Foot pad picking and placement mechanism

A foot pad and mechanical arm technology, applied in the field of automation equipment, can solve the problems of easily damaged foot pads, small foot pads, difficult to hold, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

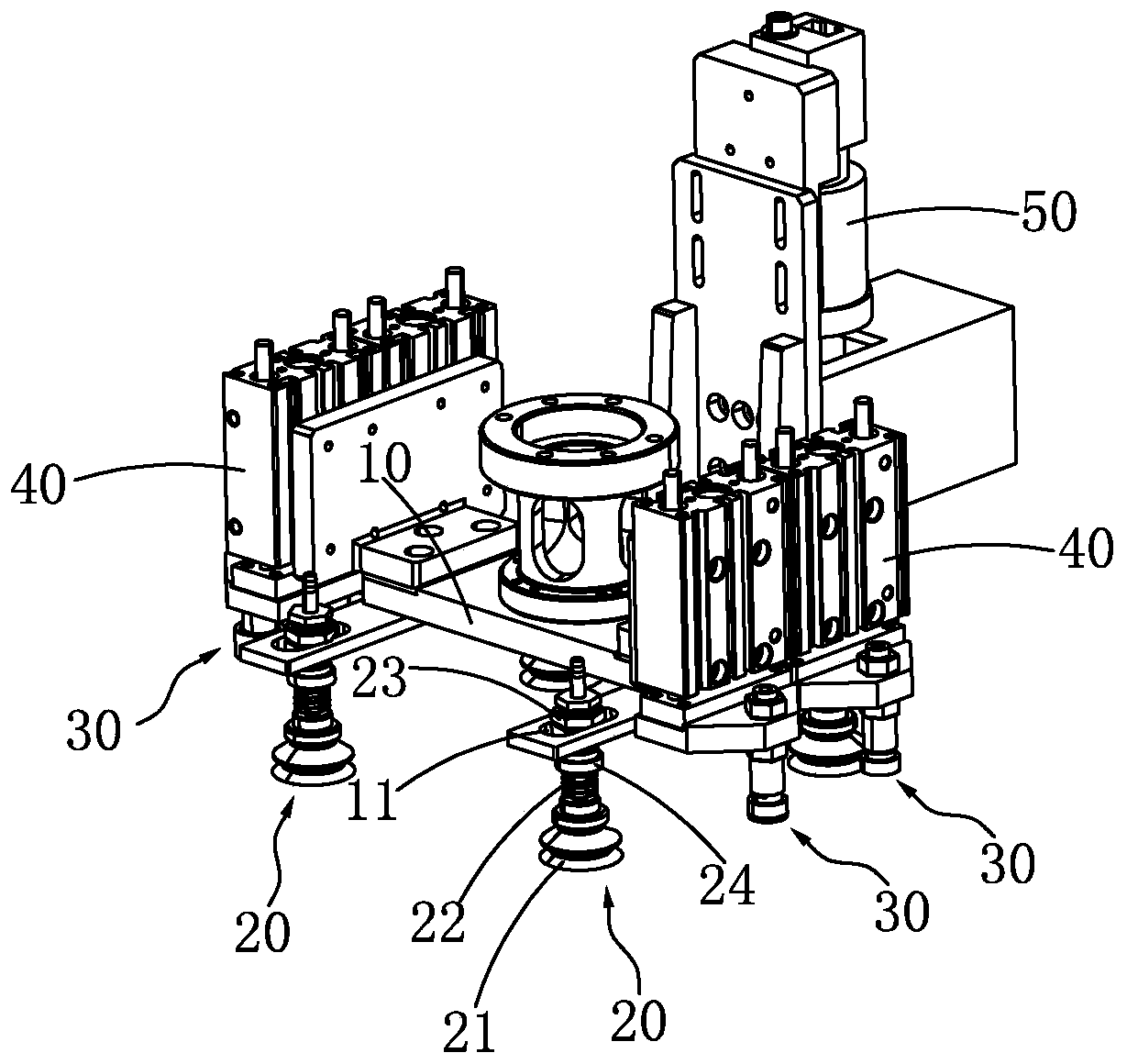

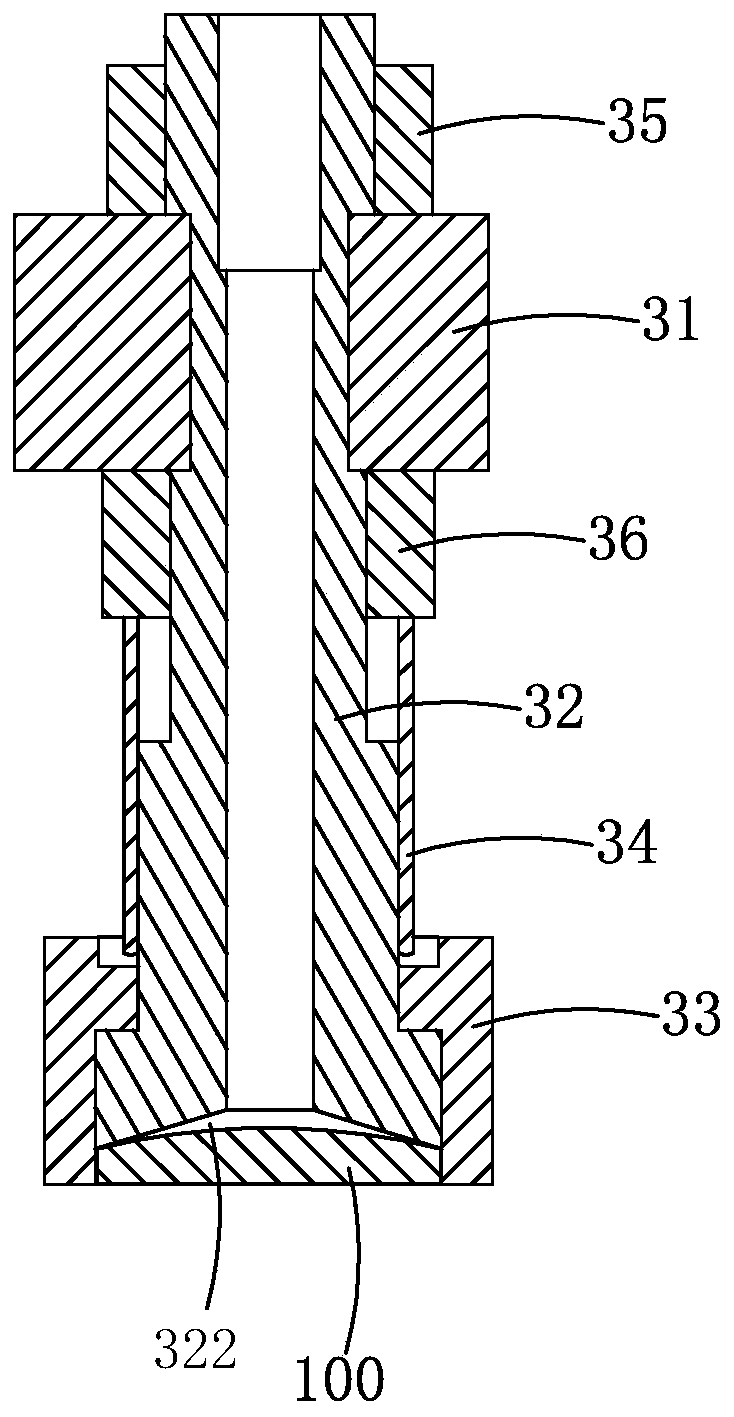

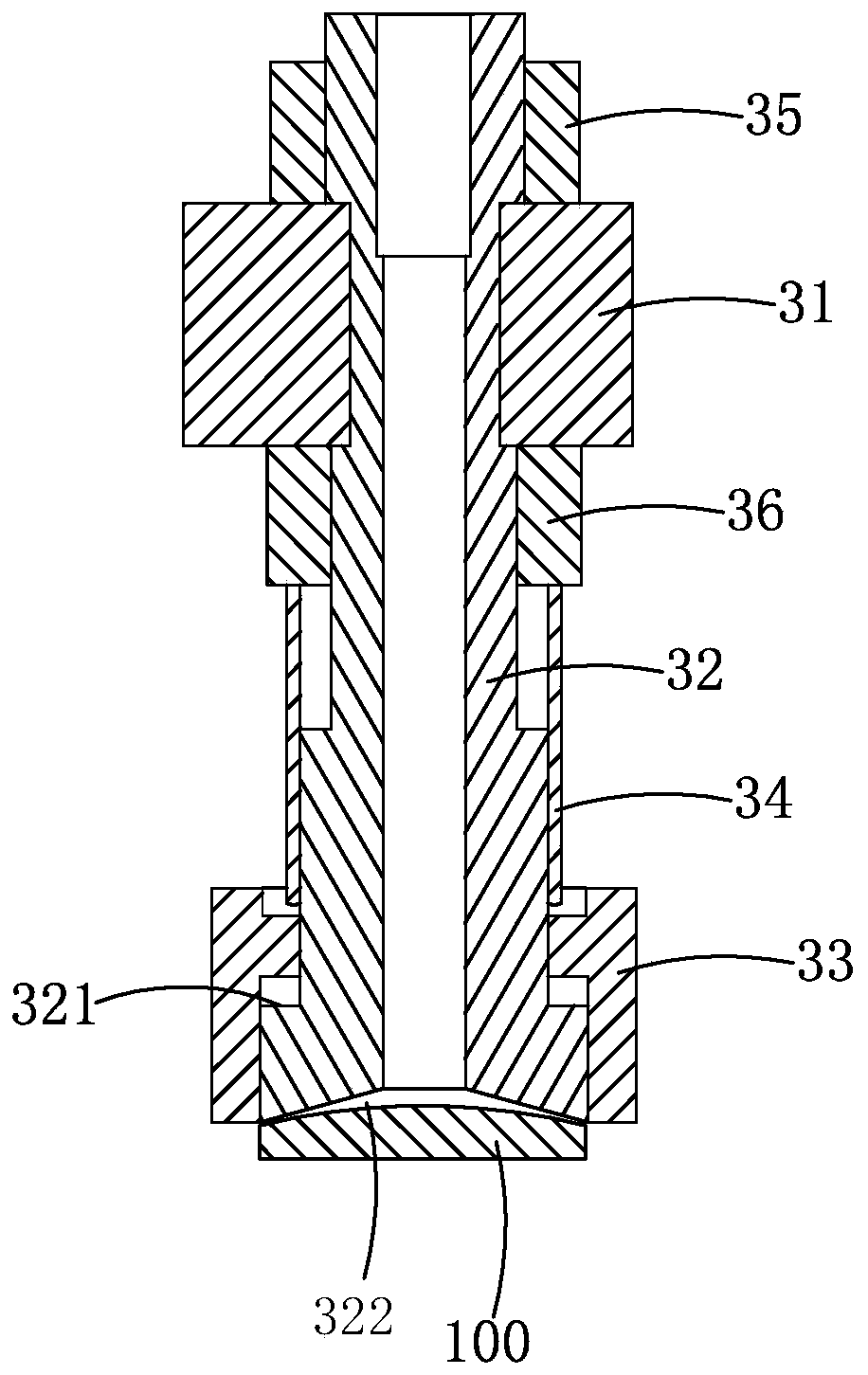

[0025] Such as Figure 1-3 As shown, a foot pad pick-and-place mechanism includes a bracket 10, at least two first elastic adsorption components 20, at least one second elastic adsorption component 30, a driving device 40, a visual positioning device 50 and a mechanical arm (not shown in the figure) . Wherein, each first elastic adsorption assembly 20 is connected on the support 10, and is used for absorbing foot pad accessories (ie release film); the second elastic adsorption assembly 20 is used for absorbing foot pads 100 positioned on the foot pad auxiliary materials; It is used to drive the second elastic adsorption component 20 to move up and down relative to the bracket 10; the visual positioning device 50 is connected to the bracket 10 for visual positioning when picking and placing the foot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com