Fine rubber powder production line

A production line and rubber powder technology, applied in the directions of magnetic separation, solid separation, smoke removal, etc., can solve the problems of unreasonable layout of fine rubber powder production line, high power consumption, unreasonable structure of collection cover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

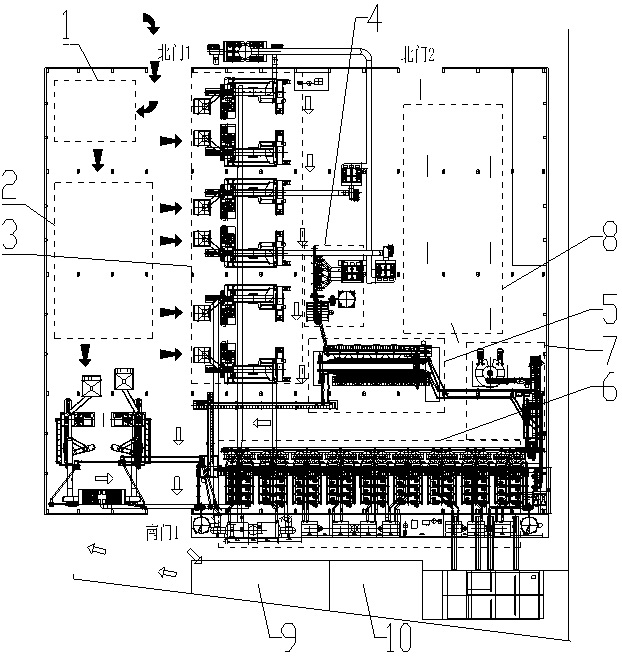

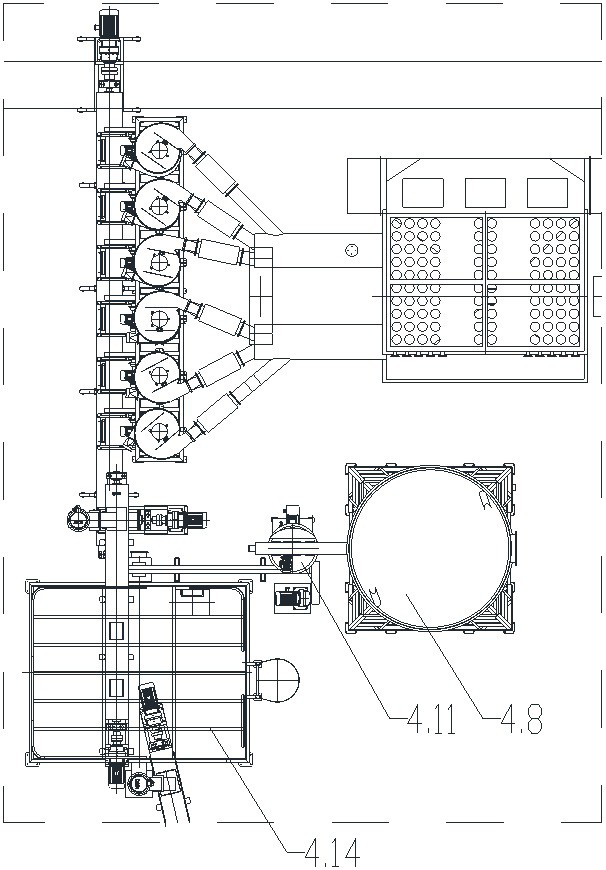

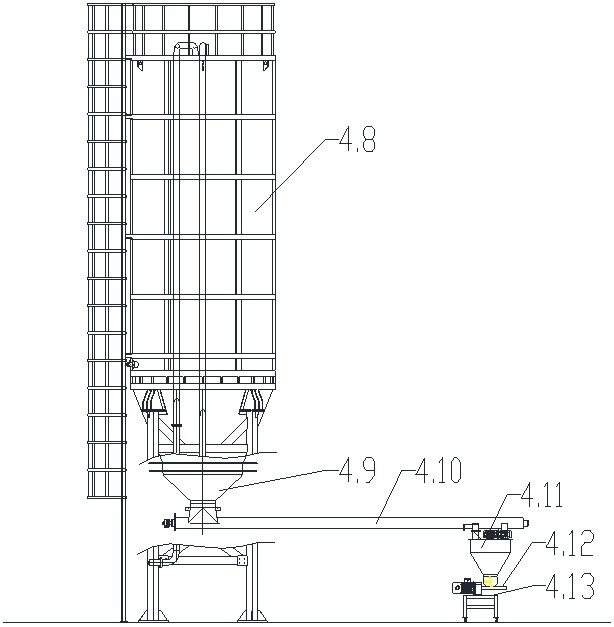

[0074] see figure 1 , the present invention relates to a fine rubber powder production line, comprising a block making area 1, a stacking area 2, a gel breaking area 3, a magnetic separation area 4, a screening area 5, a grinding area 6, a collection area 7, a fine rubber powder finished product area 8, a wool Silk stacking area 9 and collar stacking area 10;

[0075] ①. Tires are disassembled in Blocking Area 1; waste tires are sent to Blocking Area 1 through the first north gate;

[0076] Blocking area 1 includes a bead cutting machine (not shown in the figure);

[0077] After selecting hard materials such as steel nails, stones, and tiles, the waste t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com