Air suction purification decontamination valve for air compressor

A technology of decontamination valve and air compressor, applied in mechanical equipment, machine/engine, liquid variable capacity machinery, etc., can solve problems such as troublesome use, and achieve the effect of ensuring normal operation, reducing trouble, and improving adhesion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

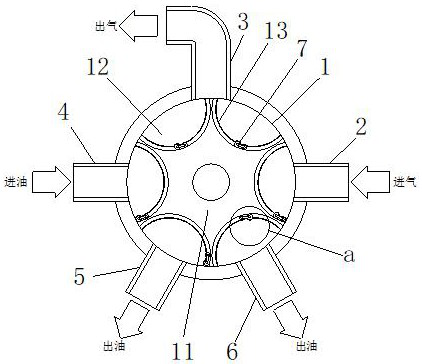

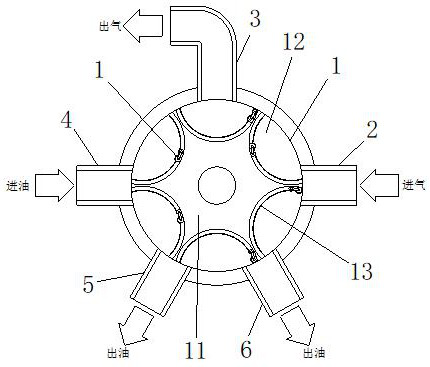

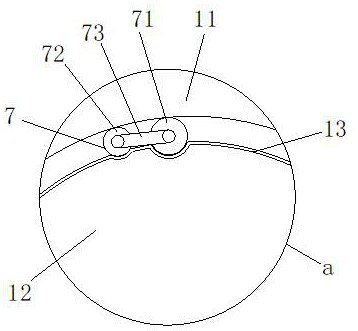

[0029] Embodiment 1, please refer to figure 1 and image 3 , an air suction purifying decontamination valve for an air compressor, comprising a valve body 1, characterized in that: the valve body 1 is a cylindrical barrel, the valve body 1 is fixedly installed with an air inlet pipe 2 and an air outlet pipe 3, and the valve body A rotating body 11 is fixedly installed at the center of 1, the central axis of the rotating body 11 is fixedly connected to the output shaft of the rotating motor, the rotating body 11 rotates counterclockwise in the valve body 1, and the rotating body 11 divides the internal space of the valve body 1 Divided into six processing chambers 12, the air inlet pipe 2 is not connected to the air outlet pipe 3, and the oil inlet pipe 4, the oil outlet pipe 1 and the oil outlet pipe 2 6 are fixedly installed on the valve body 1, and the rotation speed of the motor is opened and controlled to ensure that the rotating body 11 Rotate stably counterclockwise in ...

Embodiment 2

[0030] Embodiment two, please refer to figure 1 and image 3 , on the basis of Embodiment 1, the rotary body 11 is a turntable with six partition plates and the partition plates extend outward. The inner wall of the body 1 forms six identical spaces to ensure that the amount of air sucked by the air compressor from the valve body 1 is constant each time to achieve the effect of quantitative air delivery.

Embodiment 3

[0031] Embodiment three, please refer to figure 1 and image 3 , on the basis of Embodiment 2, the six surfaces of the rotating body 11 are all arc-shaped surfaces, and the oil injected into the processing chamber 12 from the oil outlet pipe 4 can be better distributed in the processing chamber 12 by utilizing the arc-shaped surface characteristics of the rotating body Uniformity improves the adhesion effect of the processing chamber 12 to impurities in the air, and at the same time facilitates the movement of oil in the processing chamber 12, facilitating the transportation and recovery of oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com