Textile thread positioning device of textile machine

A positioning device and textile thread technology, which is applied in the directions of transportation and packaging, conveying filamentous materials, and thin material processing, etc., can solve the problems of winding and winding of textile threads, and achieve reduced friction, reduced quantity, and reduced cost input Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

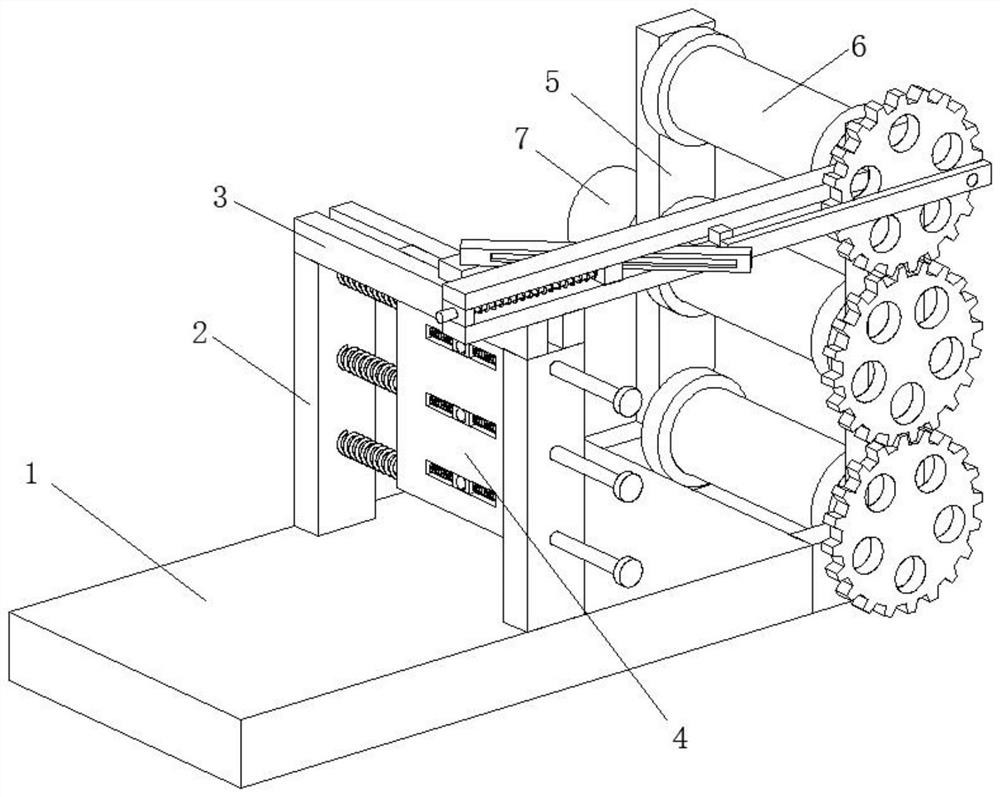

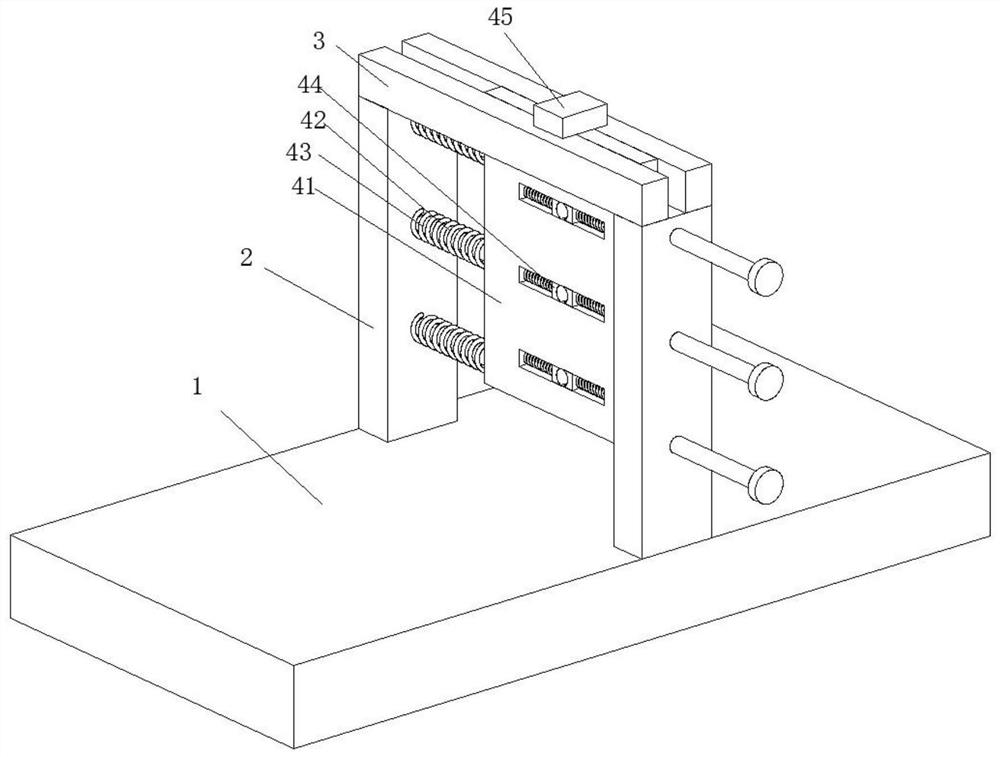

[0034] A textile thread positioning device for a textile machine, such as Figure 1-Figure 8 As shown, including workbench 1, two support plates 2 are vertically welded on workbench 1, two baffle plates 3 are respectively welded on the top of support plate 2, positioning mechanism 4 is arranged between two support plates 2, the working Two support columns 5 are respectively welded at the rear of the table 1, and a winding mechanism 6 is arranged between the two support columns 5, and a motor 7 is connected to the left side of the support column 5 through bolts; a motor 7 can drive the textile thread at the same time Rewinding can drive the positioning mechanism 4 to position the wire, thereby reducing the number of motors 7 placed, thereby reducing cost input and maximizing benefits.

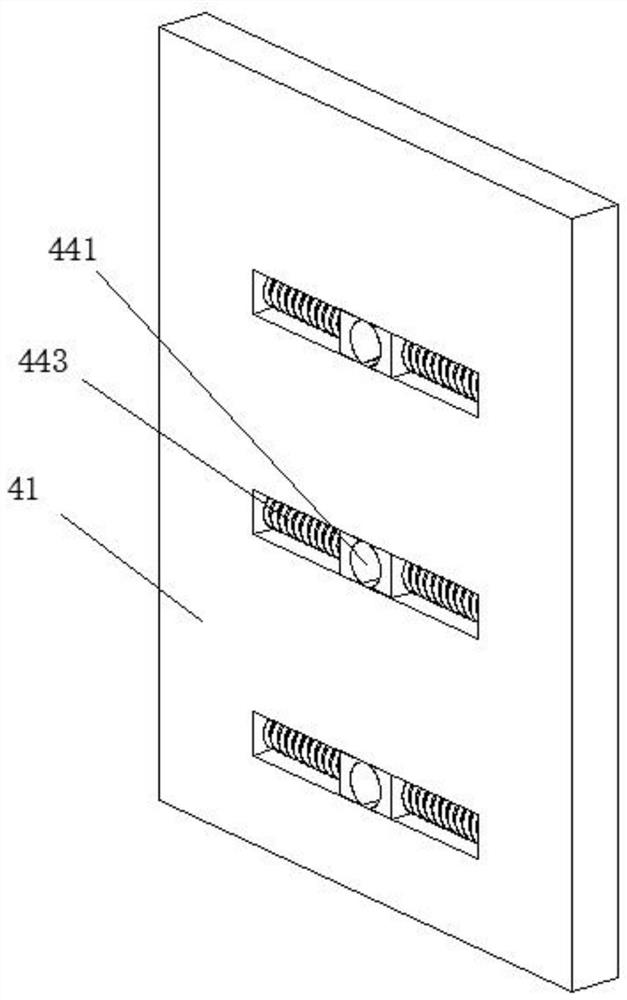

[0035] In this embodiment, the positioning mechanism 4 includes a moving plate 41, the two sides of the moving plate 41 are welded with guide rods 42, the surface of the guide rod 42 is sleeved ...

Embodiment 2

[0041] Such as Figure 7-Figure 10 As shown, the left side of the connection block 67 is slidably connected with the inwall of the fixed rod 65, the front portion of the connection block 67 is movably connected with the rear portion of the push rod 612, the rear portion of the slide plate 68 is movably connected with the inwall of the push rod 612, and the guide post The surface of 69 is slidingly connected with the inner wall of fixed rod 65, and the two ends of No. 2 spring 611 are in contact with the front portion of slide plate 68 and the inner wall of fixed rod 65 respectively, and the lower surface of push rod 612 is connected with the upper surface of slide block 45 in rotation , the lower surface of the fixed rod 65 is welded and fixed with the upper surface of the baffle plate 3, the connecting block 67 and the push rod 612 can rotate and slide, so that the connecting block 67 can push the push rod 612 to rotate with linear motion, and the slide plate 68 and the push r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com