Sheet takeout device

A technology for taking out devices and sheets, which is applied in the directions of transportation and packaging, thin material handling, and separation of objects, etc., can solve problems such as damage to sheets and pollution, and achieve the effect of preventing pollution and damage and preventing sliding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

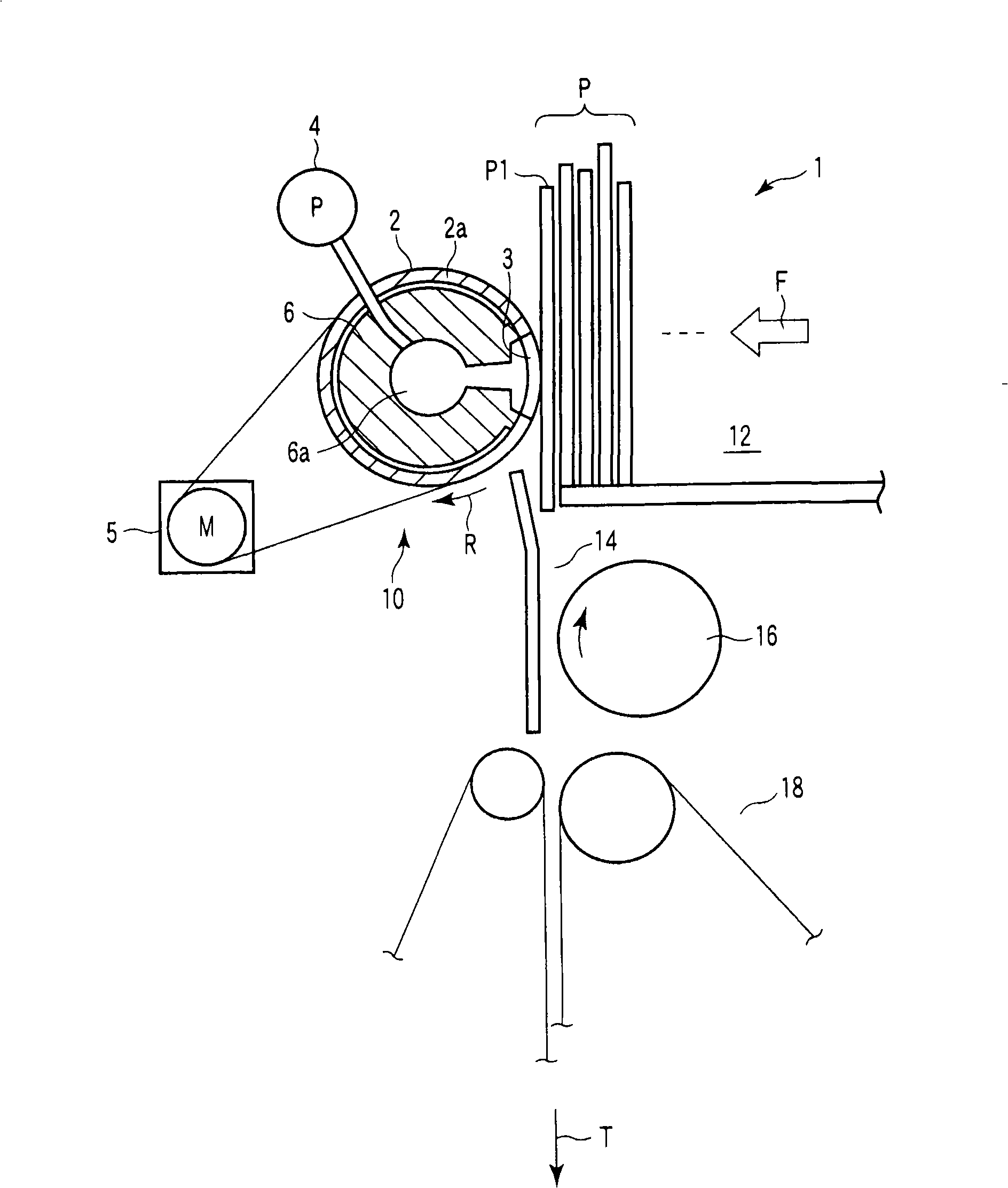

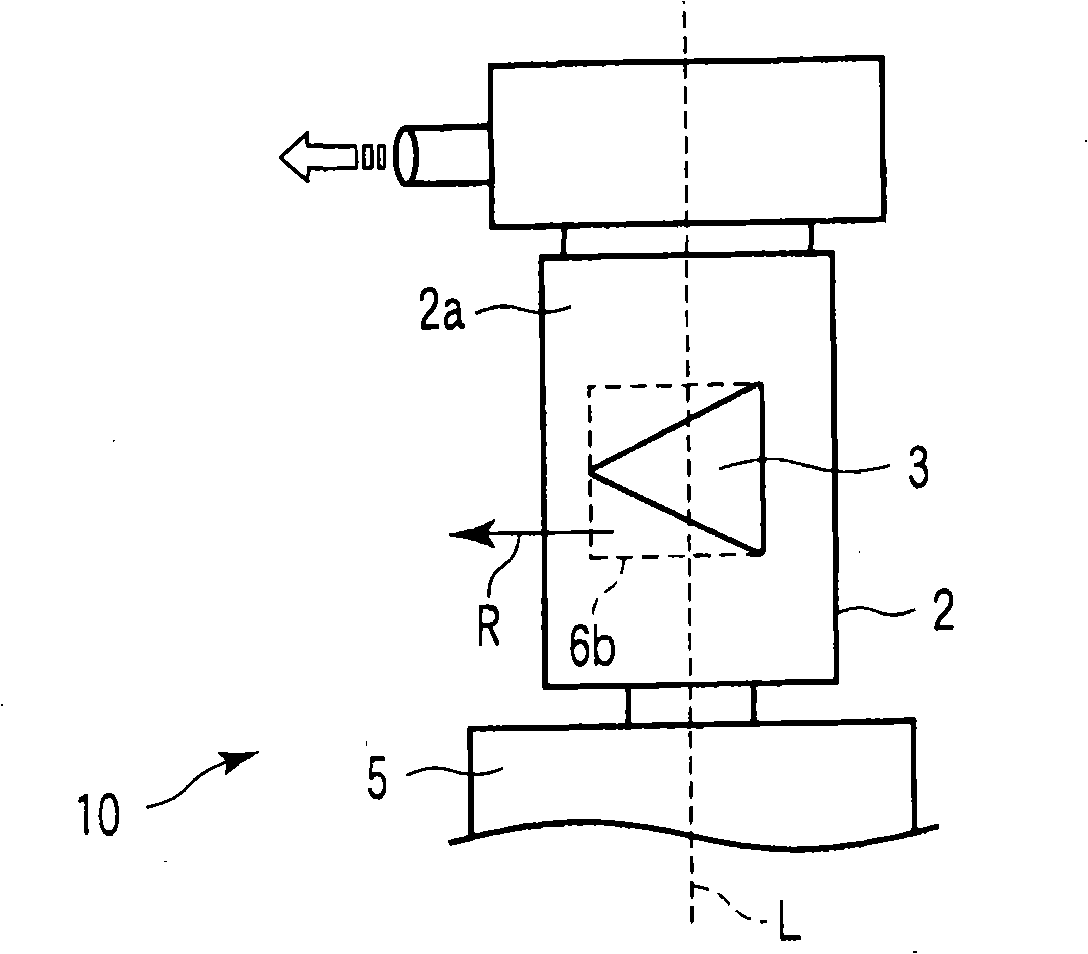

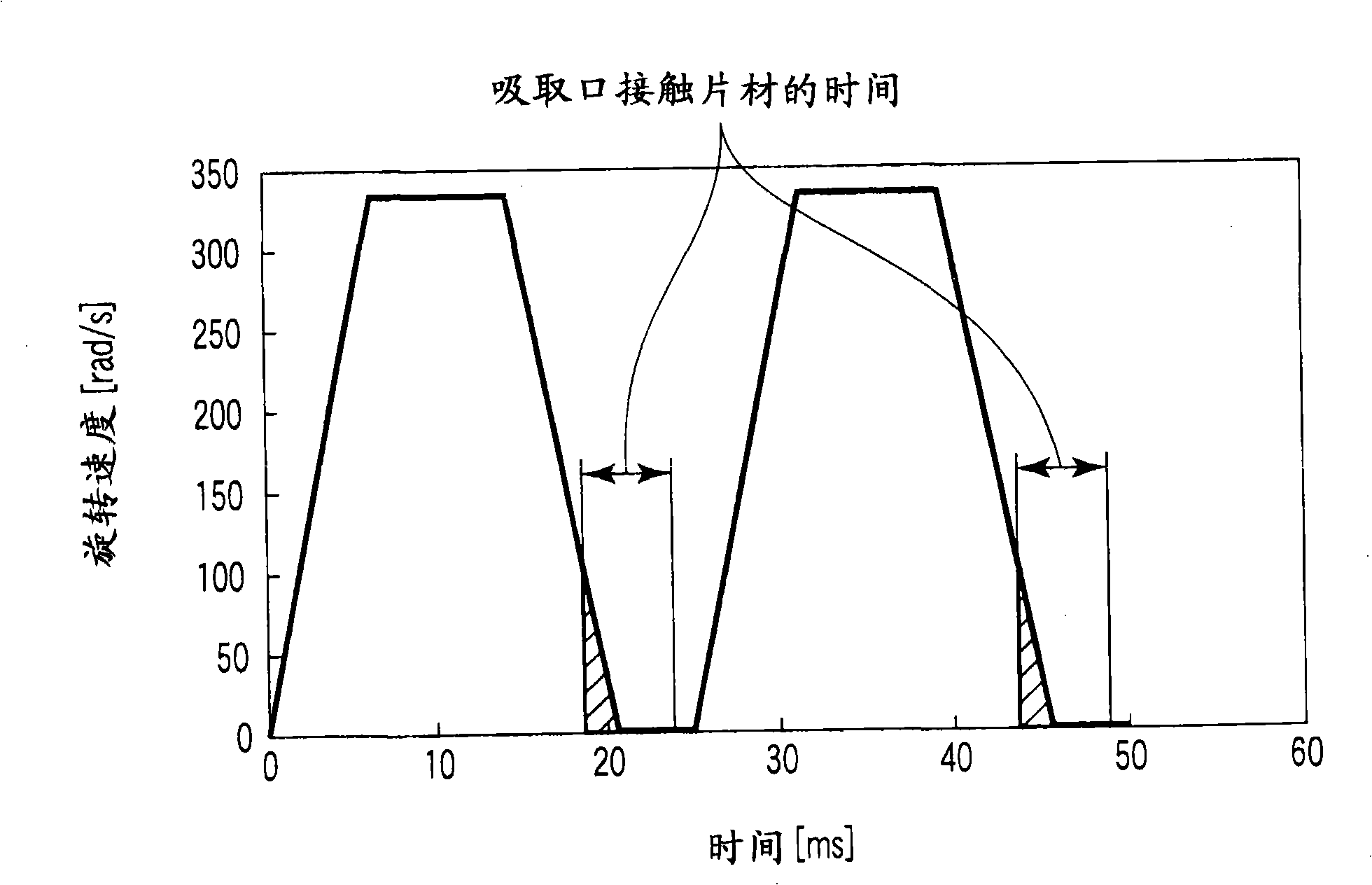

[0035] figure 1 A schematic plan view of a sheet take-out device 1 (hereinafter simply referred to as take-out device 1 ) according to a first embodiment of the present invention is shown. figure 2 is an enlarged view of the suction port 3 included in the take-out roller 2 in the take-out device 1 . image 3 is an example of a velocity diagram showing the velocity at which the take-out roller 2 rotates intermittently.

[0036] Such as figure 1 As shown, the take-out device 1 has: a loading section 12 on which a plurality of collected sheets P such as mail or slips to be processed are loaded in an upright position; a feeding mechanism (not shown) on which The feeding mechanism moves the loaded sheets P along the collecting direction ( figure 1 in the direction of the middle arrow F), and feed the first sheet P1 located at the front end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com