A high-density forward-moving agile storage and sorting system and its working method

A sorting system and working method technology, applied in the field of warehousing and logistics, can solve the problems of high construction and use costs of automated three-dimensional warehouses, the inability to realize first-in-first-out of goods, failure to save storage operation time, etc., to improve space utilization , avoid storage and storage operations, and save working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

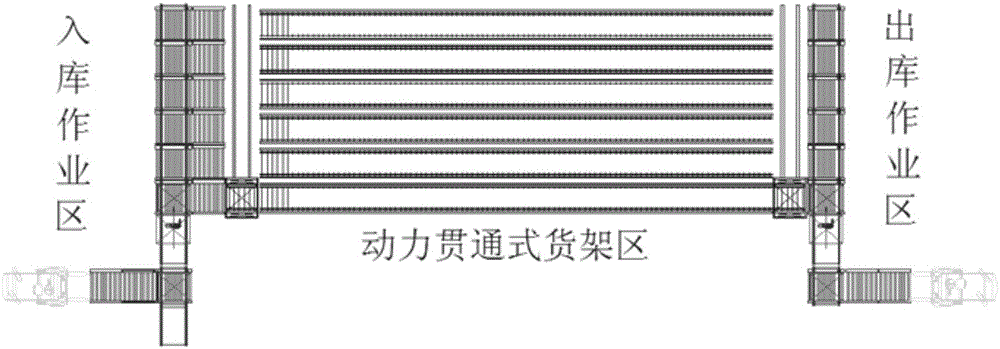

[0062] Such as Figure 1 to Figure 11 As shown, a high-density forward-moving agile storage and sorting system applied to the modern warehouse logistics industry provided by the present invention mainly includes three parts: the power through-type shelf, the lifting shuttle and the push-type self-propelled rail car;

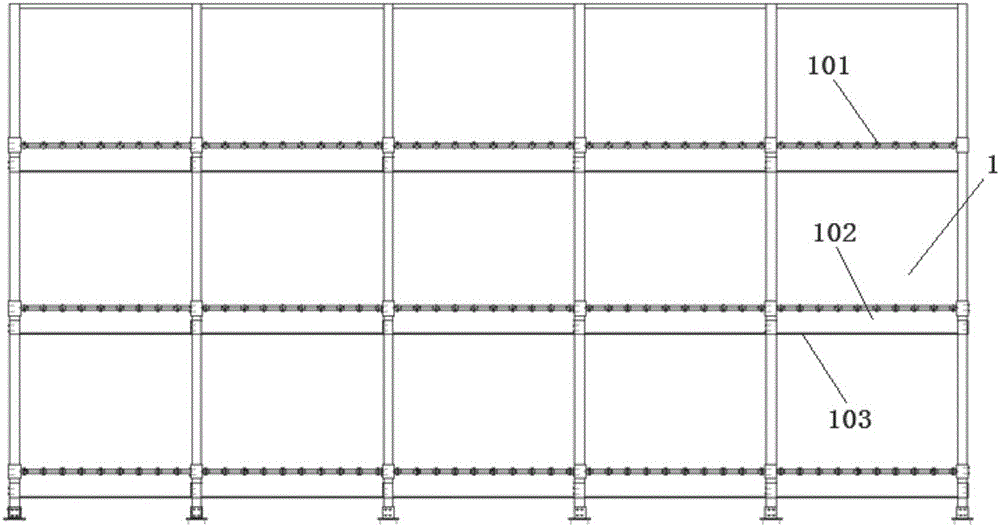

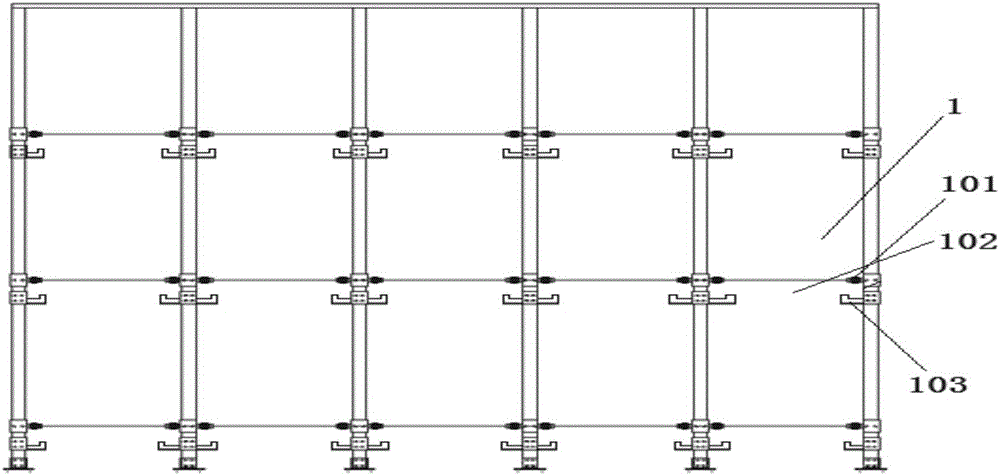

[0063] Among them, the power through-type shelf is a purely mechanical structure design, including vertically arranged three-layer shelves, each layer of shelves includes five horizontally arranged independent cargo lanes 1, and each cargo lane includes the upper part for pallets. The mechanism and the lower part are used for the walking track of the push-type self-propelled rail vehicle; one side of the power through-type shelf is the entrance side of the goods, and the other side is the exit side of the goods.

[0064] The pallet conveying mechanism includes two steel beam roller frames arranged in parallel, and a plurality of rollers 101 are arranged on the ro...

Embodiment 2

[0076] The present invention provides a high-density forward-moving agile storage and sorting system applied to the modern warehousing and logistics industry. The structure is as described in Embodiment 1. In terms of stability, stabilizing wheels 20 are provided on both sides of the fixed frame 8 of the lifting shuttle through the stabilizing wheel frame 4 .

Embodiment 3

[0078] The present invention provides a high-density forward-moving agile storage and sorting system applied to the modern warehousing and logistics industry. The structure is as described in Embodiment 1. Place the push-type self-propelled rail car, dispatch the push-type self-propelled rail car by lifting the shuttle, and transport the push-type self-propelled rail car to the cargo lane to be operated. When a cargo lane is about to be operated, the lifting shuttle can dispatch the push-type self-propelled rail vehicles in the cargo lane that is not currently operating to the cargo lane to be operated, so that part of the push-type self-propelled rail vehicles can be saved. It is also not necessary to place push-type bicycle rail cars in all cargo lanes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com