Flaky inductance tin soldering equipment

A technology of soldering and inductance, which is applied in the field of chip inductor soldering equipment, can solve problems such as unfavorable soldering, impact on growth, and chip inductors cannot be cooled quickly, and achieve the effect of improving operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

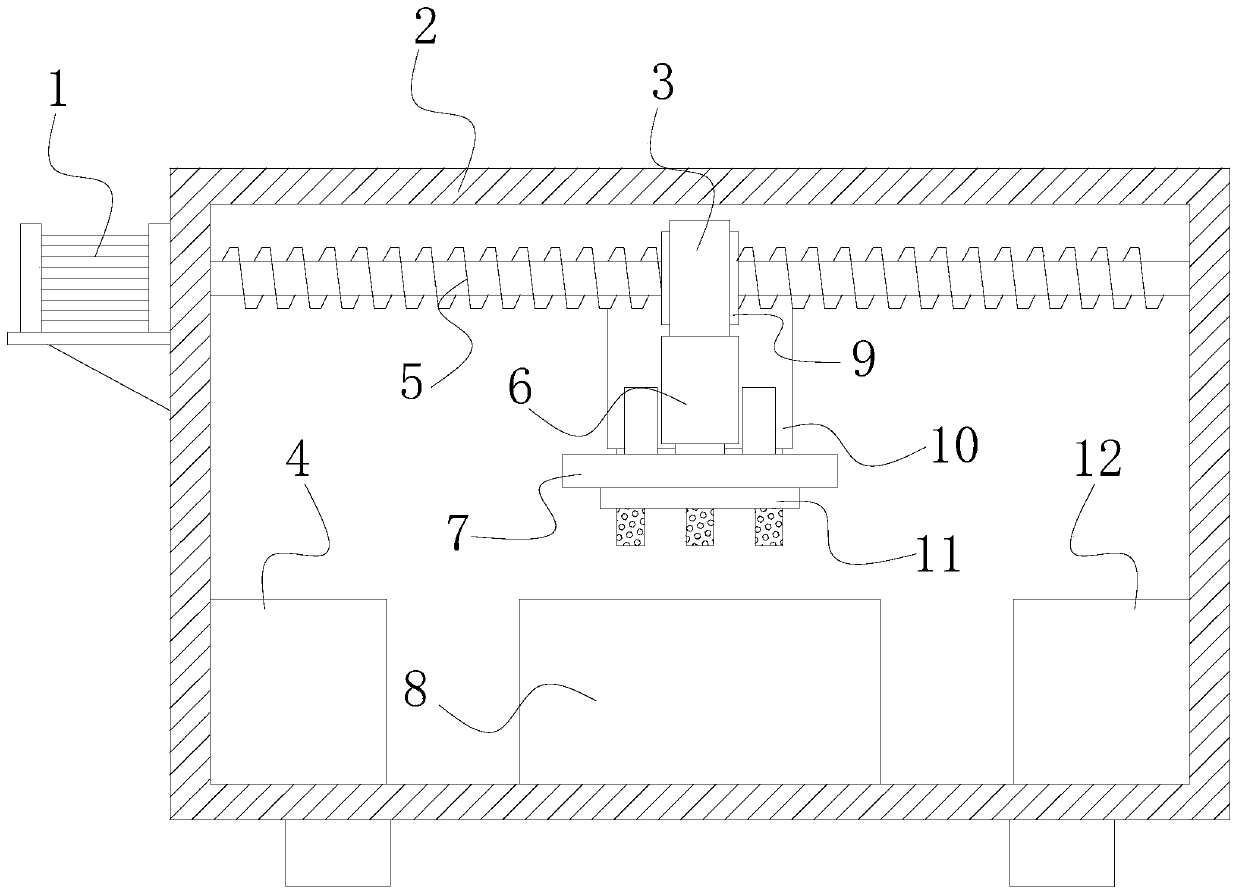

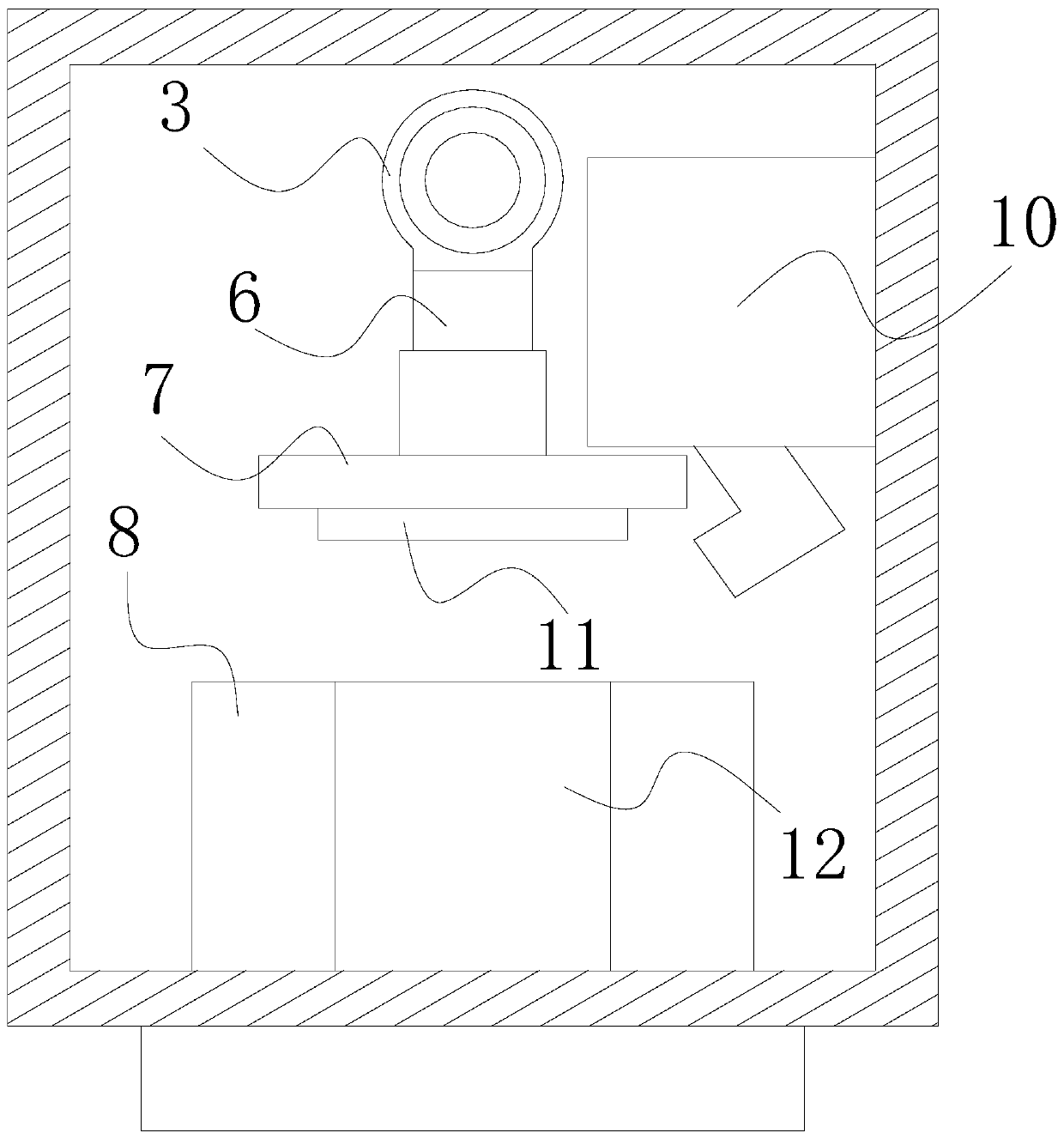

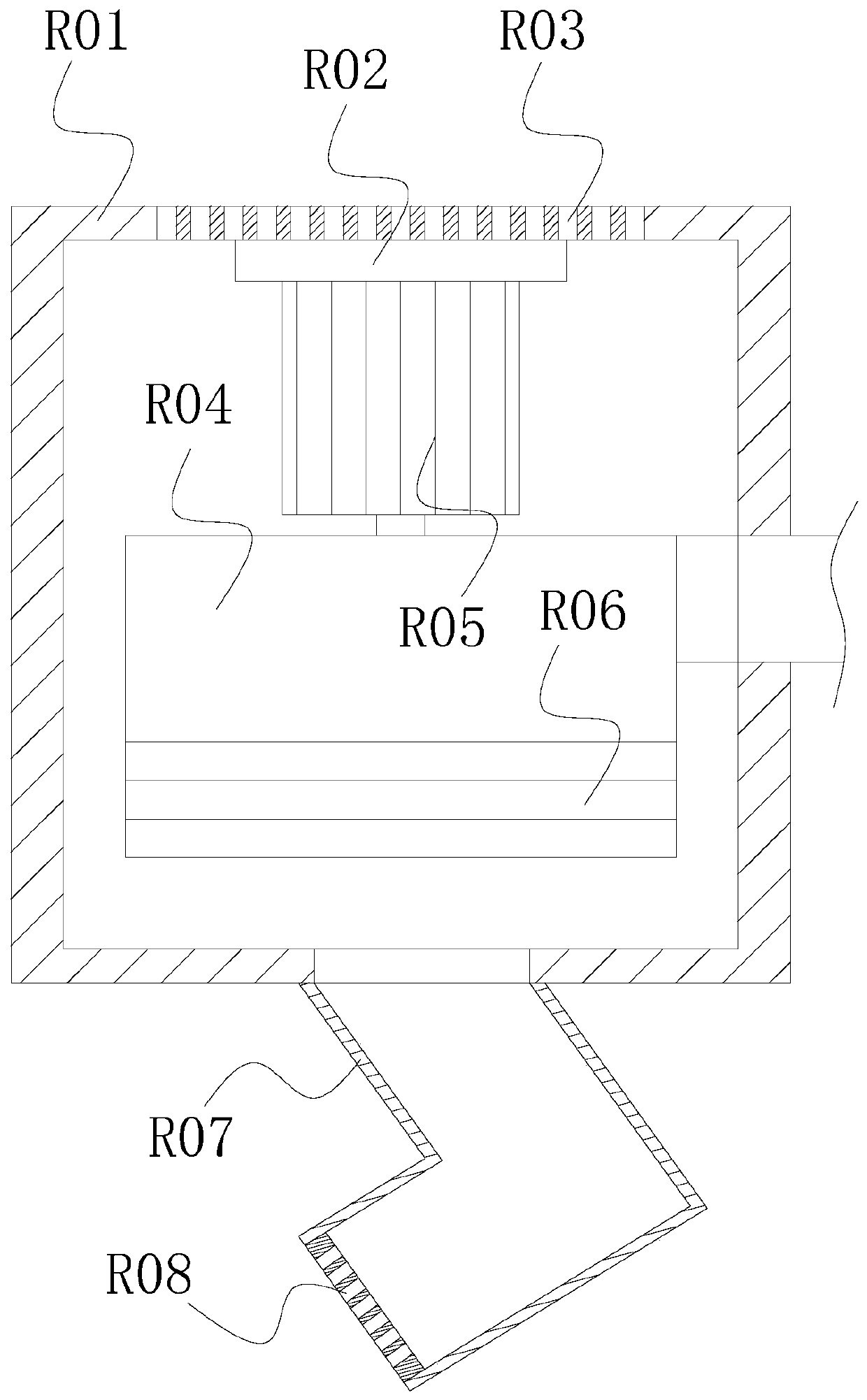

[0036] see Figure 1-4, the present invention provides a technical solution for sheet-shaped inductance soldering equipment: its structure includes a high-efficiency energy-saving motor 1, a body 2, a mounting sleeve 3, a finished product placement cylinder 4, a screw rod 5, a hydraulic cylinder 6, a cooling device 7, a tin furnace 8, Nut pair 9, smog absorption and purification device 10, electromagnetic panel 11, and a tube 12 for placing parts to be soldered. A tin furnace 8 is fixed in the center of the inner bottom surface of the body 2. One side of the tin furnace 8 is provided with a finished product placement tube 4. One side is provided with a tube 12 for placing the parts to be soldered, and the tube 4 for placing the finished product and the tube 12 for placing the parts to be soldered are all connected to the inner wall of the body 2, and the tube 4 for the finished product can place the chip inductor that has been soldered. The setting of the solder part placement...

Embodiment 2

[0041] see Figure 1-6 , the present invention provides a technical solution for sheet-shaped inductance soldering equipment: its structure includes a high-efficiency energy-saving motor 1, a body 2, a mounting sleeve 3, a finished product placement cylinder 4, a screw rod 5, a hydraulic cylinder 6, a cooling device 7, a tin furnace 8, Nut pair 9, smog absorption and purification device 10, electromagnetic panel 11, and a tube 12 for placing parts to be soldered. A tin furnace 8 is fixed in the center of the inner bottom surface of the body 2. One side of the tin furnace 8 is provided with a finished product placement tube 4. One side is provided with a tube 12 for placing the parts to be soldered, and the tube 4 for placing the finished product and the tube 12 for placing the parts to be soldered are all connected to the inner wall of the body 2, and the tube 4 for the finished product can place the chip inductor that has been soldered. The setting of the solder part placemen...

Embodiment 3

[0047] see Figure 1-8 , the present invention provides a technical solution for sheet-shaped inductance soldering equipment: its structure includes a high-efficiency energy-saving motor 1, a body 2, a mounting sleeve 3, a finished product placement cylinder 4, a screw rod 5, a hydraulic cylinder 6, a cooling device 7, a tin furnace 8, Nut pair 9, smog absorption and purification device 10, electromagnetic panel 11, and a tube 12 for placing parts to be soldered. A tin furnace 8 is fixed in the center of the inner bottom surface of the body 2. One side of the tin furnace 8 is provided with a finished product placement tube 4. One side is provided with a tube 12 for placing the parts to be soldered, and the tube 4 for placing the finished product and the tube 12 for placing the parts to be soldered are all connected to the inner wall of the body 2, and the tube 4 for the finished product can place the chip inductor that has been soldered. The setting of the solder part placemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com