Vertical driller chipping collection tool

A vertical drilling machine and debris technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem that debris is not easy to clean and collect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

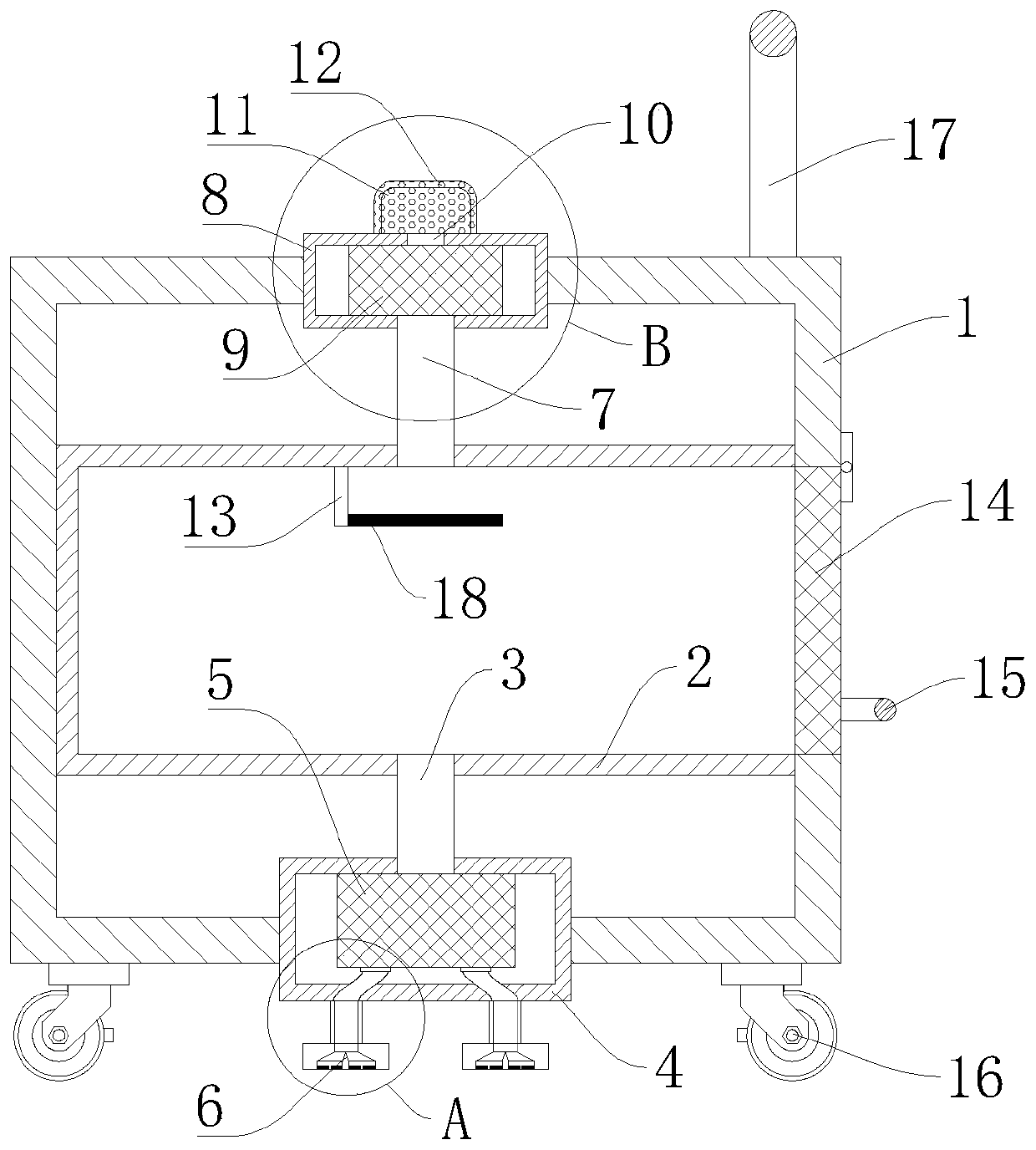

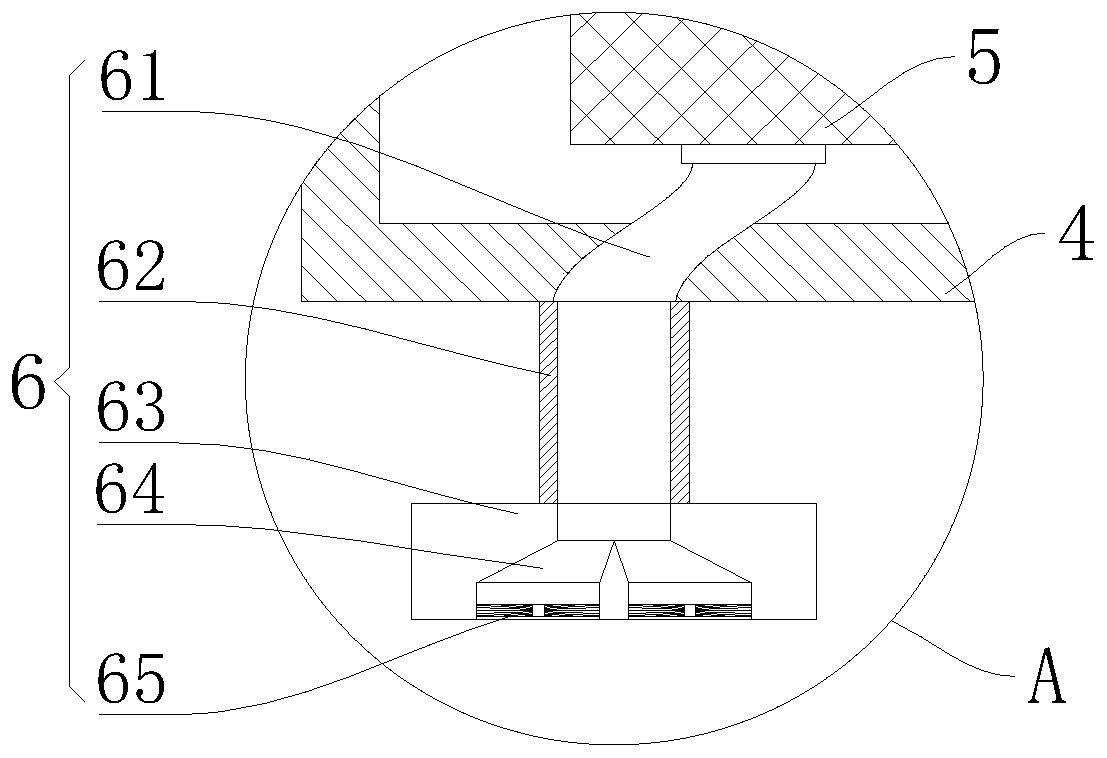

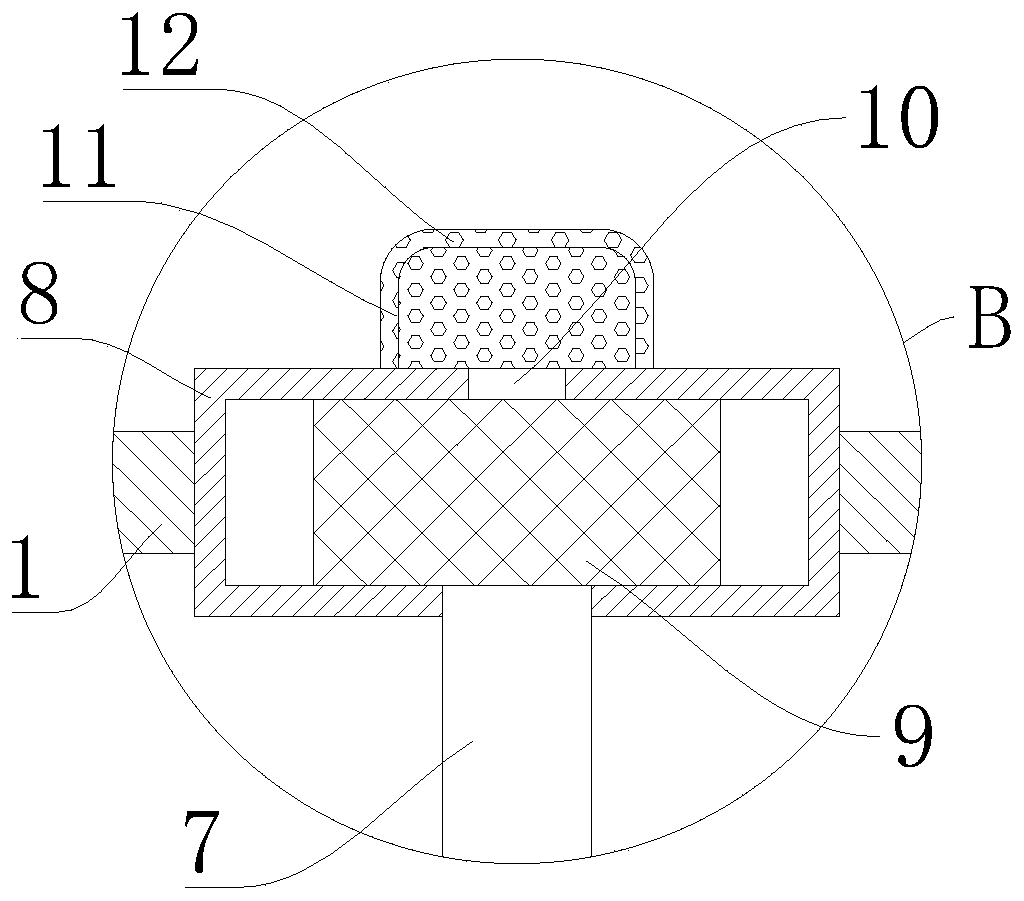

[0018] refer to Figure 1-3 , a vertical drilling machine debris collection tool, including an outer box 1, an armrest 17 is fixedly installed on one side of the upper surface of the outer box 1, and the device can be moved through the handrail 17, and a collection box 2 is fixedly installed inside the outer box 1 to collect The box 2 is used to collect debris and dust. One side of the collection box 2 is installed with a door 14 through hinge rotation, and a handle 15 is fixedly installed on the outside of the door 14. The door 14 can be opened through the handle 15. The upper end of the collection box 2 is fixed and connected. A second inlet pipe 7 is provided, and a second suction fan 9 is fixedly installed on the upper end of the second inlet pipe 7 .

[0019] The second suction fan 9 is fixedly installed in the second fixed frame 8, and the second fixed frame 8 is fixedly installed inside the upper surface of the outer box body 1. The upper end of the second suction fan 9...

Embodiment 2

[0024] refer to figure 1 As another preferred embodiment of the present invention, the difference from Embodiment 1 is that a fixed frame 13 is fixedly installed on the inner wall surface above the collection box 2, and a wet sponge cover 18 is set on the outside of the fixed frame 13, and the wet sponge cover 18 is located at the second Below the secondary pipe 7, the wet sponge cover 18 can purify the wind with dust blown in from the second suction fan 9, so that the dust is stained on the wet sponge, preventing the dust from scattering and affecting the collection effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com