller (2). When a negative pressure is exerted on the sheet via the suction port (3), the suction force is weak at the beginning of suction and then increases gradually.

Owner:KK TOSHIBA

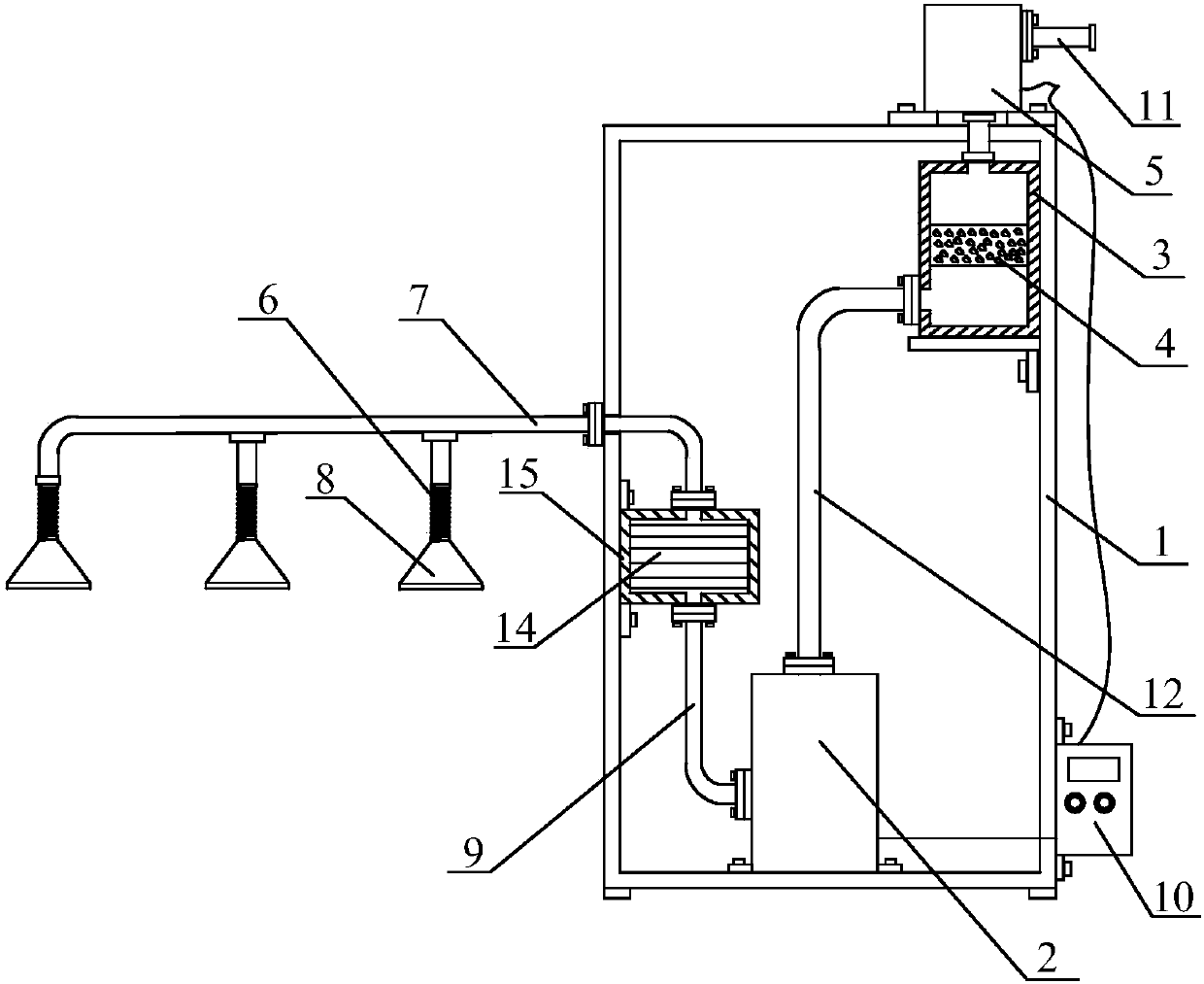

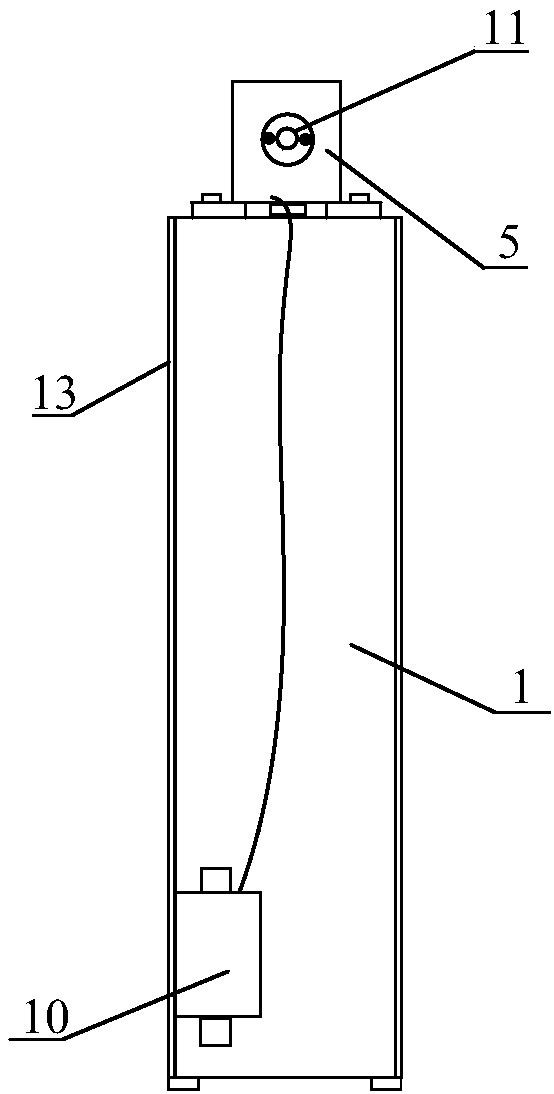

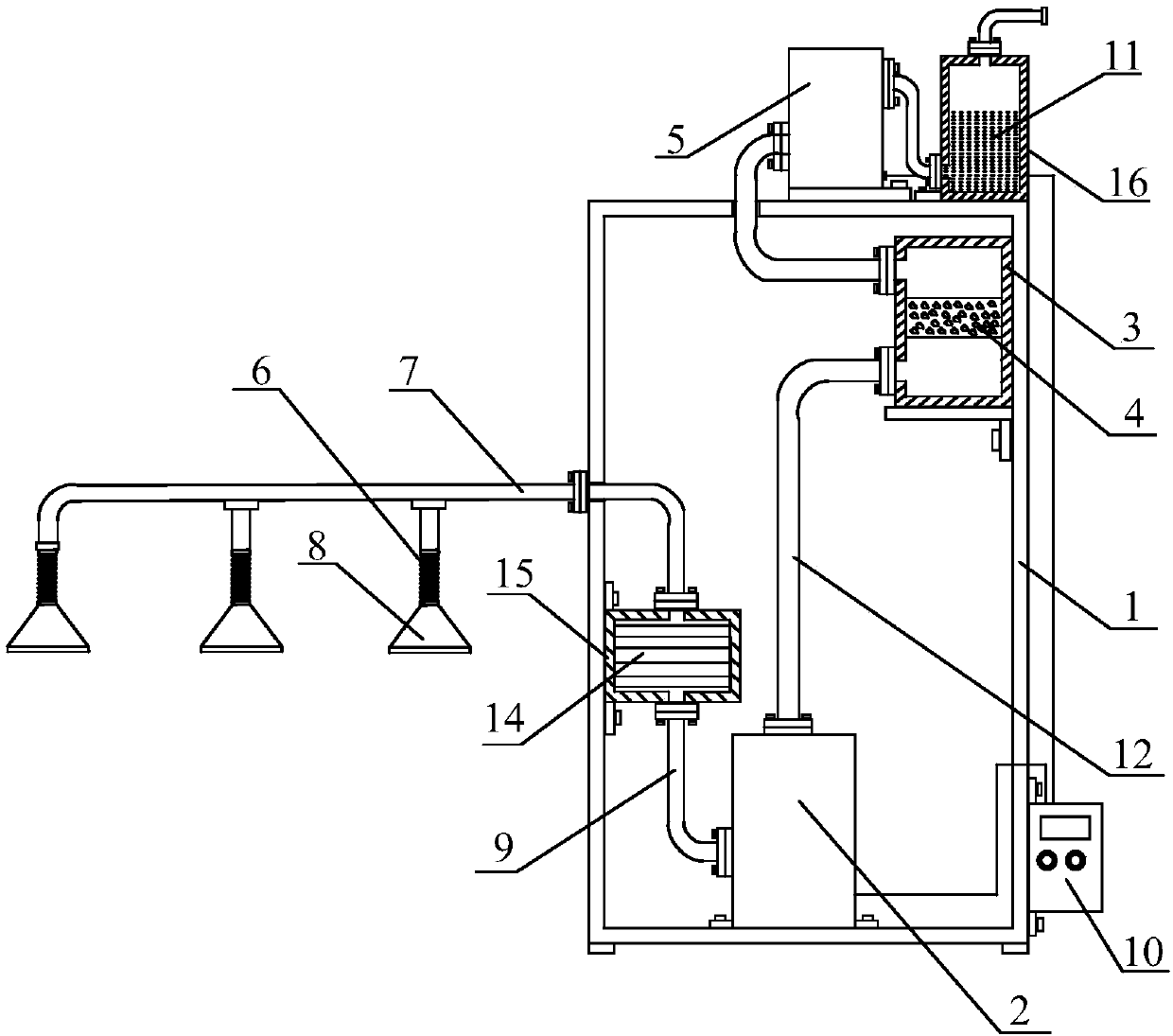

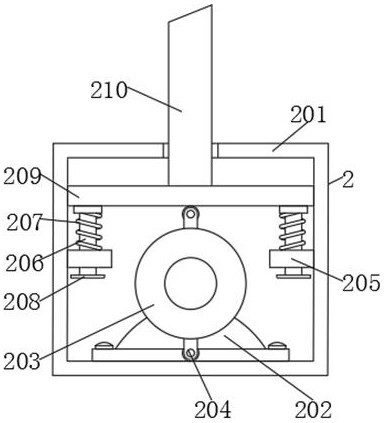

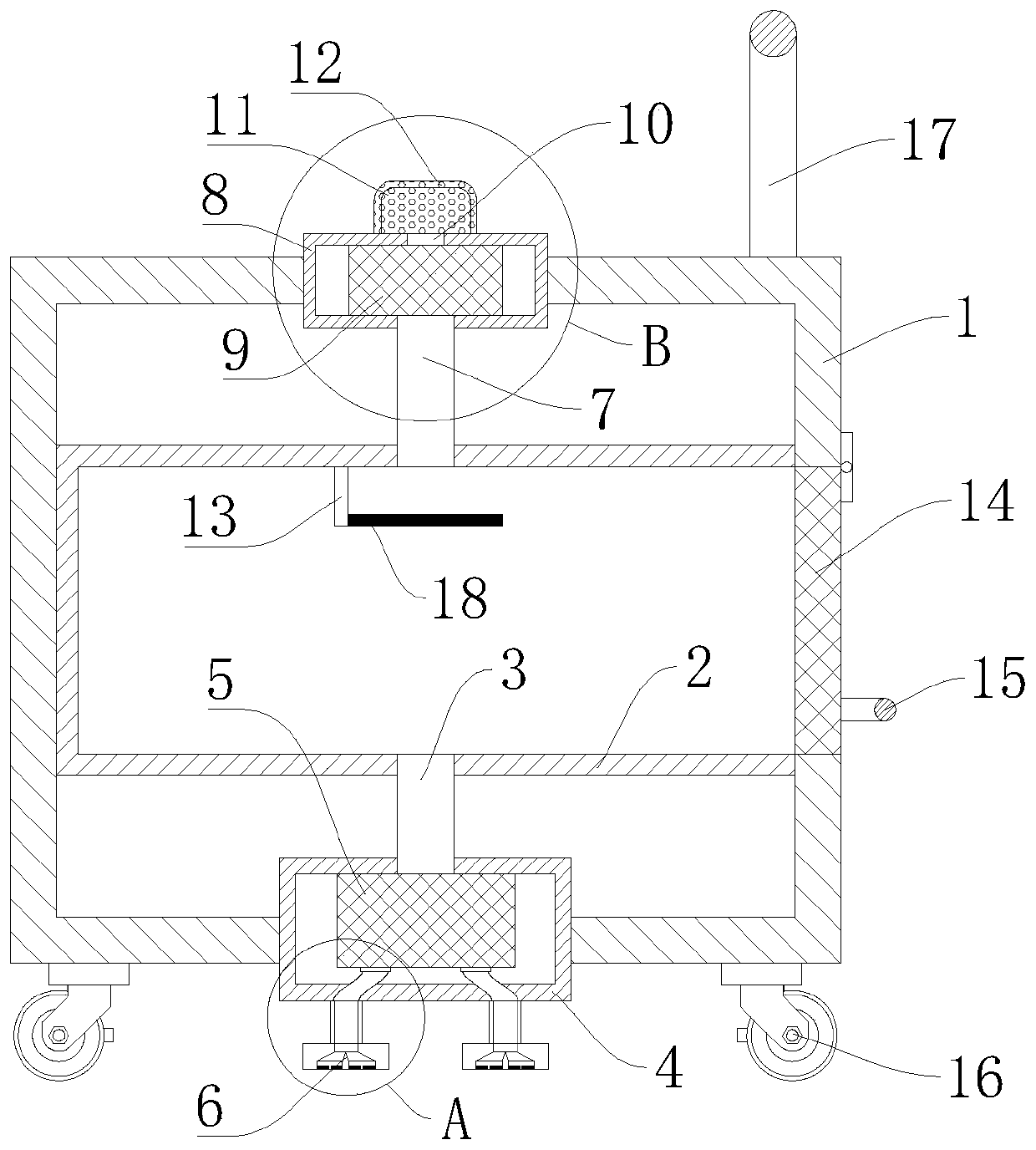

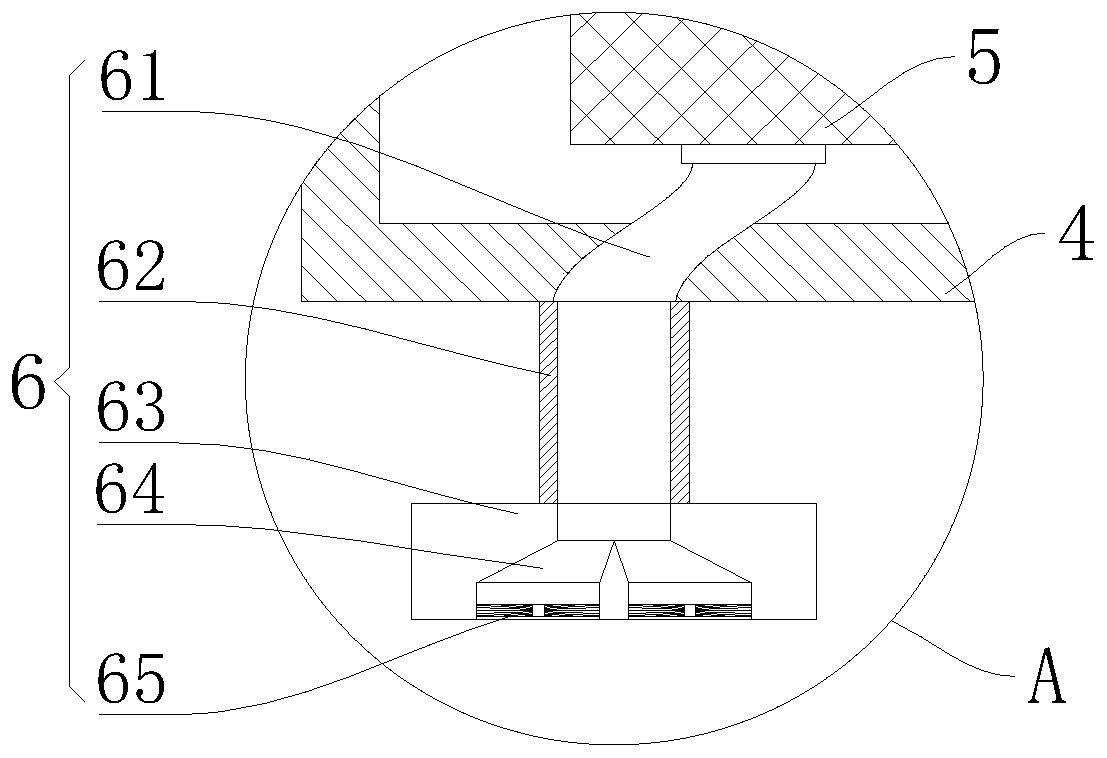

Electronic welding smoke emission equipment

InactiveCN107775137AGuaranteed stabilityEfficient absorptionDispersed particle filtrationSoldering auxillary devicesImpellerFlue gas

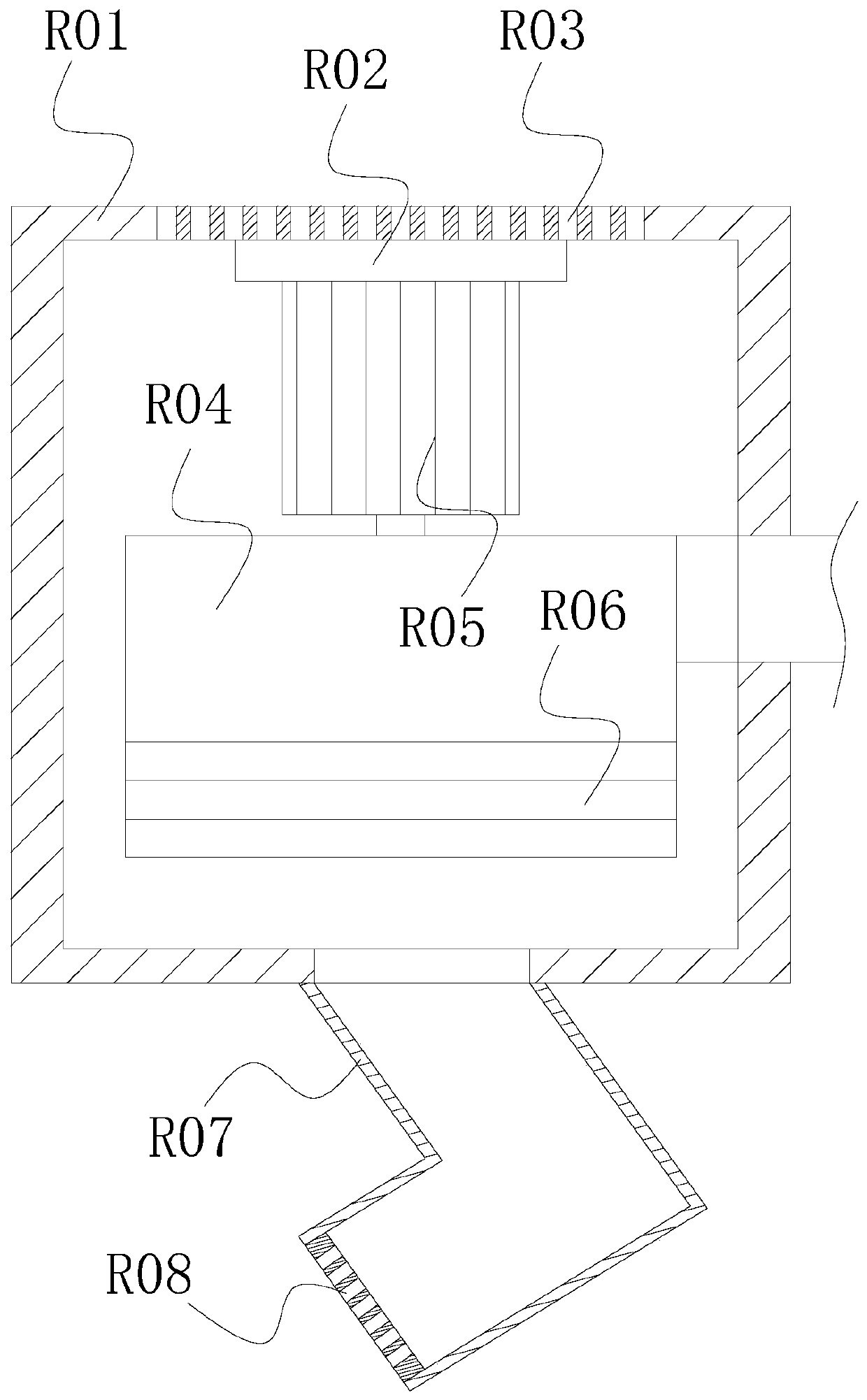

The invention discloses an electronic welding fume discharge device, which is characterized in that it comprises a bracket (1), an exhaust fan (2), a smoke filter device, a purification tank (3), an exhaust fan (5), an air suction device, and controller (10). The invention cooperates with the air suction device and the exhaust fan to effectively absorb the smoke generated by electronic welding; and the smoke filter device arranged between the air suction device and the exhaust fan can filter the dust particles in the electronic welding smoke Filtration is carried out to prevent the impeller of the exhaust fan from being polluted by dust, so that the load on the impeller is too large, which effectively ensures the stability of the exhaust fan; at the same time, the rosin component in the electronic welding fume is filtered through the set purification tank, so that The electronic welding fume is cleaner, so that the present invention can well solve the problem that the existing electronic welding fume equipment cannot purify the fume.

Owner:成都左右互动科技有限公司

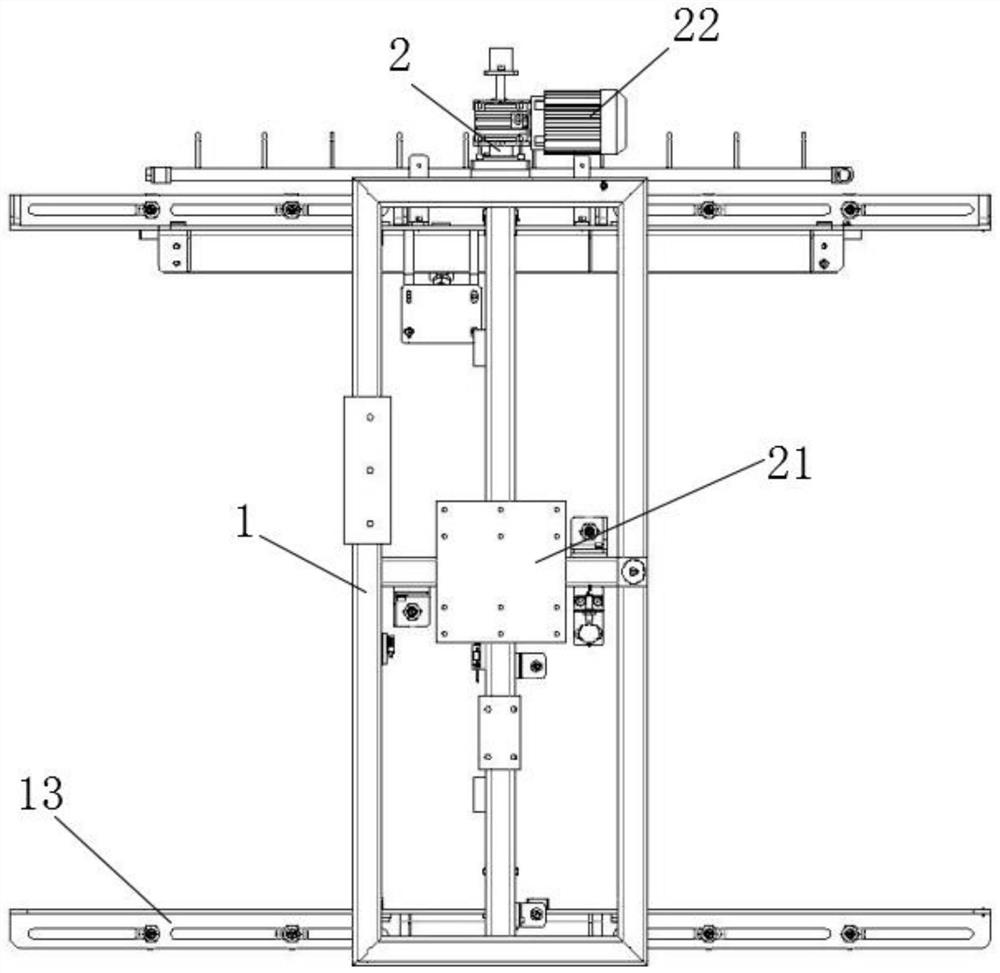

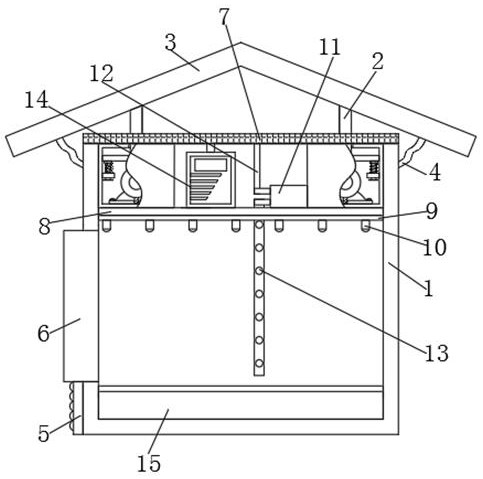

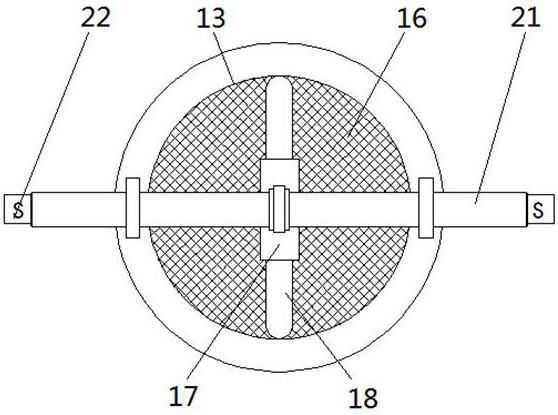

Sucking device driven by motor and capable of automatically regulating width as well as working method thereof

The invention discloses a sucking device driven by a motor and capable of automatically regulating width. The sucking device comprises a fixed frame, wherein the two ends of the bottom surface of thefixed frame are fixedly provided with two end bases separately; the middle positions of the two ends of the bottom surface of the fixed frame are provided with bearing bases; a screw is arranged between the two bearing bases; the two sides of the screw are separately provided with limiting rods; and the two ends of each limiting rod are separately arranged on the end bases. A hydraulic rod pulsesthe fixed frame to move upwards, and a gas cylinder controls a piston rod inside to move towards the outer side and the inner side of a cylinder body in a circulating mode in an upward moving process,so that the piston rod drives the rotary rod to rotate back and forth, and a second placing plate rotates back and forth to form plate shaking; meanwhile, a gas blowing tube blows gas to plates, so that the gas enters the two plates to realize separating work of plates which are stuck together, and therefore, multiple plates are prevented from being sucked once during sucking, and follow-up processing of the plates is convenient.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

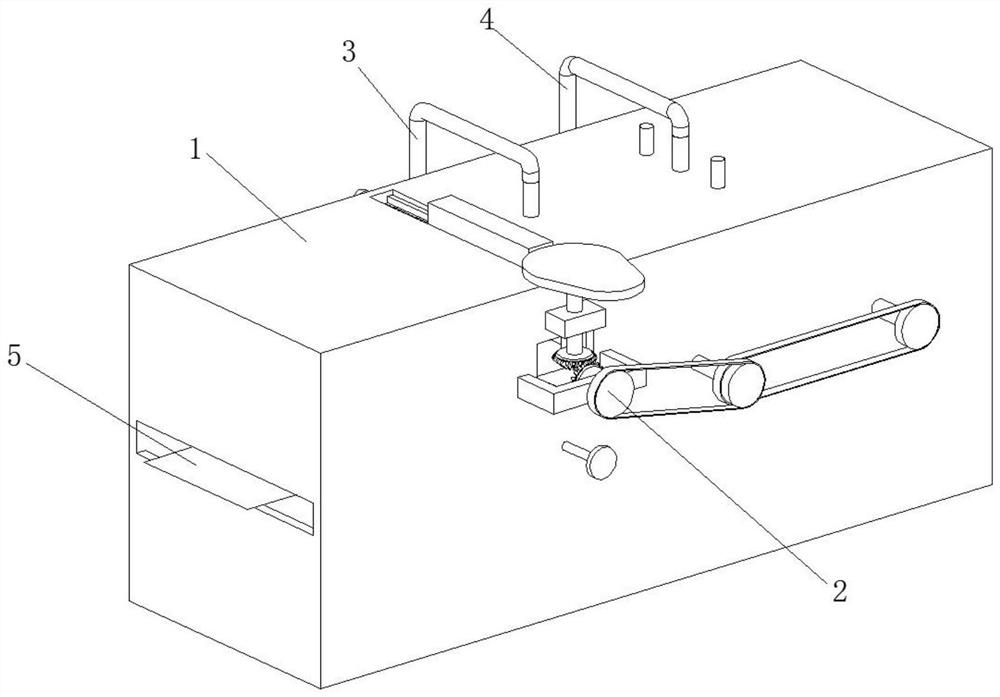

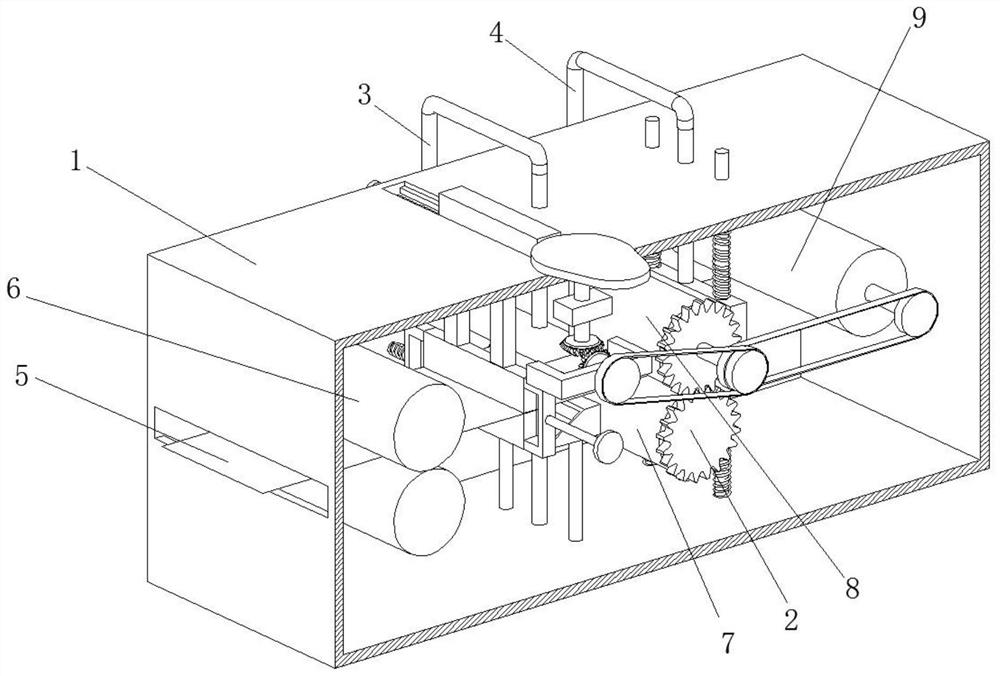

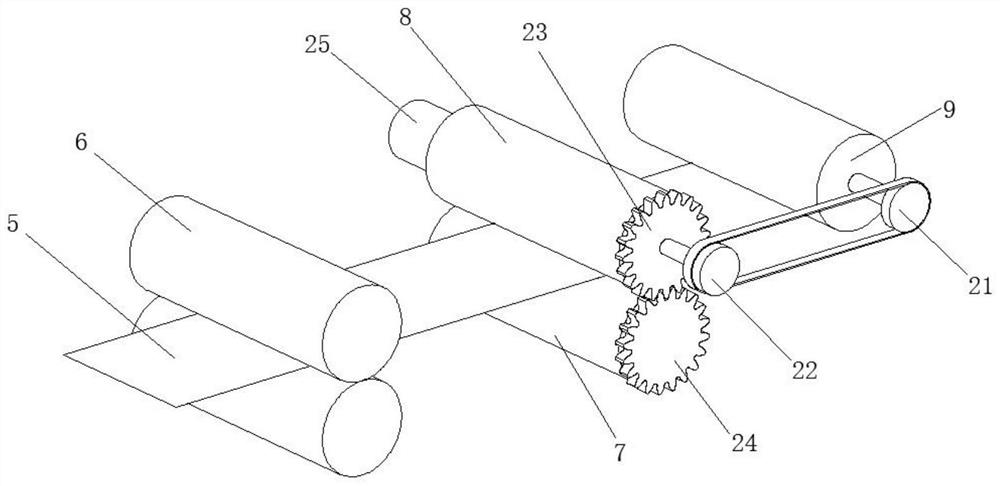

Textile device capable of conveniently flattening and rolling textile fabric

PendingCN112141775AAchieve cleanupAvoid dirtMechanical cleaningPressure cleaningTextile technologyMechanical engineering

The invention relates to the technical field of textiles, and discloses a textile device capable of conveniently flattening and rolling textile fabric. The textile device comprises a box body, whereina transmission mechanism is arranged on the right side of the box body, a dust collection mechanism and an ironing mechanism are correspondingly arranged on the left side of the box body, and the dust collection mechanism is located in front of the ironing mechanism; and a transmission roller, a lower roller, an upper roller and a rolling roller are rotationally connected to the inner wall of thebox body, wherein the rolling roller is located behind the transmission roller, and cloth is movably connected to the surfaces of the transmission roller, the lower roller, the upper roller and the rolling roller. According to the textile device capable of conveniently flattening and rolling the textile fabric, through cooperated operation between the transmission mechanism and the dust collection mechanism, the cloth can be cleaned, so that the cloth is prevented from being rolled together with dust during rolling, and the cloth is further prevented from being contaminated; and in addition,the cloth with wrinkles can be ironed by the ironing mechanism, so that the situations that finished cloth is uneven and then unqualified products are produced due to the fact that the cloth with thewrinkles get rolled are prevented.

Owner:ZHEJIANG MEILAIYA TEXTILE

Electroplating unit capable of efficiently cleaning electroplated parts

The invention discloses an electroplating unit capable of efficiently cleaning electroplated parts. The electroplating unit comprises a hollow shell. A transverse partition board is arranged in the shell and divides the interior of the shell into an electroplating cavity and a water storage cavity. The electroplating cavity is located over the water storage cavity. The partition board is providedwith a containing groove with an upward opening. The partition board is provided with a plurality of through holes. The sidewall of one side of the shell is provided with a feed port. A cover plate isrotatably connected to an opening of the feed port. The sidewall of the cover plate is provided with a handle. A first air cylinder is fixedly connected to the inner wall of the upper side of the electroplating cavity. The output end of the first air cylinder is connected with a first piston rod. The end, far away from the first air cylinder, of the first piston rod is fixedly connected with a fixed plate. Connecting plates are symmetrically and fixedly connected to the sidewall of the lower side of the fixed plate. The electroplating unit is easy to operate and convenient to use. A water source for cleaning electroplated parts and processing plates is repeatedly used. Water is saved. The production cost is reduced.

Owner:陈海霞

Cell lysis buffer, kit and method for yeast genome extraction

PendingCN113265397AShorten the lysis timeGood effectDNA preparationGuanidine isothiocyanateThiocyanic acid

The invention relates to the technical field of DNA extraction, and provides a cell lysis buffer, a kit and a method for yeast genome extraction. The cell lysis buffer for extracting the yeast genome is prepared from the following components: 50 to 60 g / L of guanidine isothiocyanate, 1 to 10 g / L of Tris-base, 8 to 15 g / L of EDTA.2Na and 1 to 10 percent of Tween-20. Compared with the prior art, the yeast genome extraction kit provided by the invention is time-saving, labor-saving and thorough in cell lysis, chloroform is not used in the experiment process, the harm to experiment operators is reduced, and the extracted genome is high in yield and can be directly used for subsequent experiments, and does not need to be purified.

Owner:JIERUI BIOENG SHANGHAI

Online thermosensitive adhesive tape gluer device with gluing effect guaranteed easily

The invention discloses an online thermosensitive adhesive tape gluer device with the gluing effect guaranteed easily. The device comprises a framework. A traction machine is mounted at the left end of the interior of the framework, and adhesive tape unwinding bars are arranged on the lower side of the traction machine; and in addition, moving wheels are mounted at the lower end of the framework,and an adhesive tape conveying device is mounted on the upper-right side of the traction machine. Adhesive tape thin film winding bars are arranged on the lower side of the adhesive tape unwinding bars, and an adhesive tape storage support is arranged on the right side of the adhesive tape thin film winding bars. A driving roller group is arranged on the right side of the upper portion of the adhesive tape storage support. According to the online thermosensitive adhesive tape gluer device with the gluing effect guaranteed easily, the temperature of a rubber strip can be guaranteed to be the same before the rubber strip is heated by a heat gun, and accordingly, the effect for gluing the thermosensitive adhesive tape to the rubber strip is guaranteed; and in addition, exchanging of air inside and outside of the device can be reduced, the situation that the rubber strip temperature is not uniform due to exchanging of the air inside and outside of the device can be reduced, and the effectfor gluing the thermosensitive adhesive tape to the rubber strip can be further guaranteed easily.

Owner:青岛瑞鹏机电设备有限公司

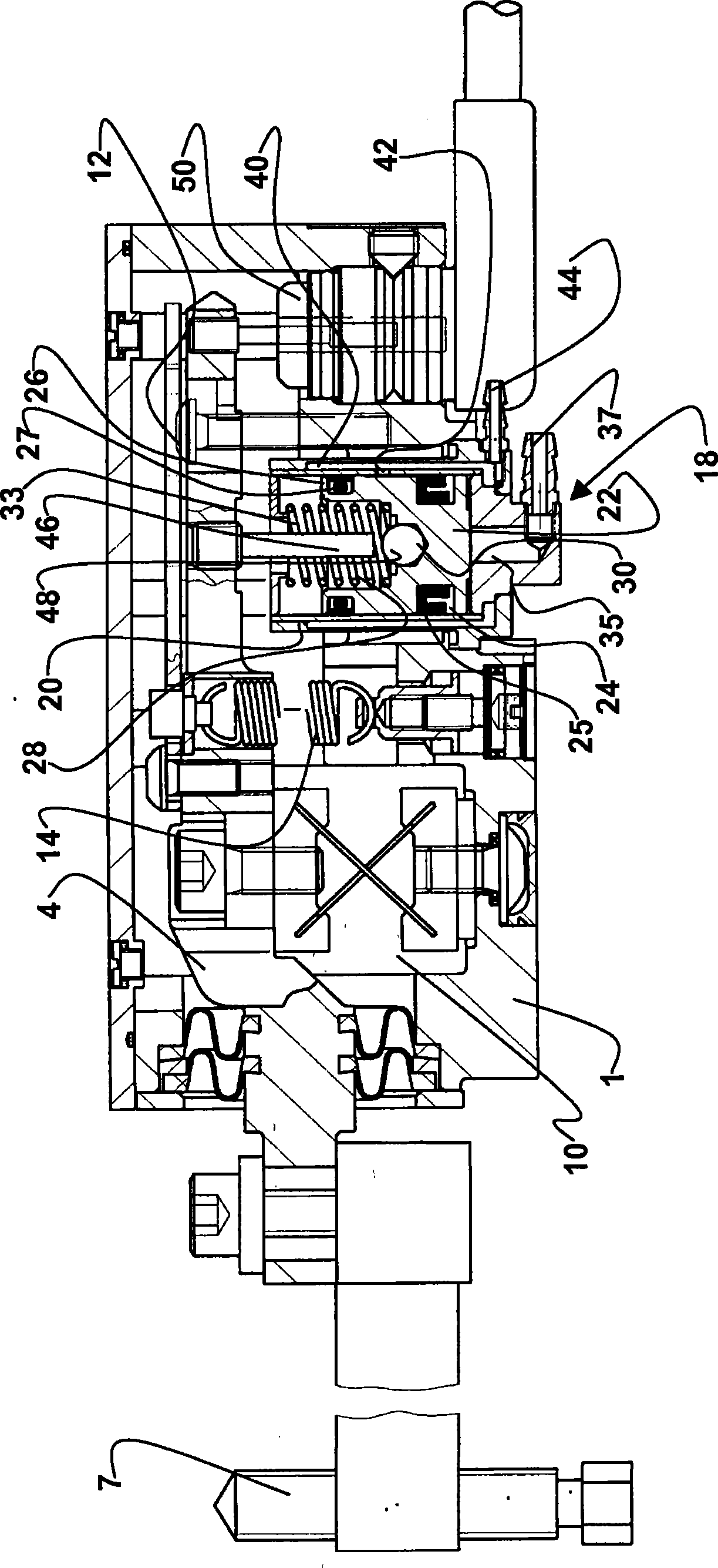

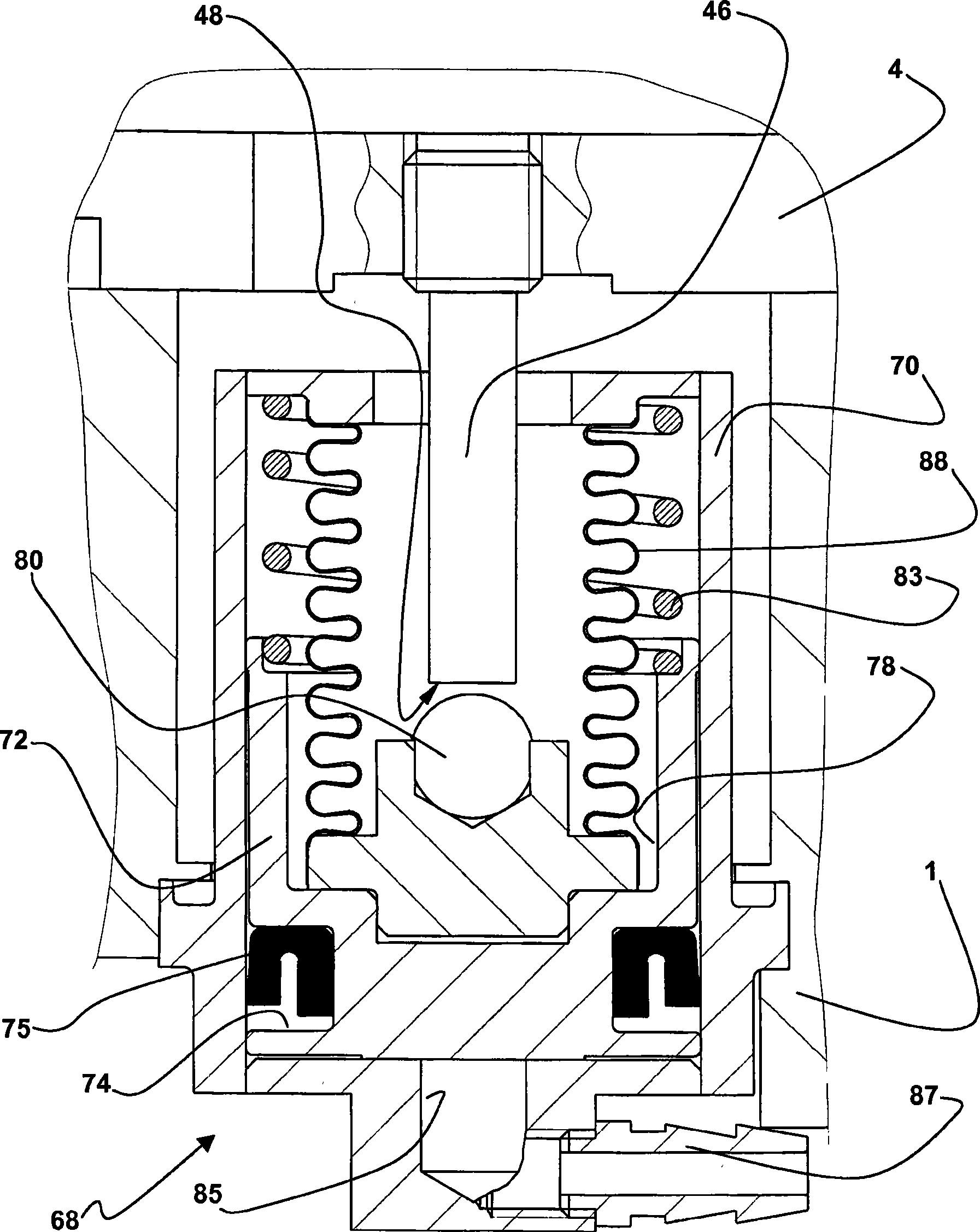

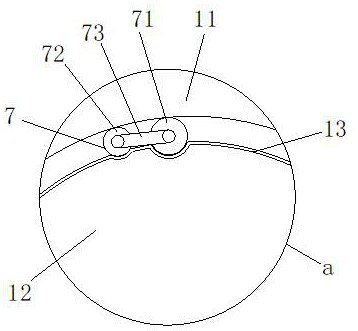

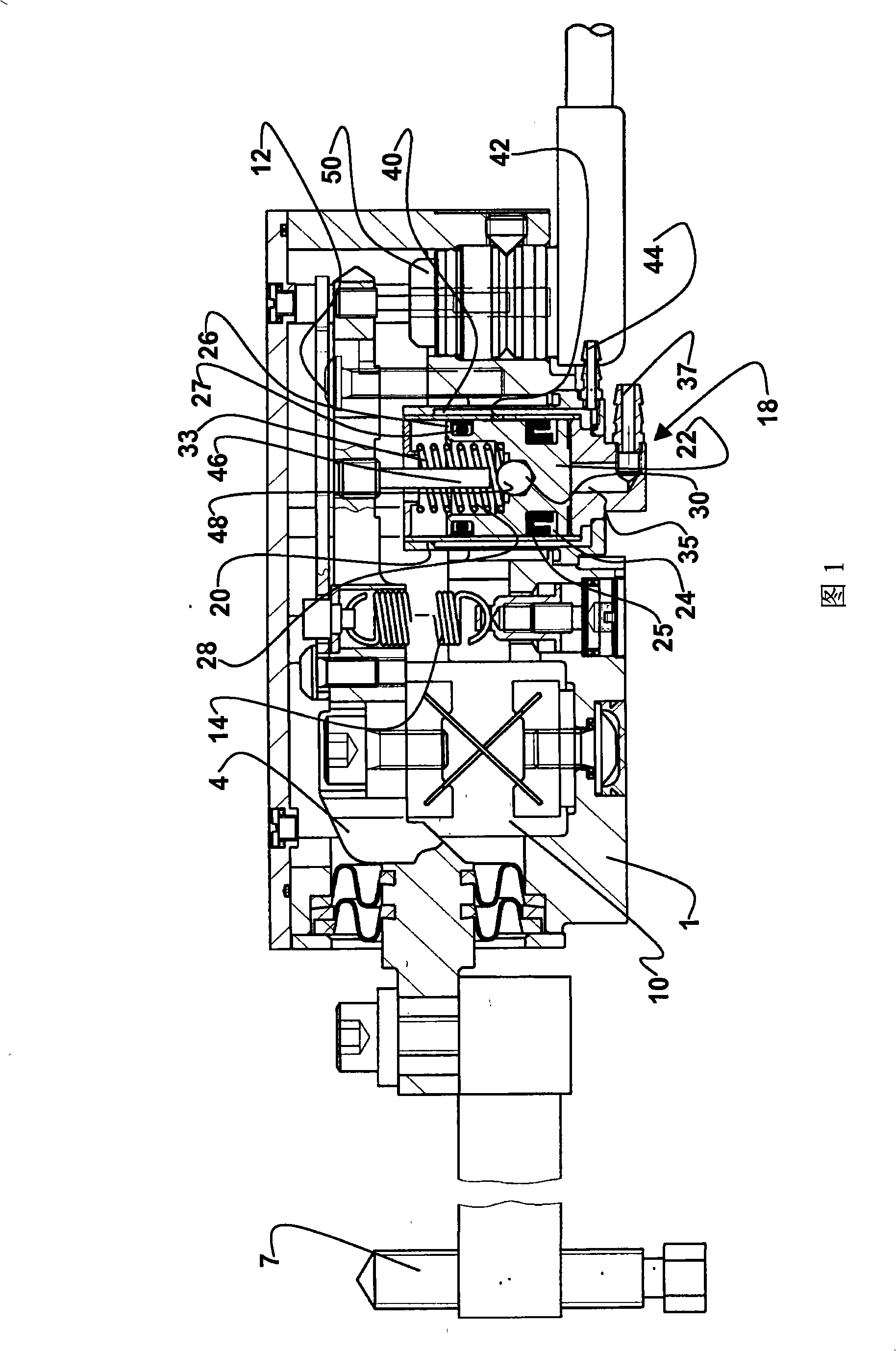

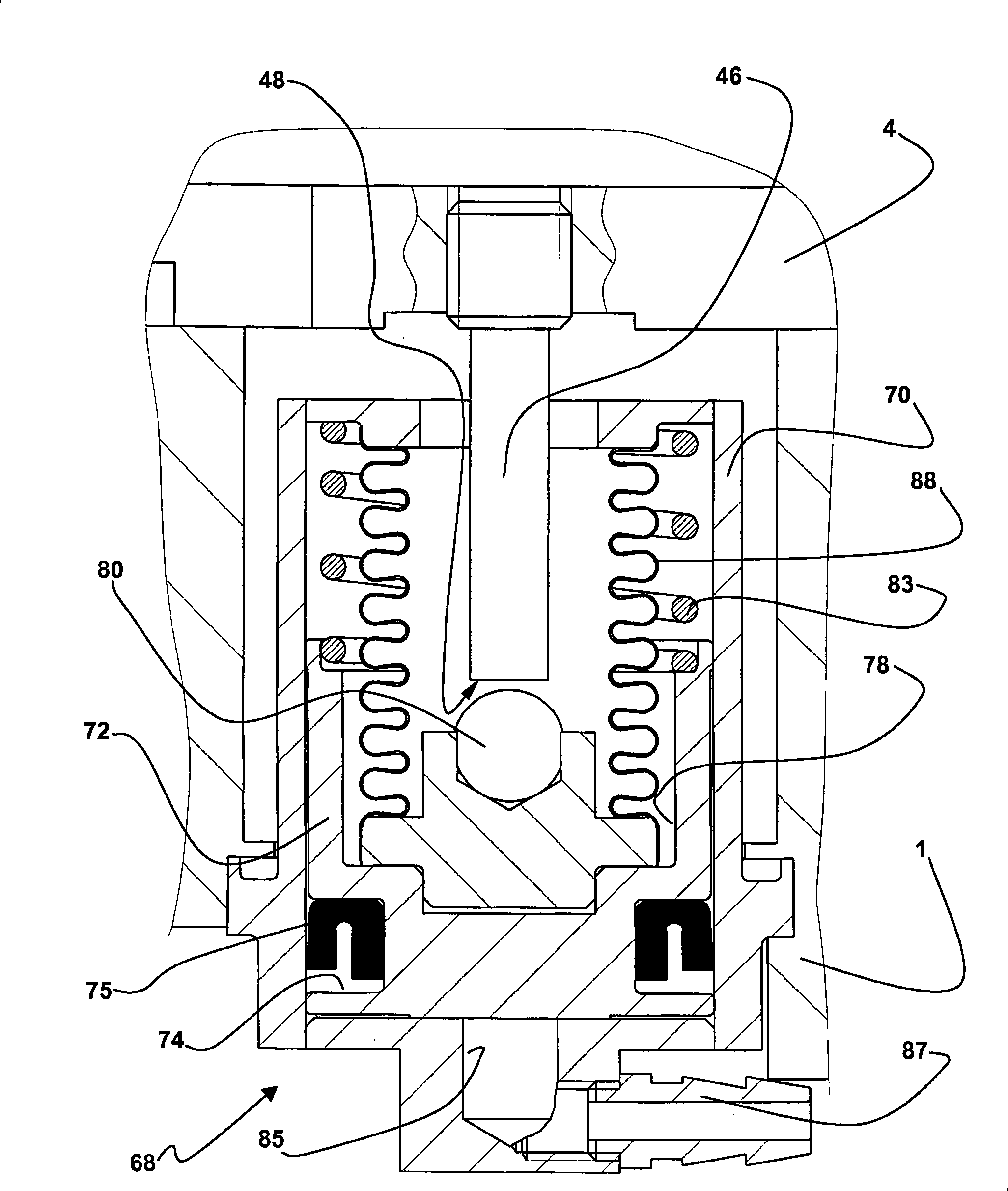

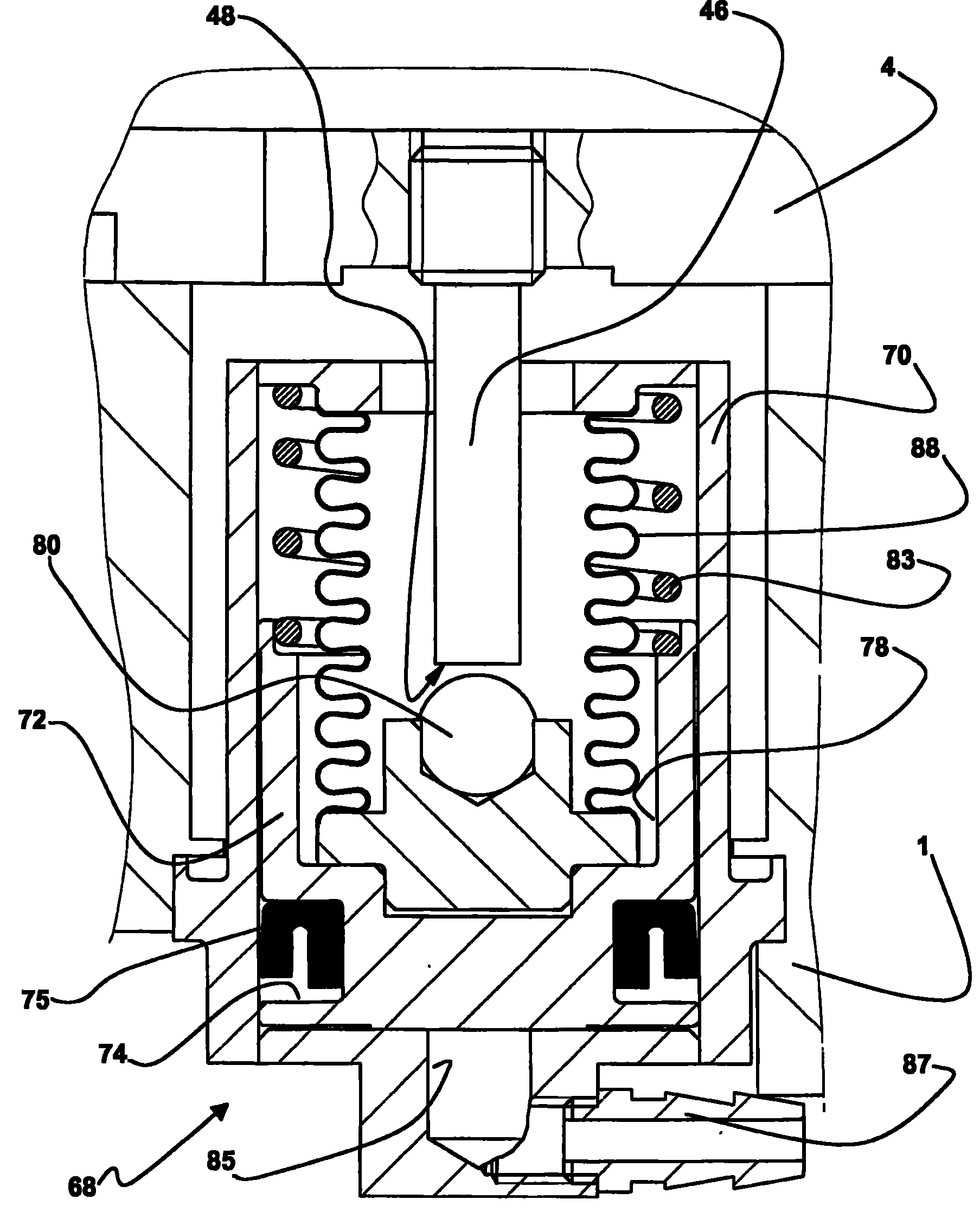

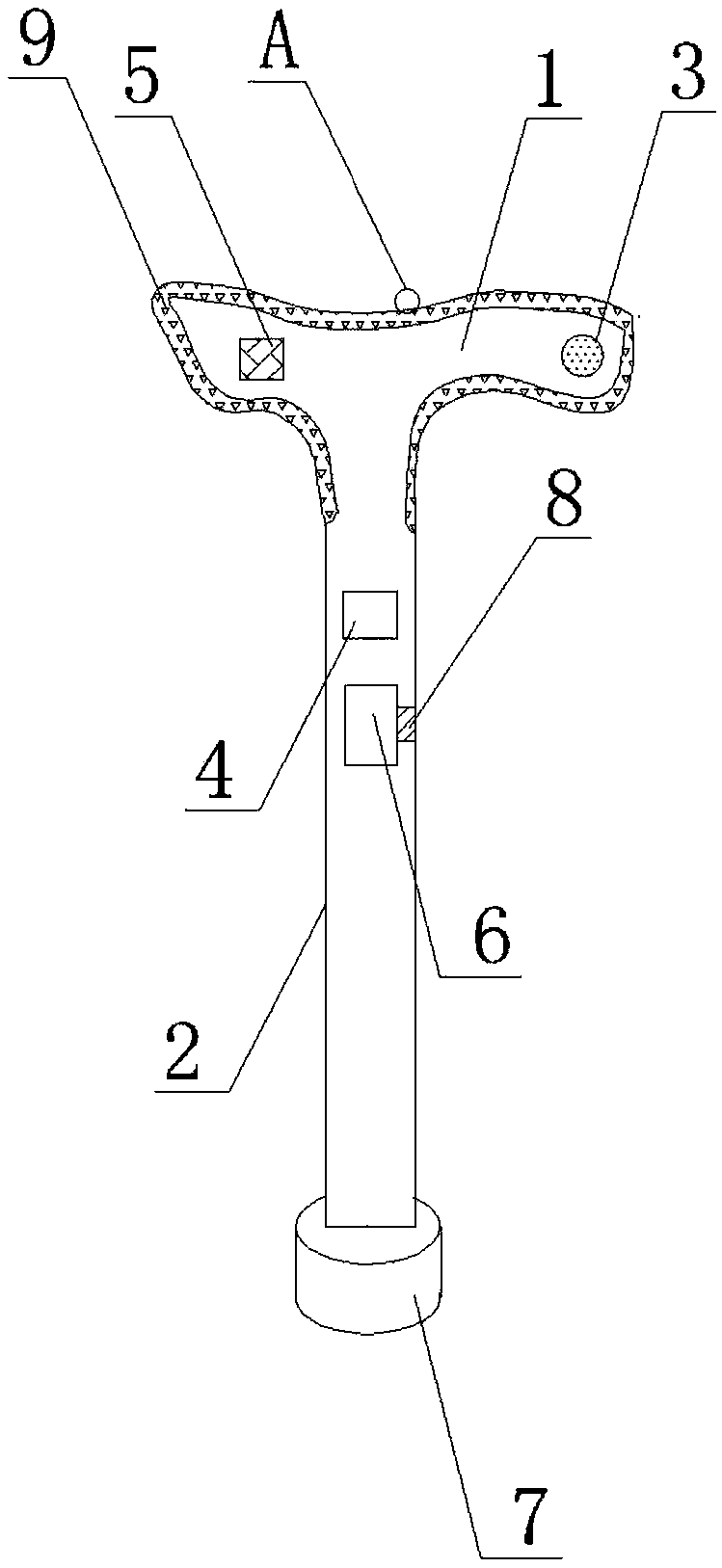

Head for checking linear dimensions of mechanical pieces

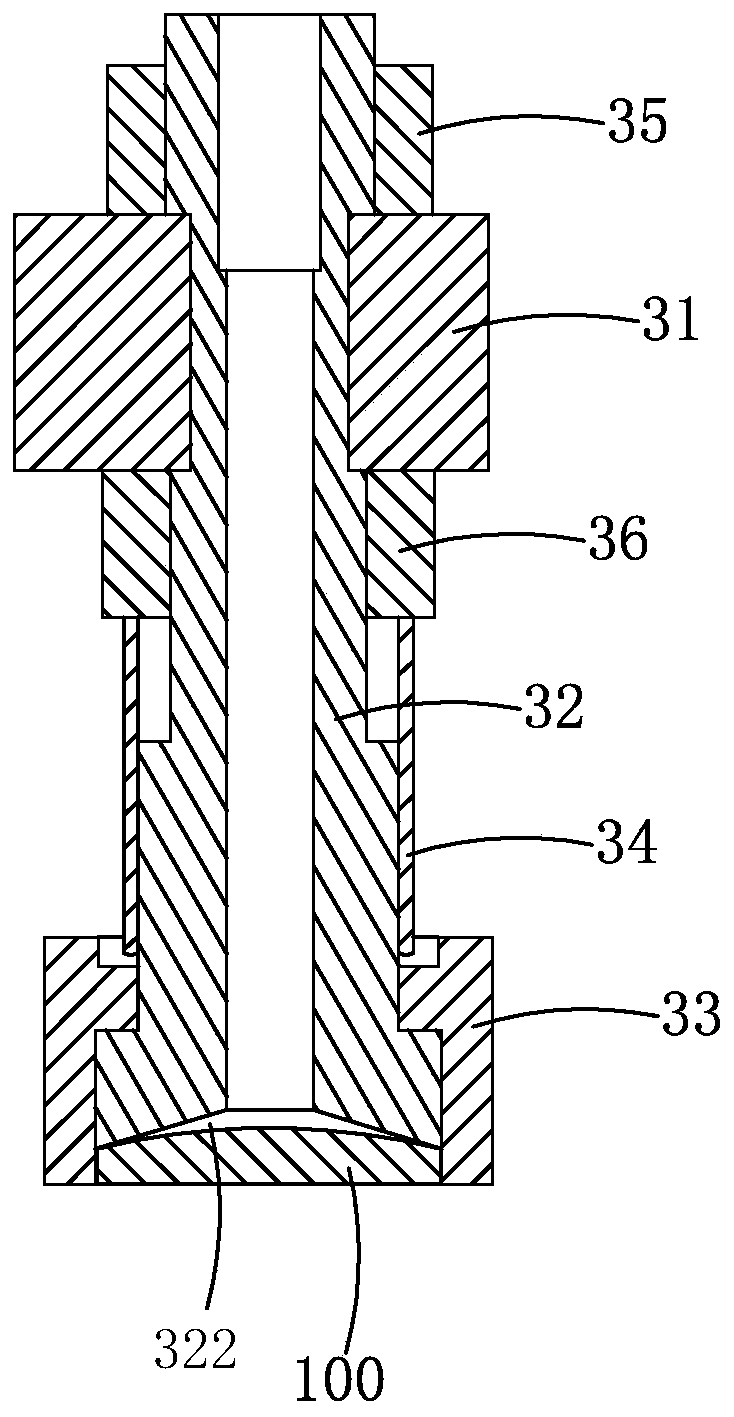

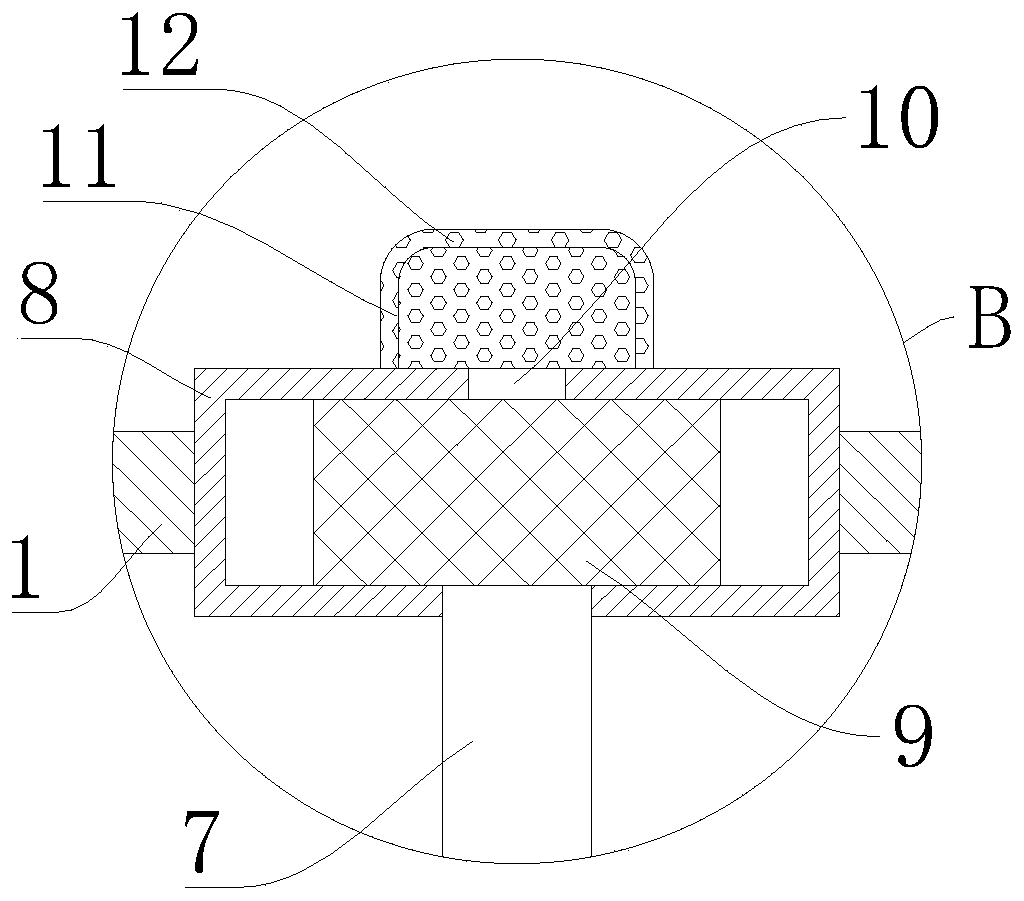

ActiveCN101506613AInterfere with normal operationAvoid absorbingUsing electrical meansMechanical measuring arrangementsTransducerEngineering

A gauging or measuring head for checking linear dimensions of mechanical pieces includes a casing (1), a movable arm (4) carrying a feeler (7), a fulcrum (10), coupled to the casing and the arm for enabling arm displacements with respect to the casing, a retraction device (68) with a cylinder (70) coupled to the casing and a piston (72) which slides therein for urging the arm to a definite inoperative position, and a position transducer (50) that provides signals depending on the position of the arm with respect to the casing. The retraction device includes a bellows gasket (88), which is housed in the cylinder and has its ends fixed to the cylinder and the piston.

Owner:MARPOSS SPA

Smog emission device with smoke filtering and smoke diluting treatment

InactiveCN107789976AGuaranteed stabilityEfficient absorptionGas treatmentDispersed particle separationImpellerFlue gas

The invention discloses a smoke discharge device with flue gas filtering and flue gas dilution treatment, which is characterized in that it comprises a bracket (1), an exhaust fan (2), a flue gas filtering device, a dilution tank, a purification tank (3), Exhaust fan (5), suction device, and controller (10). The invention cooperates with the air suction device and the exhaust fan to effectively absorb the smoke generated by electronic welding; and the smoke filter device arranged between the air suction device and the exhaust fan can filter the dust particles in the electronic welding smoke Filtration is carried out to prevent the impeller of the exhaust fan from being polluted by dust, so that the load on the impeller is too large, which effectively ensures the stability of the exhaust fan; at the same time, the rosin component in the electronic welding fume is filtered through the set purification tank, so that The electronic welding fume is cleaner, so that the present invention can well solve the problem that the existing electronic welding fume equipment cannot purify the fume.

Owner:成都左右互动科技有限公司

Flaky inductance tin soldering equipment

PendingCN111318779AAvoid absorbingPlay a limiting roleDispersed particle filtrationMetal working apparatusToxic gasHydraulic cylinder

The invention discloses flaky inductance tin soldering equipment which structurally comprises an efficient energy-saving motor, a machine body, a mounting sleeve, a finished product placing cylinder,a screw rod, a hydraulic cylinder, a cooling device, a solder pot, a nut pair, a smog absorbing and purifying device, an electromagnetic panel, and a to-be-welded tin piece placing cylinder, wherein the solder pot is fixed in the center of the internal bottom surface of the machine body. Compared with the prior art, the flaky inductance tin soldering equipment has the following benefits: two conveyor belts capable of driving in opposite directions are utilized, and separating pieces are arranged on the conveyor belts, so that a plurality of to-be-welded tin flaky inductance placing grids are formed between the two conveyor belts; to-be-welded tin flaky inductance can be separately placed and conveyed one by one; the electromagnetic panel can attract one to-be-welded tin piece each time andcan absorb and carry out purified treatment on the smog generated during the tin soldering operation, so that the situation that an operator absorbs toxic gas during operation to thread the body health is prevented, improvement of the operating safety is facilitated and the operating environment is improved; and the cooling device is arranged to fast cool the flaky inductance after tin soldering.

Owner:张永成

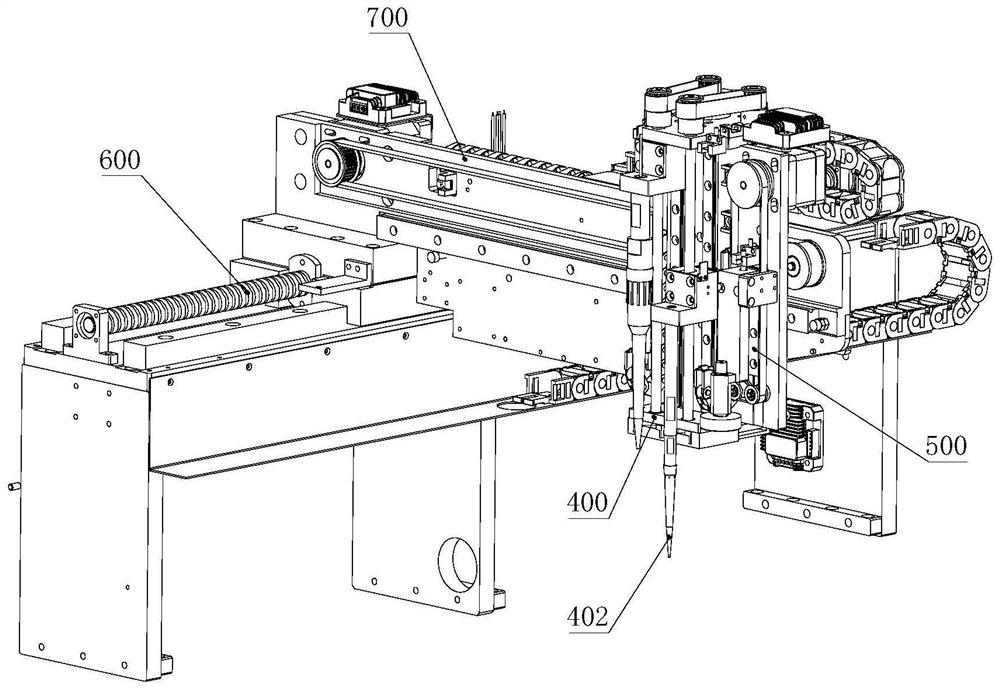

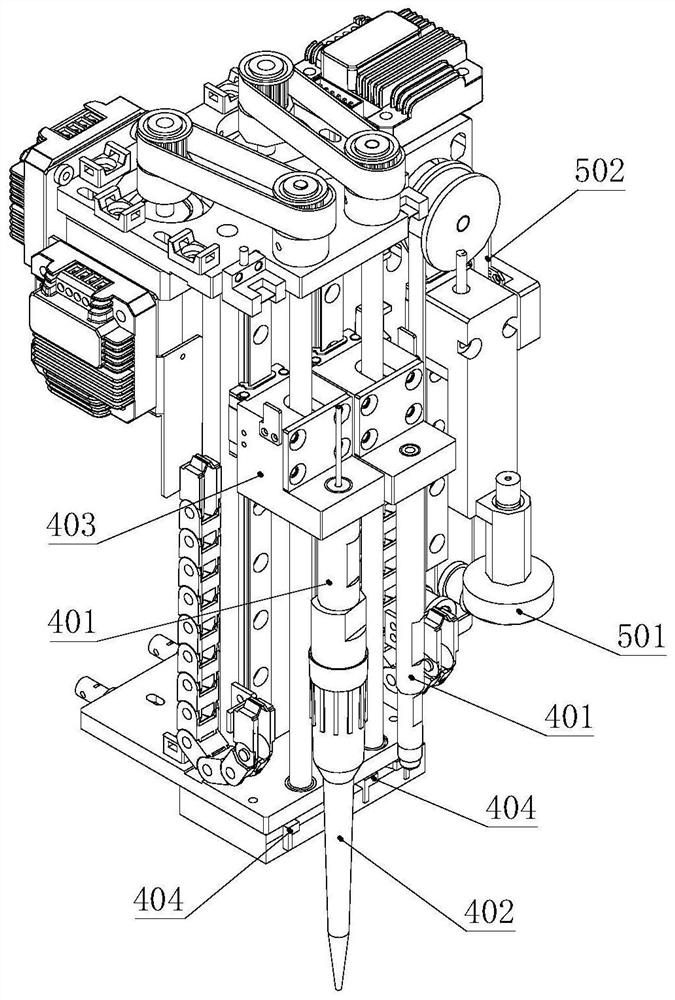

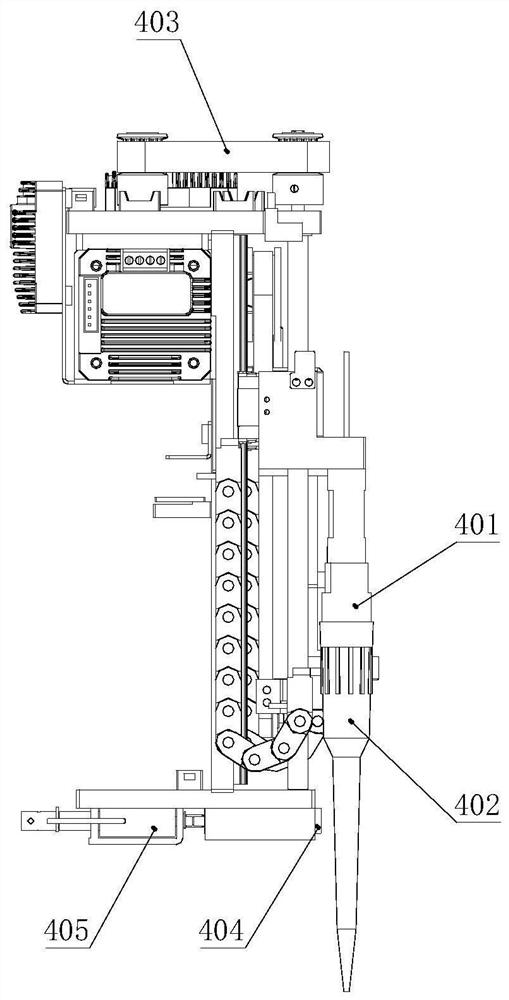

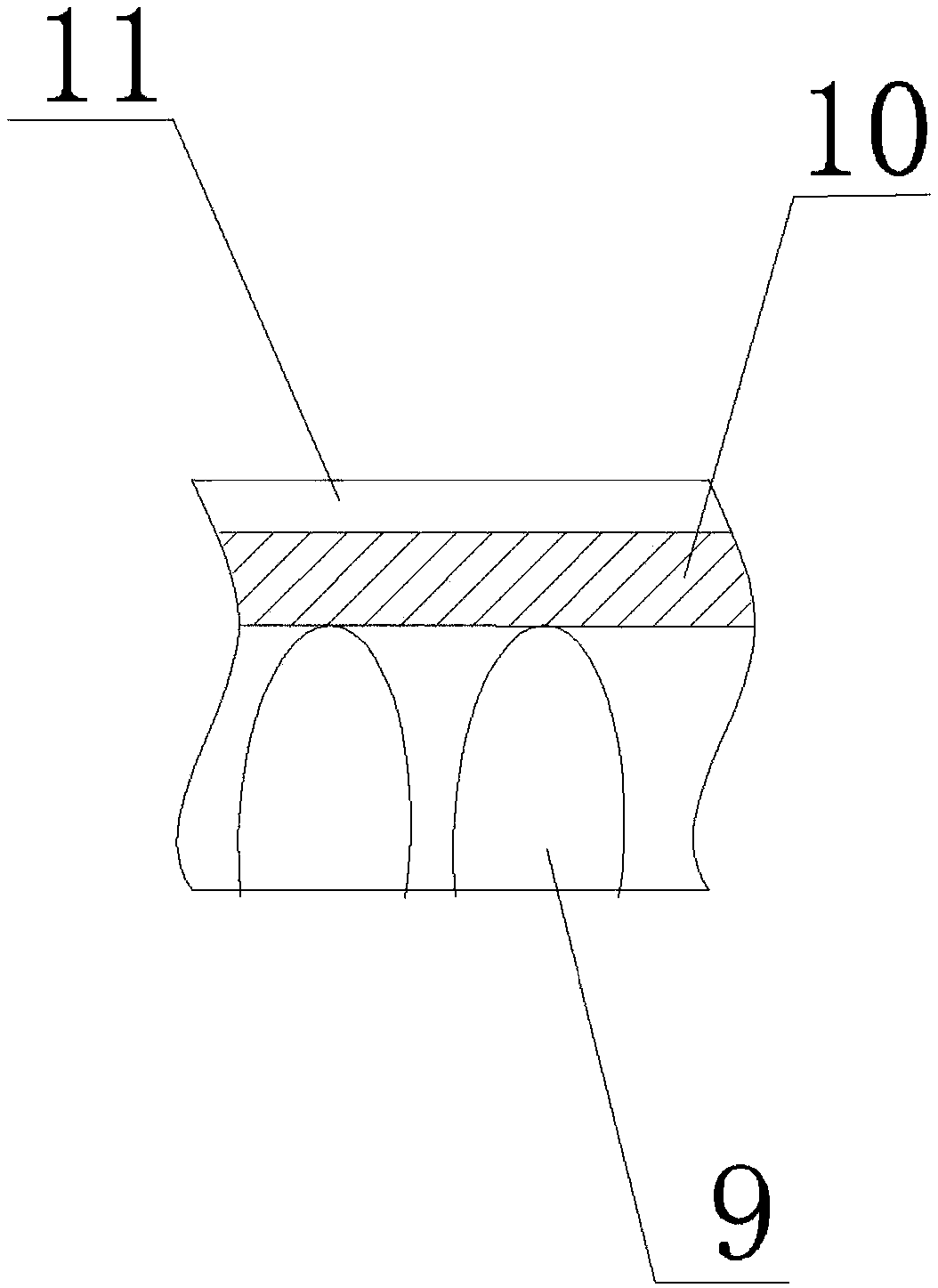

Foot pad picking and placement mechanism

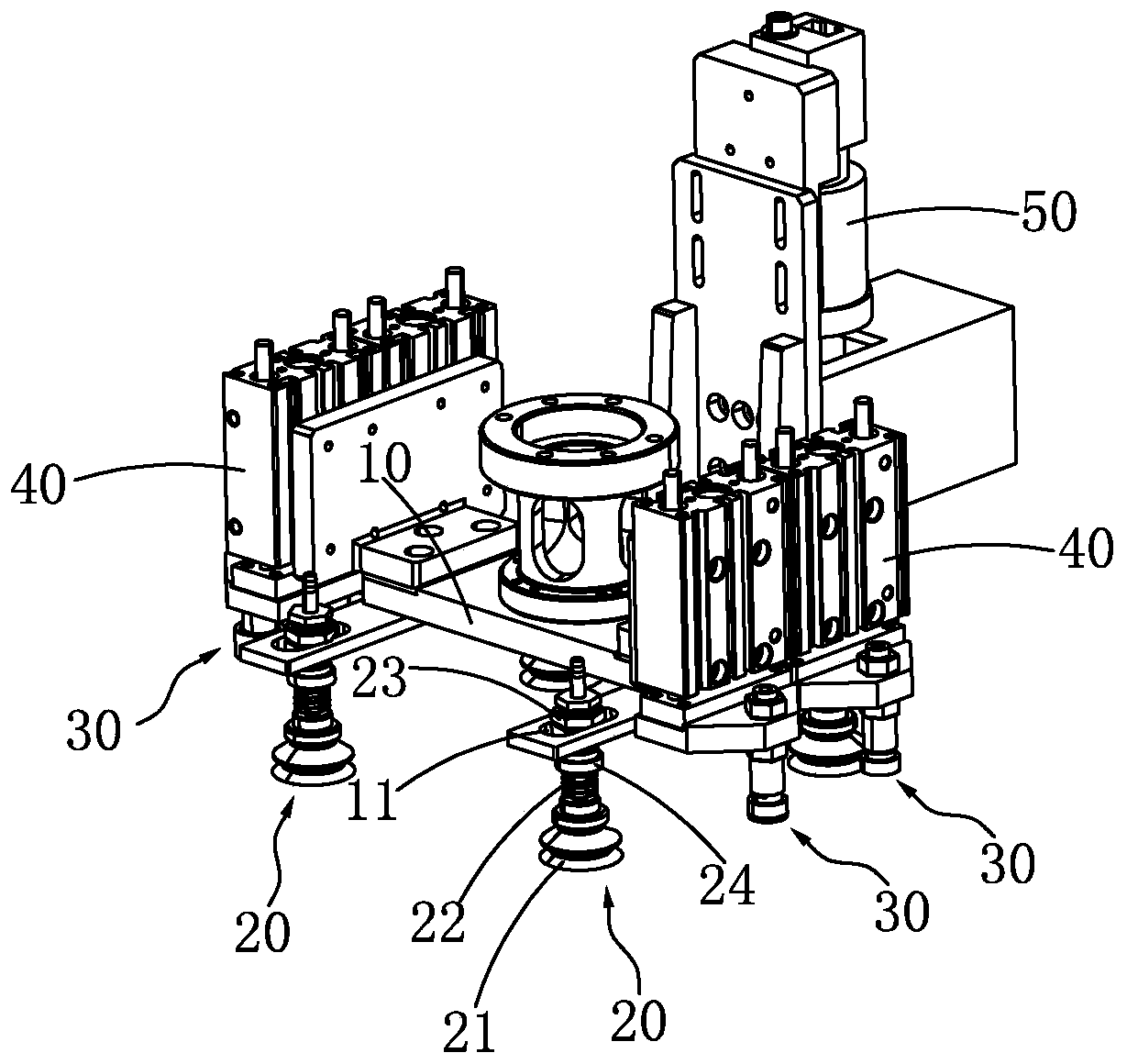

PendingCN111590543AAvoid absorbingPaste firmlyProgramme-controlled manipulatorGripping headsFoot cushionThree-dimensional space

The invention relates to the field of automatic equipment, and particularly discloses a foot pad picking and placement mechanism. The foot pad picking and placement mechanism comprises a support, a mechanical arm driving the support to move in a three-dimensional space, at least one second elastic suction assembly arranged on the support, and a driving device driving the second elastic suction assembly to move up and down relative to the support, wherein the second elastic suction assembly comprises a connecting plate, a second vacuum suction head connected with the connecting plate, a sleeveand an elastic piece; the outer periphery of the second vacuum suction head is coaxially sleeved by the sleeve; the elastic piece is arranged between the sleeve and the connecting plate, and can extend and retract along the central axis of the second vacuum suction head; and in an initial state, one end of the sleeve extends out of a suction end of the second vacuum suction head. The foot pad picking and placement mechanism disclosed by the invention has the advantages that a foot pad can be accurately picked and placed, so that the problem that the foot pad is omitted during adhesion is effectively solved, and the use is more convenient.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

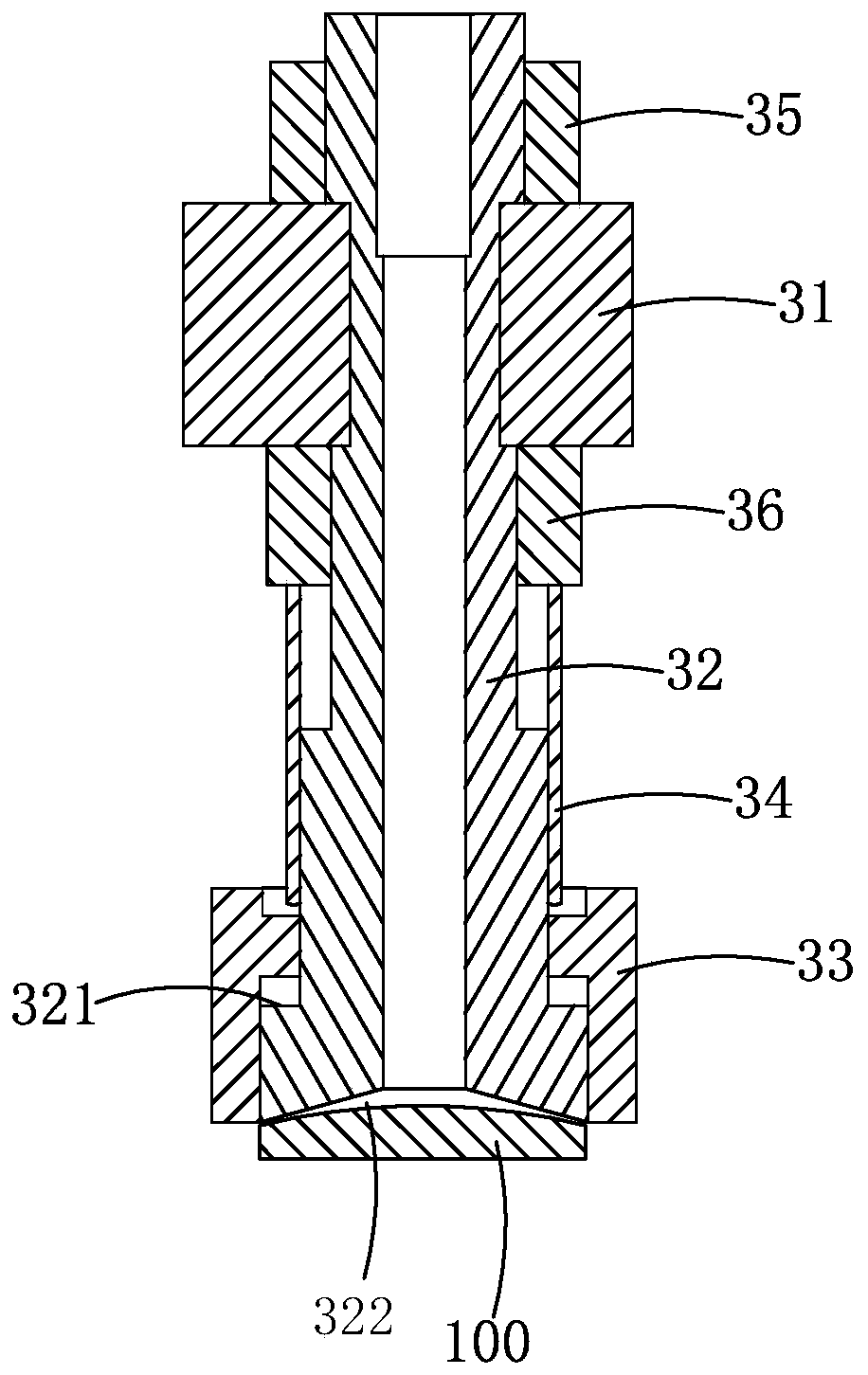

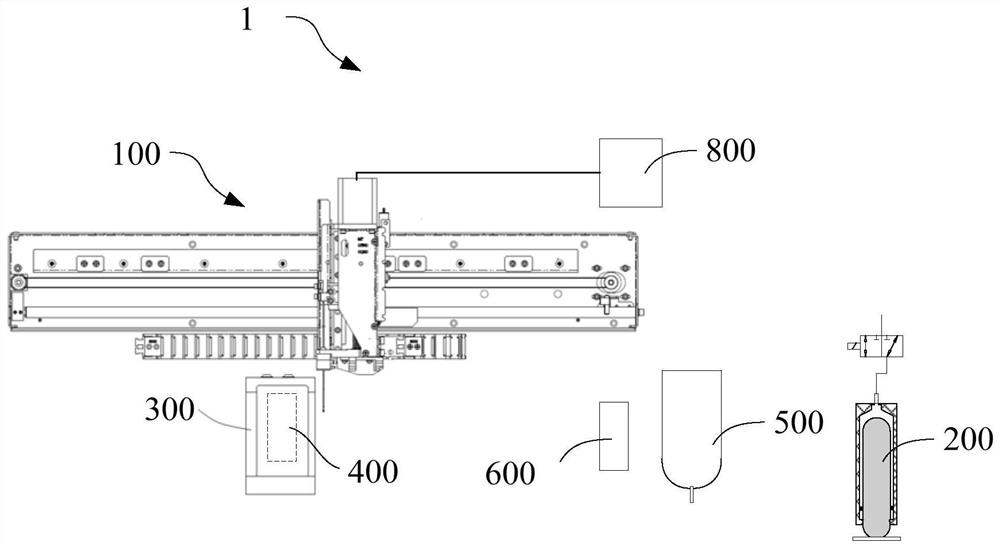

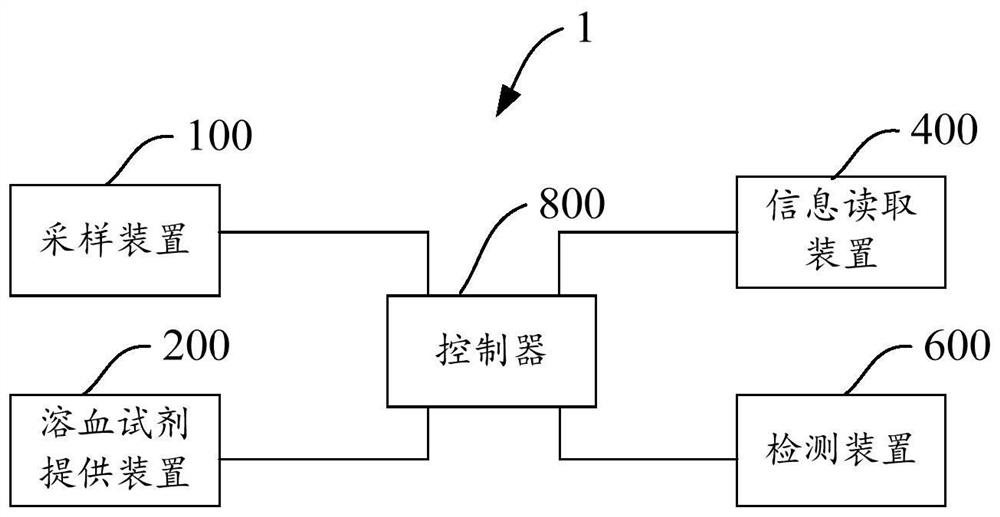

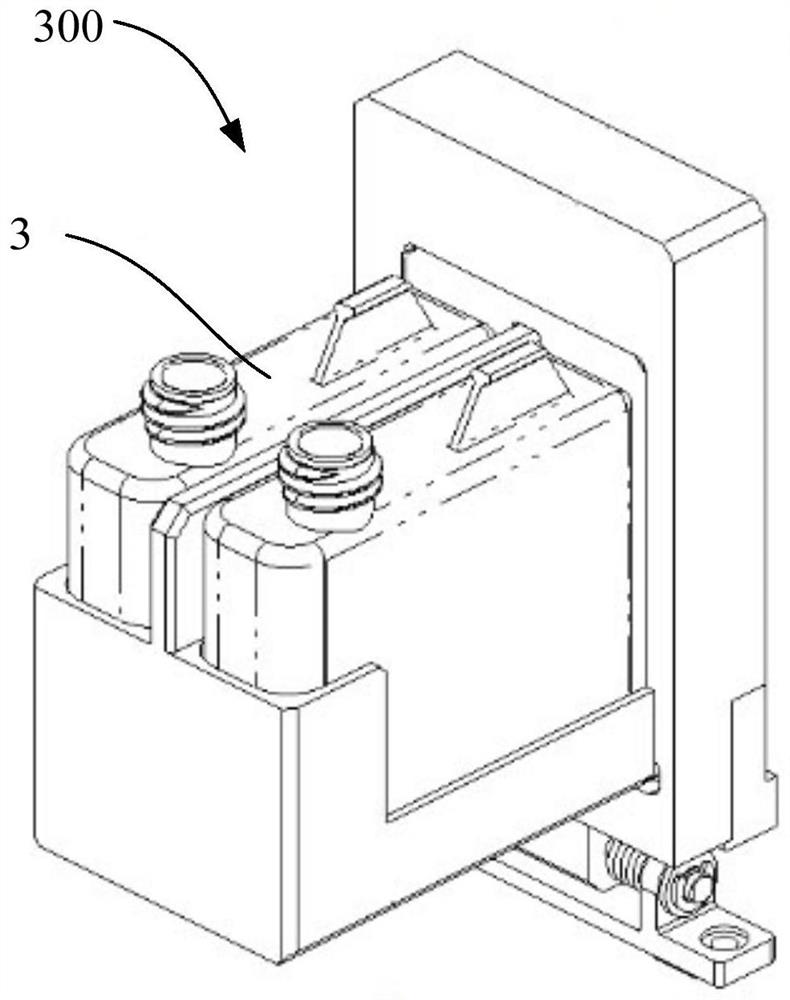

Sample analyzer and specific protein detection method

The invention provides a sample analyzer and a specific protein detection method. The sample analyzer comprises a sampling device, a hemolysis reagent supply device, a latex bin, an information reading device, a control device, a reaction tank and a detection device. The sampling device sucks a blood sample and dispenses the blood sample. The hemolysis reagent supply device is used for supplying a hemolysis reagent required by the test of a detection item. A reagent bottle is placed in the latex bin, a label carrying identification information is arranged on the reagent bottle, and the identification information at least comprises the type of a reagent in the reagent bottle. The information reading device reads the label on the reagent bottle to obtain the identification information. The controller controls the sampling device to sample and separate the latex reagent in the reagent bottle according to the identification information. The reaction tank receives the to-be-tested blood sampleseparately injected by the sampling device, the latex reagent and the hemolysis reagent so as to form a mixed sample required by testing. The detection device is used for detecting the mixed sample to obtain the specific protein concentration of the blood sample. The sample analyzer provided by the invention can be used for accurately sucking the required latex reagent.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

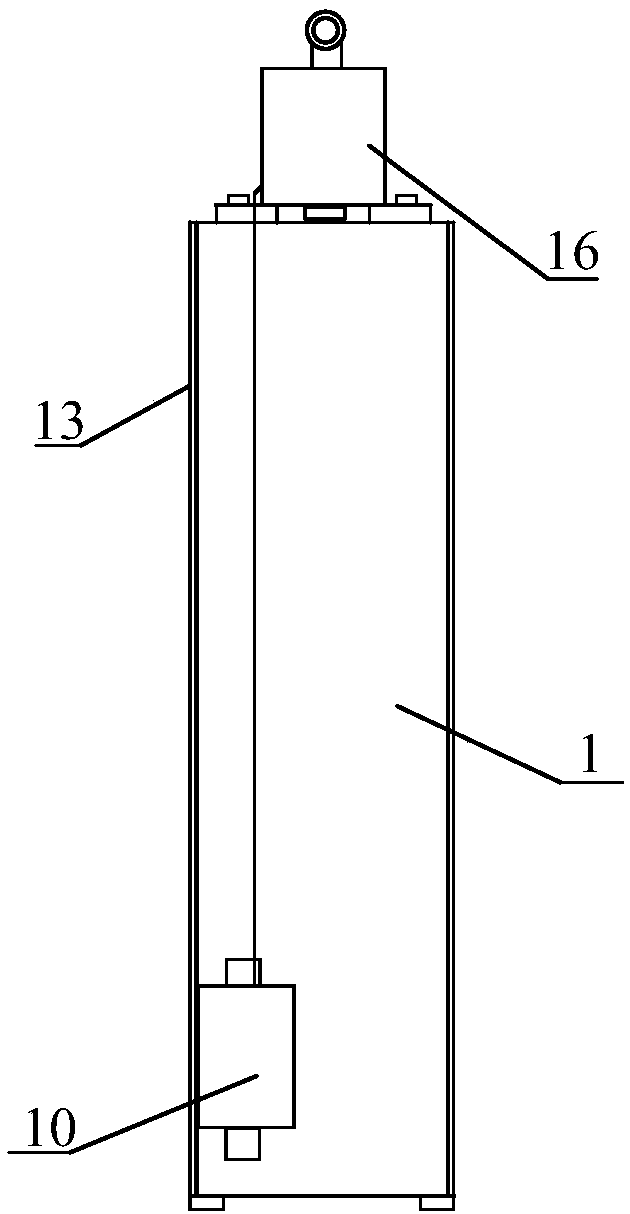

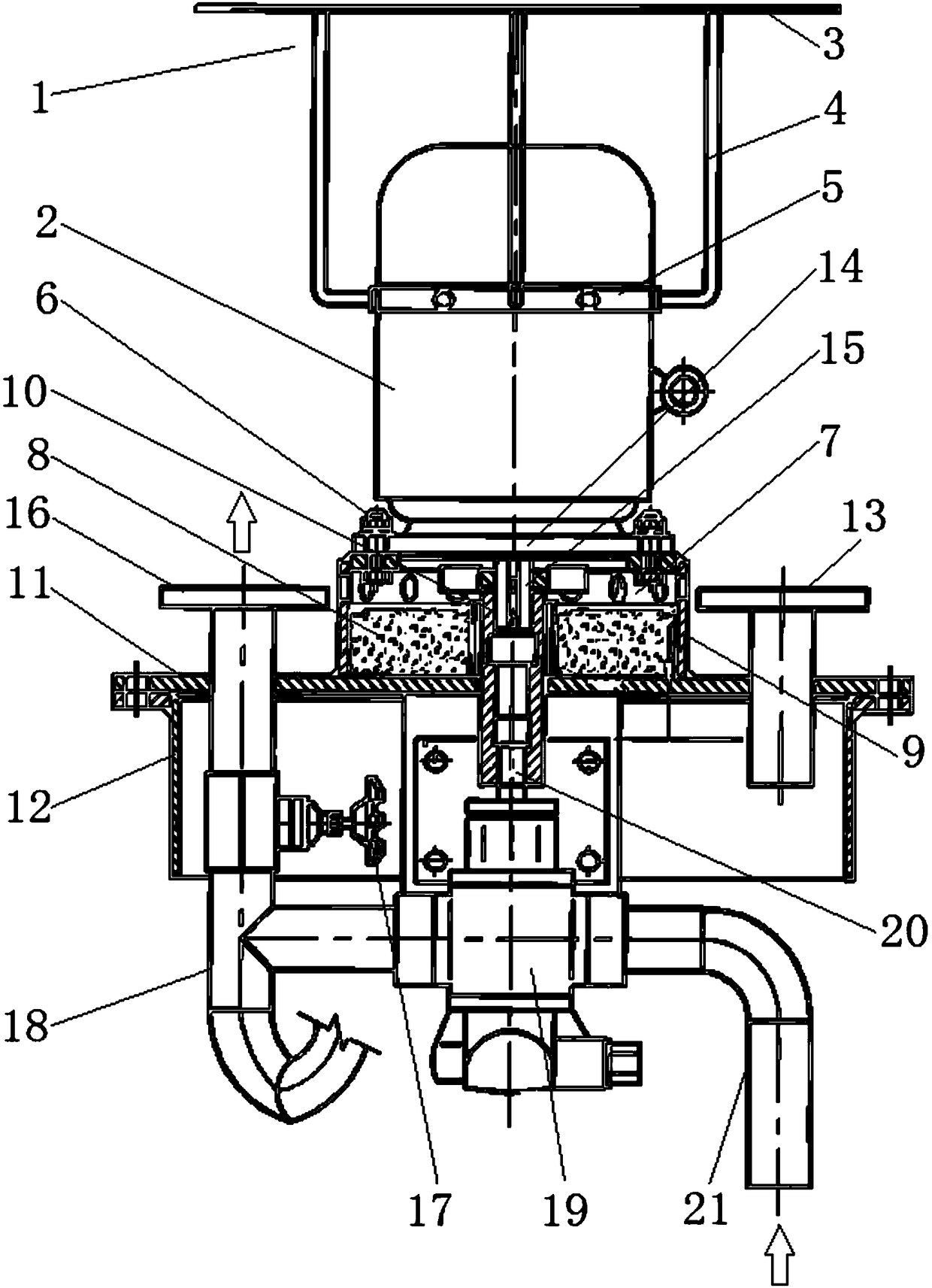

Self-heating overhead in-tank pump valve system

InactiveCN108869232AAvoid electric shockFree from pollutionPositive displacement pump componentsPump controlThreaded fastenerEngineering

The invention relates to a self-heating overhead in-tank pump valve system which comprises a motor, a pump and an asphalt pipe. The motor is mounted at the top of an asphalt tank through a supportingtube and a supporting flange and located outside the asphalt tank, and the supporting tube and the supporting flange are connected through a threaded fastener. The pump and the asphalt tube are mounted at the top of an inner cavity of the asphalt tank through a bearing cavity. The bearing cavity is provided with a flange edge and is fixed on the top inner wall of the asphalt tank through a bolt. An output shaft of the motor is connected with an input shaft of the pump through a coupling. An inner cavity of the supporting tube is filled with a heat insulation material and is internally providedwith fan blades, and the heat insulation material covers the coupling. According to the self-heating overhead in-tank pump valve system, the motor, the pump and the asphalt tube are all mounted at the top of the asphalt tank, and the pump and the asphalt tube are arranged in a built-in mode; the asphalt tank is usually not fully filled, and the pump and the asphalt tube are packed in the bearingcavity and located at the top of the inner cavity of the asphalt tank, so that the pump and the asphalt tube are prevented from being contaminated by asphalt; the rising hot gas of the asphalt can heat the pump and the asphalt tube, so that self heating is achieved, and extra energy sources are not wasted.

Owner:WUHAN CHANGSHIZHU ROAD MAINTENANCE EQUIP

Suction method and adding method of biological tissue culture solution

PendingCN113717852AAbsorption is normalAvoid air suctionBioreactor/fermenter combinationsBiological substance pretreatmentsCulture fluidSurgery

The invention discloses a suction method and an adding method of a biological tissue culture solution and relates to the technical field of biological tissue culture. The suction method comprises the following steps: extracting a negative pressure from a culture solution suction head, moving down the culture liquid suction head according to a first set distance, detecting a first state negative pressure in the culture solution suction head, and comparing the first state negative pressure with a first set negative pressure; if the first state negative pressure is greater than or equal to the first set negative pressure, stopping moving down the culture solution suction head and stopping extracting the negative pressure from the culture solution suction head, moving the culture solution suction head to a level of the culture solution, and discharging the solution in the culture solution suction head; moving down the culture solution suction head to a position below the level of the culture solution according to a second set distance and extracting a set amount of the culture solution; and after the culture solution is sucked, moving the culture solution suction head upwards and out of a culture solution bottle, and thus automatically sucking the biological tissue culture solution. The adding method comprises steps of uncovering, solution adding and covering. The biological tissue culture solution can be automatically added and a requirement for culturing biological tissues in batches is met.

Owner:重庆市盛佰昱科技有限公司

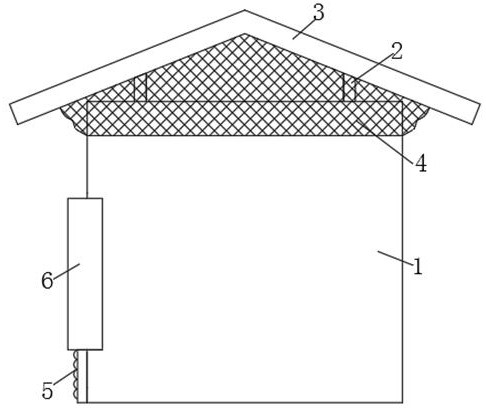

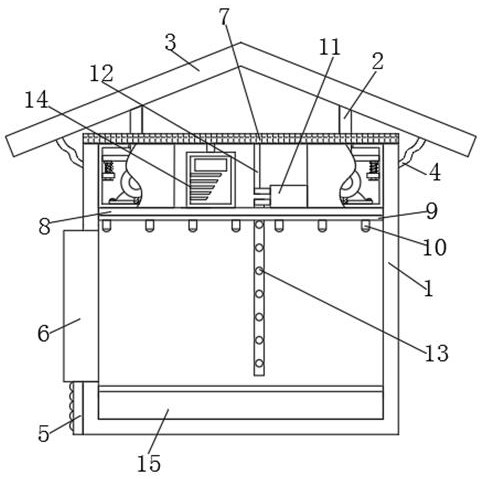

A shelter for deep well and underground driving

ActiveCN112302707BPrevent leavingAvoid enteringMining devicesDust removalElectric machineSlide plate

Owner:TONGLING ZHONGDU MINING CONSTR

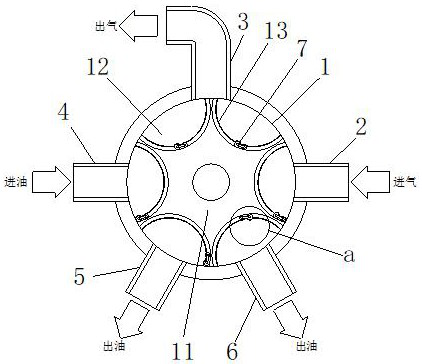

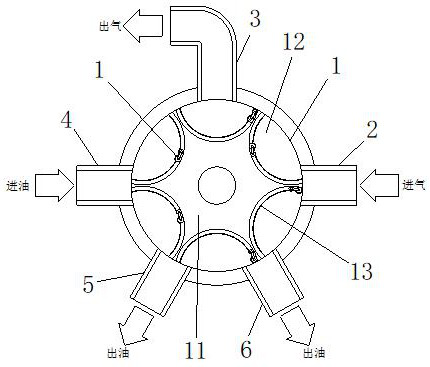

Air suction purification decontamination valve for air compressor

InactiveCN111664075AAvoid absorbingAvoid damagePositive displacement pump componentsPositive-displacement liquid enginesAir compressionEnvironmental engineering

The invention relates to the technical field of air compressors, and discloses an air suction purification decontamination valve for an air compressor. The air suction purification decontamination valve for the air compressor comprises a valve body; the valve body is a cylindrical barrel, an air inlet pipe and an air outlet pipe are fixedly mounted on the valve body; a rotating body is fixedly mounted on the center of the valve body, an oil inlet pipe, an oil outlet pipe I and a oil outlet pipe II are further fixedly mounted on the valve body, elastic films are fixedly mounted on the six arc-shaped faces of the rotating body, gaps are formed between the elastic films and the arc-shaped faces of the rotating body, pushing devices are arranged in the gaps, air in a treatment bin is sucked away by the air compressor through the air outlet pipe, and due to the fact that the air inlet pipe does not communicate with the air outlet pipe, only treated air can be sucked from the treatment bin every time air compression is conducted, the air compressor is prevented from directly sucking air from the air, air in the treatment bin is adhered by oil, and then polluted oil is automatically recovered by utilizing the rotating effect of the rotating body, so that the effect of automatically cleaning a filtering device is achieved, and troubles caused by cleaning and replacing of the filteringdevice are reduced.

Owner:北京康乾白祥商贸有限公司

Hair brush with liquid storage and automatic liquid discharge functions

The invention discloses a hair brush with liquid storage and automatic liquid discharge functions, belonging to the field of hair brushes. The hair brush with the liquid storage and automatic liquid discharge functions includes a brush handle, a brush body, a brush head and bristles; the lower end surface of the brush body is provided with a concave cavity, the inner wall of the concave cavity isprovided with a sealing partition, and the sealing partition and the upper bottom surface of the concave cavity form a liquid storage cavity; a rotating shaft is rotatably connected to the inner wallof the concave cavity below the sealing partition; at least one rolling body is coaxially arranged on the rotating shaft; a gap is provided on the sealing partition; a part of the rolling body extendsthrough the gap and enters the liquid storage cavity; the surface of the rolling body is matched with the gap in a sealing manner; a discharge groove is provided on the surface of the rolling body; the brush head is detachably connected to the inner wall of the concave cavity below the rotating shaft; the outer wall of the brush head is adapted to the inner wall of the concave cavity; a pluralityof liquid outlet holes are evenly arranged on the brush head; the brush body is provided with a battery, a switch, and a motor that are electrically connected in sequence; and the motor is mechanically connected to the rotating shaft. The hair brush with the liquid storage and automatic liquid discharge functions can not only improve the painting efficiency, but also improve the uniformity of painting.

Owner:安徽圣峰刷业股份有限公司

Head for checking linear dimensions of mechanical pieces

ActiveCN101506613BInterfere with normal operationAvoid absorbingUsing electrical meansMechanical measuring arrangementsTransducerEngineering

A gauging or measuring head for checking linear dimensions of mechanical pieces includes a casing (1), a movable arm (4) carrying a feeler (7), a fulcrum (10), coupled to the casing and the arm for enabling arm displacements with respect to the casing, a retraction device (68) with a cylinder (70) coupled to the casing and a piston (72) which slides therein for urging the arm to a definite inoperative position, and a position transducer (50) that provides signals depending on the position of the arm with respect to the casing. The retraction device includes a bellows gasket (88), which is housed in the cylinder and has its ends fixed to the cylinder and the piston.

Owner:MARPOSS SPA

Medicated diet cigarette as well as preparation method and equipment thereof

ActiveCN113519891ARefreshing effectEliminate dependenciesTobacco preparationCigarette manufactureBiotechnologyRadix Astragali seu Hedysari

The invention discloses a medicated diet cigarette and a preparation method and equipment thereof. The cigarette comprises tobacco shreds filled in the cigarette, and the tobacco shreds are prepared from the following traditional Chinese medicine raw materials in parts by weight: 5-20 parts of ginkgo leaves, 5-20 parts of ginseng leaves, 5-20 parts of lily leaves, 5-20 parts of tea leaves, 5-20 parts of boxthorn leaves, 5-20 parts of red date leaves, 5-20 parts of bulbus fritillariae cirrhosae leaves, 5-20 parts of loquat leaves, 3-10 parts of pericarpium citri reticulatae, 3-10 parts of radix astragali seu hedysari extract, 5-15 parts of rhizoma polygonati extract, 3-10 parts of rhizoma chuanxiong extract and 2-10 parts of liquorice root extract. The medicated diet cigarette can retain the shape and taste of the cigarette, can be brewed and drunk, and has the effects of moistening the lung, nourishing yin, conditioning internal organs and refreshing the mind and restoring consciousness.

Owner:胡阳兵

Novel stamped part suction tool

InactiveCN105964827AEasy to take outEfficient collectionStripping-off devicesSuction equipmentEngineering

The invention discloses a novel stamped part suction tool. The novel stamped part suction tool is characterized by comprising a handle, a first connecting rod, a second connecting rod and a sucker; the handle, the first connecting rod and the sucker are connected in sequence, the second connecting rod is connected to a rod body of the first connecting rod, the sucker comprises a sheet disc body, and a plurality of air suction holes are formed in one side face of the disc body; air suction channels are formed in the handle, the first connecting rod and the second connecting rod, the air suction channel in the first connecting rod is communicated with the air suction holes, the air suction channel in the handle is communicated with the air suction channel in the first connecting rod, the air suction channel in the handle is connected with air suction equipment, the air suction channel in the second connecting rod is communicated with the air suction channel in the first connecting rod and connected with dust collection equipment, and a filter screen is arranged in the air suction channel in the first connecting rod and located at the joint of the air suction channel in the second connecting rod and the air suction channel in the first connecting rod. The novel stamped part suction tool is easy and convenient to use.

Owner:苏州誉衡昌精密机械有限公司

Vertical driller chipping collection tool

InactiveCN111215956AAvoid absorbingPrevent emptyMaintainance and safety accessoriesStructural engineeringMechanical engineering

The invention relates to the technical field of drillers, in particular to a vertical driller chipping collection tool. The vertical driller chipping collection tool comprises an outer box body, and acollection box is fixedly installed in the outer box body; one side of the collection box is rotationally provided with a sealing door through a hinge, and the outer side of the sealing door is fixedly provided with a handle; the upper end of the collection box is fixedly provided with a second inlet pipe in a communicating mode, and the upper end of the second inlet pipe is fixedly provided witha second suction fan; the second suction fan is fixedly installed in a second fixing frame, and the second fixing frame is fixedly installed in the upper surface of the outer box body; the upper endof the second suction fan is fixedly provided with a connection pipe, and the upper end of the connection pipe penetrates and extends to the upper side of the outer box body; a pierced cover is fixedly installed on the upper surface of the outer box body and located on the outer side of the connection pipe; and the lower end of the collection box is fixedly provided with a first inlet pipe in a communicating mode. The collection tool is good in collection effect and worthy of popularization.

Owner:老河口市生龙机械有限公司

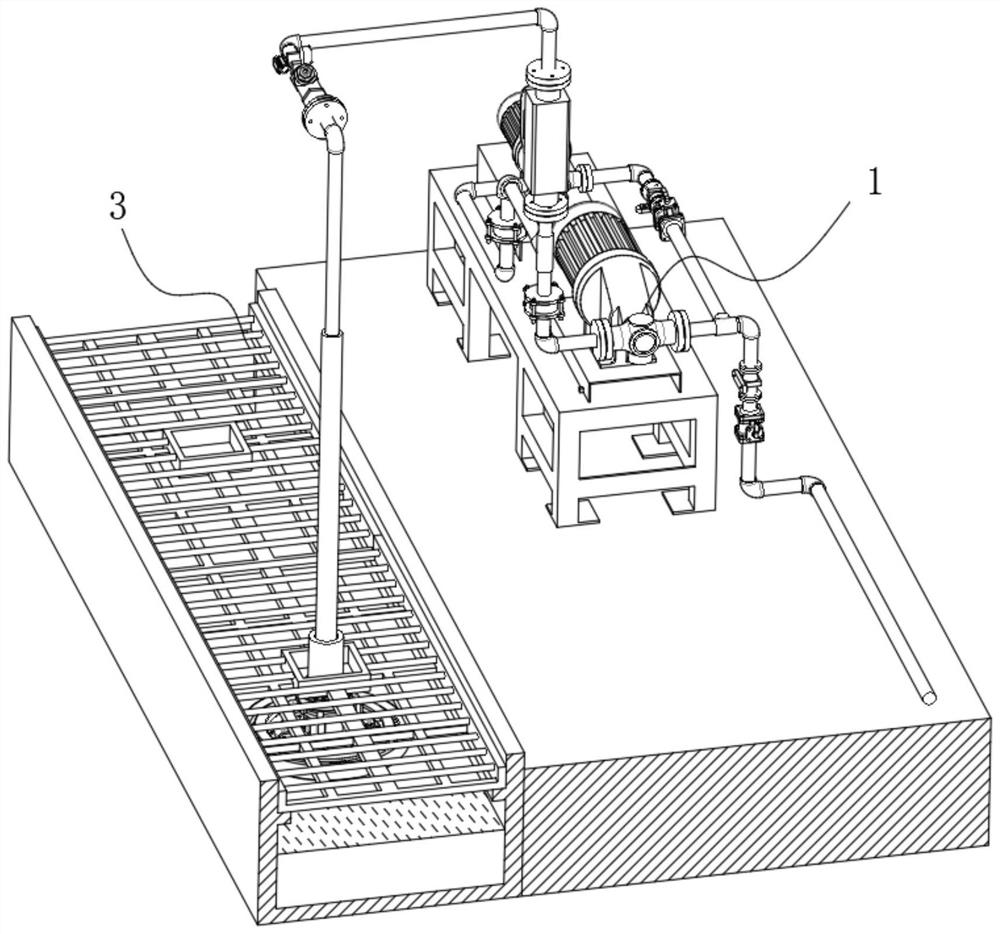

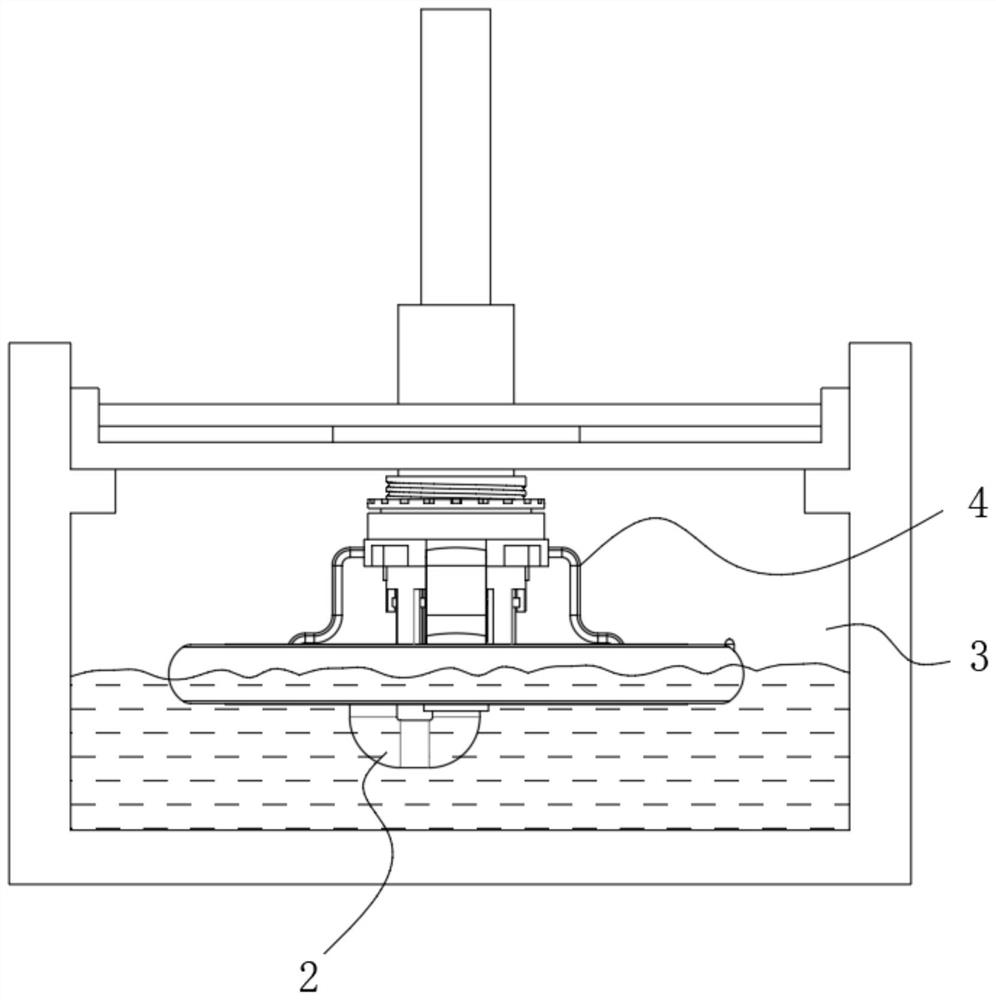

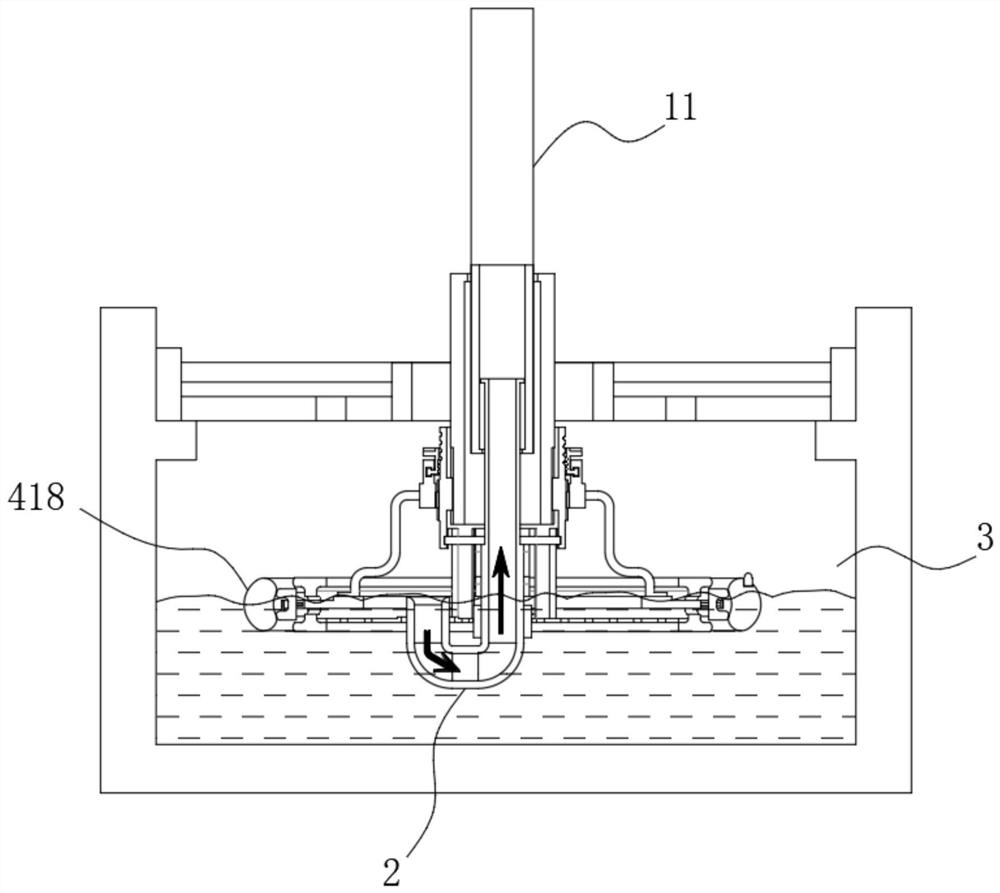

Foundation pit drainage device and using method thereof

The invention relates to the technical field of hydraulic engineering construction, in particular to a foundation pit drainage device and a using method thereof.The foundation pit drainage device comprises a drainage pump and a water collecting well, the drainage pump is arranged on one side of the water collecting well, and the water drawing end of the drainage pump is movably connected with a bent pipe with an opening facing the position above the sewage liquid level in the water collecting well. One end of the drainage pump is connected with the bent pipe capable of moving up and down, meanwhile, the pipe opening of the bent pipe is arranged upwards, turbid impurities at the bottom of the water collecting well are prevented from being sucked into the pump pipe through suction force, and the drainage device capable of floating on the water surface in the drainage well is arranged on the outer side of the bent pipe; the bent pipe is driven to move along with ascending or descending of the liquid level, impurities with large sizes in water can be isolated through the base plate at the bottom end of the drainer, sewage is filtered to a certain degree, and the possibility that a pump pipe is blocked is reduced.

Owner:赵丽嘉

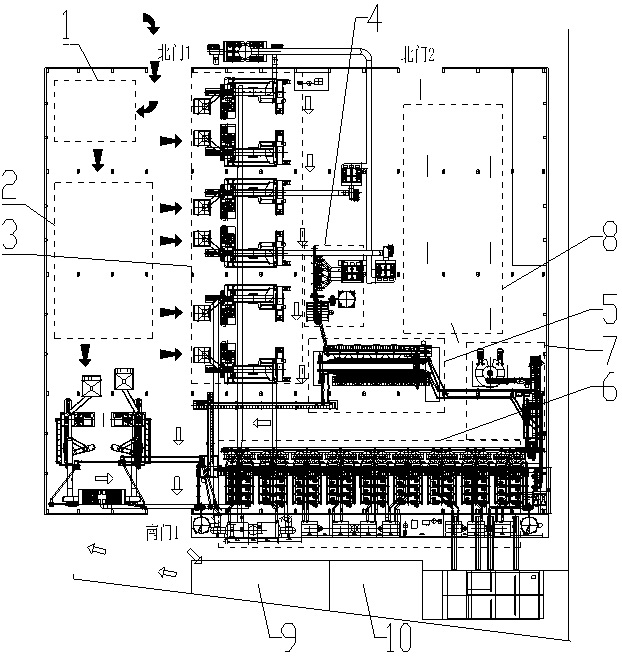

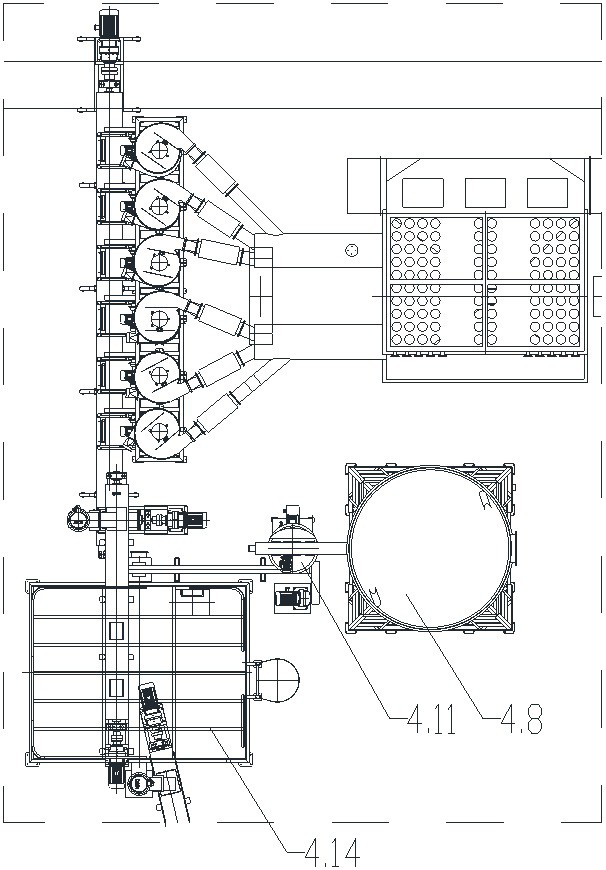

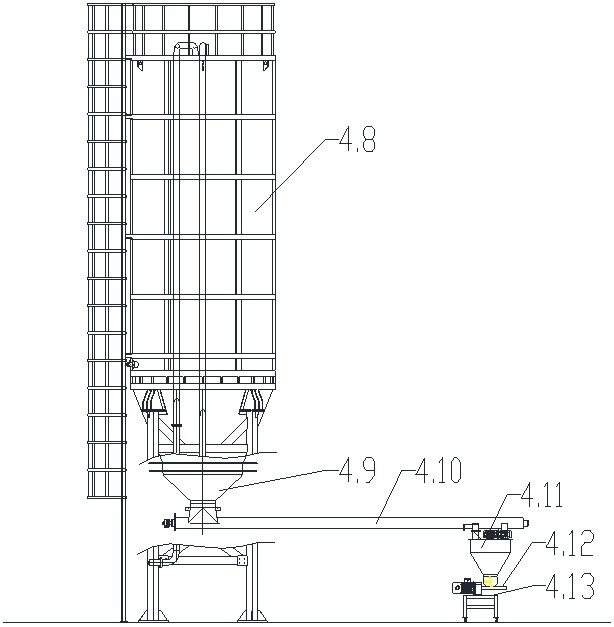

Fine rubber powder production line

PendingCN113070145AStrong synergyIncrease productivityVortex flow apparatusDirt cleaningWaste tiresMagnetic separator

The invention relates to a fine rubber powder production line. A tire is decomposed into a tire top, tire sides and opening rings in a block decomposing area; the tire top and the tire sides are cut into blocks in the block decomposing area and then fed into a rubber breaking area; rubber blocks are broken into rubber powder and steel wires in the rubber breaking area, and the rubber powder and the steel wires meeting the mesh number enter a magnetic separation area; steel wires in the rubber powder are separated and collected through a magnetic separation unit in the magnetic separation area, and the rubber powder is conveyed to a rubber powder bin; the rubber powder subjected to magnetic separation is fed into a closed screening machine for screening, the rubber powder meeting the mesh number is sent into a collecting area by blowing, and the rubber powder not meeting the specification is sent into a grinding area for grinding; in the grinding area, the rubber material passes through a material distributing spiral and then enters a pulverizer to be ground into rubber powder with a smaller particle size, the rubber powder meeting the required mesh number is conveyed to a collector to be packaged, and the rubber powder not meeting the mesh number requirement is conveyed back to the pulverizer to be crushed again; and finally, packaging is performed in a collecting area, and transportation is performed in a fine rubber powder finished product area. According to the fine rubber powder production line, from the waste tires to the fine rubber powder, multiple procedures are high in collaboration and do not interfere with one another, the production efficiency is high, and the production cost is low.

Owner:JIANGSU ZHONGHONG ENVIRONMENT TECH CO LTD

Cell lysis solution for extracting animal DNA, kit and method

Owner:SICHUAN AGRI UNIV

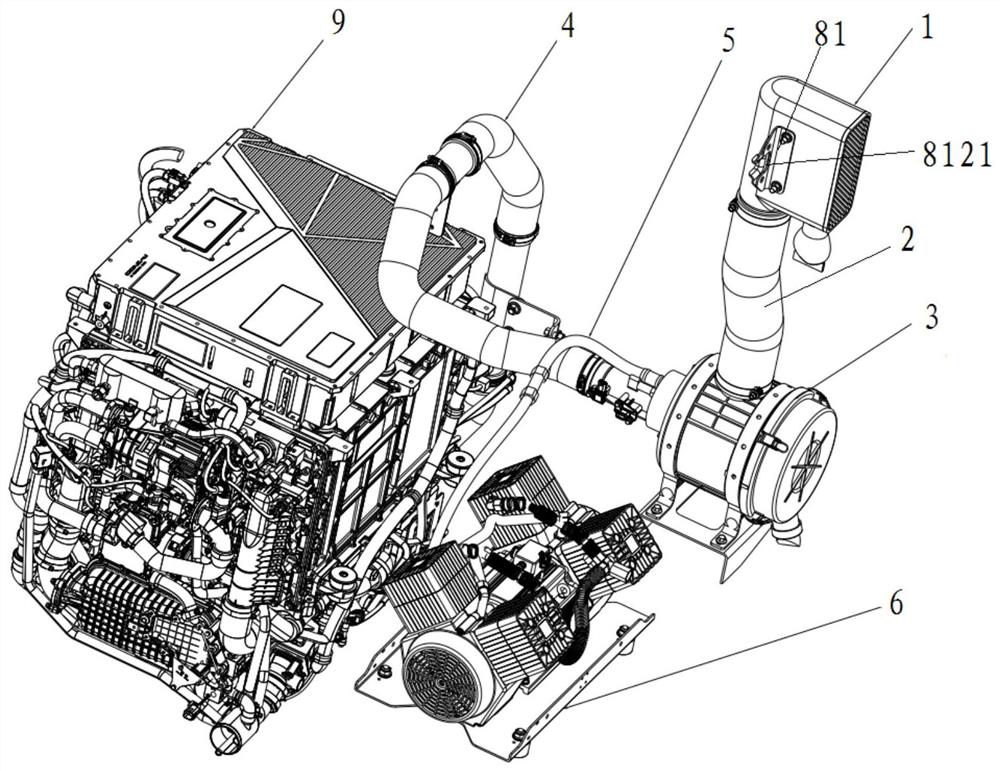

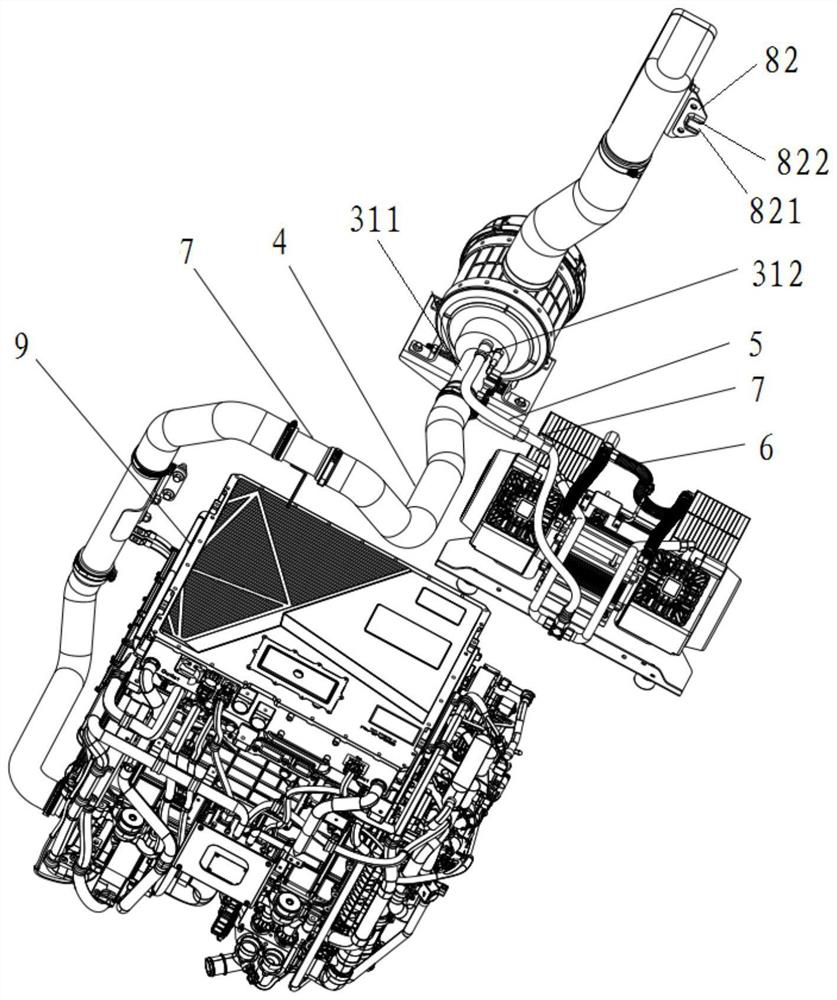

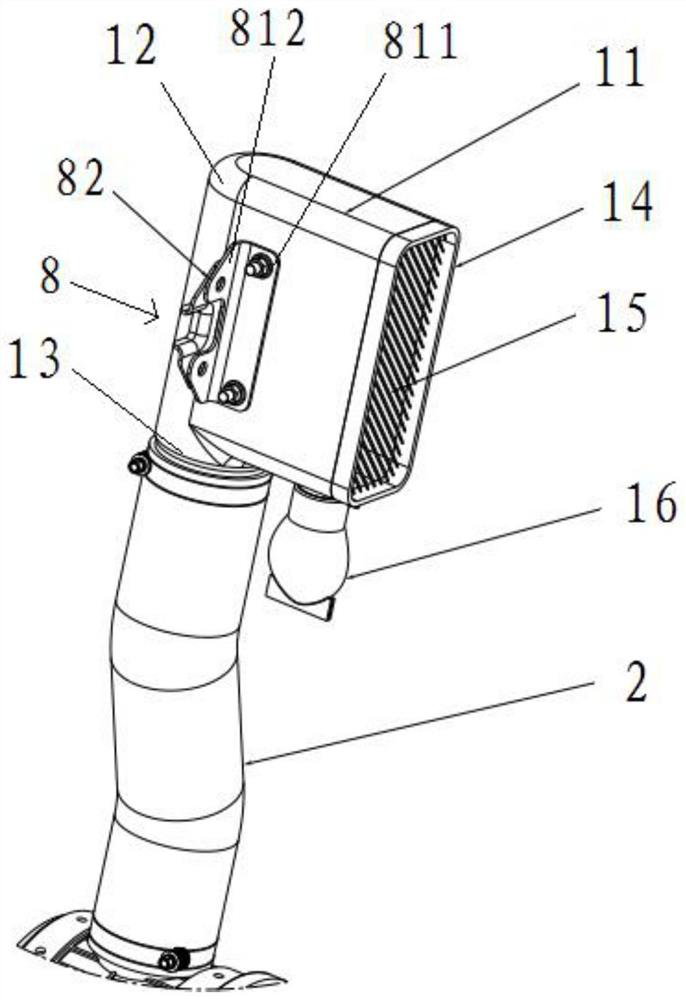

Air filter air inlet system of fuel cell vehicle

ActiveCN114030350ALow costReduce maintenance frequencyPump/compressor arrangementsAir treatment devicesFuel cellsMarine engineering

The invention discloses an air filter air inlet system of a fuel cell vehicle, and relates to the technical field of vehicle engineering, the fuel cell automobile air filter air inlet system comprises an air inlet leading-in pipe assembly, the air inlet leading-in pipe assembly comprises an air inlet cylinder and an air inlet entering pipe which are communicated with each other, the air inlet direction of the air inlet cylinder is obliquely upward, and the air inlet area of the air inlet cylinder is larger than or equal to the cross sectional area of the air inlet entering pipe; an air inlet of the air filter is connected with an air outlet of the air inlet pipe, and an air outlet of the air filter is respectively communicated with an engine air inlet pipeline and a brake air compressor air inlet pipeline; and one-way valves are arranged in the engine air inlet pipeline and the brake air compressor air inlet pipeline. According to the air filter air inlet system of the fuel cell vehicle, occupied space can be saved, the cost of the whole automobile can be reduced, the air inlet quality can be comprehensively improved, and the maintenance frequency of a brake system dryer is reduced; and meanwhile, air backflow can be effectively prevented, the situation that one air compressor sucks air from the other air compressor when working is avoided, and it is ensured that all air sources come from the air filter.

Owner:DONGFENG COMML VEHICLE CO LTD

Self-driving fish school type seawater sucking and collecting device for marine environment safety

InactiveCN113390678ARepelling is effectiveEasy to cleanWithdrawing sample devicesAnimal repellantsFisheryEngineering

The invention discloses a self-driving fish school type seawater sucking and collecting device for marine environment safety, which comprises a device body, a servo motor, a transmission rod, a collecting box and a one-way valve, the servo motor is fixedly mounted in the device body, the output end of the servo motor is provided with the transmission rod, the side of a side gear is provided with a guide rod, the upper end of a flow guide pipe is fixedly installed on the collecting box, a movable rod is installed on the side of the center rod, a banister brush is fixedly connected to the inner side of the movable rod, the upper end of the beating plate is installed on the side of a clamping plate, and a bottom magnet is fixedly installed at the lower end of the clamping plate. According to the self-driving fish school type seawater sucking and collecting device, impurities in seawater can be prevented from being sucked into the device during sampling, impurities attached to a filter screen can be conveniently cleaned in the sampling process, and meanwhile, surrounding gathered fish schools can be effectively driven.

Owner:张明宇

Walking stick with magnetic massage device

InactiveCN111317231APrevent the elderly from fallingPrevent slippingWalking sticksWalking stickEngineering

The invention relates to a walking stick provided with a magnetic massage device. The walking stick comprises a handle and a stick rod, wherein the handle and the stick rod are of an integrally-formedstructure, and the handle and the stick rod are both of a hollow structure; a sensing device is arranged at the tail section of the handle; the magnetic massage device is arranged on the handle; andthe magnetic massage device is wrapped by a sweat absorption device. According to the walking stick with the magnetic massage device, when an old person falls down, a gravity sensing device arranged on the handle is touched, and an alarm sound is given out, so that people can conveniently find and rescue the old person in time; and an anti-skid device arranged on the walking stick can effectivelyprevent the old person from falling down; the magnetic massage device arranged on the walking stick can effectively perform magnetic massage on the hand holding the walking stick, so that the walkingstick is beneficial to body health; and the sweat absorbing device arranged on the walking stick can effectively absorb sweat in the hand, and moreover, the walking stick is effectively prevented fromsliding off from the hand.

Owner:张海燕

Evasion room for deep well underground mining

ActiveCN112302707APrevent leavingAvoid enteringMining devicesDust removalMining engineeringElectric machinery

Owner:TONGLING ZHONGDU MINING CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com