Yarn twisting device for spinning

A technology of twisting and mounting boards, which is applied in the field of textile twisting devices, can solve the problems of different thicknesses of twisted threads, appearance and use of winding and winding, and small application range, so as to reduce the number of placements and maximize the benefits The effects of generalization and increased scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

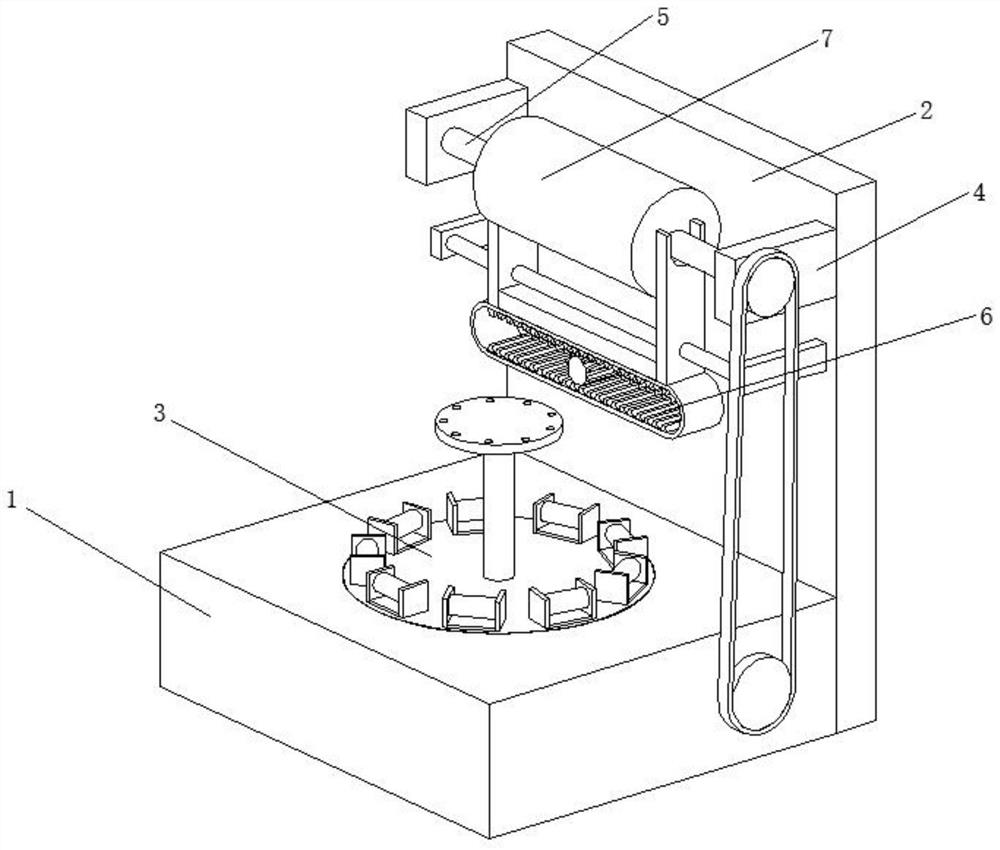

[0031] A twisting device for weaving, such as Figure 1-Figure 6 As shown, it includes a workbench 1, the rear of the workbench 1 is welded with a mounting plate 2, the inside of the workbench 1 is provided with a twisting mechanism 3, and the front of the mounting plate 2 is welded with two support plates 4, and the two support plates 4 are movably connected with a rotating shaft 5 , the surface of the rotating shaft 5 is movably connected with a winding drum 7 , and the front portion of the mounting plate 2 is provided with a winding mechanism 6 , and the winding mechanism 6 is located below the support plate 4 .

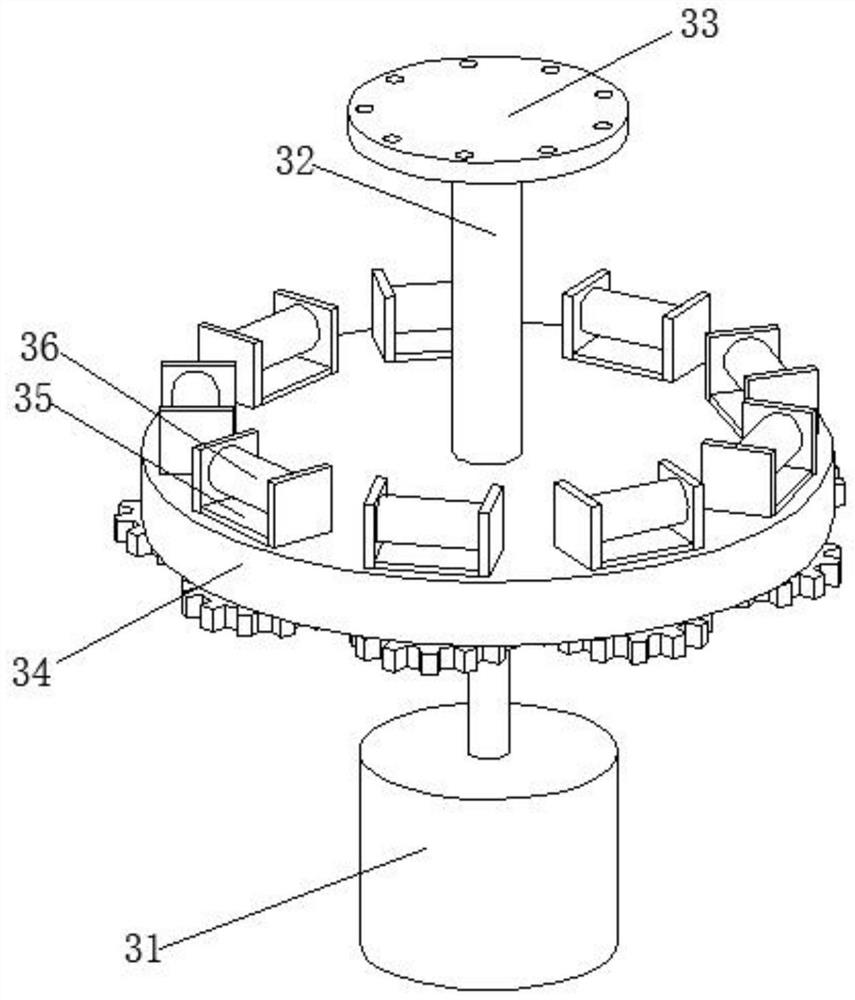

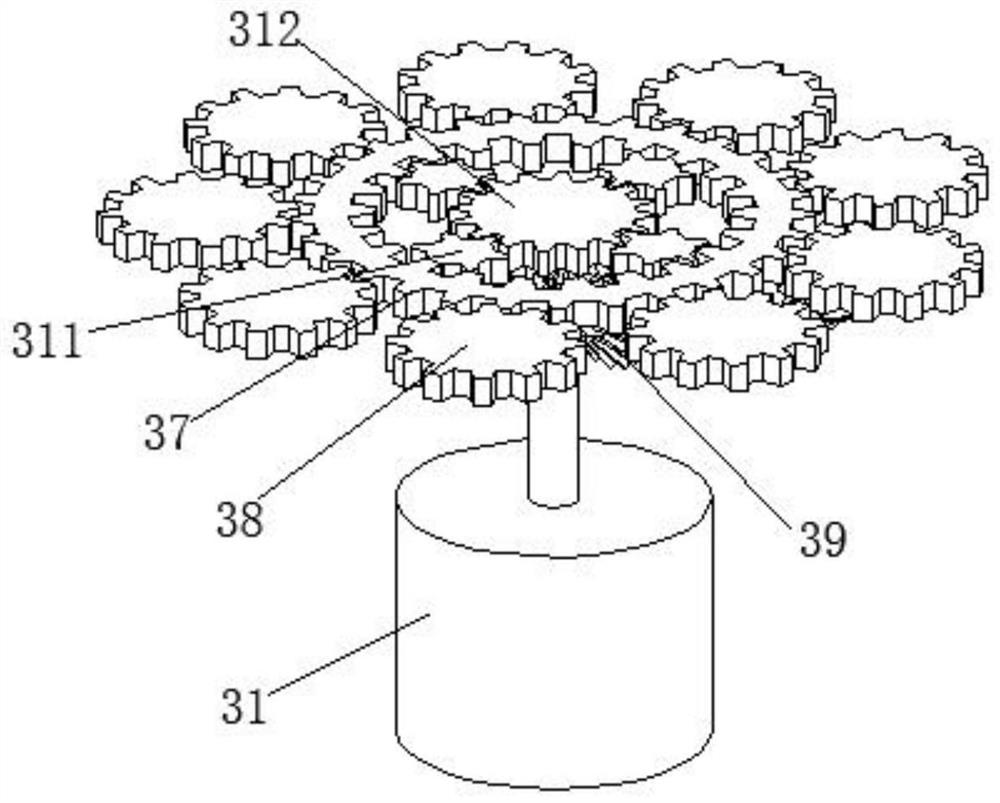

[0032] In this embodiment, the twisting mechanism 3 includes a motor 31, the output end of the motor 31 is clamped with a connecting shaft 32, the top of the connecting shaft 32 is welded with a fixed disk 33, and the surface of the connecting shaft 32 is welded with a rotating disk 34, and the surface of the connecting shaft 32 is welded with a rotating disk 34. ...

Embodiment 2

[0041] Such as Figure 6-Figure 7 As shown, on the basis of Embodiment 1, in this embodiment, the rear portion of the fixed plate 61 is welded and fixed to the front portion of the mounting plate 2, and the surfaces of the two moving plates 63 are in contact with the two ends of the winding drum 7 respectively. , the winding mechanism 6 is located above the twisting mechanism 3, which can move the twisted thread directly upwards for winding, without guiding to other planes for winding, which can reduce the setting of a guide wheel, reduce the cost, and reduce the cost. The friction of the guide wheel against the wire minimizes the risk of breakage due to friction.

[0042] It is worth noting that the adjustment device 64 includes a moving block 641, the inner wall of the moving block 641 is welded with teeth 642, the surface of the teeth 642 is meshed with a driving gear 643, and the axis of the driving gear 643 is welded with a transmission rod 644. The number of teeth of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com