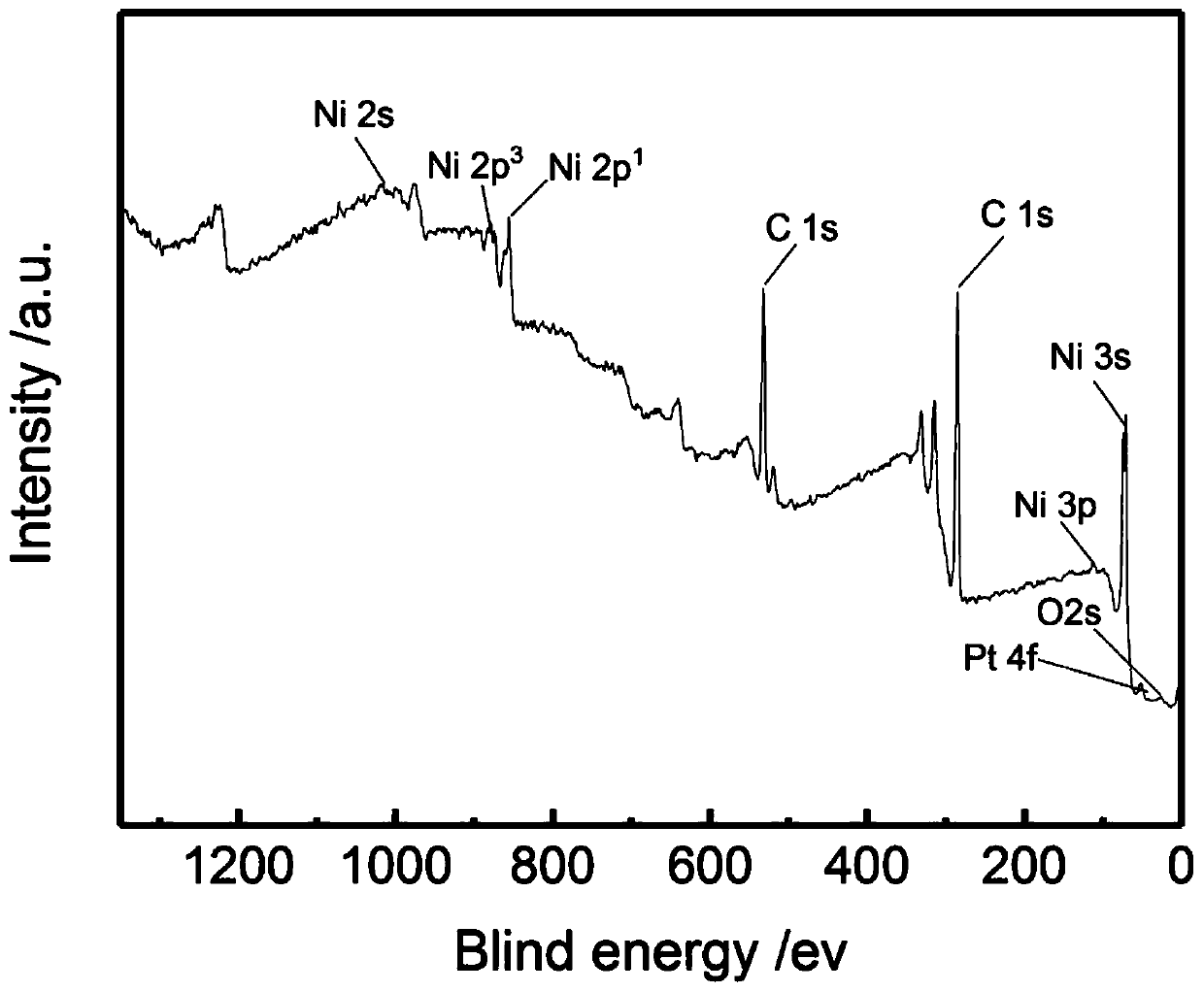

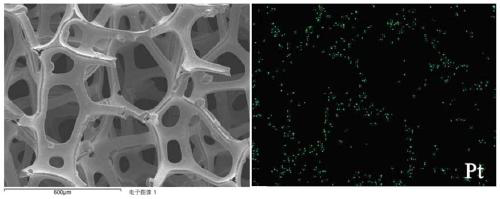

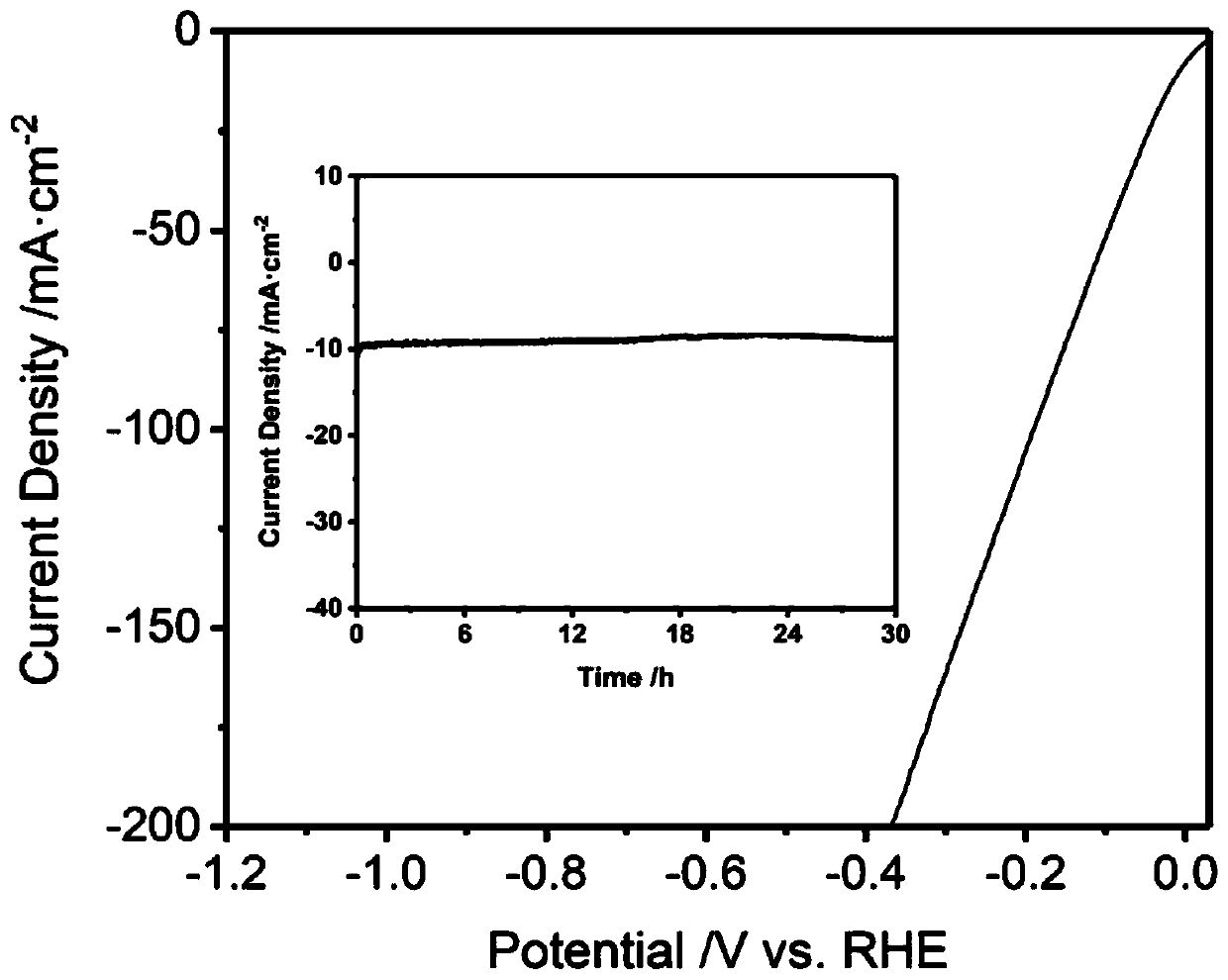

Modified foamed nickel supported noble metal catalyst hydrogen evolution electrode and preparation method thereof

A technology of noble metal catalysts and hydrogen evolution electrodes, which is applied in the direction of electrodes, electrode shapes/types, metal material coating processes, etc., and can solve problems such as inability to effectively control the dispersion of noble metal catalysts, shedding of active components, and weakening of electrocatalytic stability of electrodes , to achieve excellent electrocatalytic hydrogen evolution activity and stability, achieve dispersion, and improve the effect of electron transport ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The commercial nickel foam (thickness is 1.6mm, area density is 320g / m 2 ) cut into 2×3cm 2 Placed in 3mol / L hydrochloric acid aqueous solution for ultrasonication for 15min, rinsed with water, then placed in absolute ethanol and deionized water for ultrasonication for 20min respectively, and then placed in a constant temperature drying oven at 60°C to dry to constant weight. The dried nickel foam was placed in a tube furnace and heated with H 2 15% H by volume 2 / Ar mixed gas for temperature-programmed reduction treatment, the reduction treatment temperature of nickel foam is 350 °C, the temperature program rate is 10 °C / min, the reduction treatment time is controlled at 1 h, and the pre-treated nickel foam is obtained after cooling to room temperature.

[0035] Prepare 0.005mol / L NH 4 F electrolyte, with ethylene glycol and water as a mixed solvent, the volume ratio of ethylene glycol and water is 1:0.1, the pretreated nickel foam is used as the anode, the commerci...

Embodiment 2

[0040] The commercial nickel foam (thickness is 1.2mm, area density is 300g / m 2 ) cut into 2×3cm 2 Placed in 3mol / L hydrochloric acid aqueous solution for ultrasonication for 15min, rinsed with water, then placed in absolute ethanol and deionized water for ultrasonication for 20min respectively, and then placed in a constant temperature drying oven at 60°C to dry to constant weight. The dried nickel foam was placed in a tube furnace and heated with H 2 5% H by volume 2 / Ar mixed gas for temperature-programmed reduction treatment, the reduction treatment temperature of nickel foam is 300 °C, the temperature program rate is 5 °C / min, the reduction treatment time is controlled at 1 h, and the pretreated nickel foam is obtained after cooling to room temperature.

[0041] Prepare 0.005mol / L NH 4 NO 3 Electrolyte, with ethanol and water as a mixed solvent, the volume ratio of ethanol and water is 1:1, the pretreated foamed nickel is used as the anode, the commercial platinum she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com