Cleaning and maintaining mechanism for medical apparatus and instruments

A technology of medical equipment and discharge mechanism, applied in the field of medical equipment, can solve the problems of high labor intensity, low efficiency, manual cleaning, scratch infection, cleaning efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

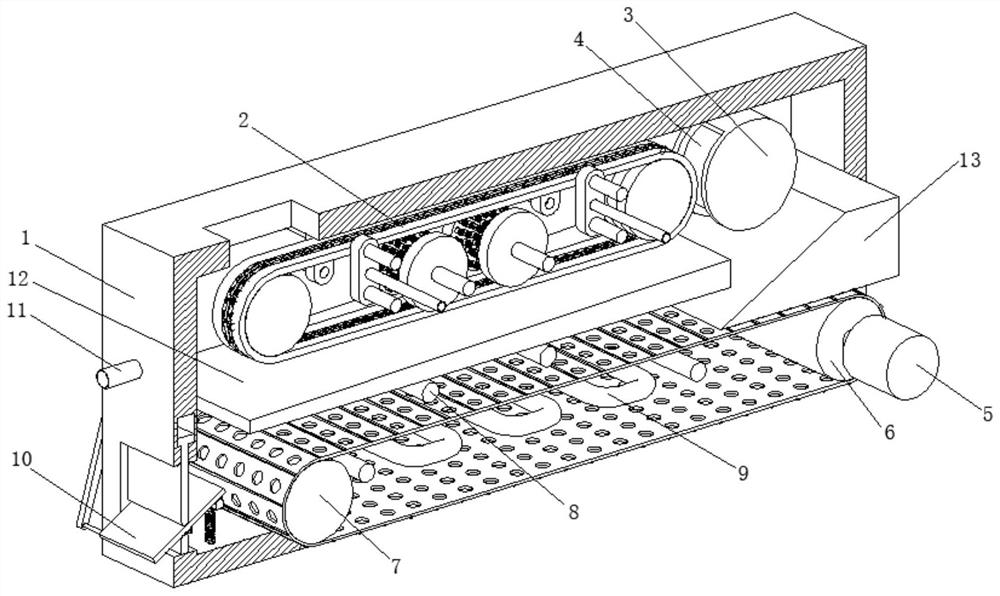

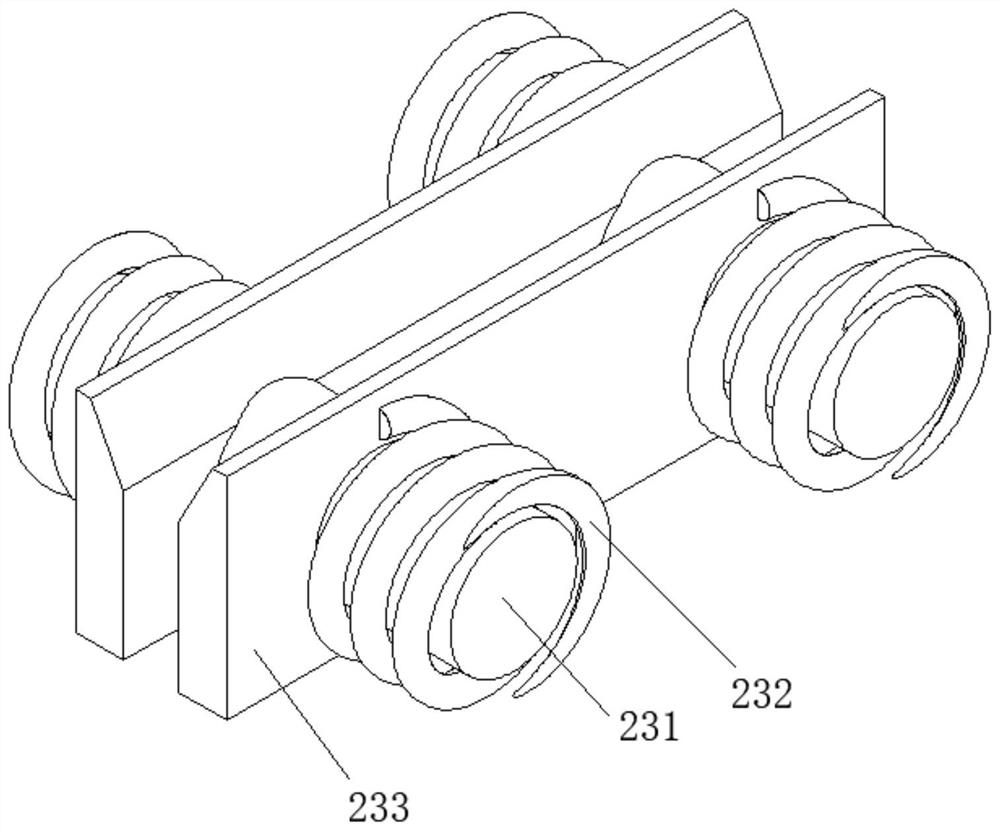

[0030] A cleaning and maintenance mechanism for medical equipment, such as Figure 1-Figure 5 As shown, the box body 1 is included, the inside of the box body 1 is provided with a cleaning mechanism 2, the top wall inside the box body 1 is welded with a casing 3, the inner wall of the casing 3 is rotatably connected with a magnet 4, and the right side of the box body 1 is provided with a transmission Mechanism 5, the inner wall of the box body 1 is respectively connected to the driving roller 6 and the driven roller 7, and the driven roller 7 is located at the front of the driving roller 6, and the surface of the driving roller 6 is connected to the surface of the driven roller 7 through a conveyor belt. The inner wall of the box body 1 is fixedly connected with an ultraviolet lamp 8 and a heating tube 9 respectively, and the ultraviolet lamp 8 and the heating tube 9 are located between the driven drum 7 and the driving drum 6, and the ultraviolet lamp 8 is located above the he...

Embodiment 2

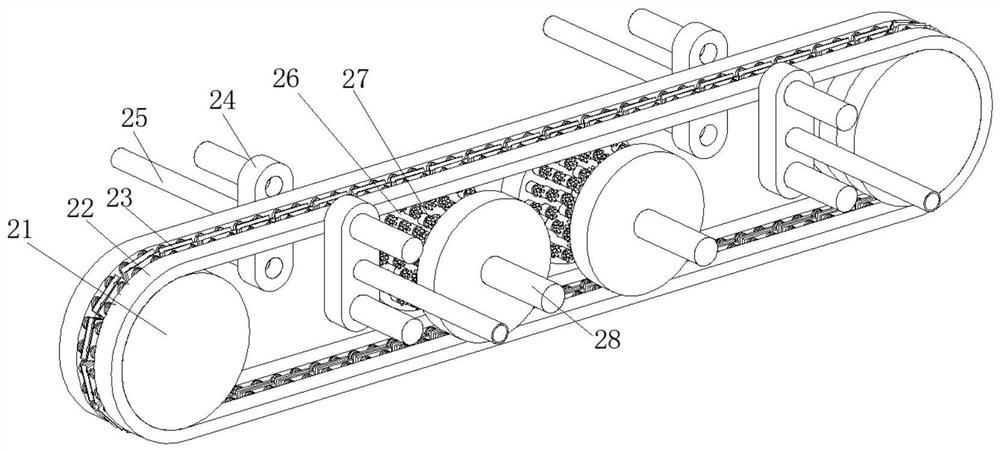

[0039] Such as Figure 5-Figure 7 As shown, on the basis of Embodiment 1, in this embodiment, the left side of the motor 51 is connected to the right side of the box body 1 by bolts, and the output end of the motor 51 is clamped and fixed with the shaft center of the drive roller 6. The axle center of No. belt pulley 53 is clamped and fixed by the axle center of connecting rod and magnet 4, and the axle center of No. three pulley 56 is clamped and fixed by the axle center of connecting rod and sprocket wheel 21, double-layer pulley 57 and four The axle center of No. belt pulley 58 is welded and fixed with the left end of two rotating shafts 28 respectively, and the surface of No. 1 gear 54 and No. 2 gear 55 is provided with through hole, can reduce the material needed during manufacture, and then reduce cost and input, and also Its weight can be reduced, it is convenient to install and maintain it in a subsequent sequence, and it has high practicability.

[0040] The discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com